The idea of compression of air and practical use of its in new condition not new. Alexander Belyaev in his work “the Seller of air” introduces us to the prospects of this direction. The hero of his works Bailey clutched the air in the balls and kept them at a temperature equal to absolute zero.

The idea of compression of air and practical use of its in new condition not new. Alexander Belyaev in his work “the Seller of air” introduces us to the prospects of this direction. The hero of his works Bailey clutched the air in the balls and kept them at a temperature equal to absolute zero. My idea also comes from low temperatures, but rather from the fridge to make the compressor. To begin, I took no refrigerator, no compressor. (the compressor in this instance had already been taken). Soon the good people profiteer and the “heart” of the refrigeration unit motor-compressor. However, this unit had to be supplemented by compressed air storage, which I wanted to use for their needs.

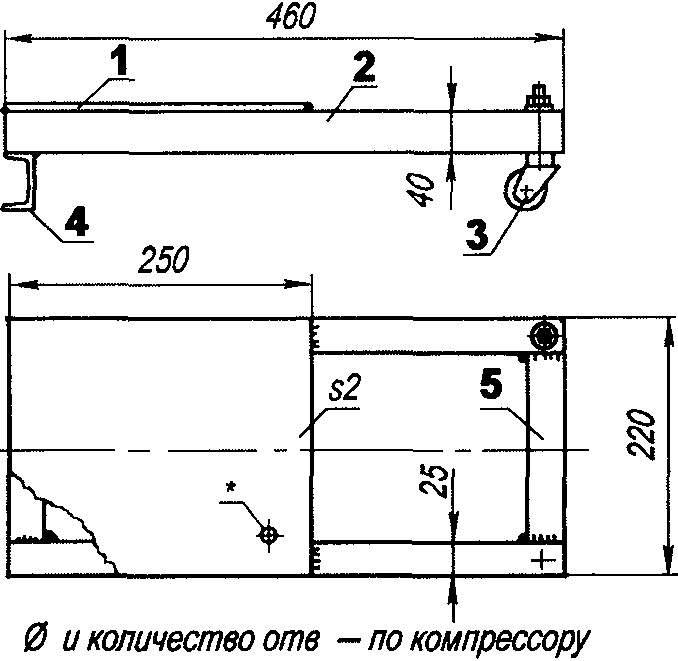

A suitable option is found in the form of five-liter container for gas stoves. Using the rest of his content, I was the lucky winner and cherished vessel. The receivers, and compressor wheels have now had it all to unite on some basis. Frame welded from rectangular pipe section 40×25 mm (if pipeline is not quite suitable and the steel area) the Wheels, with which it all began, they were asked to do at the new place of residence, I told them, figuratively speaking, did not deny they Stuck to the frame like family.

In the “Modeller-designer” has repeatedly seen articles on the use of the compressor of the refrigerator. Many thanks to the authors and the editorial Board for ideas. In many cases, craftsmen used the units of “retirement” age, in which the engine is burned, soured or broken valves, etc. They had to change the lubrication system, to use to drive another motor, etc. I also got a completely defective motor-compressor, so there is nothing did not change. The refrigeration compressor is able to produce a pressure up to 150 MPa (15 ATM), and maybe more. I such high performance is not needed, and I wondered how to keep the pressure in the desired range. First, it is necessary to visually control. This problem is easily solved — with a gauge and second, to restrict the upper limit at the desired level. The way suggested case. Had to swap wheels on the bike and at that moment I look at the nipple in the camera. With the skills of an experienced surgeon and came to the old cell is removed from it so I need the “Appendix”. The valve had to be adjusted to the necessary pressure (taken from Bicycle, motorcycle, autoconer, one opened at 2.5 MPa, others 5 — 7 MPa). My performance of this element is 5 ATM , anything higher — is released into the wild via the nipple.

