From the depths of centuries, the shovel has reached us, to which V. Dal, the creator of the Explanatory Dictionary of the Living Great Russian Language, gave an amazingly apt definition: “a blade tool for digging and scooping loose materials.” This hand tool is well-known to owners of dachas and garden plots, not to mention those who from childhood have been closely connected with the earth as a source of sustenance. However, the most inquisitive, knowing the pros and cons of the ancient shovel, increasingly try to improve it or replace it altogether with another, more suitable hand tool for performing a number of highly specialized tasks.

I would like to introduce the magazine’s readers to interesting technical solutions found by our neighbors—hereditary farmers and gardeners.

DIGGING FORKS

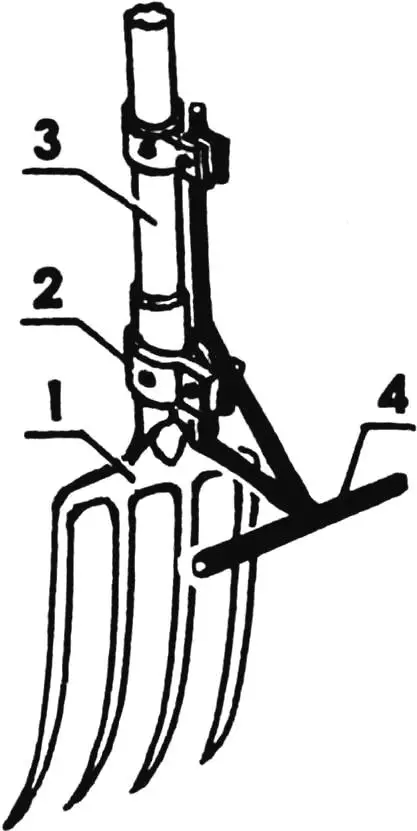

It is known that a lever fixed on the back of a shovel handle greatly facilitates work. This is understandable: resting on the ground, such a device takes on a significant part of the load, allowing the digger to work quickly without bending over. Why not modernize ordinary forks in a similar way? It is enough to equip them with a removable device in the form of a T-shaped support welded from steel reinforcing bar. This construction is attached to the forks with two metal clamps. Moreover, the bracket tightened by them is reinforced with a welded bar-brace.

1 — standard forks; 2 — clamp with tightening bolt and nut (2 sets); 3 — handle; 4 — T-shaped support with brace (welded construction from reinforcing bar)

Using such forks is initially unusual. However, quite soon comes a feeling of ease and convenience in work. The vertically standing tool is driven into the ground with the foot until it stops. Then the handle is pulled toward oneself and down. With minimal effort, maximum results are achieved!

HOLE CUTTER

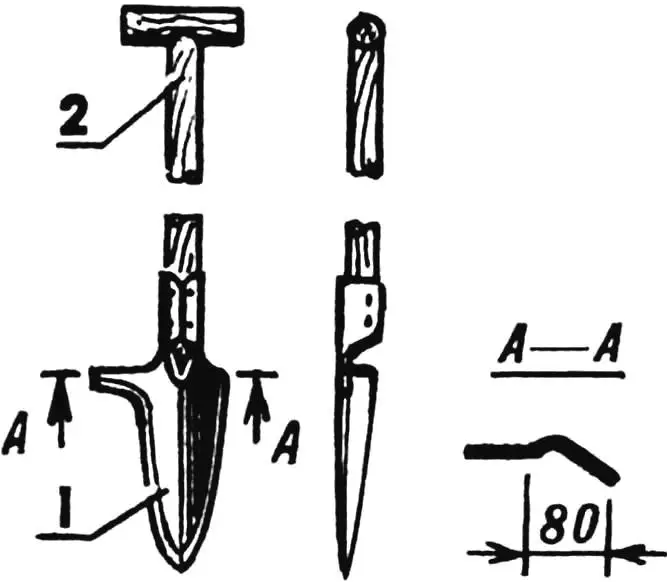

Extracting large weeds with deep and powerful roots from clay soil is not an easy task. However, the task is significantly simplified when using a homemade tool made from an old shovel.

