The driving force of the engine during the flight of model airplanes, aerovision or aeromobile is the thrust of the propeller. The quality of the workmanship and clarity of the selection of the propulsion depends largely on the General characteristics of the constructed model. It is therefore clear that the design process of the propellers is paid maximum attention. However, the calculation methods of the selection of propellers is highly intricate, time-consuming and not very accurate. Today we recommend a number of well-established screws, already tested on a mass micro-motors internal combustion.

The driving force of the engine during the flight of model airplanes, aerovision or aeromobile is the thrust of the propeller. The quality of the workmanship and clarity of the selection of the propulsion depends largely on the General characteristics of the constructed model. It is therefore clear that the design process of the propellers is paid maximum attention. However, the calculation methods of the selection of propellers is highly intricate, time-consuming and not very accurate. Today we recommend a number of well-established screws, already tested on a mass micro-motors internal combustion.

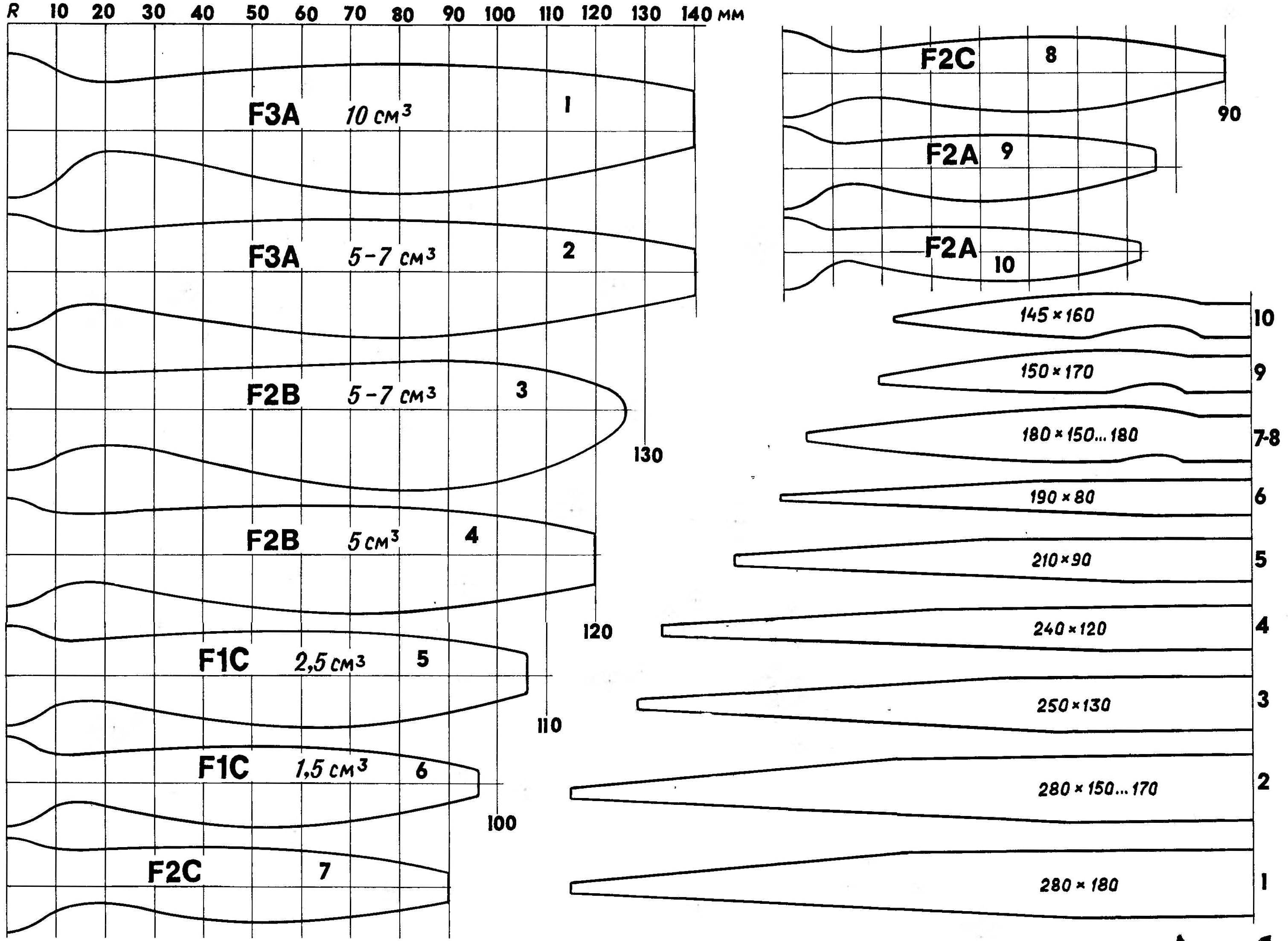

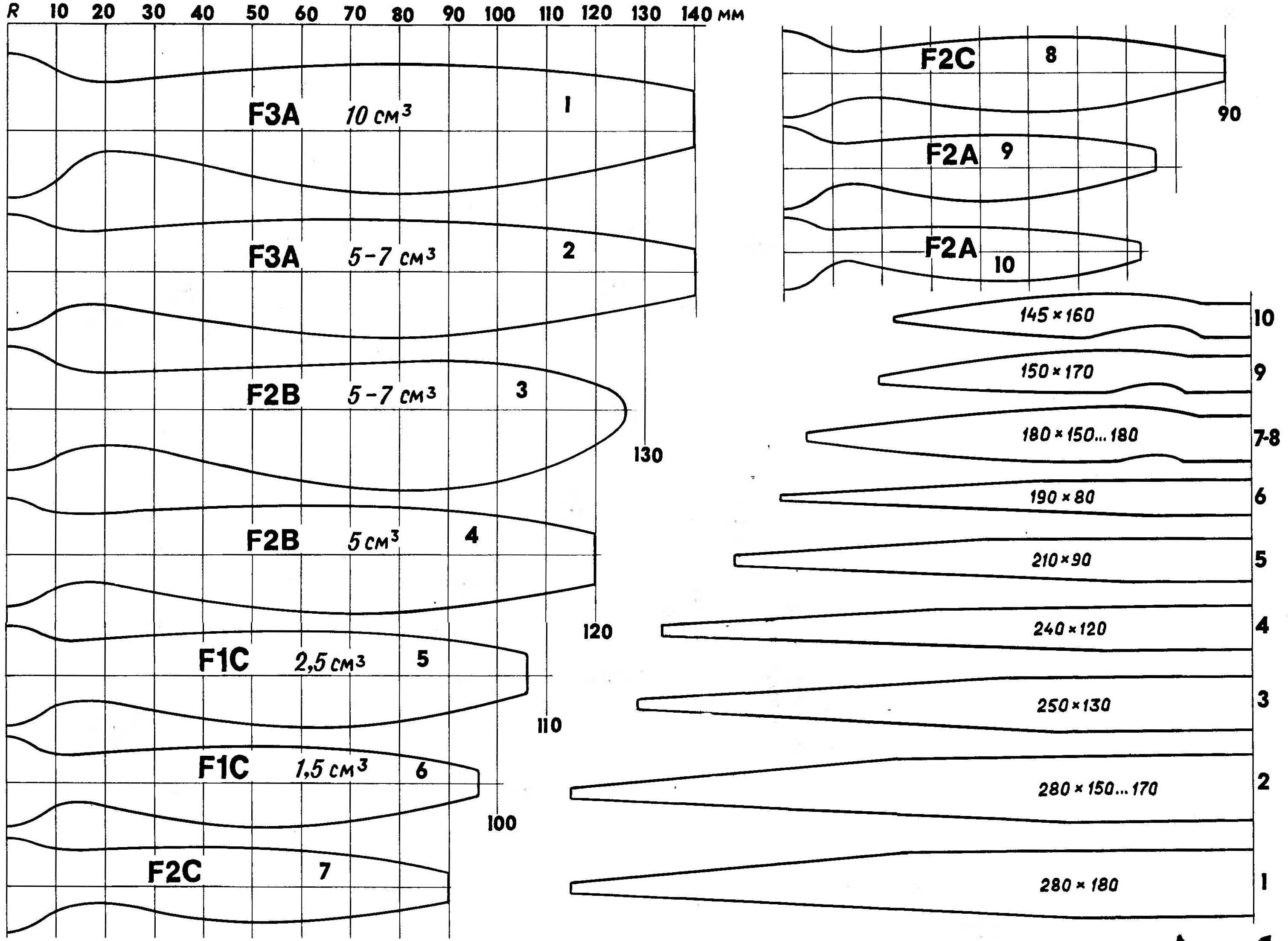

The drawings show the propeller templates for common classes of models. Next to the serial number of the specified propeller diameter and pitch. Manufacturing technology is simple. Cut out of thin plastic or heavy paper patterns “in plan View” and “side View”, applied to the wooden blank and gently tracing the outline with a pencil. The markings on all sides of the bar. After that, the workpiece is shaped, sootvetstvovala cross section. Final profiling of the blades is carried out using a knife, files and sandpaper. During the finishing profile to the given section is controlled by the balance screws. Final finishing of propeller — polishing with fine emery paper and three to four-fold. coating amelita followed by protection of the surface with a light layer of two-component parquet lacquer with dopolnitelnym control balance.