The idea is to make a mini-tractor ripe at once: an allotment I have a small, but because I was without equipment. In General, it was more a desire to test their capabilities. In the garage by that time had accumulated suitable assemblies and mechanisms. So, the wheels gave me friends (they have many years of lying idle) and the engine gave a friend, because I helped him to restore an old “Moskvich”.

The idea is to make a mini-tractor ripe at once: an allotment I have a small, but because I was without equipment. In General, it was more a desire to test their capabilities. In the garage by that time had accumulated suitable assemblies and mechanisms. So, the wheels gave me friends (they have many years of lying idle) and the engine gave a friend, because I helped him to restore an old “Moskvich”.

Most of the auxiliary units, assemblies and mechanisms has picked up in the Vtorchermet and “cemeteries” of technology. This selection and left the lion’s share of time spent on the construction of mini-tractors, which amounted to a total of about a year.

Constructive scheme for mini-tractors has chosen is not quite normal — with “broken” (articulated) frame. In my opinion, this is the most suitable scheme for such equipment. It allows the best way to build the engine and front wheels, which in the normal version (when wheel steering) requires a relatively large space.

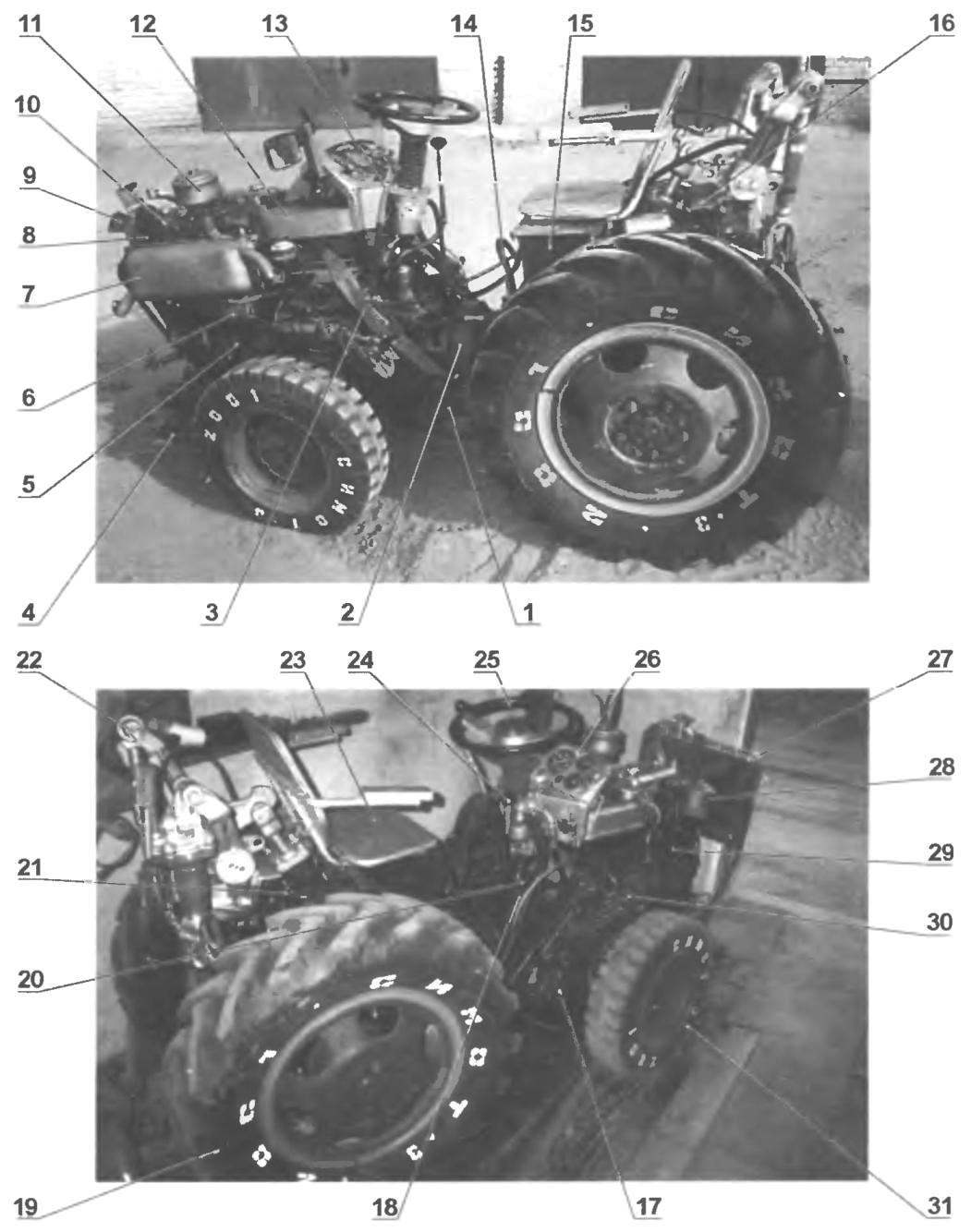

Engine mini tractor — diesel, 2-cylinder, liquid-cooled. Don’t even know what brand it is and what equipment it — except cast on the block of the quality mark and the inscription: “Made in USSR”, it did not have any “badge”. But preserved most life-supporting devices and assemblies fuel pumps, injector(each cylinder has its own), filters, pipes, glow plugs(without them, the engine is not running), etc.

Estimated engine power about 20 HP As shown by operation, the motor unpretentious and reliable equipment for this purpose is important.

