Working on the model start with the manufacture of the keel of duralumin sheet thickness of 1.5 mm. About this operation carefully. The accuracy of the layout and processing will depend on the correctness of the contours of the entire boat, only the symmetric case will make it keep the course. Then take the frames. They are cut out of plywood with a thickness of 3-4 mm. cuts under the stringers cross-section 3X3 mm adjust work under planed slats of the longitudinal component of the hull. It’s the best way to collect on smooth Board-the slipway the keel up. Apply to the stocks of the drawing set that are drawn 1:1 scale, set the keel glued to the front bulkhead. Now it komovi frames. Fixed in such a way the position of the keel, glued the rest of the transverse set. Securing four stringers (pine slats 3X3 mm), we can assume that the hull is mostly assembled. Do not forget from the outset that the aluminum before gluing should be thoroughly degreased and proshkurit and best for the model is glue based on epoxy.

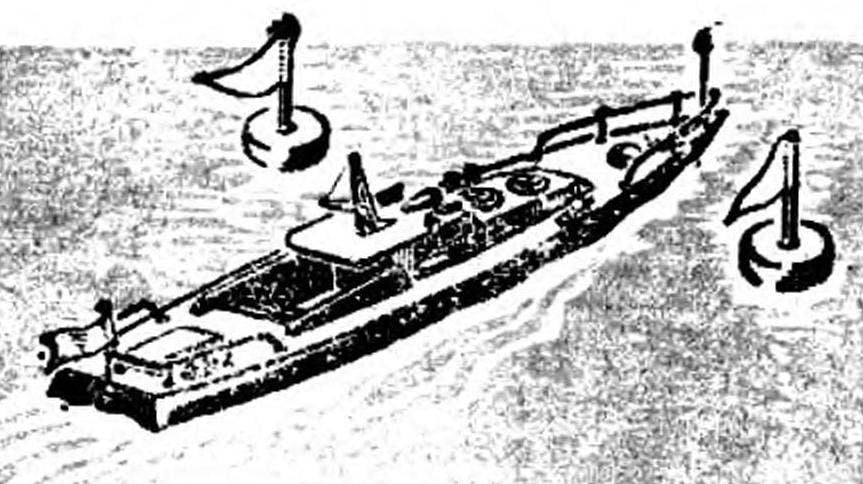

Fig. 1. Model speed boats:

1 Kil, 2 — the front frame, 3 — hull bottom, 4 — skin side, 5, 7, 9 — frames, 6 — motor with stern tube, 8 — battery box, 10 — plate clamp, 11 — propeller 12 — transom frame 13 — the wheel. 14 — stern flagpole, 15 — feed sernoe fence, 16 — Luke 17 — the fence of the cockpit, 18 — degree ladder, 19 — canopy felling, 20 — wall cutting, 21 — mast. 22 — gaff rig, a 23 — bulkhead of the pilothouse, a 24 — flashlight the distinctive side navigation fire, 25 — side glazed cabin, a 26 — spotlight, 27 — the front wall of the wheelhouse, 28 — hook (starboard oar), 29 — buoy 30 — Jack stock, 31 — front glazed cabin, 32 — front part of the deckhouse, 33 — mooring bollards, 34 — deck, 35 — Luke the nose compartment, 36 — anchor.

Vishkarev stringers in the form of contours, get the hull bottom of the hull, using cutting mm plywood customized but place the cardboard templates. After the adhesive has cured remove the housing from the pile and panel side of the same plywood, pre-cut down and vishkarev zygomatic gluing the bottom and stringers.

While polymerized resin, make lodgements under the model out of plywood with a thickness of 5 mm and connect them to the Linden rail cross-section of 12X12 mm and a length of 270 mm. install the case on lodgements will greatly facilitate later work.

Start with gluing the plant, which is our industry in the form of finished products especially for boat. Check her work carefully and make sure that rear oil seal deadwood was not allowed to penetrate the water inside the tube. After removing the prop, insert the engine into the housing, fasten again the screw and cover of deadwood in the bulkhead and keel. The rear end of the clamp tube between the two curved plates riveted to the keel. Then cover the entire body from the inside with epoxy resin diluted in a solvent for nitropaints that will protect the boat from accidental ingress of water inside the case. In the same way and need to trim the entire surface of the box for flat batteries power the motor, the workpiece which is cut from thin plywood. When the glue fully hardens. install the box in place. The deck can also be plywood. But far more beautiful will look like the deck is composed of separate slats, and fake section 2X5 mm must alternate with thin plastic (strips of wood veneer of a width of 2 mm). Assemble the model, which with a margin covers the entire body, sand paper, bring it to a thickness of 1.5 mm and top epoxy varnish. Before gluing the deck, cut the required holes and turn-over, where necessary, their end faces. Lacquer the deck above and below, install it and treat the shape of the hull, glue the steps and the side plates of the frame of the cockpit. Work on the case ends with a sticker outline matousek — set on rib lath section Formed 2×5 mm. above the deck, the protrusion height of about 3 mm will serve as the landing place of the add-in and prevent the boat from getting water through this connector. Check for gaps between the deck and the frames bounding the engine compartment, and in the way that the volume of the box for the batteries. Optionally, fill these joints with diluted resin.

