The staggers (expansion) spars mounted open cabin with comfortable seats: for the driver above the left wheel on the wing, and the wing of the right — seat passenger. Outside to the front of the cab in the middle of it placed the grille, and on the sides of the headlights. The rear frame set large wooden body, and underneath the box for the battery.

The engine of the truck with the loud name “Hercules” American-made 2-cylinder, 4-stroke, with cast-iron block and liquid cooling. Bought it

on the occasion of a neighbor’s cottage, which he knows how he got and lay for many years. The motor was not new to the same “unfrozen” with a broken top face of the cooling system. He drew its compactness. Ul UD-2 that was standing on a mini-tractor, was almost twice the size and power of 8 HP.

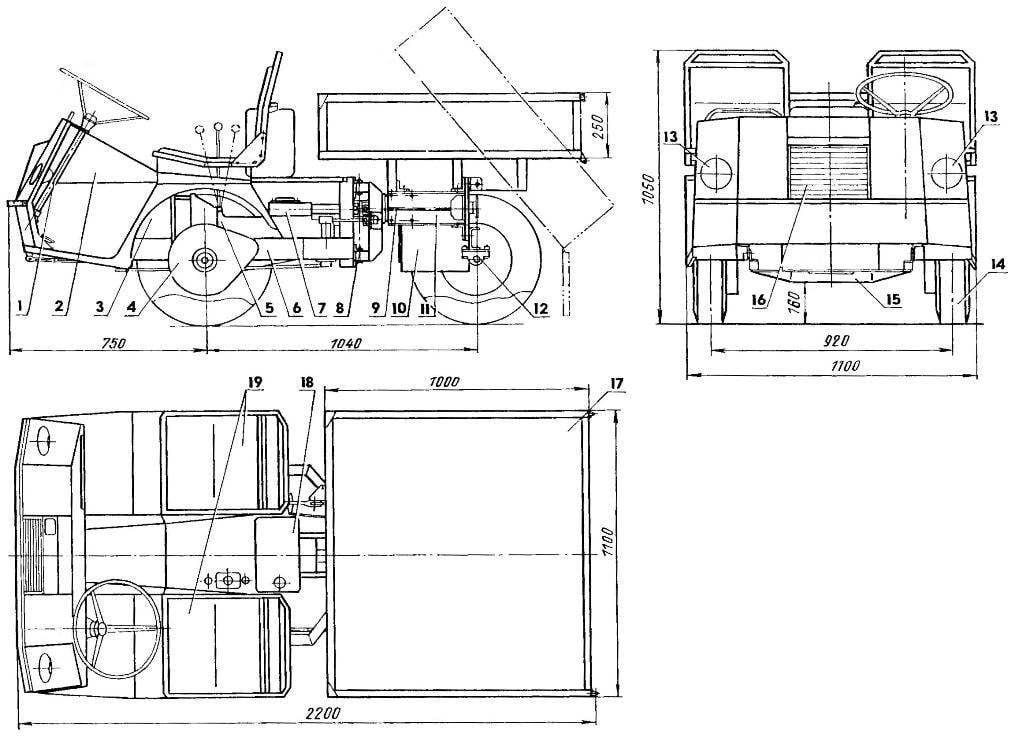

Rear of frame:

1 — lug; 2 — strut; 3 — bushing; 4 — connecting plate; 5 — the case of the swivel bearing unit; 6—pinch pin Ml2; 7 — bearing 1000915 (2); 8 — swivel bushing; 9 — horizontal edge; 10 — upper tie bar; 11 — rear transom plate; 12 — rear axle beam (steel, channel No. 8); 13 — axis bracket; 14 — axis of the rear wheel; 15 — adapter plate (steel 20, s6, 2 PCs.); 16, the lower cross member (steel, corner № 6,3); 17 — vertical fin (steel, corner № 6,3, 2); parts 1 to 11, 13,14,17 — mini tractor (see “modelist-Konstruktor” No. 5’2002)

Front of frame (all connecting parts, bolts M10):

1 — axle front wheel (steel 45, d85, L138, 2); 2 — corner cross member (channel No. 8, L320, 2); 3 — bracket cross-beam (steel, sheet s6, 2 PCs); 4 — cross beam (channel No. 8); 5 — eyelet squares (area No. 6,3, LI54, 4-piece); 6 — (corner № 6,3, L365, 2); 7 — under engine area (steel, sheet s6); 8 — removal (area No. 4. L560. 4x); 9 — mount the wheel sector gear (utolok No. 6,3, 2); 10 — spar (channel No. 8, 2 PCs)