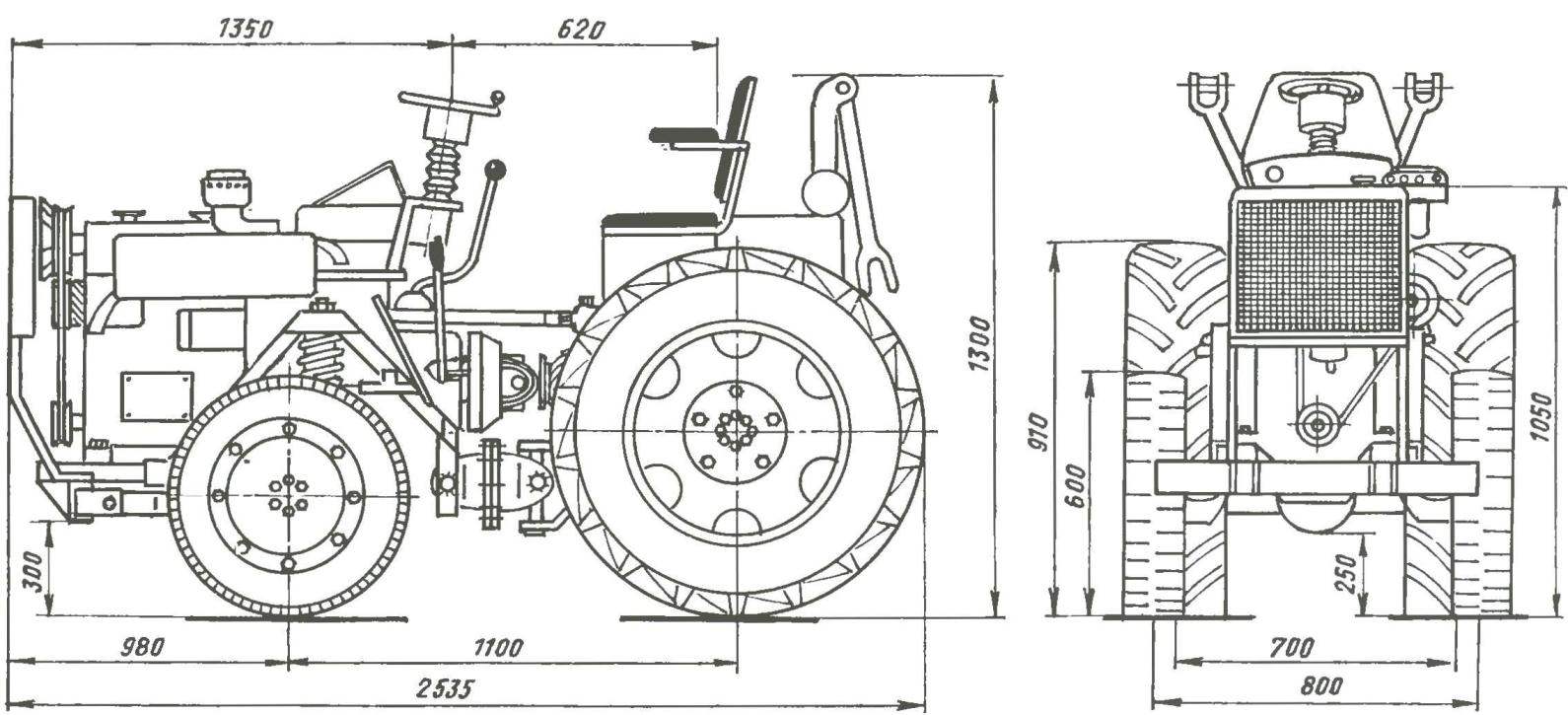

Geometry mini-tractor

The layout of the mini-trachoma:

1 — the hinge of an articulated frame (gimbal mechanism from MAZ); 2 — brake drum (GAZ-51); 3 — clutch; 4 — the suspension of the front wheels (from the ZAZ-968, 2pcs); 5 — engine (2 cylinder diesel); 6 — starter (GAZ-51); 7 — muffler (ZAZ-968); 8 — generator (GAZ-53); 9 — impeller (from agricultural equipment), 10 — pump; 11 — air filter; 12 — fuel tank (from a wheelchair); 13 — arm brakes (GAZ-51); 14 — araneus hydraulic (farm); 15 — battery box; 16 — oil tank 17 — PTO (BTR); 18 — gear shift (from car GAZ-51); 19 — rear wheel (for tractor “Belarus”, 2); 20 — hydraulic hoses (electric vehicle); 21 — the valve (electric vehicle); 22 — a charge for equipment (tractor “Belarus”); the 23 — seat 24 — shift lever (GAZ-51); 25 — steering wheel with power steering (electric vehicle); 26 — instrument panel (from the tractor “Belarus”); 27 — the radiator (from the car “Lada”); 28 — oil filter (from the tractor “Belarus”); 29 — fuel pump; 30 — throttle; 31 — front wheel (electric vehicle, 2 PCs.)

However, something had the power unit retrofitted: fuel tank is 20 liters and the muffler is adapted from an old wheelchair, the oil tank is welded by myself, borrowed from the “Lada” radiator and fan, alternator— GAS-53, the starter from the GAZ-51. Have replaced the starter gear (Bendix) on the right to the teeth of flywheel ring gear, although the engine can be started and the handle.

