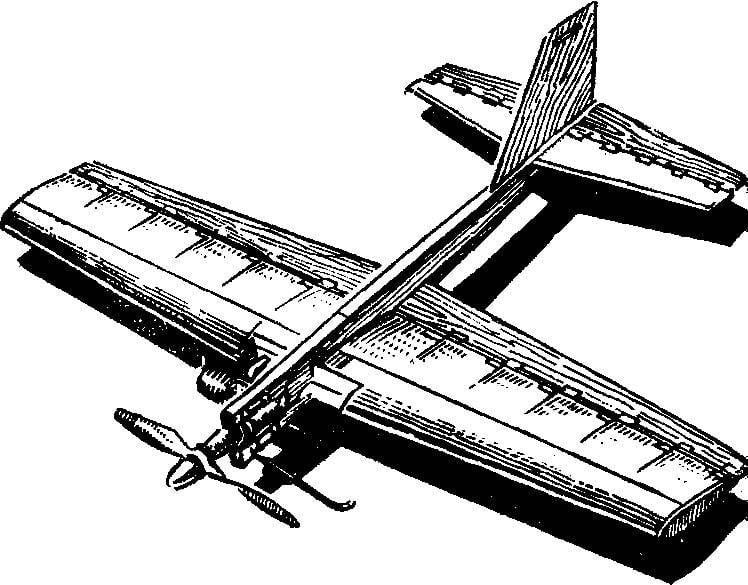

This “bouzoukia” developed in the aeromodelling circle regional station of young technicians in the city of Murmansk. Speaking with her at the regional competitions, an eighth-grader Sasha of Beidou became the champion among students. Design feature — a fiberglass sock of the wing, much increasing its survivability.

This “bouzoukia” developed in the aeromodelling circle regional station of young technicians in the city of Murmansk. Speaking with her at the regional competitions, an eighth-grader Sasha of Beidou became the champion among students. Design feature — a fiberglass sock of the wing, much increasing its survivability.

