He is still a pilot. Because I do not imagine myself without the sky. However, today the pilot He doesn’t goes up to the sky at the controls of an aircraft in the air it shoots miniature rockets, to which Vladimir Menshikov put your love to the sky, the pursuit of excellence. It was here that he realizes what gave him the aircraft.

He is still a pilot. Because I do not imagine myself without the sky. However, today the pilot He doesn’t goes up to the sky at the controls of an aircraft in the air it shoots miniature rockets, to which Vladimir Menshikov put your love to the sky, the pursuit of excellence. It was here that he realizes what gave him the aircraft.

And the path to the lofty heights of Vladimir started with flying models. It was his first step in a large aircraft, to which he has devoted more than 30 years. Having gone on a holiday, to relax and not think. His irrepressible energy and thirst for creativity does not give him no rest. He’s always finding something to offer, inventing, implementing all of this in the work of the teacher is sports-technical club in the Siberian town of Urai.

How many know the film (which is about 30 years, so can afford to call him by his name), he always strives for perfection. And it is fully implemented in the athletic achievements of his children, and, of course, in the individual sport results. He is one of the most renowned in the world rocketmodeler three-time world champion, repeated winner of European Championships, multiple pion than Russia.

Another convincing victory was won by Vladimir Menshikov, and at the first open Asian championship on sport flying, becoming the winner in the category of raketoplana (Ѕ4А) and taking second place in the class S7 (model copy). No need to say that win Modeler-athlete’s sport is unthinkable without a good “shell” model. And, in my opinion, is a model of the rocket plane Menshikov (drawings and description) — will be interesting to readers-the rocket men.

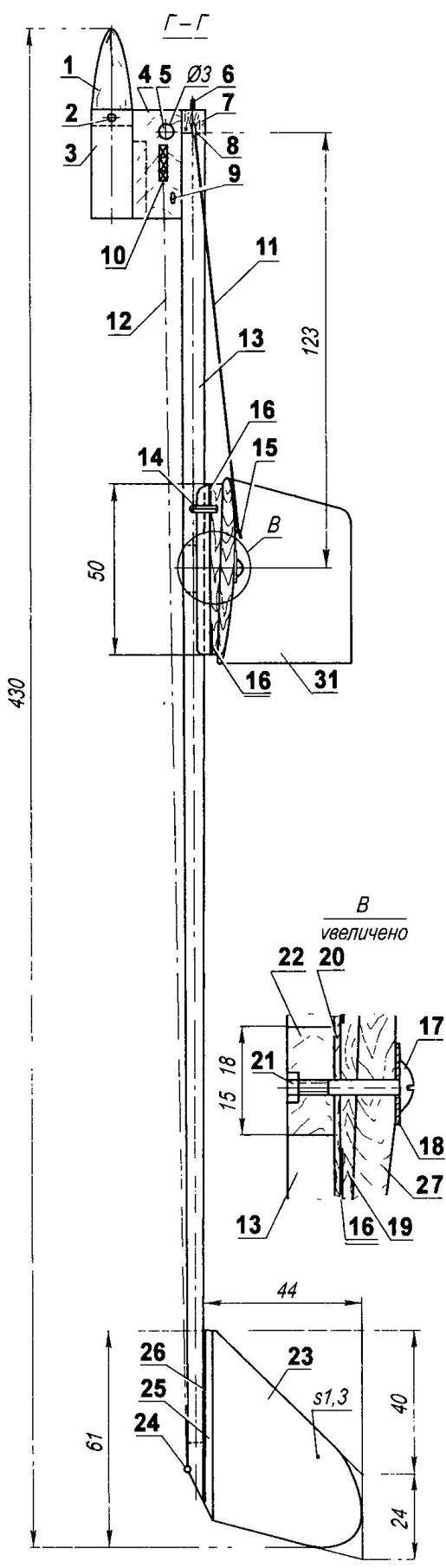

First I want to note that in this model Menshikov removed from their traditional sizes — reduced size scale—up to 500 mm and length up to 430 mm. And another innovation — adaptation forced landing. But about this in detail at the end of the article.

The design is based on a rail-the fuselage tapered beam with a length of 390 mm with a diameter of 7 mm front and 4 mm at the end. The beam othermovies of carbon fiber in a special conical mandrel according to the conventional technology Materials FRP sheets with a thickness of 0.02 mm and the resin VC-9, equipment — bar and a drying Cabinet. In the absence of the latter will fit the radiator of water heating. After curing of the resin the mandrel is clamped in a lathe and I-beam handle with sandpaper and cut to the desired length.

