Measurement of flow rate of water is carried out using a stopwatch, and a float on the fixed section of the river (channel, etc.). Control the length of this portion is about 10 m. Float measurement item (light ball, a piece of foam, etc.) installed at rapids, will travel without nataliana obstacles. And Sorokoletova value, during which the float will take these 10 m, allowing easy access to… calculate the speed of the flow.

Relevant measurements performed at three points. The average data find cross section. Knowing the velocity, calculate the flow rate.

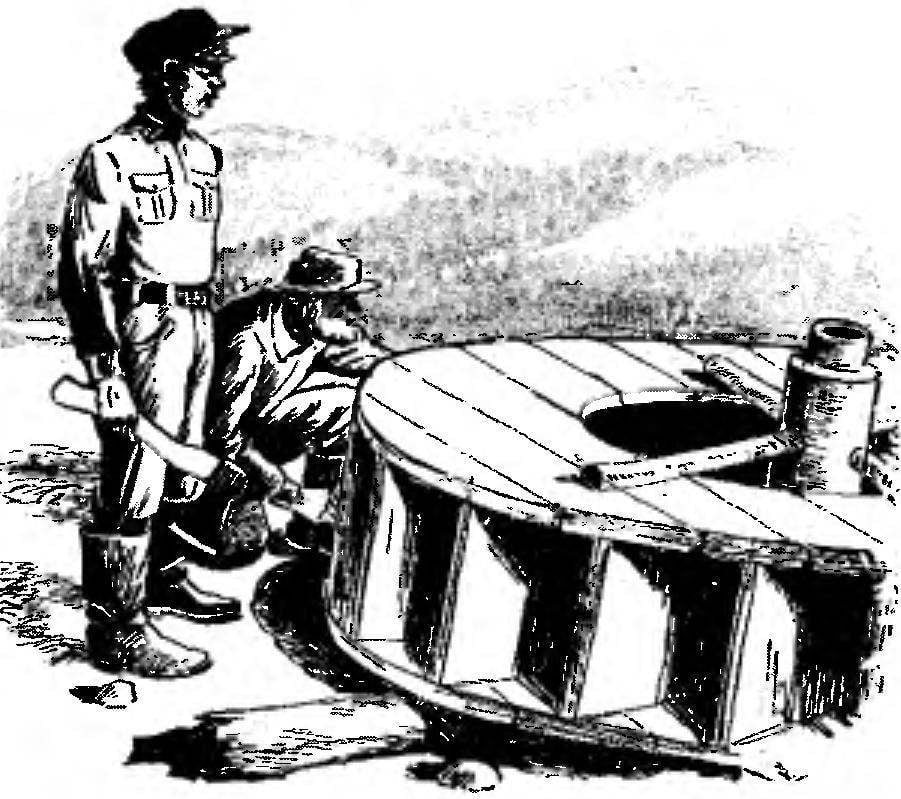

Create the desired differential water levels (transport channel) requires certain engineering works; quite bulky, but absolutely necessary to the relevant structures (see Fig.). The potential energy of the flow is calculated by the formula:

m is the mass of water that falls per second on a turbine (this is where the previously found flow!);

Power that can ideally get from the turbine proposed for self-production, is about 10 kW. Working in a real micro hydro, a variant of which is shown in Fig., this turbine is able to give to the load (taking into account the inevitable losses here) 800 watts. On this basis and the selected generator. It has the following settings: 800 W, 24 V, 700 rpm.

If you take into account the fact that the evening and at night electricity is mainly for lighting (not consumed only for 3-4 hours), and the day is used to supply 1-2 refrigerators, that is, apparently, makes sense to accumulate in batteries connected for charging and network with a voltage of 24 V. But requires that the batteries are as close as possible to the switchboard. Because the losses grow in proportion to the length of the line and the cross section of the power cable.

The layout and composition of the micro-HPP:

1 — a river with a flow rate of the main flow (option) 1.2 t/s, 2 — limiter flow rate (see details in the text), 3 — channel transport with a flow rate of 0.4 t/s, 4 — tray guide rail on stilts (from materials for example boards of appropriate sizes and species of wood), 5 — technical room (beams and paneling), 6 — riser power (with a fortified it with porcelain insulators), 7 — power line (two-wire aircraft), 8 — hidroelectricidad (a — cascading water flow, b — flow turbine Assembly, transmission V-belt two-stage, g — node, the intermediate shaft, d — generator, e — plate-base, steel, W — piles of larch or oak), 9 — drain wastewater.

Turbine:

1 — ring-crown (5-mm sheet steel, 2 PCs.), 2 — blade (5-mm, stainless steel, 12 PCs), 3 drum (1.5 mm, tin), 4 — needle (500-mm segment 26 mm corrugated steel reinforcement of 8), 5 — screw M12 (2 piece), 6 — Bush-the hub (cut from seamless steel tube 100×20), 7 — shaft turbine (St 45), 8 — bearing housing (farm equipment, self-aligning, 2), 9 — the supporting plate (piece of steel channel No. 18, 2), 10 — bolt M20 with nut self-locking (4x), 11 — large wood screw with countersunk head (16 PCs.), 12 — pile (of bamboo, bast or larch, 2150 mm, 4 PCs.).

