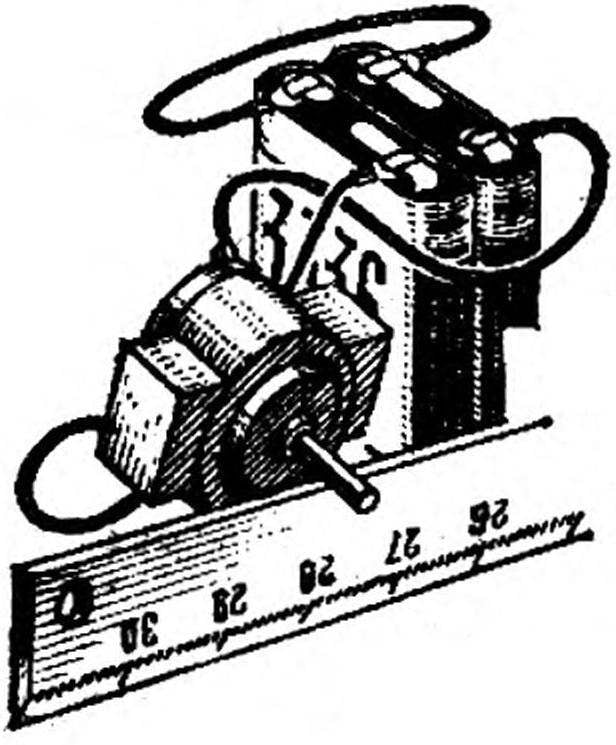

Probably the majority of readers, modelers had to build a model microelectrophoresis. These are good motors, easy to maintain — put it on the car, hooked up the batteries, and you can experience the new design in action. But how well able to use the power of the motor depends on the manufacturing quality of the drive. First and foremost, from its driving member connecting the motor with the mechanism. The slightest imbalance mounted on a gear shaft, the runout of the friction roller or pulley, and the engine will not even crank gear. The origins of the errors most often lie in the landing accuracy of a leading element on the axis of the armature. As a rule, planting the diameters of the parts do not match, and you have to wind on the shaft threads with glue or pull on it cuts the vinyl chloride pipe. It is clear that to talk about alignment in these cases is not necessary.

Probably the majority of readers, modelers had to build a model microelectrophoresis. These are good motors, easy to maintain — put it on the car, hooked up the batteries, and you can experience the new design in action. But how well able to use the power of the motor depends on the manufacturing quality of the drive. First and foremost, from its driving member connecting the motor with the mechanism. The slightest imbalance mounted on a gear shaft, the runout of the friction roller or pulley, and the engine will not even crank gear. The origins of the errors most often lie in the landing accuracy of a leading element on the axis of the armature. As a rule, planting the diameters of the parts do not match, and you have to wind on the shaft threads with glue or pull on it cuts the vinyl chloride pipe. It is clear that to talk about alignment in these cases is not necessary.

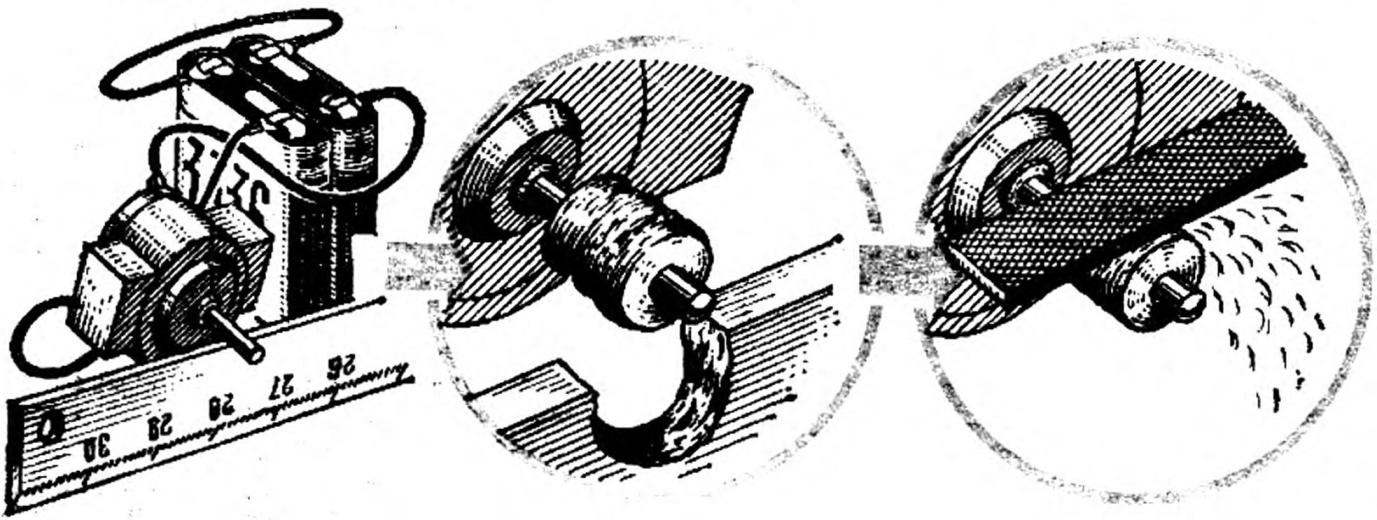

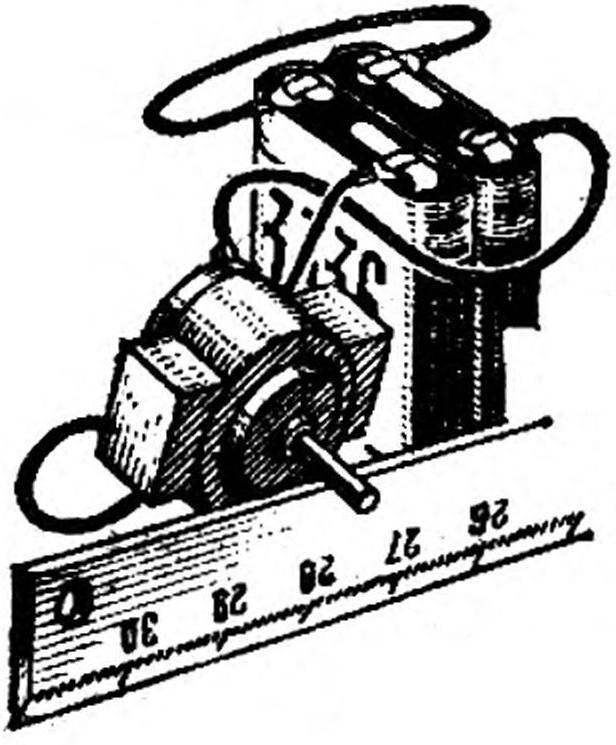

Time to get rid of such problems will help the unusual method proposed by Moscow schoolboy Mikhail Plotnikov. The problem is solved very easily. The motor is connected to the source voltage, twice the work, and to the rapidly rotating shaft with the edge pressed against the polystyrene chip line. The plastic is quickly heated, melts and covers the axle evenly. Within seconds, manages to weld the barrel bushing Ø 6 mm and a length of about 7 mm. plastic is Cooled, grind it with needle files directly into the engine, turning now to “lathe”. The friction bushing and the pulleys do not need: they are cut from the material of the weld of the sleeve; to fit the shaft diameter at gear too easy. If the bushing is not needed, it cut down on the engine.