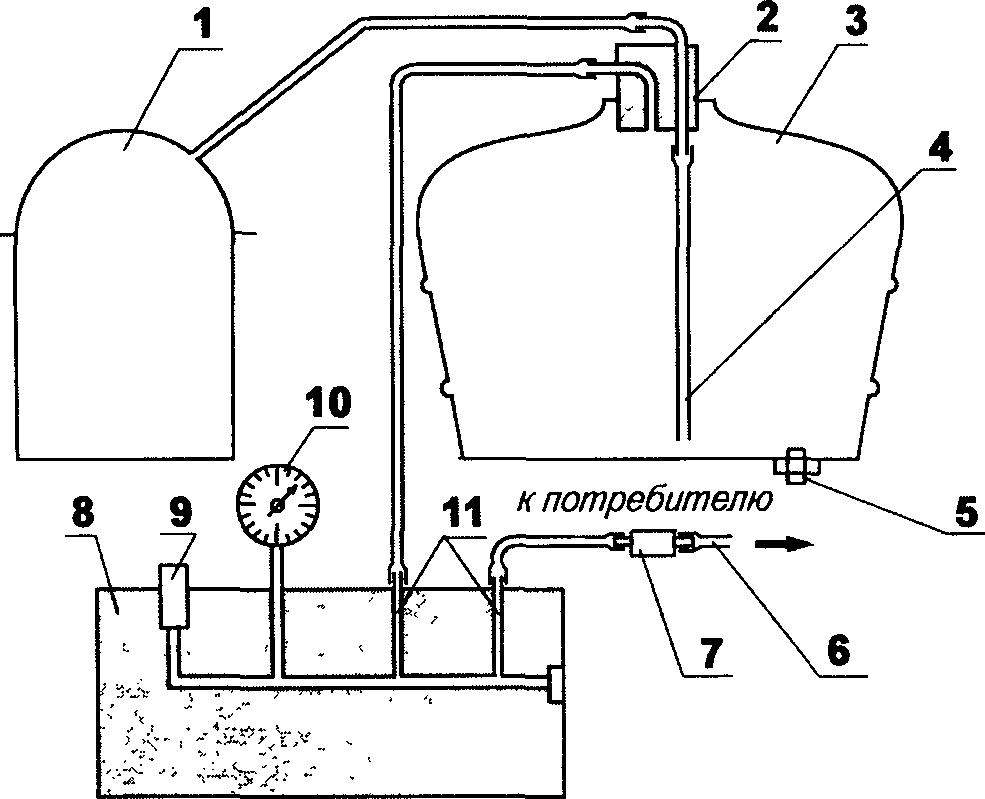

The circuit compressor unit:

1 — compressor (from a refrigerator), 2 — tube (modified valve 5-liter gas cylinder), 3 — the receiver (5-liter gas cylinder), 4 — separator of moisture vapor and oil (vinyl chloride tube); 5 — drain plug, 6 — pressure hose 7 — filter (car filter), 8 — body of the valve, 9 — pressure relief valve (Schrader valve from AutomationElement, maximum pressure — 50 MPa), 10 — monometer, 11 — fitting.

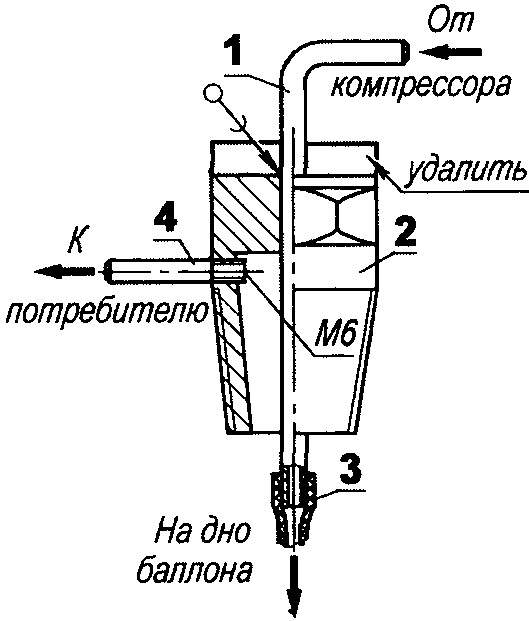

Tube:

1 — underwater pipe (copper Ø 5); 2 — the valve (from gas 5-litre tank), 3 — lagoudianaki pipe (vinyl chloride pipe), 4 — output fitting (tube Ø 6 M6 thread).

Frame:

1 — the deck under compressor, 2 — longitudinal, 3 — wheel (from the refrigerator, 2 pieces), 4 — fixed support (channel), 5 — cross member.

Pressure gauge, nipple, two connectors (for input and consumption of compressed air) have joined to block the metal bar, drilled at four points, connected by one channel. The holes tapped for the corresponding elements. This unit (call it “splitter-limiter”) is secured by two screws to the frame. Compressed air from the compressor through the hose is fed into the receivers. The gas cylinder kept the standard a bit cropped from the top valve. He removed the valve, and in its place soldered a copper tube, which is put inside the vinyl chloride tube going to the bottom of the receiver (for separation of moisture vapor and oil). To drain the condensate from the receivers in the bottom made plugged hole (welded nut M8 and tighten the bolt). Welding on the cylinder hold, filling it with water — that it left all the remnants of gas, which is explosive. According to another copper tube that is screwed into the threaded M6 hole in the valve, the air gets in above the splitter, and it is delivered to the consumer camera, ball, spray gun, etc.

Starting to think nothing was — to use a regular relay, fixing it to the frame. When painting a gun for the separation of moisture vapor in the hose is inserted the filter of thin clearing fuel for vehicles (well it retains moisture) and before work checked, to avoid condensation in the receiver.

This unit is compact, malacanan and fits easily on the desktop of homebrew.

M. MOSKVICHEV, Gomel, Belarus