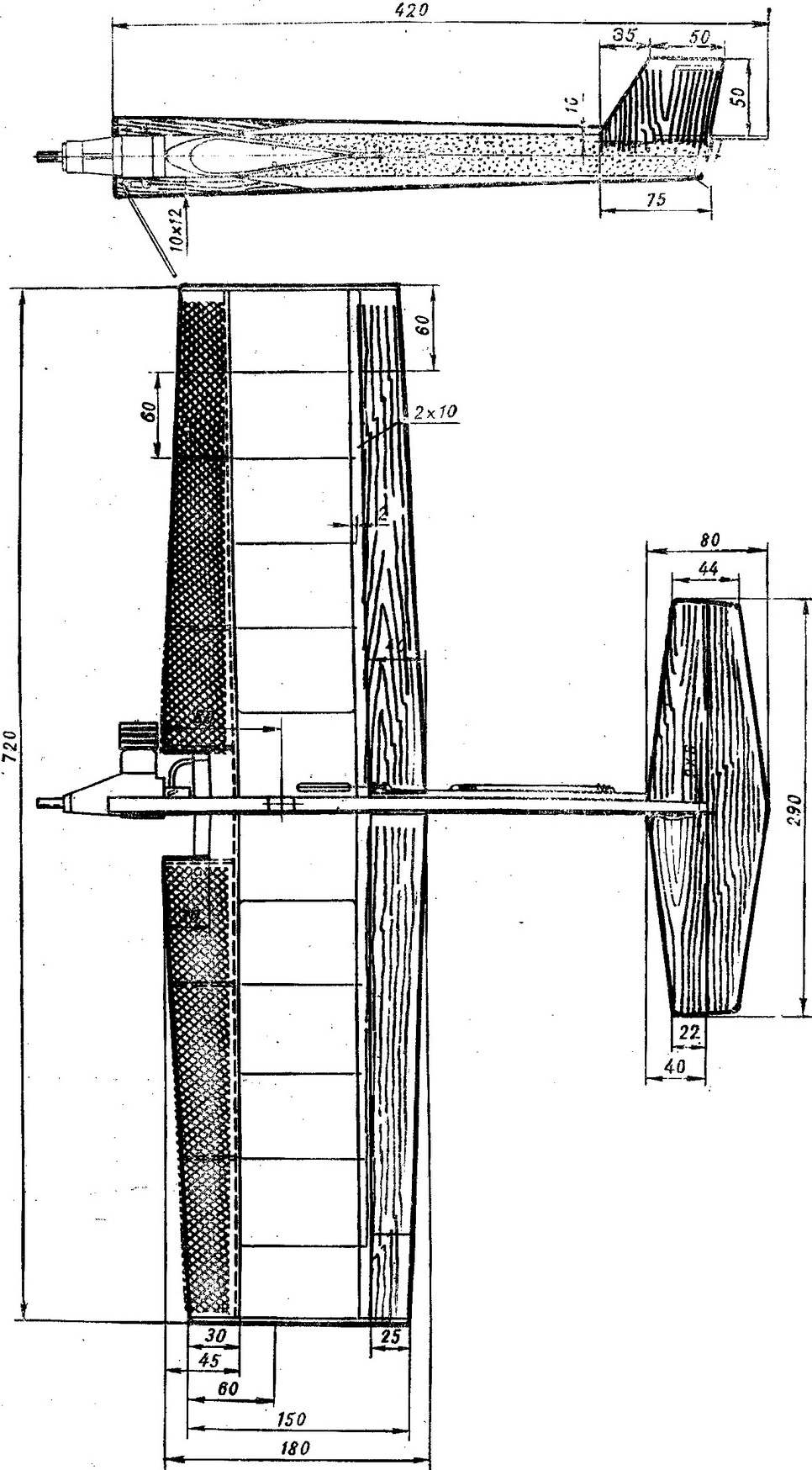

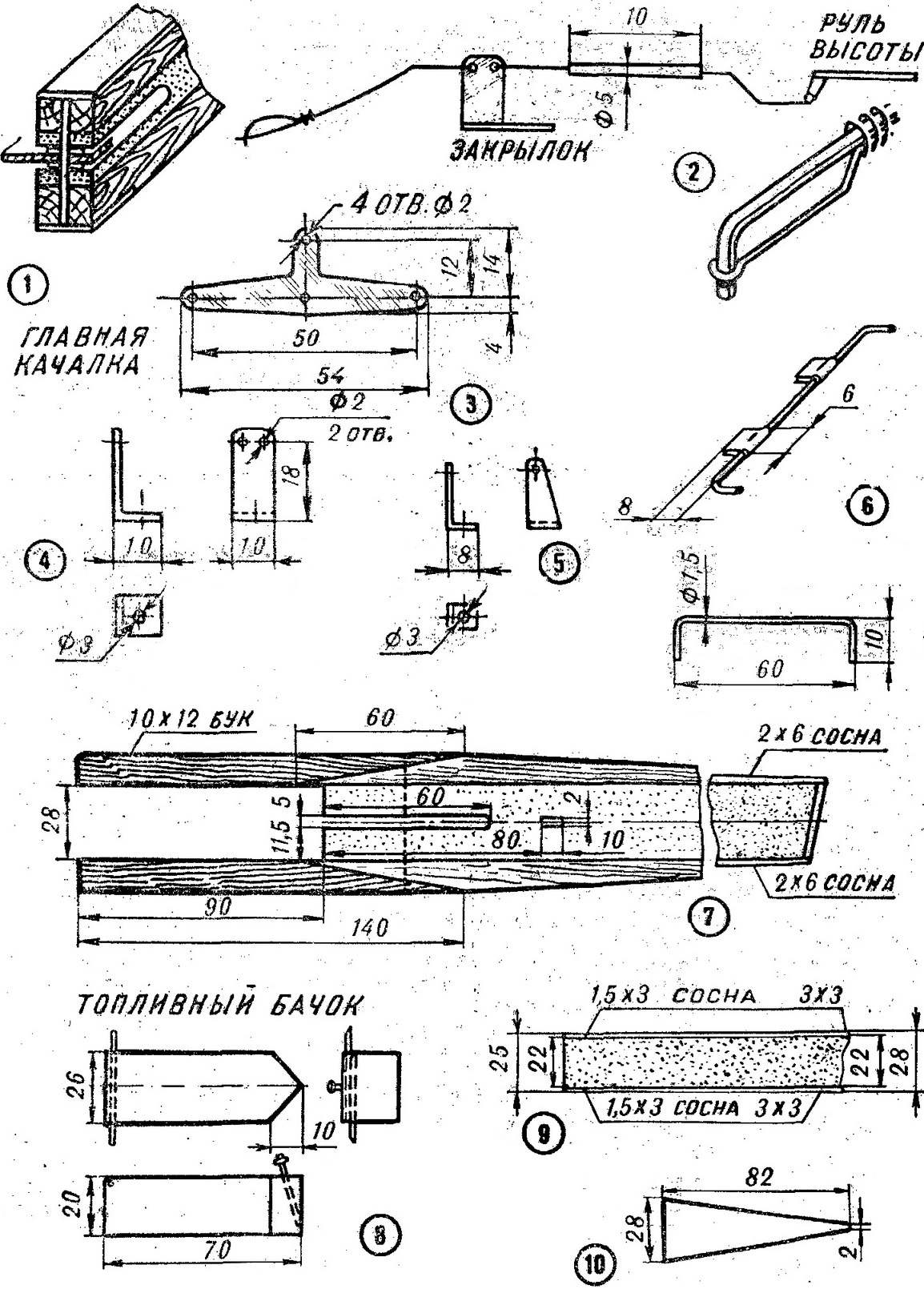

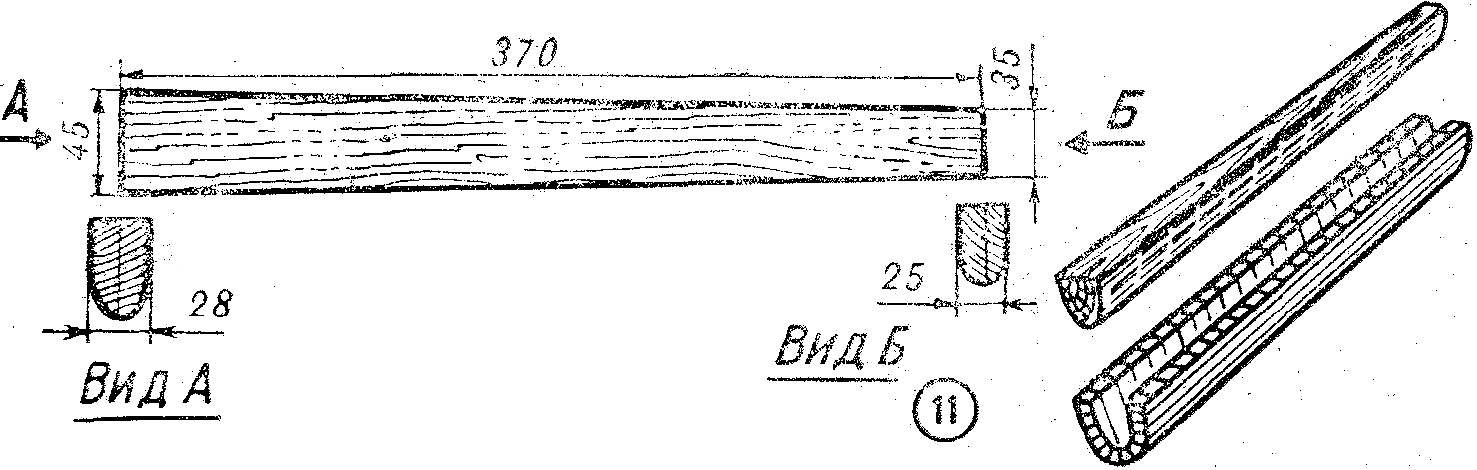

Production models start with the wing, as this is the most difficult element of the design. For forming of the sock make a snap — matrix and a punch. Last vystrugat of a pine bar, cover six layers of Amalita and sand. The matrix is made by punch from two layers of fiberglass glued between the rails for rigidity. The gap between the surfaces of the matrix and punch in the range of 0.6—0.8 mm.