Baydachny svobodnensky mini-hydro design engineer B. Kazhinskiy:

1 wooden landing stage on the two floats (catamaran type), 2 — the water wheel is connected by a V-belt of a multiplier to an electric generator, 3 — room accessory, 4 — stretching with conventionally not shown anchor (6 PCs), 5 — room technical, 6 —power line (aerial wire). The features used here a water wheel is given in the text.

The kinematics of one of the variants improvised hydro with detailing the main components (turbine wheel conventionally not shown):

1 — shaft turbine (Steel 45), 2 — wheel hub flywheel-pulley (Article 5), 3 — M12, 4 — flywheel-pulley leading to first-stage V-belt transmission (Shall 20), 5 — bolt M10 (4 holes) 6 —self-locking nut M10 (4 PCs), 7 cordoroy strap wedge (2 piece), 8 — a pulley of the intermediate shaft (Steel 20), 9 — key wedge, 10 —intermediate shaft (Steel 45), 11 — plate steel, 12 — the case of the bearing unit with covers (CI 3), 13 — 180206 ball bearing (2 PCs), 14 —Bolg M8(8pcs), 15 — washer (8 PCs.), 16 nut M8 (8пгг.), 17 — a DC generator (800 watts, 24 V, 700 rpm), 18 —screw with large washer (6 PCs.), 19 — the pulley of the generator (Steel 20).

Fortunately, they do not go beyond the “norm” in our 150-meter line, where cable is used, the total cross-section of aluminum conductors is 25 mm2.

So on the energy of the water to the micro hydro was not losing a single watt, resort to what is provided with turbine blades mounted at an angle conducive to the maximum utilization of the kinetics of flowing stream. Successive blades will not be braked “tired” of exhaust water. The friction here is kept to a minimum. Because the inner surface of each of shaped blades (vanes) and the turbine drum (a kind of “bowls”) carefully polished. Extremely reduced and losses in V-belt transmission, bringing the number of revolutions of the generator to optimum values. All shafts on ball bearings. The belts are not slipping (their tension is adjustable on the mounting location supports).

Now, about other a particular proposed design. Trehsotmillionnogo turbine (see Fig.) made of two rings-crowns (sheet steel), twelve blades (stainless steel), tin drum, the eight spokes of steel bars (diameter 26 mm) and the bushing-hub, fixed on the work shaft with two bolts M12. The shaft rotates on two self-aligning (and definitely sealed for water protection) ball bearing.

All this is located on two supports, which are able to withstand loads up to tons. The latter are mounted on four, driven into the ground 1.5 meters, the piles of 0 200-250 mm (from acacia). On the turbine shaft is a flywheel (diameter 700 mm, weight about 80 kg), which is both a leading two-step pulley V-belt transmission. The rotation speed — 80 rpm (idle) and 60 rpm (under load).

To obtain the desired generator 700 rpm introduced an intermediate shaft with pulleys: driven (D = 150 mm) and the leading (D = 350 mm). With the latter the torque is transmitted already on the shaft of the DC generator. A pulley here, we can assume, lead (Z= 130). And therefore it is better to take it for our micro-hydro ready. For example, finding the decommissioned agricultural equipment. As, however, all the previous ones. But you can also make yourself. According to the method repeatedly and with sufficient completeness published in the journal, and is therefore familiar to many of our homebrew the Rest of the design, I think, clear from the illustrations.

It should also be noted that the development of micro hydropower plants (on 24 V and 800 W) was successfully implemented on the territory of the forest Kosova to provide electricity to the tents of the forest tourist base in the valley to avoid certain actions (600 metres above sea level)

Of course, there are other equally valuable developments. Including made in Russia. But here the technical thought of old were sent to damless use the energy of freely flowing water.

In particular, in several papers, Dating back to the XVI century, it refers to the construction in the Cossack settlements in the don mills driven by the power of the river currents. Wheel of these mills is shipped on 1/4 in the rapids, attached to the shaft between two canoes or Baidakov. The name floating foundations, such structures are referred to as since “baydachny”. Moreover, further development of technical ideas in this direction stimulated originated and is increasingly establishing its influence in the national economy… electrical engineering.

Unfortunately, the first world war, and then the civil war interrupted research in this area. And only in 1926 (with the growth of the industry) the idea of cheap, quickly created damless power plant using the energy from river current for power supply of collective farms, state farms and peasant cooperatives, and received their practical development in design “baydachny hydroelectric engineer B. Kazhinskiy”. For the period from 1926 to 1930 these power plants (see Fig.) built 11. And that is to repeat today’s DIY project.

When the diameter of the water wheel of 6 meters with 24 blades-blades (length and width respectively equal to 4.5 and 1.0 m) in the Russian rivers (with flow rate 1… 1.5 m/s) the “heart” of this mini-hydro makes 10-12 revolutions per minute, developing shaft power up to 6 kW. The last (thanks to the V-multiplier) is transferred already to the generator.

Design, as you can see, simple. Besides the test of time. And if anyone of the readers and subscribers of the journal will decide to recreate it, the loser will not.

A. RYE, Altai mountains

Recommend to read NOT A BUTTON, AND WEDGE How often in the lectures or lessons on a stand, posters and other visual AIDS? Of course, stationery buttons! In recent years, however, they comes to the aid of sticky tape. However,... THE BTR – 60PB Scale model 1:25. By order of the Minister of defence of the USSR from 29.06.1964 the Soviet Army was adopted by the BTR-60PB, created by the design Bureau of Gas under the leadership...