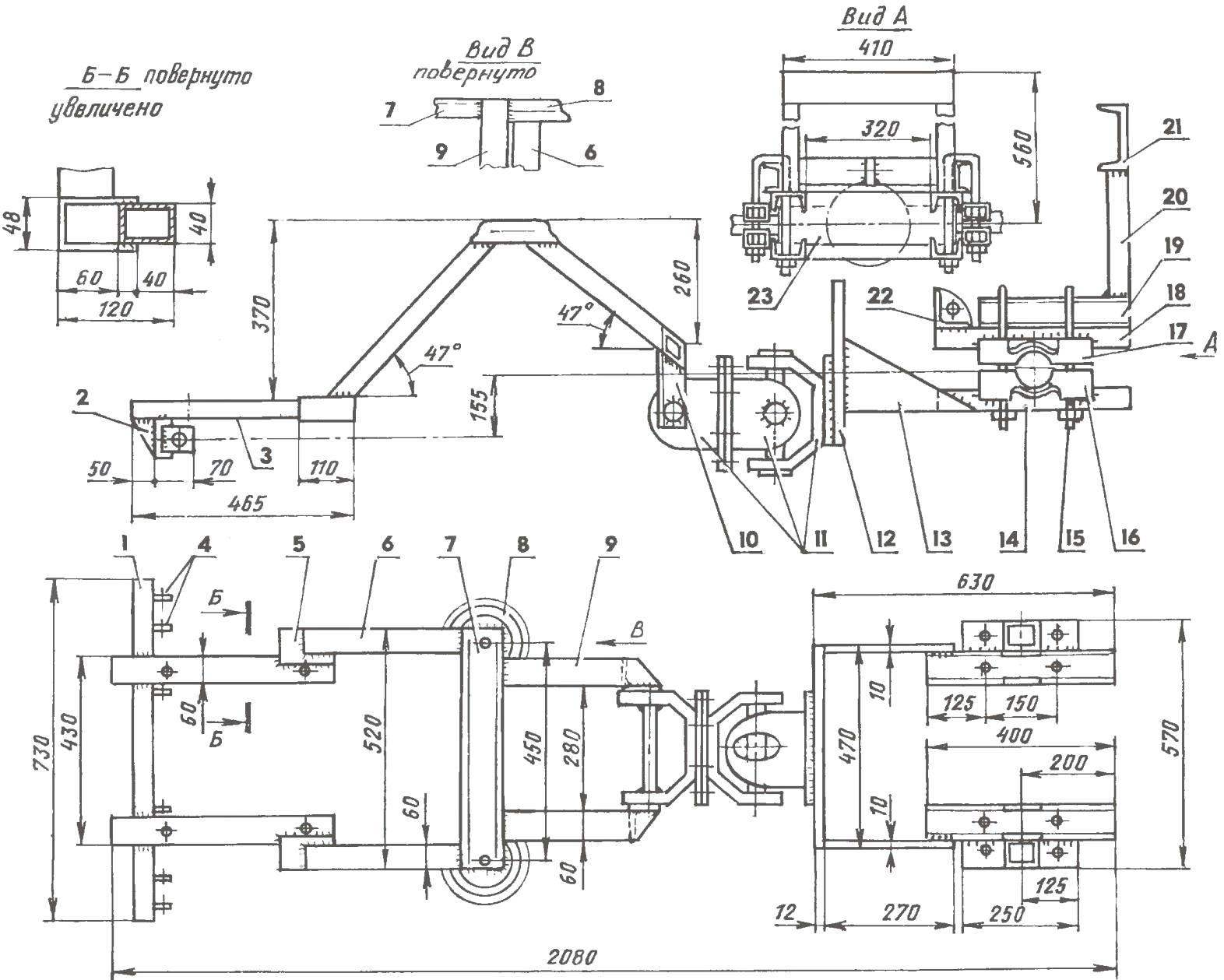

Frame mini-tractor, as mentioned in the beginning, articulated a “breaking” in the vertical plane. The articulation is made on the basis of the u-joint from MAZ. While the d-pad one pair of opposing pins mounted vertically, and the other itself stood horizontally, and welded them to the middle fork and the vertical left open and allow the rear fork to turn them.

The flange of the rear fork is welded to a vertical lateral wall steel plate 12 mm thick and the flange of the middle fork privernuli bolted to the flange of the front fork welded to the vertical uprights of the front articulated.

Frame (on the top view of the frame and stand is not shown):

1 — bumper (channel № 6,5); 2 – solitaire (steel sheet s4, 8 PCs); 3 — front side rail (pipe 60×40, 2); 4 — lugs front suspension (steel sheet s4, 8 PCs); 5 – support front slant rack (steel sheet s4, 2); 6 — front sloping strut of the portal (pipe 60×40, 2); 7 — transverse beam of the portal (from the truck); 8 — suspension strut (part of the disc wheel of the car, 2 pieces); 9 — rear oblique strut of the portal (pipe 60×40, 2); 10 — vertical stand front articulated (area 70×70, 2); 11 — solenaye joint (universal joint from MAZ); 12 — transverse wall (steel sheet s12); 13 — longitudinal wall (steel sheet s10, 2); 14 – lower (inner) side member rear half-frames (channel № 6,5, 2); 15 — M16 ladder (steel bar of Ø16, 4 PCs.); 16 the upper (outer) side member rear articulated (pipe 60×40, 2); 17 — outer lower spar of the subframe (pipe 60×40, 2); 18 — upper inner spar of the subframe (channel № 6,5, 2); 19 — longitudinal beam of the stand (channel No. 6,5,2 PCs): 20 front stand (channel № 6,5, 2); 21 — rear cross beam (channel № 9); 22 – front cross beam (area 70×70); 23 — rear axle beam (electric vehicle)