1 — shovel blade, narrowed and bent; 2 — handle with T-shaped head

The shovel blade is bent along the longitudinal axis, trimmed on the sides, and sharpened so that the cutting edges of the remaining working blade can easily enter the ground under foot pressure. The tool is thrust into the soil next to the weed and, slightly rocking, the unwanted plant is removed along with its root. Working with such a hole cutter is within the power of both a schoolchild and an elderly person.

This tool will also be useful for spot feeding of trees. Only the angle of its entry into the ground is chosen within 40—50° to the vertical. Then, rocking, the tool is turned in any direction by a quarter turn—and the hole is ready.

AUGER

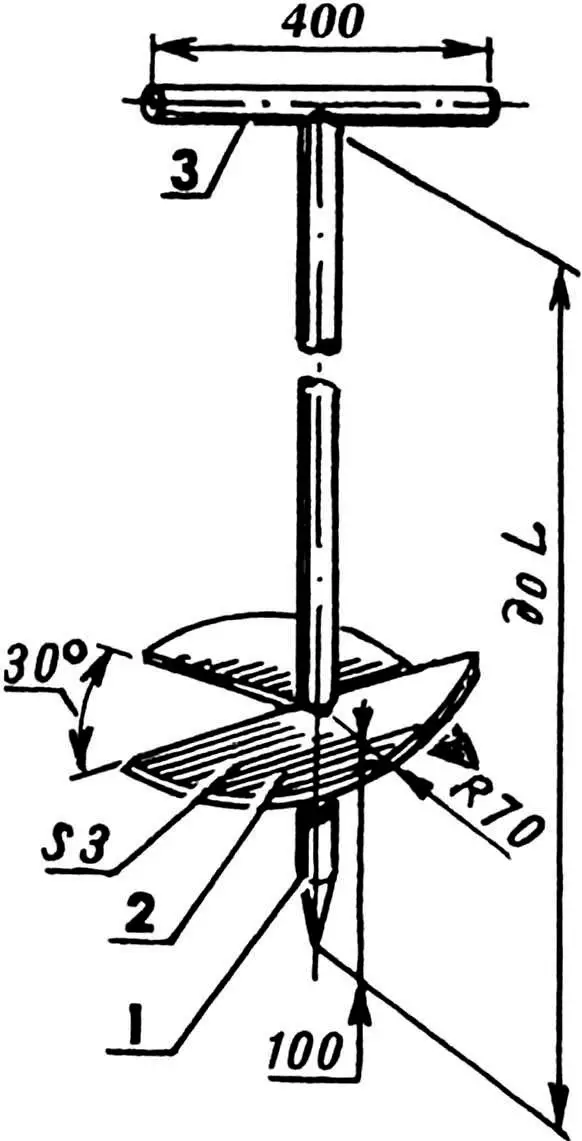

A simply constructed auger can replace a shovel when digging meter-deep holes, for example, for fence posts, and making one is not a problem in any workshop that has gas or electric welding.

First, two semicircular discs with a radius of 70 mm are cut from 3-mm steel sheet (for example, from a two-handed saw blade) with subsequent sharpening of the future cutting edges. Then the blanks are welded to a pointed steel rod (like a crowbar) with a diameter of 30 mm. Moreover, so that the semicircular discs, located 100 mm from the bottom of the rod, form an angle of 30° between them vertically. A steel crossbar-handle is welded to the top of the resulting drilling tool. And it must be welded end-to-end and reliably—the load on this unit is considerable.

1 — steel rod (crowbar); 2 — welded blade-semicircular disc; 3 — crossbar-handle; L — depth of the drilled hole

The productivity of a homemade two-blade auger is such that in ten minutes, a hole approximately 150 mm in diameter can be drilled in the soil to a depth of 1 m. A fence post fits into such a hole almost flush with the walls, and the earth may not even need to be tamped after its installation.

