For Uniform all-Union classification model civilian vessel with a length of 500 mm belongs to the class BII. The engine can be installed any. However, the credit for running the competition goes at the maximum speed, and best of all it provides a rubber motor. It allows the boat to pass quickly put distance -10 m. the Main dimensions model in mm: length -500, width — 100, height — 45, draws 25; displacement — 950

The body is rounded, dugout or laminated of papier-mache on the disc. Dugout hull. Pick up a dry bar (Linden, alder, pine) and free from knots, cracks and svilevatosti — with straight layers of wood and give it (and check the performance of a square) rectangle shape, slightly larger than the body of the model. On the side of the disc, apply a line of space (distance between frames), draw the outline of the “side view” models and with an axe and a plane roughly process the workpiece.

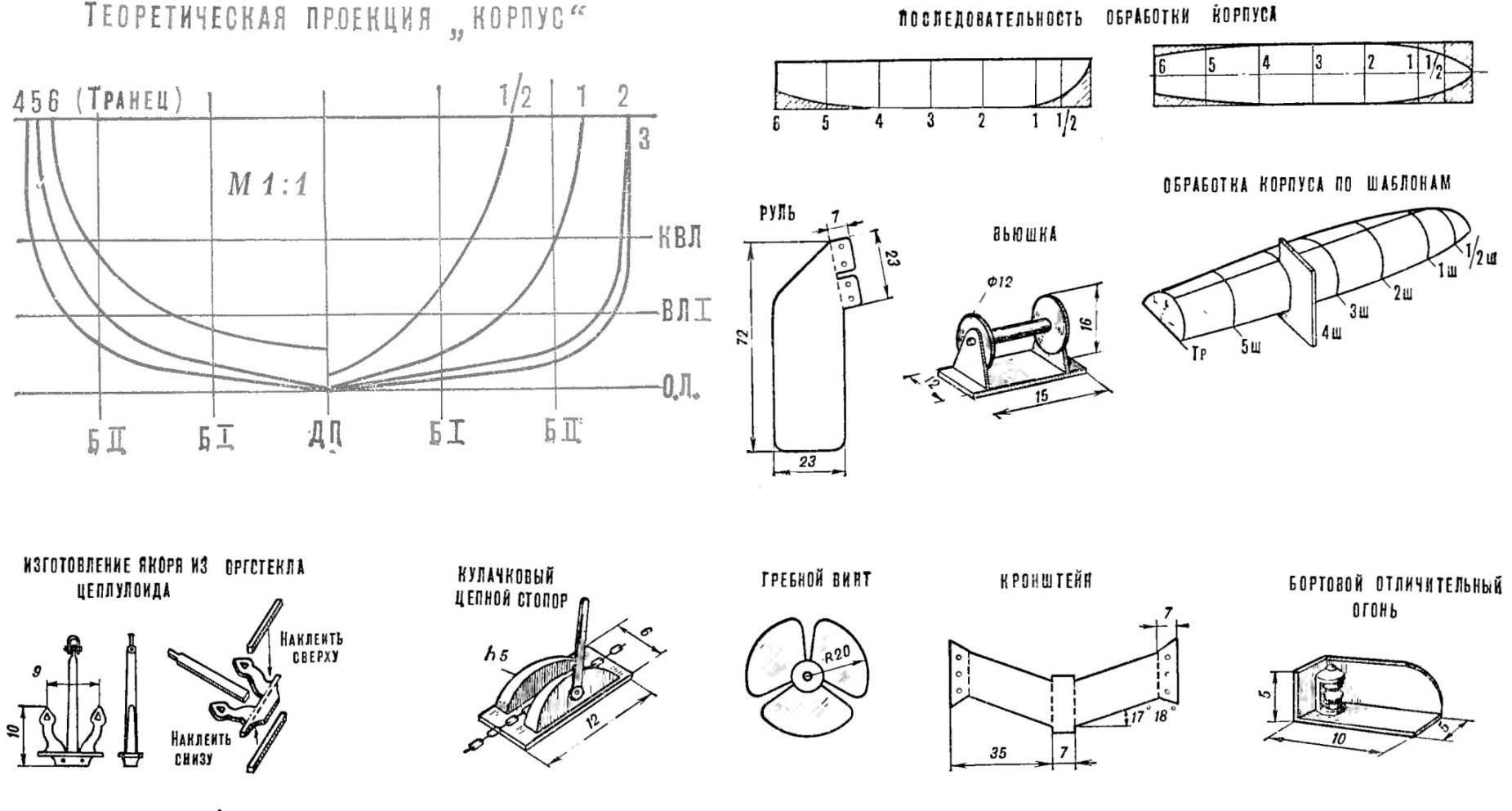

From the deck, draw diametrical plane (DP) and mark spacey. With some patterns indicate the contour of the deck again and remove the excess wood.

