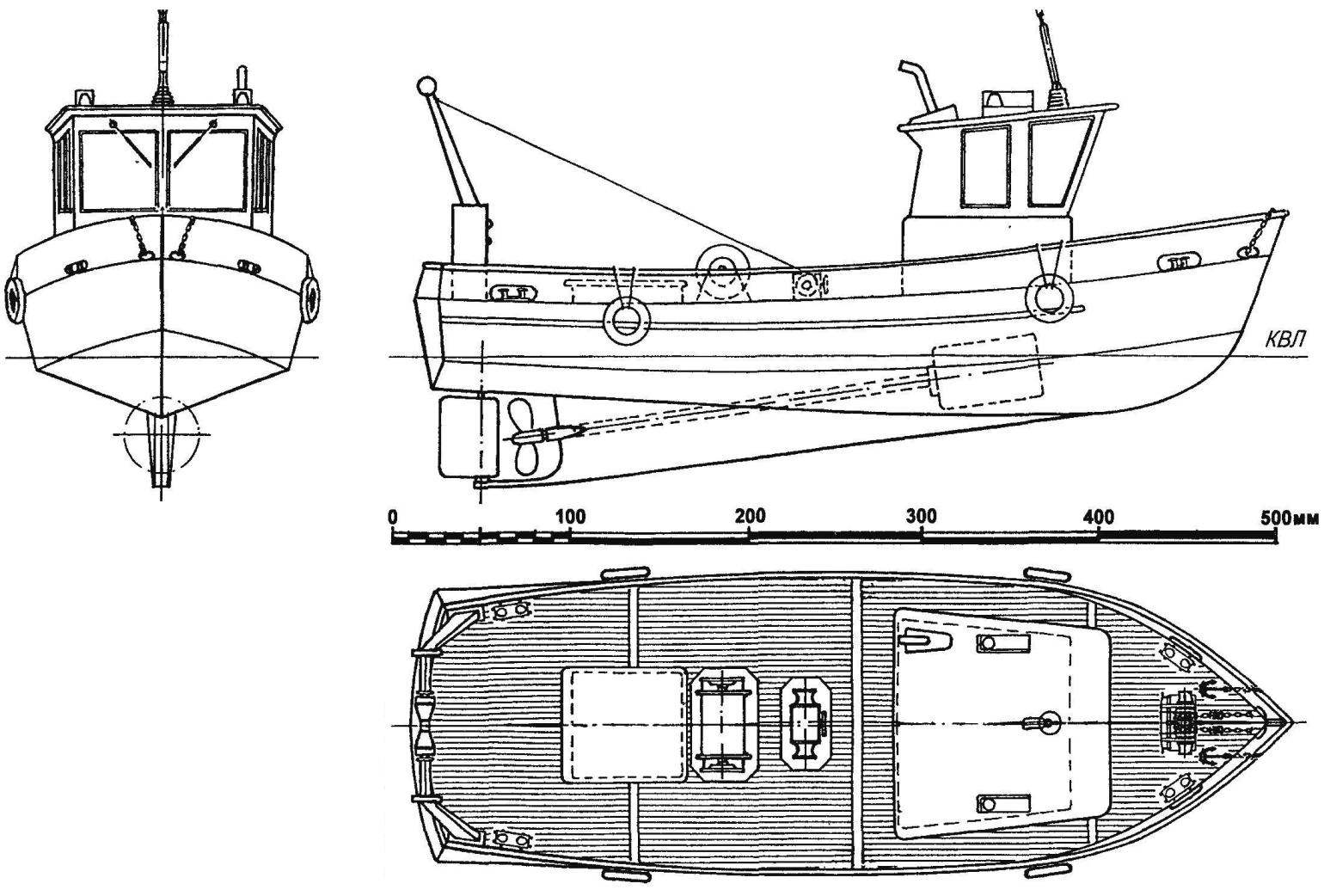

This RC model of figure procopiu course is a small fishing seiner (MPC) Murena with a displacement of about 20 tons, with a length of 13 m and a width of 4,7 m. the Ship with the hull lines of the “Grand banks”, built in the style of the tug, equipped with an engine power of about 150 HP, which allows the MPC to reach the speed of 10 knots. The model of a small fishing seiner not very difficult to manufacture, and it can be recommended to build for beginners “radio operators”.