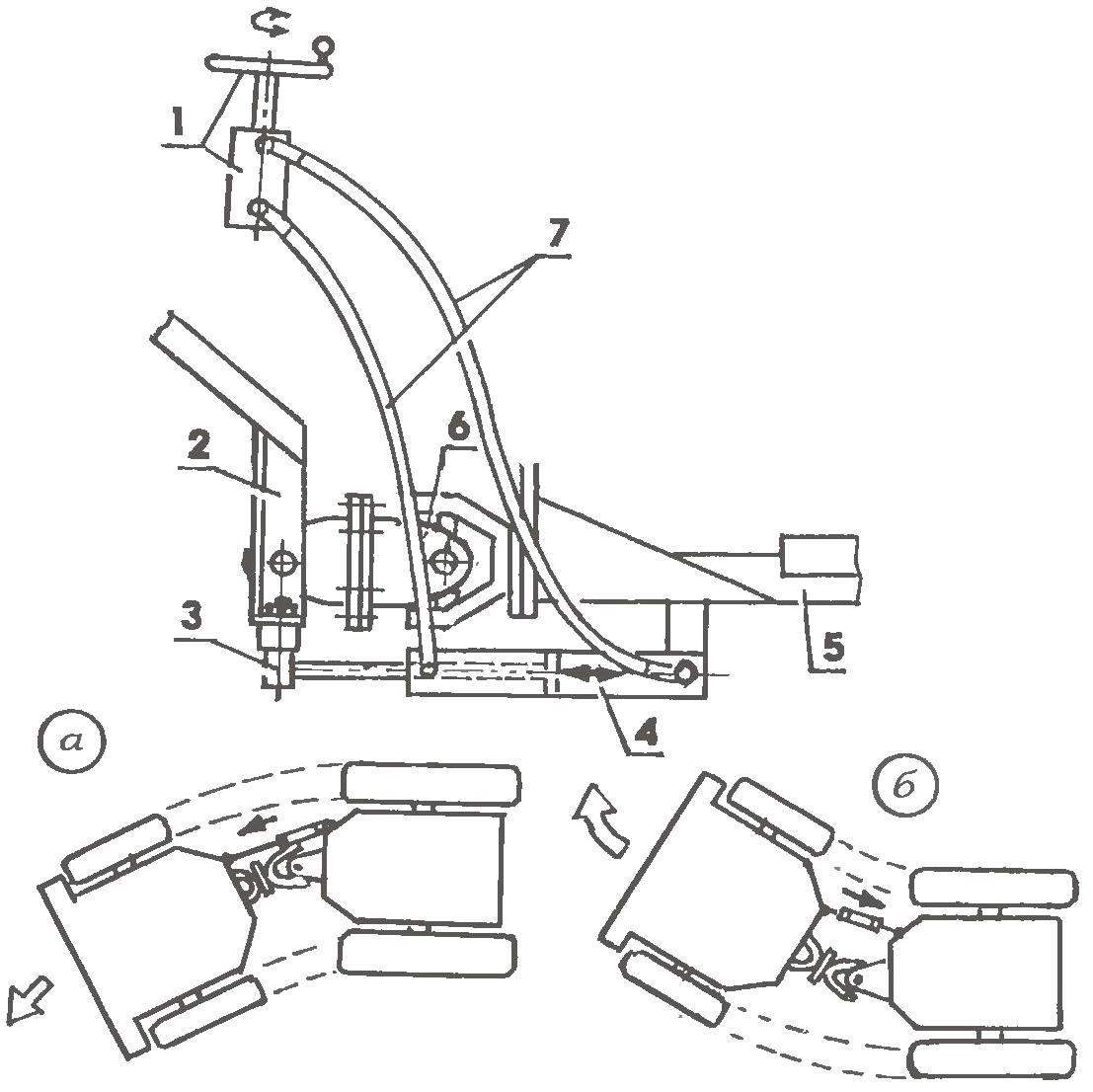

Steering control scheme (a — left turn b — right turn):

1 — steering wheel with hydraulic cylinder; 2 — vertical strut of the front articulated; 3 — retainer rod of the working cylinder; 4 — cylinder; 5 — front frame; 6 — solenaye joint; 7 — the hydraulic hoses

The back of the frame itself is very simple, but the addition of sub-frame and stand, but because as it turned out stacked Between the frame half frames and sub-frame using ladders fixed rear axle beam for which the rails are in place lodgements. The stand is fixed hitch (tractor “Belarus”) with a hydraulic cylinder for tillers. The rear drive axle to the frame is fixed rigidly, without suspension. Cushioning the rear of a mini tractor at the expense of optimal air pressure in the rear wheels.