The next stage is “finishing” the case for templates frames. Translate them into a blueprint of the theoretical drawing (the projection of “housing”), carefully transfer to the plywood or cardboard and cut out. Applying each template of the frame to the location marked on a bar, remove with a knife, a plane and a file is superfluous wood. Then hull finally looks with sandpaper first coarse and then fine.

Before gouging “core” casing, drill more holes in the deck — it is easier to choose the wood without chipping. The thickness of the sides leave at least 6 -8 mm. Back chisel through through, and the transom cut out of plywood and glued.

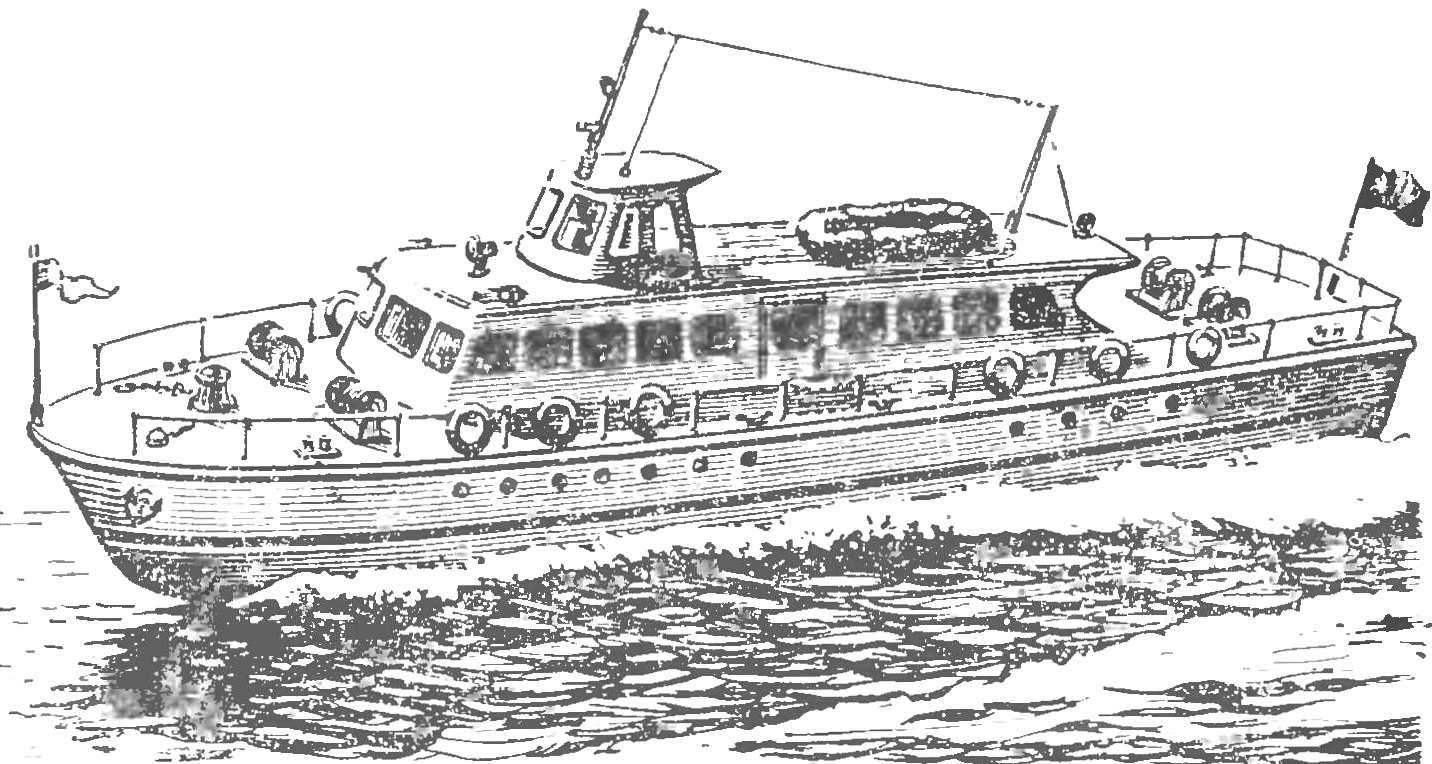

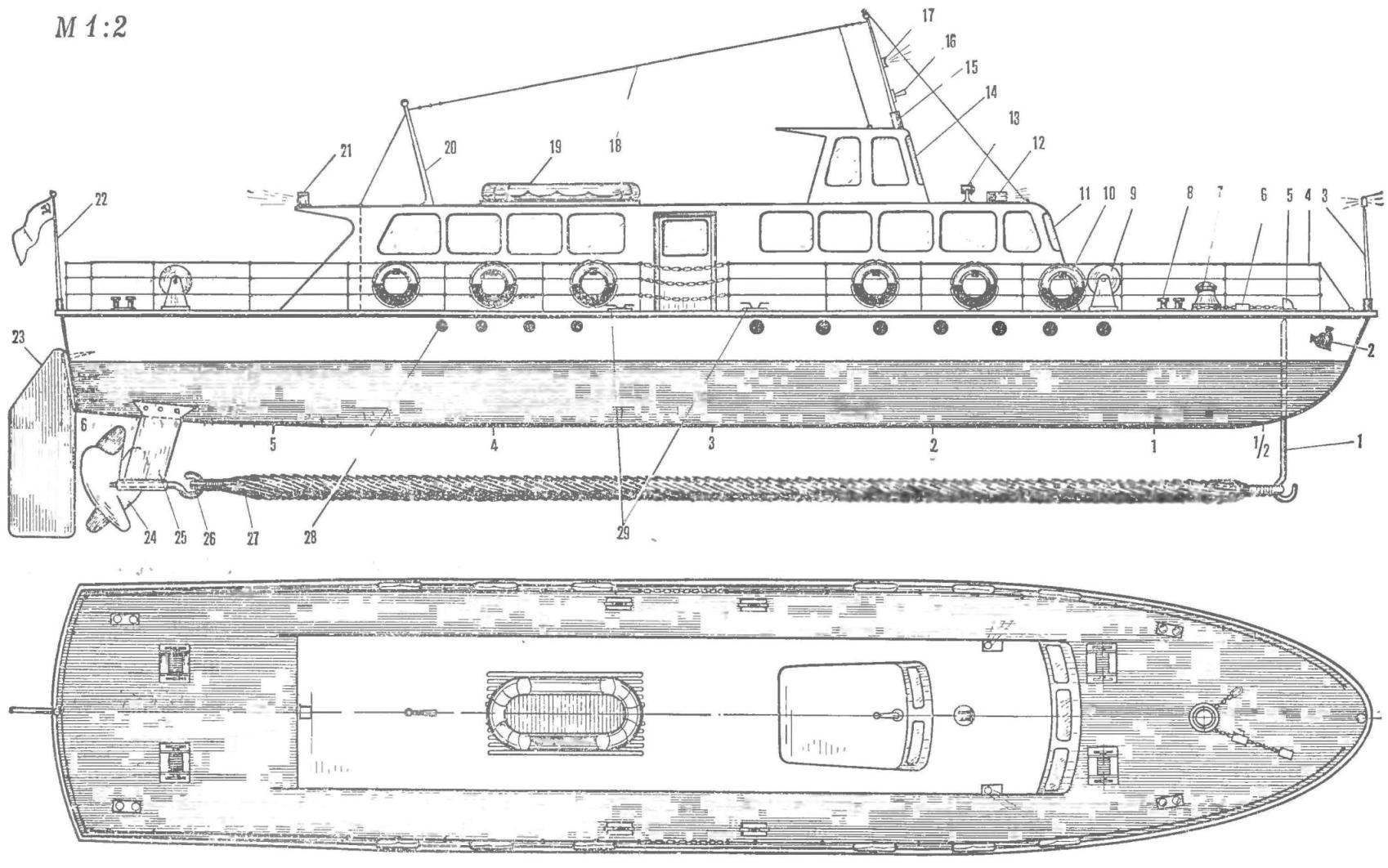

Fig. 1. Model river boats:

