It is known that most of the screws ships — lobed, And consequently, when playing them on-models necessary to accurately mark the three holes on the propeller hub, placing their centers is strictly in increments of 120°. Of course, if you need just one screw, this is not too difficult, but a lot of…

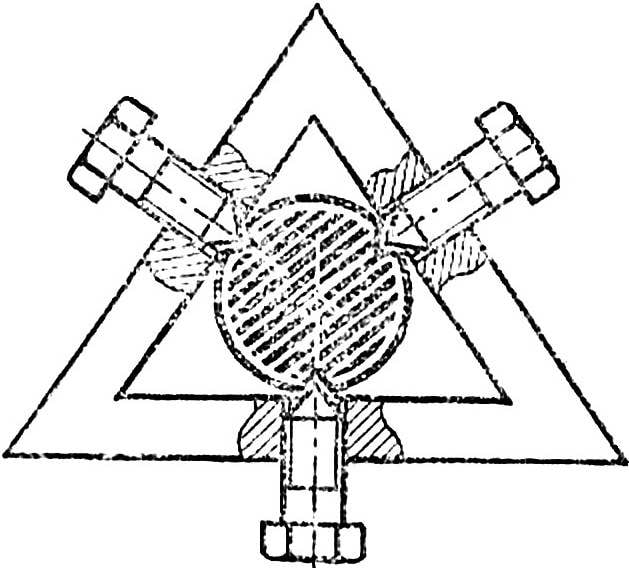

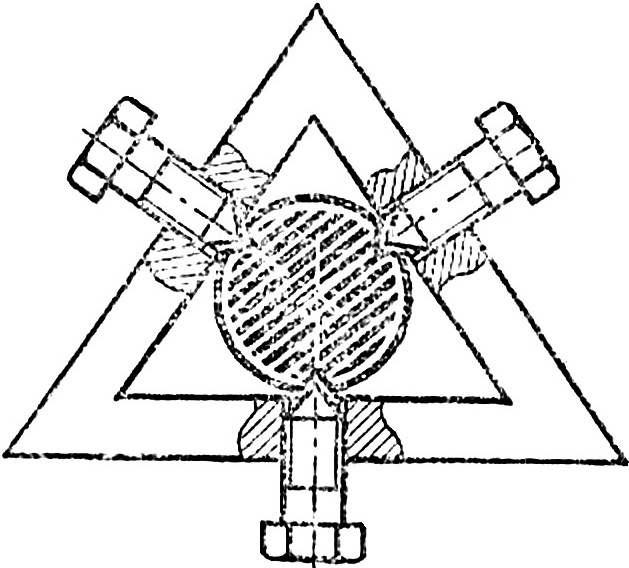

It is known that most of the screws ships — lobed, And consequently, when playing them on-models necessary to accurately mark the three holes on the propeller hub, placing their centers is strictly in increments of 120°. Of course, if you need just one screw, this is not too difficult, but a lot of… In short, I propose a simple device, with which it is easy to lay out any hub. It is a steel triangular frame, the walls of which split three threaded holes. Each is wrapped in hardened steel screw with a sharpened like core end. It is sufficient to insert between them the shaft or propeller hub and evenly tighten the screws and the workpiece will be a clear pressed-in recesses. Them remains to severity holes.