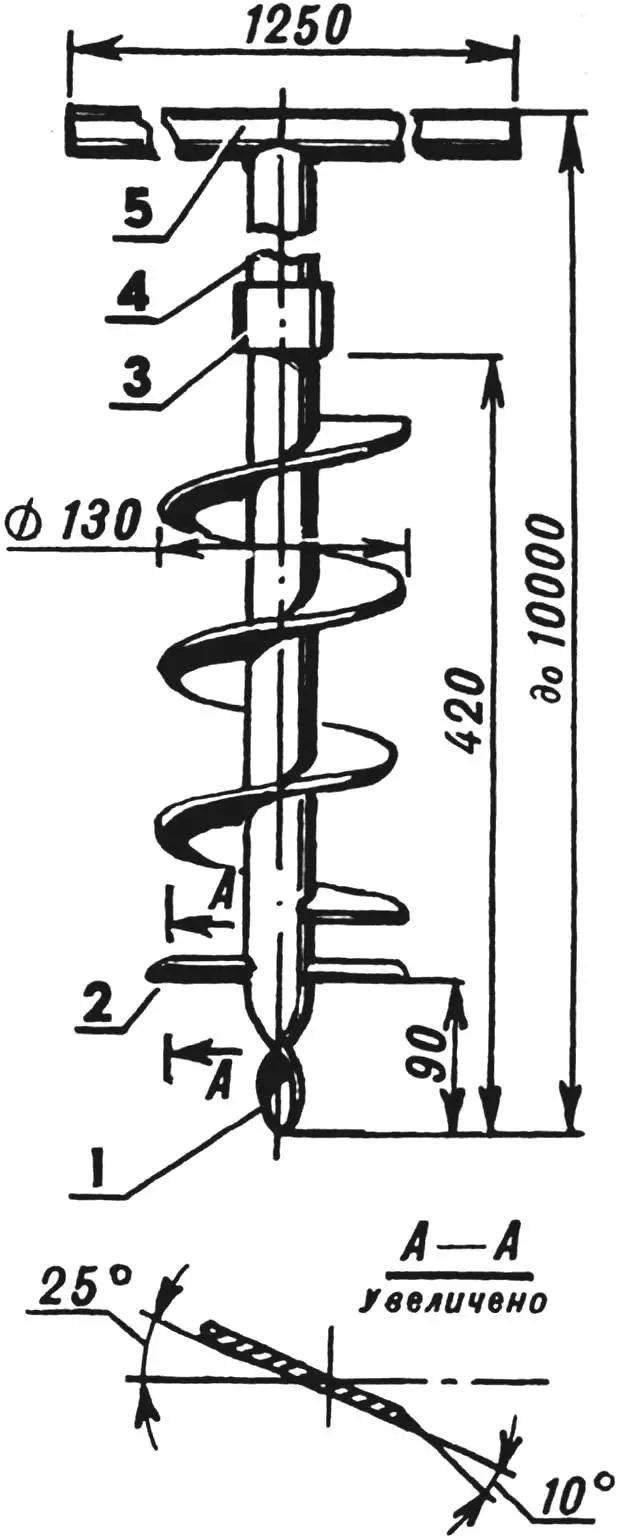

For drilling deeper holes, another homemade tool can be recommended—from an auger from a decommissioned grain harvester and threaded sections of steel pipes. The productivity of such an auger can be judged by the example of a ten-meter well with a diameter of 130 mm, which diggers armed with it can handle in approximately two hours of continuous work.

Naturally, the auger undergoes modernization. It is cut to a length of 420 mm, the lower end of the shaft is given a pointed helical shape. Then, stepping back 90 mm upward from the tip, two 55-mm blades made from a pair of worn-out cultivator tines are welded at an angle of 25° to the horizontal.

1 — auger (from decommissioned grain harvester); 2 — blade (from cultivator tine); 3 — coupling; 4 — insert; 5 — crossbar-handle

The auger head is welded. It is an ordinary inch water-gas pipe coupling, into which a pipe with a welded 1250-mm crossbar-handle is screwed on the end free of threads.

As such an auger cuts into the ground, the tool is extended with two-meter tubular inserts, each of which has threads on one end and a coupling on the other. With known skill and minimal delays in joining pipes, the well deepens right before your eyes.

N. BULYK, Khmelnytsky Region, Ukraine