For forming of the sock take three layers of glass, of a thickness of 0.08 mm as a separation layers between the matrix, fiberglass and punch use Mylar with a thickness of 0.15— 0.2 mm. After vyklicky sock will receive the mirror surface, and further processing is not required.

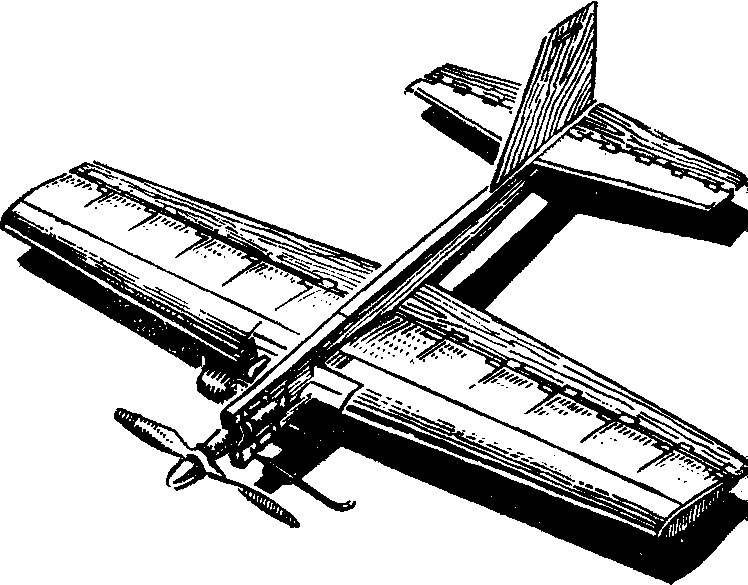

The wing spars are made of two pine shelves (the root cross-section 3X3 mm, at the end of 1,5X3 mm ) and foam filling. Material rib — pine; they are all the same shape. Wingtips are also made of pine or basswood, 3 mm thick Flaps and empennage of the pine plate having a thickness of 2 mm.

The fuselage design is the same as the wing spar. Bars motor from birch, the rest of pine.

Fig. 1. “Bouzouki” wing sock of fiberglass.

Fig. 2. Model details:

1 — mount rockers, 2 — traction control, 3 — rocker, 4 — arm flap, 5 — the lever of the Elevator deflection, 6 — drive flap, 7 — body, 8 — tank, 9 — rib, 10 — spar.

Fig. 3. Matrix and a punch for manufacturing the sock.

First, collect the right part of the wing. Rib, spar, trailing edge glue with epoxy, then insert into the fuselage. Then assemble the left wing. Ribs in the trailing parts of the wing in place. Please note that the tails of ribs on 2 mm cut into the rear edge.

Fiberglass toe and ending of stick in the last turn. To the left ending insert the brass tubes for the output cords. When you build the wing be sure to insert the drive flap. Each of them is suspended on 12 strips of nylon fabric size ones 8×20 mm. Wing covered with long staple paper three times covered with Amalita. (Editor’s note: tech for pasting model use Mylar.)

Rocking fasten on the axis of the wire Ø 1.5 mm, which insert into the hole in the bars of the fuselage and secure from falling out two plates of plywood with a thickness of 1 mm, mounted flush. Skid of wire OVS Ø 1 mm glue on the resin in the tail part of the fuselage. The Elevator is hung in the same way as the flaps of 12 strips of fabric. For protection of the propeller of the model when landing, the bottom mounting screws of the motor clip wire Ø 2.5 mm, length 100 mm.

At the ends of the control rods, install the locks (ring-locks) from sewing pins, the l-shaped ends slide into the wooden rod and secure the thread on the glue.

On models equipped with the engine KMD-2,5 screw 160X200. Tank of conventional design. Weight “bouzouki” 370,

V. NOVOSELTSEV, Murmansk