This RC model of figure procopiu course is a small fishing seiner (MPC) Murena with a displacement of about 20 tons, with a length of 13 m and a width of 4,7 m. the Ship with the hull lines of the “Grand banks”, built in the style of the tug, equipped with an engine power of about 150 HP, which allows the MPC to reach the speed of 10 knots. The model of a small fishing seiner not very difficult to manufacture, and it can be recommended to build for beginners “radio operators”.

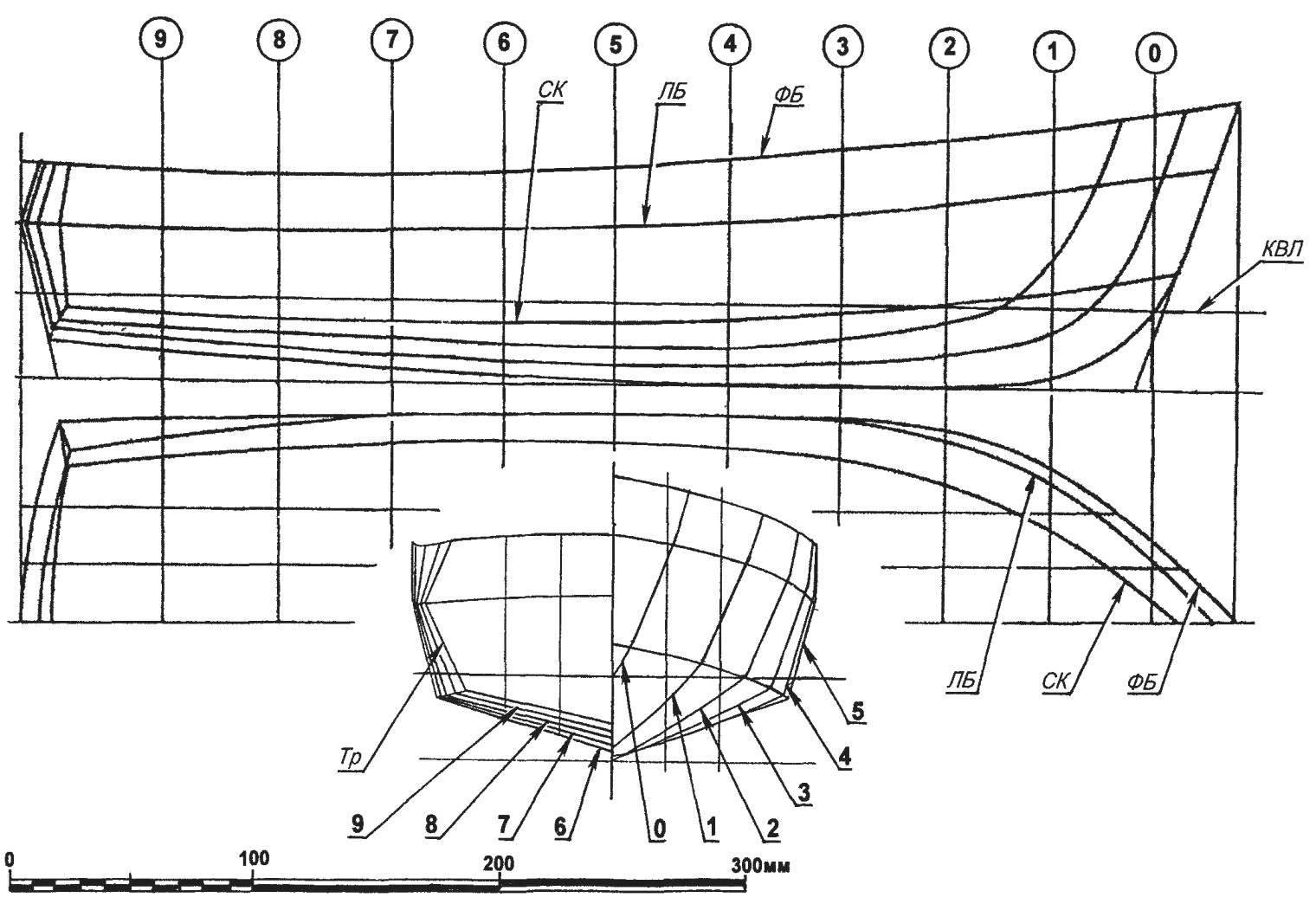

The case of the model is the easiest way to applied to the wall of fiberglass and epoxy on the foam disc to make it, you need to start to make a kind of “skeleton”, which is a cut from thin plywood frames, mounted in line with frame (distance between adjacent frames) on a flat wooden rod Should be aware that drawing on the theoretical contours of the frames correspond to external contours of the ship, for that reason, it is necessary to reduce the thickness of the fiberglass shell.

Installing on the web plywood formers, secure in the intervals between them with PVA glue wedges of packing foam. When the glue dries, cut the excess foam, razor-sharp knife with a long thin blade. Thus it is necessary to constantly monitor the smoothness of the contours with flexible plastic strips, applying it to neighboring frames to Finally bring the disc, you can use sandpaper glued to the wedges with a suitable curvature of the surface In conclusion, the disc should be covered with wax mastic parquet and raspolirovat by the Way, good antiadhesives the separator can serve the finest food film — in a typically Packed food in the shops the Advantage of this film is that it can be simply applied to the blank and to smooth with the hand — while the film as if glued to the surface.

Be applied to the wall of the body shell is best outdoors or in a well ventilated area, depending on the thickness of the fiberglass, the shell will take from four to six layers of this material.

Fig.1. The model of a small fishing seiner “Moray”

Fig.2. The theoretical drawing of the hull of the model

After the final curing of epoxy resin from the shell returns a blank (sorry, for this, it is sometimes necessary to dismember) and pasted the frames of the 3 mm plywood. Note that in contrast to pigs in enclosure design uses only the frames no 1, 3, 5, 7 and 9.