1 — hook (wire), 2 — anchor (celluloid), 3 — flag pole with anchor light (wood, wire), 4 — rail fencing (wire), 5 — tenacious Cluses (tin), 6 — chain stopper (wood, wire), 7 — spire (wood, wire), 8 — cleats, 4 PCs (tin, nails), 9 — view of the mooring rope, 4 pieces (deriso, tin), 10 — lifebuoys, 12 PCs, vinyl chloride tube, 11 — the passenger cabin (plywood, tin, plexiglass), 12 lights (left — red, right — green), 2pcs (tin, celluloid), 13 — spotlight (brass), 14 — the captain’s cabin (tin, celluloid), 15 — FLC-mast (wood, wire), 16 — siren (brass, aluminum), 17 — masthead light (Plexiglas), 18 — antenna (wire), 19 — liferaft (wood, foam), 20 — Grot-mast (wood, wire), 21 — hamborsky fire (plexiglass), 22 — flagpole (wood, wire), 23 — wheel (tin, brass), 24 — propeller (tin, brass), 25 — bracket (tin, brass), 26 — propeller shaft (wire), 27 — rubber motor (rubber thread Ø 1 mm), 28 — Windows, 22 PCs. (wire), 29 — duck mooring, 4 pieces (tin.).

The case of papier-mache. First, make a wooden disc. It is lubricated with a thin layer of grease or vaseline. Newsprint torn to pieces. The first two or three layers of moistened with water, no glue is applied directly into the fat layer, subsequent layers — starched paste. For greater strength it adds a little (6-8%) liquid wood glue. Prior work the paper is moistened with water and placed iterables, that is, every next piece should overlap the previous one. The total thickness of 8 — 10 layers of paper. Do not rush to paste the layers, it is better to do it in several stages, applying 2 — 3 layers. Before each new Villenoy don’t forget dried the body with sandpaper. The last layer is sanded very carefully, without removing from the blanks, and paste over with a gauze or old nylon stocking, using water-resistant nitrokey (emalit, AK-20, etc.). Then proceed to the final finish: putty and painting.

The add-in and running cabin is also best applied to the wall of newspaper in the dimensions indicated in the drawing.

The armature, Cam stopper, views and side lights is cut from the celluloid of a thickness of 0.8—1 mm and glued with acetone or any nitrocream. The propeller, bracket and handlebar are made of sheet tin or brass with a thickness of 0.4—0.5 mm, propeller shaft and bow hook — velocity. Raft and lifebuoys bend of vinyl chloride (rubber) tube of appropriate diameter, docked their ends on the wooden plugs. Bollards made from nails and celluloid. Stands for rail use steel pins, opasnye thin copper or brass wire. The waterline is cut from white celluloid with a thickness of 0.4— 0.6 mm and width 1.5—2 mm and glued to the Board Amalita.

Painting is one of the most labor-intensive cases. From it depends largely on the quality of all trim models. Most clean surface water resistant give nitroemali, but you can use oil paint (including art in tubes). To plaster and paint was kept tight, the surface should be primed under the oil paint — linseed oil or liquid oil paint (preferably bright colors), and under nitroemali— glue AK-20, Amalita or diluted nitro lacquer. When the primed surface is dry, all of the tread bumps fill with a thick putty. Then the surface is again cleaned with sandpaper and applied to the entire body with several layers of liquid putty. Homemade putty for oil paint is made from linseed oil, wood glue and chalk, is added before reception of working density. Under a medium ready for use putty AL-30, AL-24, etc. If necessary, you can prepare a simple nitroshpaklevok, mixed with talc (baby powder) or tooth powder on any nitroblue or nitro. During filling (and also coloring), applying 2-3 layer coating, it is necessary to smooth the body first with emery paper of size 60, 80, then 120, 170 and 280. Waterproof abrasives plentifully moisten with water, and ordinary kerosene. After sanding the model with kerosene degreased surface aviation gasoline.

Only after the model is fully puttied up, proceed to its coloring. When working with nitropaints, you must remember that they maloukryvistye and dries quickly, so you should not hold the brush in one place several times. Apply the paint with a thin layer of short strokes towards each other, moving in the same direction.

In the manufacture of the model should try to make it as easy as possible, then be able to load the hull with lead ballast, which will increase the stability and improve the stability of the model at the specified rate.

A. TSELOVALNIKOV, the master of sports