Wing Assembly is very simple. With the help of small nails slats are fixed to the Plaza-the stock (do not forget to cover it with plastic wrap!); between the front and rear edges are attached to the ribs; the connection of the frame elements promazyvaetsya casein or epoxy glue. After drying, the adhesive frame is processed cloth and fitted by a Mylar film or vellum. The latter is covered in several layers of Amalita or improvised composition of solvent for nitropaints and debris celluloid. The technology of stitched wing Mylar film is well known to readers of our publications.

The fuselage model and a cord going from the base, carved from lime wood thickness of 10 mm, and two plates of mm plywood glued on both sides of the base in the mounting area of the engine. The tail part of the fuselage is the same and the rudder is assembled from pine slats with a cross-section 3×6 mm. Connection elements of the keel — butt joint, using epoxy glue. If Assembly is casein glue, it is recommended that the connection vpoldereva with a lift to the junction of cotton thread.

The fuselage is exactly the same as the wing, fitted by a Mylar film or vellum. In the upper part of the keel is fixed a triangular horizontal tail, collected from pine slats cross section of 3×5 mm and covered with Dacron or rubber stamp.

Chassis cord model — double column, with the tail crutch. Structurally, the front wheel and crutches represent a single detail, from curved steel wire brand 50KHFA or OBC Ø 2,5 mm. Mount this stand to the model is the screw diameter mm 3х30 using aluminum square washer-lining. By the way, this screw connects into one wing and the fuselage. For fixing the wing relative to the fuselage serve beech pins glued into the fuselage.

In the rear of the wing fixed handlebar height — plywood strip 3 mm thick and 25 mm wide. Mount the rudder to the trailing edge by using the five string loops. The thread for this, it is best to use nylon holes for hinge drilling polumillimetrovogo drill bit or stud of the same diameter with a pitch of 2 mm on a plot of 15 mm.

Rocking control cut from the sheet duralumin with a thickness of 2.5 mm control rod Elevator is bent from a Bicycle spoke. Hog steering — aluminum, material thickness of 1.5 mm. is Properly adjusted, the control system provides a deflection of +10° with full stick control model.

The fuel tank soldered tinplate with a thickness of 0.3 mm. However, it is easier to use any plastic bottle from the medication — for example, drops “Galazolin”. To secure it to the fuselage, the latter is cut out groove. Filling and feeding tubes are introduced into this tank through the tube, instead of the drainage tube in the top of the tank provides a hole diameter of 1 mm.

Cord model is designed for operation with engine MK-17, but it will fit and MC-12B, and “МАР3” with a working volume of 2.5 cm3. The engine is mounted on the fuselage with screws M2,5 or M3 nuts and washers.

To run the model is to use steel cords with a length of 10 to 12 m and a diameter of 0.3 mm.

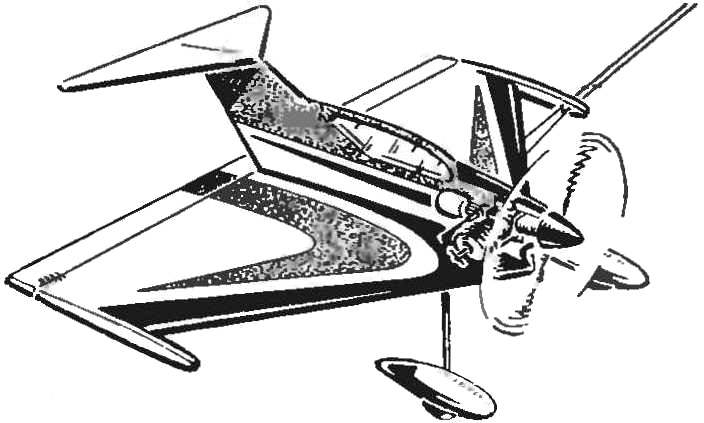

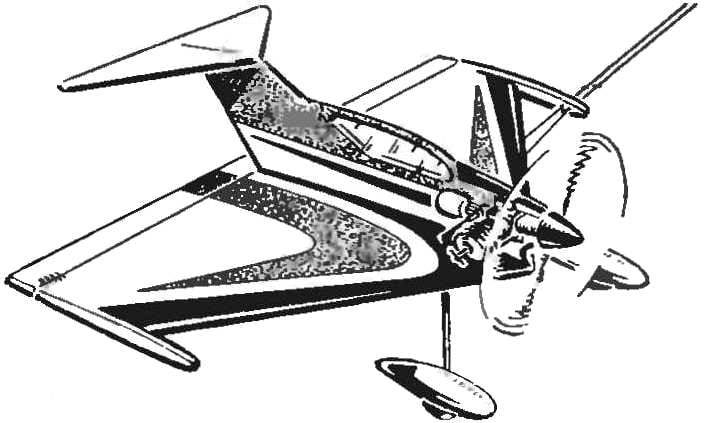

Training cord model:

1 — Kok-nut, 2 — propeller, 3 — pad (plywood with a thickness of 1 mm, 2 EA.), 4 fuselage (lime plate thickness of 10 mm), 5 — fuel tank 6 — the leading edge of the keel (pine rail section 3×6 mm), 7 — rib (pine rail section 3×6 mm), 8 — end rib (pine rail section 3×6 mm), 9— rear edge of the keel (pine rail section 3×6 mm), 10 — the tail and nose landing gear (steel wire grade optical fiber or 50ХВА Ø 2.5 mm), 11 — clip on the landing gear (dural band thickness: 2 mm), 12 — screw 3х30 mm, 13 — wheel chassis, 14 — pin (beech rod Ø 4 mm), 15 — wingtip (Linden rail thickness 4 mm), 16 — end rib of the wing (plywood thickness of 3 mm), 17 — spar (pine rail section 4×6 mm), 18 — filament loop of the Elevator, 19 — Elevator (plywood plate of 3 mm thickness), a 20 — trailing edge of the wing (pine rail section 3×6 mm), 21 — rib wing (plywood plate of 3 mm thickness), 22 — rib stabilizer (pine rail cross section of 3×5 mm), 23 — the trailing edge of the stabilizer (pine rail cross section of 3×5 mm), 24 — front edge of the stabilizer (pine rail cross section of 3×5 mm), 25 — pylon rudder (aluminium 1,5 mm) 26 — pull Elevator control (Bicycle spoke), 27 — leaders of the control system (steel cords Ø 0.3 mm), 28 — rocking chair of management (duralumin with a thickness of 2.5 mm), 29 — boss (lime bar), 30 — the leading edge of the wing (pine rail section 6×6 mm) 31 — front scarves (lime bars), 32 — Central rib (Linden, thickness 10 mm), 33 — Klondike (beech bar). The fuselage, wing and stabilizer, the engine side projection, the planned projection of the fuselage not shown.

Recommend to read

OUT OF THE ORDINARY — SPECIAL

OUT OF THE ORDINARY — SPECIAL

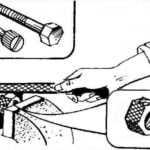

Many products have elements of quick fixing which uses a special manual nut or screws with knurled head. Losing such detail — it is simple, but to pick up then another of the same — much... LOOP ON THE CRANE

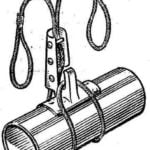

LOOP ON THE CRANE

What kind of "aerobatics" not started accidentally discharged the cargo to be hoisted, it will reliably keep a simple but effective lifting device, manufactured by the Leningrad pioneer...