![The engine and gearbox with clutch basket (bonnet removed)]()

The engine and gearbox with clutch basket (bonnet removed)

The mechanism of the “turning point” of the frame, a drive axle with plastycznej rubber coupling and brake disc

Rear axle and flange PTO

I “Hercules” provisional — surprisingly the parts had almost no wear and the rust hasn’t got to them. The crack on his shirt patched with sealant VGO-ZO-1. Good ger-metic, withstands temperatures up to 250 °C (although the coolant to a temperature not heated), and now time-tested the tightness of the shirt doesn’t break.

In the engine cooling system includes a fan casing, a centrifugal pump (pump) and the radiator — compact but with increased almost twice (in comparison with conventional same size) heat transfer. Fan and pump are driven from the engine crankshaft V-belt transmission. To control the temperature of the coolant at the engine block sensor and on the instrument panel — a pointer.

But the sensor and the fuel gauge didn’t even need.

The tank is translucent plastic canister, is on view between the seats of driver and passenger. Fuel (gasoline of the lowest quality) gravity fed to the carb via shutoff valve with filter. Next to the temperature sensor of the liquid on the dashboard — the ignition switch. The engine starts by the starter.

Ignition system — magneto. Headlight with main and dipped light and the starter feed from the battery. Light control — by toggle switch on the dashboard.

Collaboration starter from the car “Zaporozhets” flywheel “Hercules” at last had to mount the ring gear from the flywheel of Zaporozhye.

Chassis truck — tractor type with rigid suspension of wheels. All wheels same size, from motorized FDD. Leading and brake — front. Depreciation — due to the tires.

The drivetrain consists of the clutch with the gearbox from the car “Zaporozhets”, the axle shafts with elastic couplings (front driveshaft from the car “Lada”) and improvised wheel reducers. Reducers, in addition to a significant decrease in the number of revolutions (I = 6,35), change the rotation of the rod on the back, as the gearbox on the truck deployed to 180° relative to its position on the “zaporozhtse”. Same rubber couplings compensate for misalignment of axles wheel shafts gears. On the input shafts of the reducers are rigidly mounted (welded) brake discs.

To drive the PTO shaft (PTO) from the transmission I removed the top cover, and in its place established the mechanism on the PTO. The shaft is a cardan transmission of several “tribes” with hinges. His first “knee” is docked to the shaft of the firing mechanism through the keyway. In place of “fracture” frame PTO has a dual hinge (from pair crosses). In the rear frame it is held in two bearing units and between them is another “helicopter” hinge. At the end of the last “knee” for the transom plate includes a flange to which may be attached a return flange of the drive shaft of any machine or mechanism. The rotation speed of the PTO is governed by the speed of the engine.

Managing truck classic: to the left of the steering column — clutch pedal right — brake pedal and throttle.

Steering column and steering gear with a bipod from a car “Moskvich”. The force for the rotation of the rear the frame is transmitted by a linkage, rockers and levers. The latest thrust in the place of “fracture” of the frame has a crossbar.

Since the pedals control van located on the port side, and controls the throttle valve of the carburetor, the clutch and the right brake pad is on the right, then to transmit forces from the pedals from one side to another used shafts with the levers. Further efforts to the actuators are transmitted again with the help of rods, levers and swings. For compactness the core shaft of the clutch laid in the tubular brake shaft in plain bearings —. nylon bushings are inserted into the ends of the tube.

The rear frame is placed a wooden body. Frame it — from bruskov by section 35×35 mm sheathing plywood. For samosvalnaya cargo body is mounted on polarg me hinged on the axis of the two eyes, and the back Board is folded.

The body is raised due to the displacement of the center of gravity back. To exclude spontaneous recovery in the transport position, the body is additionally attached to the rear frame with two screws M10.

The maximum speed of the truck — a little more than 40 km/h. I Think that for this vehicle are quite enough. The power of the engine enough for starting a loaded machine even with the 3rd transmission, and empty and 4th. To the management of truck we need to adjust the rotation using the “fracture” of the frame after the control car is quite unusual.

Although after the arrangement of a suburban area, the need in the truck, in General, disappeared, while holding it together with “the Zhiguli” under one roof. Disassemble the parts can not be solved — successful machine.

E. Evsikov, Lyubertsy, Moscow region.