Front of frame in the spatial and the execution is more difficult than the rear. This design happened because the front wheels have suspension, and independent. Suspension arms, springs and dampers are used from the car “Zaporozhets” in addition, in the future, the front wheels are suppose to do the leading, and therefore immediately laid the possibility of such alterations even in the design of the frame.

The engine is mounted on the side members of the front articulated rubber cushions.

Rear axle with main gear, differential and axle shafts from the Bulgarian electric vehicle. It is almost perfect for mini-tractor. I don’t even altered. But that track was exactly 700 mm (width between rows), wheel (used the front of the tractor “Belarus”) has established the opposite — the convex side of the discs out, rearranging them on the tires to tread again were “Christmas tree” forward the Front wheel is also from the Bulgarian electric vehicle. Because they have no tyres and the rims just rubber, for cushioning each of them provided a suspension. Levers suspensions and dampers taken from the old car “Zaporozhets”(where they stood at the rear wheels), the Hinges swinging levers secured to the front bumper. For cups (the upper stops) springs and dampers made a special portal. The portal bypasses the wheel so that does not preclude the possibility (if necessary) to bring him the prop shafts to do and the front wheels are also the leading. On top of the cross beam of the portal secured area. It set the steering column bracket, instrument panel (GAZ-53), and under panel — fuel tank.

Minimum ground clearance front 250 mm, rear 300 mm (potato leaves during processing is not damaged).

Transmission mini tractor conventional: clutch, gear shift, the driveline Gear ratio of the transmission with the engine speed and speed “traktorista” — a high speed it is not necessary, and the necessary good traction.

All transmission units from the truck GAZ-51 (apparently — truck). The transmission has a window to podstanovki Carter and mechanism of the PTO shaft. It was used from the APC — he and Carter came to the checkpoint without any alterations. This mechanism of two levers — the one I use to activate the oil pump NSH-10 hydraulic system and the other directly to the PTO. Oil tank of 10 l was placed under the seat, near the battery box. The casing of the clutch docked to the engine through a transitional thick steel plate which is made corresponding holes for its attachment to the engine and for mounting to her basket. Drive clutch actuation is hydraulic, from the GAZ-51.