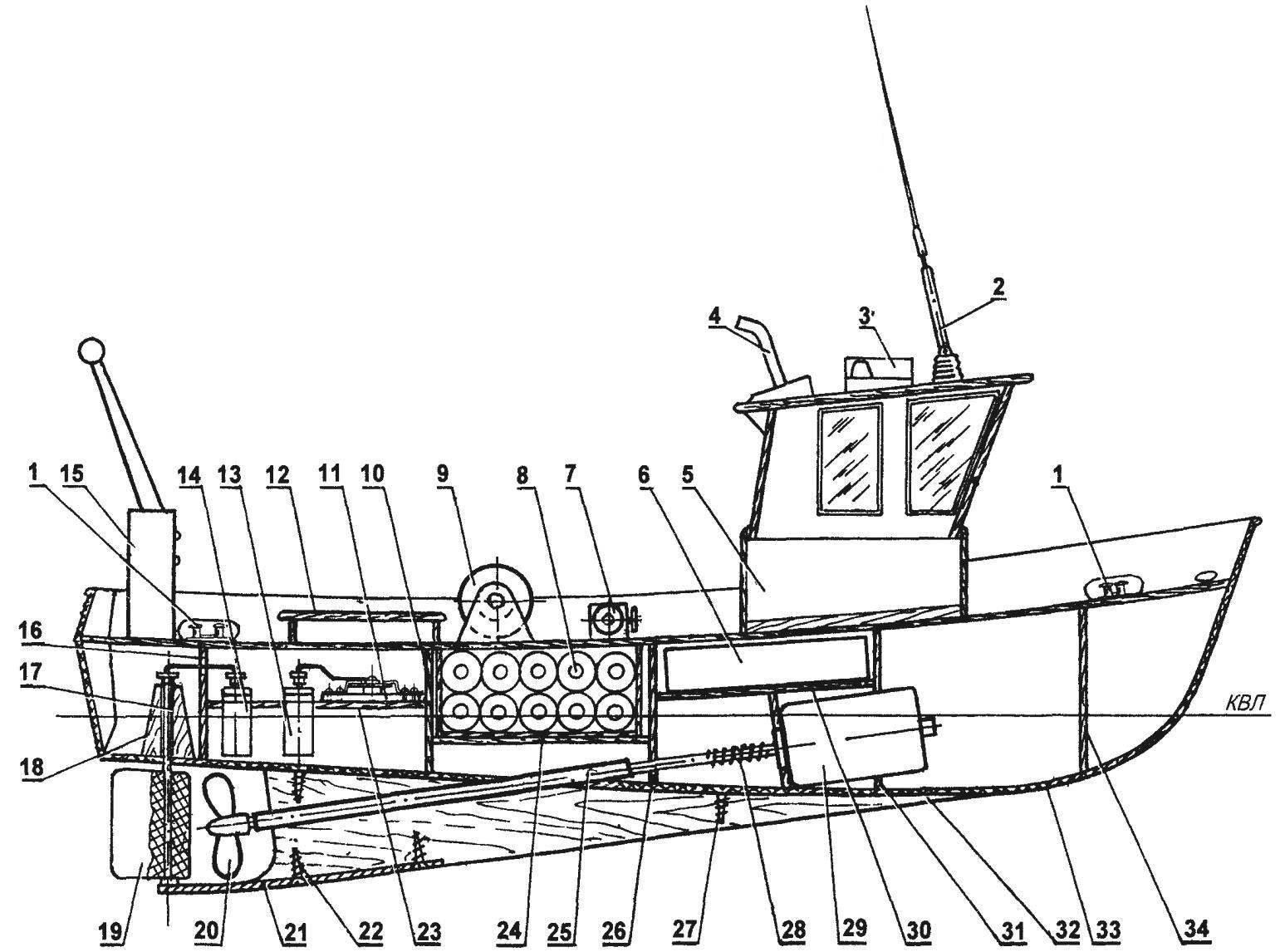

The power plant model consists of the engine Speed 600 Graupner company, of deadwood, and two-bladed propeller with a diameter of 45 mm Stern tube shaft diameter 5 mm is connected with the motor through a spring clutch Pipe deadwood dural, diameter 8×1 mm, at the ends of her sleeves are PTFE. When assembling the deadwood tube is filled with grease of type “Litol” Engine secured in the engine room, between frame No. 3 and an additional polosamota.

In the aft compartment there are two servos — one of them is connected with longitudinal traction with a tiller (lever) on the rudder stock and the other with a switch engine that allows movement forward and backward, and stop the motor.

Switch homemade — it consists of base, carved from Plexiglas, the rotor of foil Micarta, two Teflon washers and a couple of brass brushes. Note that the rotor foil cut off (or bled with a solution of ferric chloride) so that the Micarta is left with only two conductive sector.

Sectors podpisatsja conductors coming from the battery to the brushes, the conduits from the engine.

The switch is adjustable so that the neutral position of the lever on the remote control, the motor was de-energized at a deviation of it from myself included at “full speed ahead” and when you reject yourself, respectively, “full back”.

The chassis batteries are located in a compartment between frames No. 5 and No. 7 Battery consists of series connection of ten Nickel-cadmium elements of the dimension AA is the total voltage of about 12 In her, so that the motor is designed for 8.4 V will work on the model with a little “periculum”.

Receiver remote control equipment installed in the compartment between frames No. 3 and No. 5 receiver Antenna is mounted on the wheelhouse.