Run the add-in does not require special explanation. Fully gathered it, decorate the outer surface of walnut veneer and glue some glass cut from thin acrylic plastic. A prerequisite is the density of the add-on framing matousek. Covering the detail of the outside and inside varnish, do some small elements. Boat hook and paddle, carved from solid wood, saturate the stain with lacquer, and then put them back into the brass clips on the superstructure. Brass also cut out the edging of the Windows, sheet duralumin — reflectors, navigation lights, each of which insert on the right simulates the lantern a piece of red plastic to the left green. Plastic will blow the spotlight, the mast can be made of any rail, lifeline — from chetyrehkilometrovoy plywood. On the rear bulkhead of the cockpit, glue the door — plate with rounded edges.

Fig. 2. Details of the lodgement of the model.

In the case of small less detailed, they are installed only after the end of exterior: processing of sand paper, a two-fold filling with a mixture of nitrocellulose lacquer and talc and colouring by nitroenamels. Leave intact only the deck if it stacked. The paint scheme of the case the following: above waterline — white or ivory color; below the waterline — dark brown (chocolate); line — yellow. Silverfish top the mast with black paint — the body of the floodlight and fencing navigation lights. Solder hand rails bow and stern railings, wrapped the joints of the individual parts of the copper wire and the Gulf of solder to get in these places balls. Drill the deck holes and insert the fence. Mooring bollards wooden, covered with black paint. Orange colored buoys. The anchor can be made of wood, but much more spectacular looks machined from brass. Don’t forget the Jack stock, which will help accurately aim, and about the ensign Lacquer unpaintable items.

So, the model is ready… can’t wait to start? A little wait — we still have to balance your microcode. Surely the waterline, caused by drawing, found higher water levels. With lead shot until the desired precipitation is a precondition for successful races. When at last the boat is correctly installed in the water, pour the fraction of epoxy resin (needless to say, during debugging you have inserted the batteries in place), it also secure the tube to the nose compartment.

Before going on the water area of the grate model autobella. From time to time renovating this coverage, you will be able to maintain the boat in excellent condition for several years of operation. Now try how the model behaves on the move. Better to keep her on a leash at first — a thin fishing line length of about 20 m. the Straightness of the course encourage bending the rudder. A stop is carried out using the gap of the power circuit of the timer .used in photography. Thinking in Matousec and connection to the power supply, try to place the timer as low as possible.

One last tip: between races to take short breaks. They will give you the opportunity to relax and gain strength not only you but also the batteries.

Ya VLADIS, engineer

Recommend to read “HIDDEN” HALLWAY Behind the scenes of the hanger, if you make it movable, you can hide a built-in closet or even a small storage room in your hallway.

This “two-layer” solution for a home wardrobe in... AEROBATICS OF A KITE That a kite can be under the control of a pilot to perform almost a full range of aerobatics, very few people know. It should be noted that the modelers individual samples of superslow...  In his hands standing on the bridge of a schoolboy elegant model powerboats. The boy winked one eye, as if before the shot. Finally, the wind has abated a little — it is possible to produce a model. Raising astern low backwash water, the boat went to the goal. After fifty meters posed a number of buoys, medium form the gate width of two meters. It is best to get it in them — a rating in the highest. With a frozen heart, waiting for the young athlete how to behave microcode. There is a hit! Even the rising wind and waves did not prevent him to enter into the Central gate.

In his hands standing on the bridge of a schoolboy elegant model powerboats. The boy winked one eye, as if before the shot. Finally, the wind has abated a little — it is possible to produce a model. Raising astern low backwash water, the boat went to the goal. After fifty meters posed a number of buoys, medium form the gate width of two meters. It is best to get it in them — a rating in the highest. With a frozen heart, waiting for the young athlete how to behave microcode. There is a hit! Even the rising wind and waves did not prevent him to enter into the Central gate.