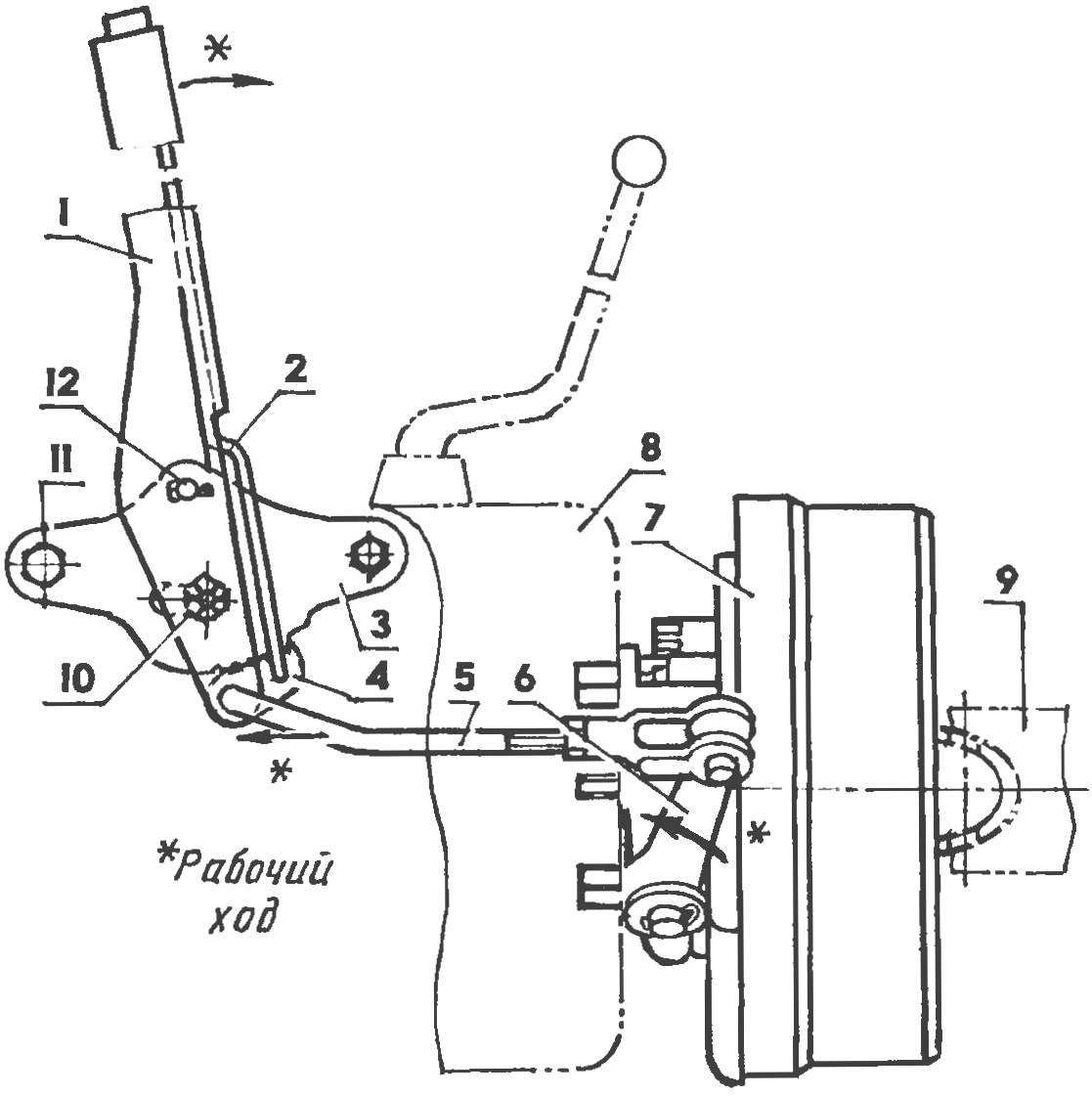

Diagram of brake system:

1 — arm; 2 — the leash of the withdrawal stopper; 3 — gear; 4 — doggy-stopper; 5 — pull fork with adjustable tip; 6 — actuating lever; 7 — the drum brake mechanism; 8 — a gear shift; 9 — universal joint; 10 — stroke limiter of the lever; 11 — a bolt of fastening of the toothed sector to the transmission case; 12 — the lever axle