Fig.3. The layout of the model:

1 — mooring cleats, 2 — antenna, remote control equipment 3 — way fire, 4 — tailpipe engine, 5 — wheelhouse, 6 — receiver, remote control equipment. 7 — santerna winch, 8 battery pack, 9 — drum, 10 — frame № 7, 11 — switch to engine control 12 — hatch cover and the coaming of the cargo hold; 13 — steering machine control switch; 14 — steering machine steering, 15 — Salerno equipment, 16 — frame №9, 17 — the rudder stock. 18 — bushing spindles, 19 — wheel 20 — thruster, 21 — end of the keel, 22, 27 — tapping screws f 3, 23, 24, 30, septum, 25 — stern tube, 26 — frame № 5, 28 — spring clutch, 29 — way motor Speed-600, 31 — frame № 3, 32 — Gil, 33 — case model 34 frame No. 1

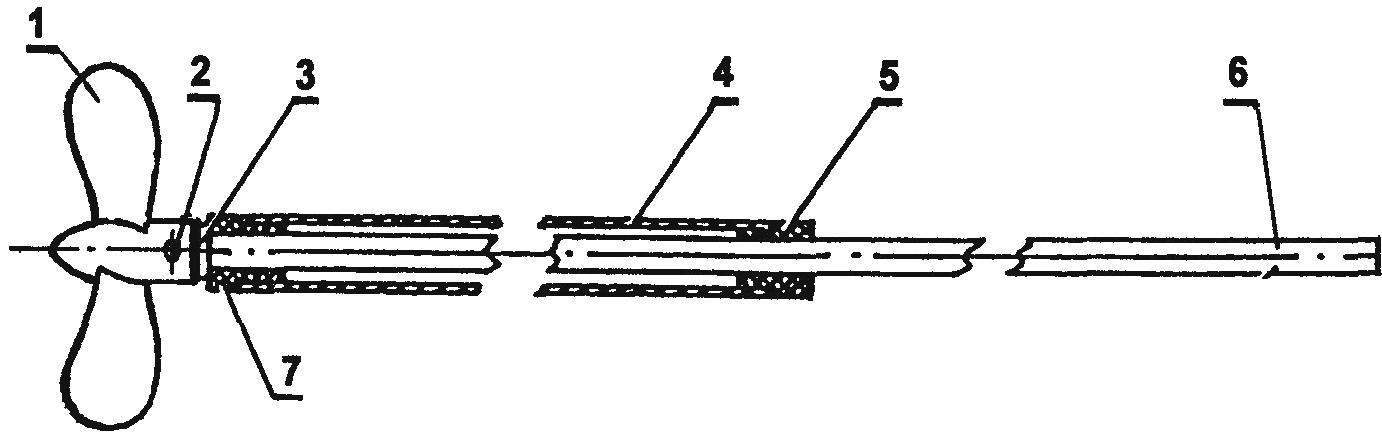

Fig.4. Drive propeller:

1 — propeller (brass), 2 — pin (steel, Ø 1,5); 3 — washer (steel); 4 — stern tube (aluminum pipe 8×1), 5,7 — hub (PTFE), a 6 — stern tube shaft (steel rod Ø5)

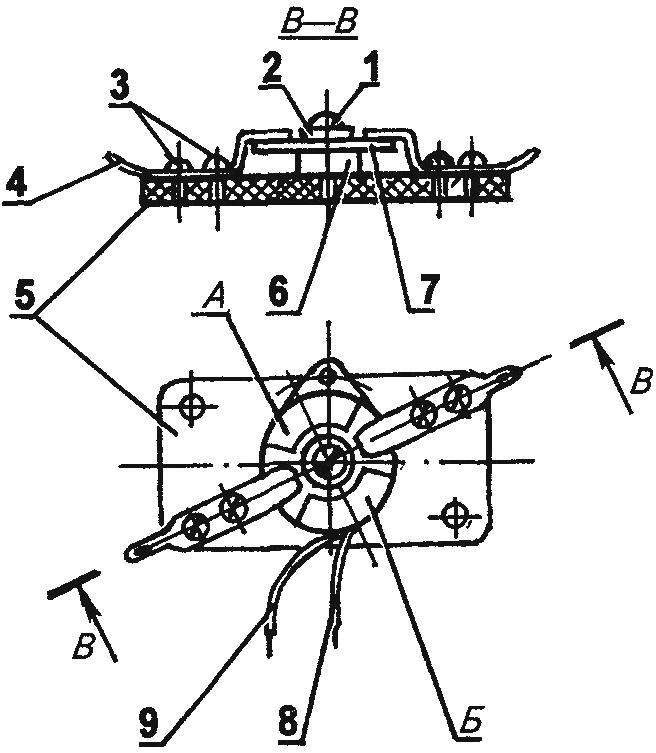

Fig.5. Switch travel motor (A and B — “plus” and “minus” of the slats of the rotor):

1 — axis of the rotor (screw M3); 2, 6 — washers (PTFE), 3 — mount brushes (screw M3); 4 — brush (brass, sheet of 0.3 s), 5 — base (plexiglass s 5), 7 — a rotor (foil getinaks s 2), 8 — entrance from the “plus” of the battery; 9 — entrance from “minus” of the battery

Deck models cut from 4 mm plywood to provide her with the necessary bending, the workpiece is soaked in water and dried in the folded state.

The most notable detail on the deck is the wheelhouse Going from plywood blanks; glass — of celluloid or plexiglass. In addition to the receiver antenna, on the roof of the wheelhouse are running lights, and exhaust pipe of the engine.

Along the bulwarks are mooring cleats — two of everything. In the bow — windlass and two anchors Hall In aft deck installed Synergie drum and winch and also a hatch cover and the coaming of the cargo hold.

RECOMMENDATIONS FOR PAINTING THE MODELS

For easy painting of models of ships and vessels made by the method of veclachi of fiberglass and epoxy resin, it is better to use automotive enamel.

In preparing the model surface for coating it is necessary to eliminate the defects of the body (burrs, cracks, etc.) with skins. Priming the hull for paint is not required.

To eliminate the roughness after the first coat, the surface must be sanded First, you will need to use waterproof sandpaper No. 48 — 80; then n 140 — 170 — 280.

The coating quality of the model depends largely on the practical skills of a constructor of ship models, on its ability to prepare the surface and apply paint brands Painting is best done with the spray gun so that the spray was directed perpendicular to the substrate, the distance which must be within 250 — 300 mm to Move the gun should uniformly with constant speed In too rapid motion of the enamel will lay down a thin layer of slow — fat as a result, may appear stains, Apply paint parallel stripes, Each stripe shall overlap the adjacent 10 — 20 mm is Necessary to maintain the proper ratio of air pressure and density of enamel coming from the gun, Small details can “blow out” the easiest spray gun (for this purpose, enamel divorce is quite liquid) or using commercially available cartridges.

When working with brushes it is important that the grade of the hair — the best are the brushes made of squirrel, korkovogo, badger or bear fur.

During painting the brush is held at an angle of 45° — 55° to the surface and apply the coating light and free movements With the need to ensure that the paint will lay down a uniform thin layer and does not form streaks.

When working with nitropaints it must be remembered that they dry very quickly. Therefore, to conduct twice in one place with a brush should not be. Strokes to do the short in one direction If the surface is accidentally got a big drop it should be immediately rubbed the First layer helps to detect defects remaining on the prepared surface must be eliminated by repeated grinding.

Before applying each subsequent layer prior should be well dried.

Polishing of the model is the final stage It is produced with a special paste for cars or a GOI paste It was applied to a soft rag, piece of felt or felt and in a circular motion bring the surface to a mirror finish Then use a polishing with water, kerosene or oil.

I. KARAMYSHEV