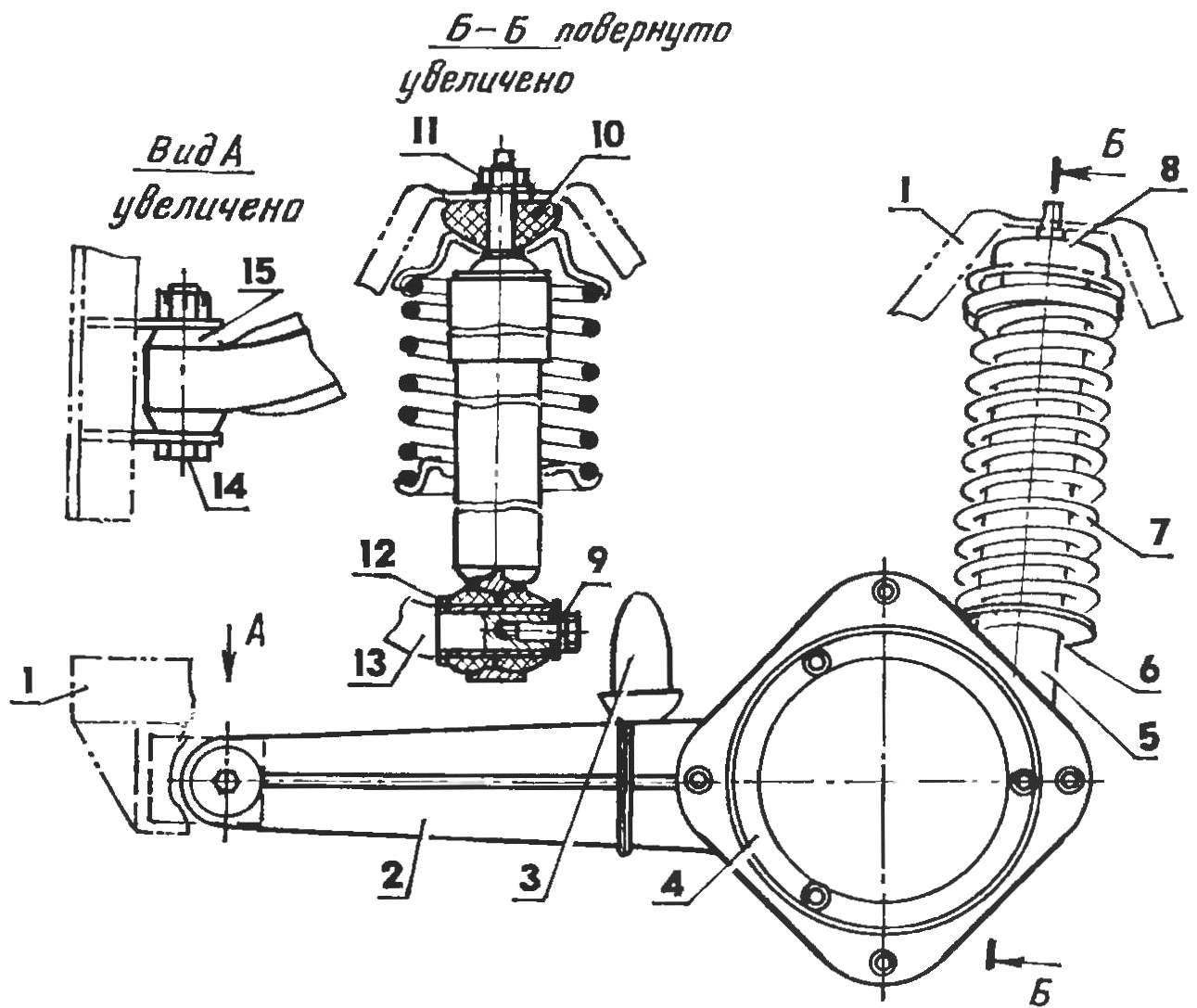

The suspension of the front wheels (POS. 2,3,4,5,6,7,8,9,11,12,13,15 — car ZAZ-968):

1 — portal frame; 2 — arm (from the car “Zaporozhets”); 3 — rubber bumper; 4 — flange; 5 — shock absorber 6 — the bottom Cup of a spring; 7— spring; 8 — the top Cup of the shock absorber; 9 — screw with washer: 10 — rubber gasket; 11 — nut and washer; 12 — a rubber shock absorber; 13 — pin bracket arm; 14 — a bolt with a split nut (2 sets.); 15 — silent-block lever (2 PCs)

The driveshaft is short but with two joints and without interference because it transmits torque from the transmission to the main transmission, even at the maximum “break” the frame on turns

Here, the shaft establishes a mechanism and a drum handbrake. He is also work — because the speed of the tractor is small.

Steering is used on lift truck, popularly referred to as “Slacker,” It is simple he has no kinematics, and only one hydraulics. So with the engine running, when the hydraulic system works, the controls are very easy: it is the usual steering wheel,while the rotation comes from “fracture” of the frame in a vertical plane with the hydraulic cylinder.

Another similar hydraulic cylinder provides lift (or lower) hinge mechanism connected to the plow or some other agricultural tool. Cylinder and linkage are located behind the seat, between the rear wheels. Under seat mounted battery box, near the right — four-position directional control valve (tractor “Belarus”), and the left — a homemade oil tank 10 liters.

Electrical mini-tractor 12-volt. So to start the engine using the battery of their cars. Necessary in light signalling is not, therefore, operate the tractor without it. But rear view mirrors set, so as not to twist constantly a head, watching laid furrow.

O. STARIKOV, p. Ostrovtsy, Moskovskaya obl.