In the tail part of the beam insert tube in which is fixed a wire ring for installation of a rope of determinator. Top glue the balsa plate with a thickness of 1 mm. Processing the surface of the stabilizer is set at zero angle (to compensate for the obliquity of the beam). Then the plate is glued the tailplane — stabilizer and fin. They are cut from balsa plates with a thickness of 1.3 mm, handle contour and covered with a nitrocellulose lacquer. First, install the stabilizer, and after drying attached to it at the butt of the keel.

Then at a distance of 123 mm from the front end of the beam with resin glue inside her boss of lime length 15 — 18 mm. It is necessary to enhance this place of the fuselage right here through the vertical hole will be a screw mount and rotate the wing. When drilling it is necessary to ensure strict perpendicularity of the hole to the plane of the stabilizer. In place of the inserts of the lugs on the beam secure the “landing” of the wing — balsa plate with a thickness of 4 mm and dimensions 50×7 mm. For this purpose in its lower surface makes the fillet a round file and glue with epoxy.

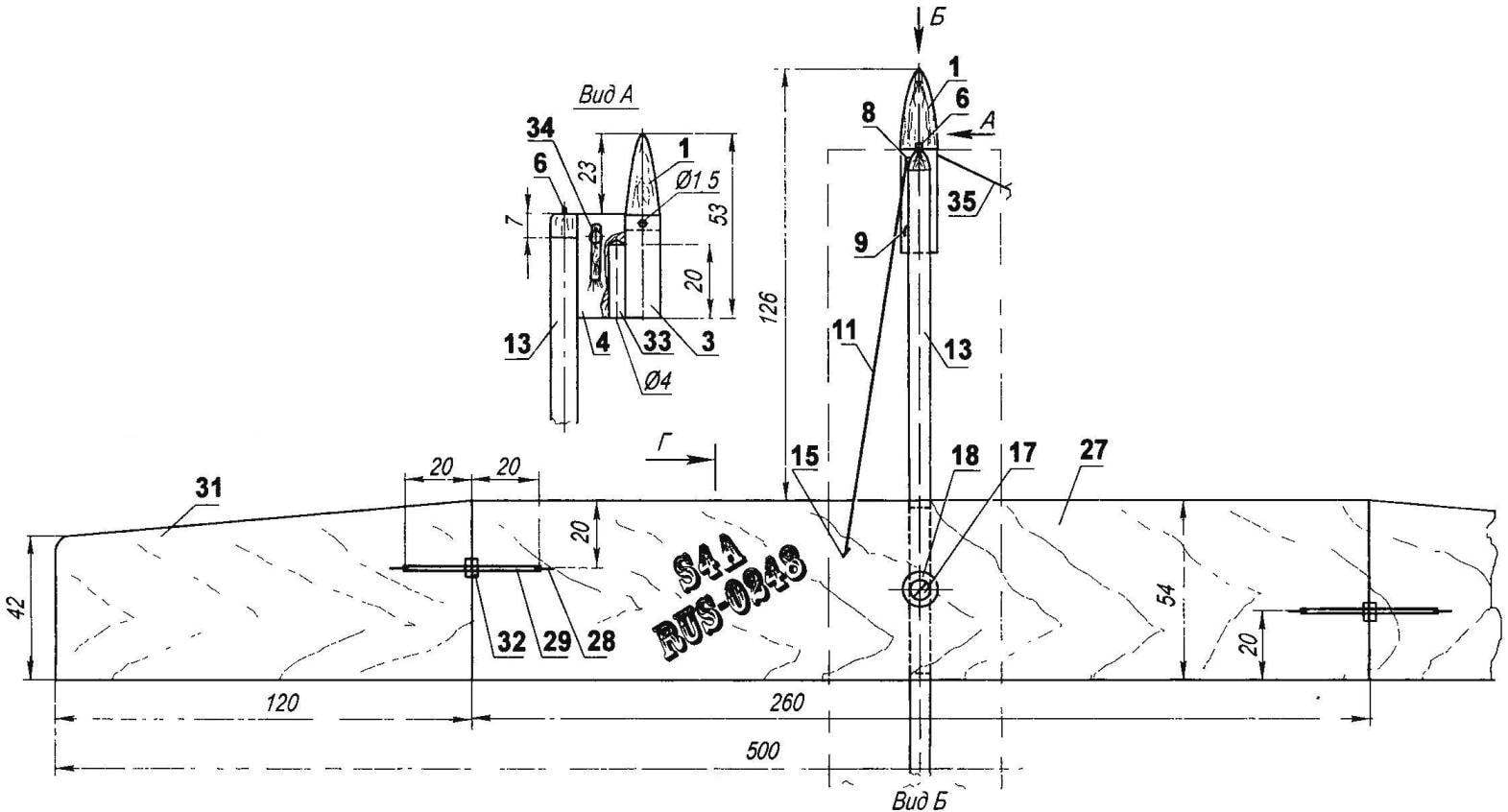

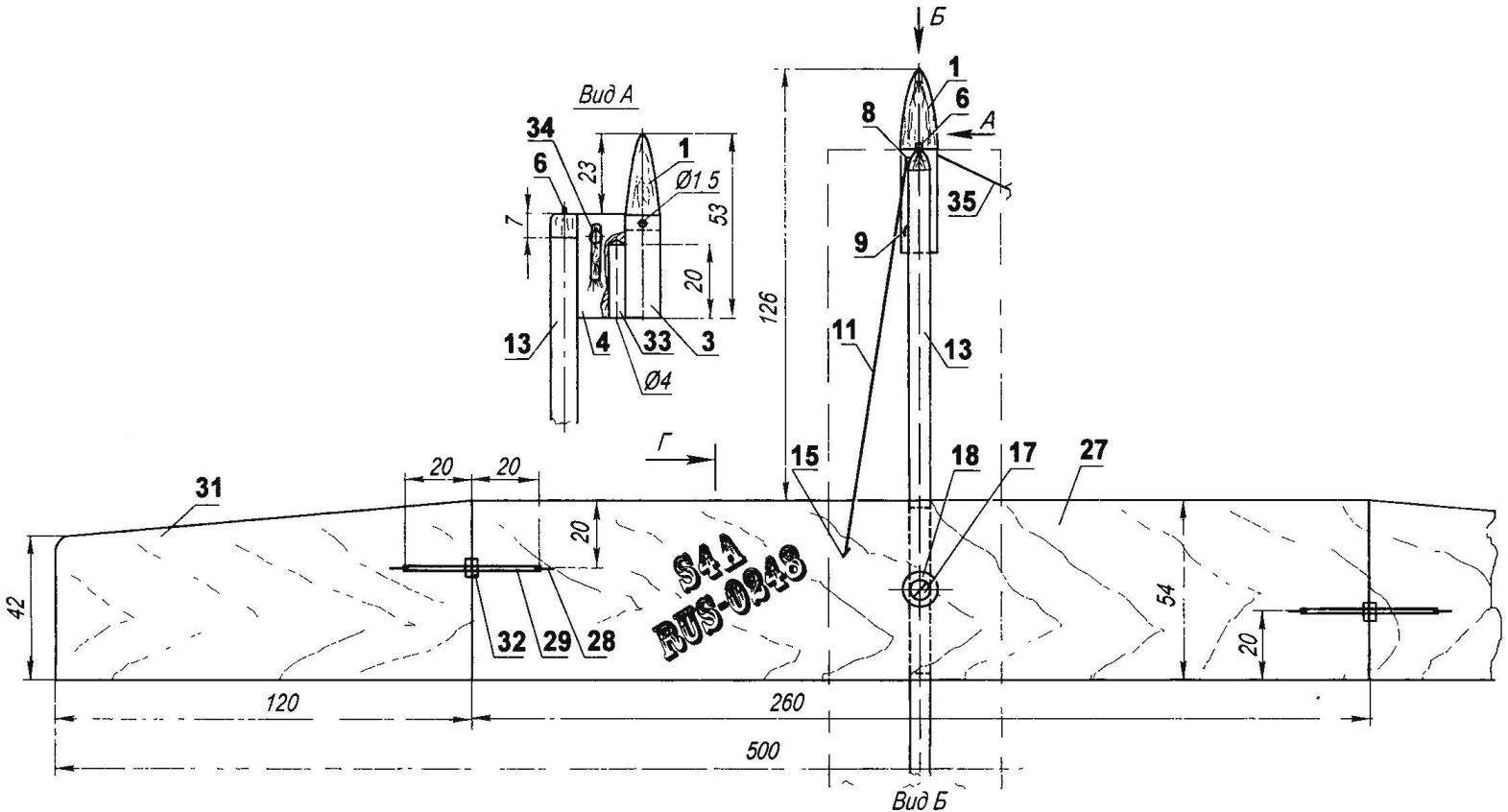

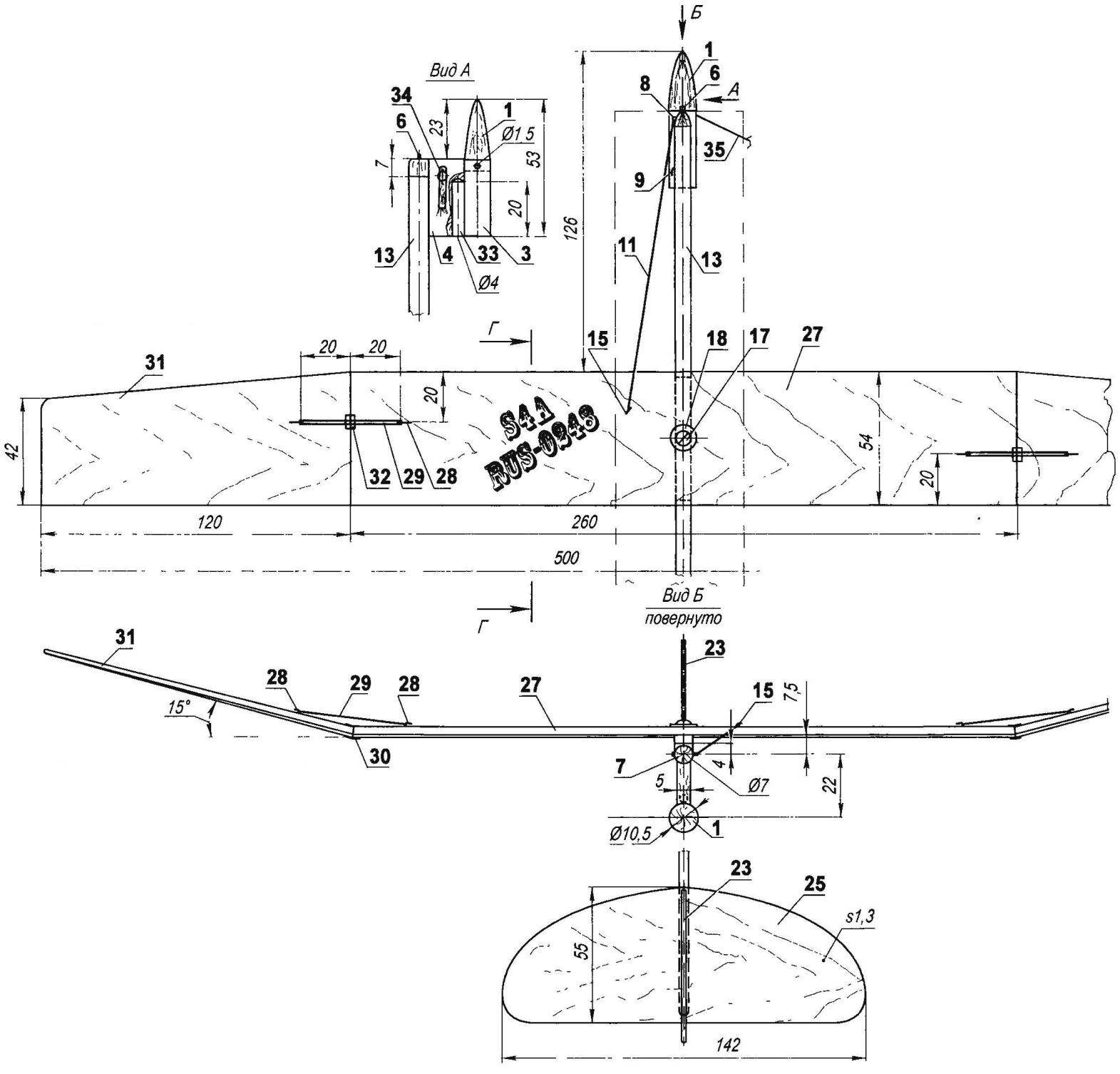

Model rocket modeling class S4A V. Menshikov (G. Uray) — Asian champion in flying sports 2007:

1 — the fairing of the container (balsa), 2 — hole for the thread of the fixing wing 3 — container mrad, 4 — pole container (balsa 30x16x5), 5 — hole for the threads of the wick, 6 — hook fastening leg of the fuse wire 0,6), 7 — fairing Reiki fuselage (basswood), 8 — hook elastic rotation of the wing (wire 0,6) 9 — hook bone fixation wick (wire 0,6), 10 — weight of dehermetization, 11 — elastic rotation of the wing 12 — the cord of determinator, 13 — the rake-the fuselage and 14 focus wing (0.7 wire), 15 — hook fastening elastic rotation of the wing (wire 0,7), 16 — plate sliding of the pylon (celluloid, s0.5), 17 — wing mount screws M2, 18 — washer (celluloid, s0,5), 19 — pylon wing (balsa z,5). 20 — Playground landing wing (balsa. 50x7x4), 21 —nut M2,22 boss (Linden), 23 Kil (balsa, s1,3), 24 — ring cord of determinator, 25 — stabilizer (balsa, s1,3), 26 — the lining of the stabilizer (balsa, s1), 27 — center section (the balsa. s3,2), 28 — hook-and-gum disclosing console (wire 0,6), 29 — gum disclosing the console, the 30 — hinge of the folding wing (parachute silk), 31 — console (“ear”) (balsa, s,2), 32 — reinforcing pad (celluloid, s0,5), 33 — cavity for the brake band mrad, 34 wick (“timer”) limit the time of flight, 35 — thread fixing the wing folded

Later in the forward part of the beam glued the fairing of lime, process it and attach the bottom pole MRD. The pylon is made of 5 mm balsa plate dimensions 30×16. The leading edge is slightly sharpen. To the bottom surface of the container MRD is attached to the fairing. Container — cut a fiberglass tube inner diameter of 10.4 mm and a length of 30 mm. Fairing carved from balsa. In the container, drill two horizontal holes with a diameter of 1.5 mm. They are used to posting threads fixing of the wing when folded for takeoff.

At the rear end plane of the pylon (towards the container) drilled longitudinal blind hole depth of 20 mm with a diameter of 4 mm and glued it to the fiberglass tube. In this way form a cavity for placement of the brake band MRD. In the upper part of the pylon close to the front edge of the drill through the transverse hole 3 mm in diameter and glued it in the cut copper pipe with a length of 4 mm. Through it runs the thread of the fastening of a fuse and gum of decimalization. The lateral plane of the pylon with the location of the wick cover with heat-resistant varnish.

The wing consists of a rectangular center section with a length of 260 mm (chord — 54 mm) and two brackets (“ears”) with a length of 125 mm trapezoidal shape in plan with slightly rounded ends, wing Made of balsa plate with a thickness of 3.2 mm (at the ends of the “ears” thickness reduced to 1.8 mm), the profile PLANO-convex. The connection of the consoles with the center — hinged, with strips of parachute silk, width 14 mm, attached at the bottom with glue “Moment” Angle transverse “V” for “ears” — 15° (from horizontal). On top of the wing in places of joints of the center section and consoles, at a distance of 20 mm from the fixed folding hooks for hanging rubber bands, revealing the bearing surface. Their arch of steel wire with a diameter of 0.6 mm. where you touch the gums of the planes of the wing to reinforce a lining of celluloid of a thickness of 0.5 mm. from the Top glued two hooks one on the right (close to the edge) thread for fixing of the wing folded for takeoff (not shown), the other almost at the center, on the left is for attaching the elastic return of the wing to plan. In the middle of the center drill hole with a diameter of 2 mm, preliminary on top of increasing this place in a celluloid washer. Bottom center, glue the pylon balsa plate length of 50 mm and a width of 7 mm with variable thickness front 3.5 mm, rear — 1.5 mm. This difference (2 mm) achieved the desired installation angle of the wing In place of the touch pad I-beam pylon-fuselage embed plates of celluloid with a length of 18 mm for better sliding. Additionally for the same purpose, contact surfaces are treated with a simple lead pencil.

In front of the pylon (5 mm) glued to the side of the focusing of the wing. His arch of two segments of a steel wire with a diameter of 0.7 mm, coaxial and sealed. Form another l-shaped (when viewed from the front).

The axis of rotation of the wing is machined from duralumin bolt M2 with a length of 15 mm (thread length 6 mm) with a spherical head with a diameter of 6 mm with a notch under direct screwdriver. The bottom axis is screwed into the nut embedded in the boss the Entire model painted in diagonal stripes of pale crimson. The starting weight of the model is about 15 G. the Center of gravity is located at a distance of 20 mm from the leading edge of the wing.

Before starting the wing mounted on the beam-fuselage and light pressure tighten the axle bolt to Hang up all the gum on the hooks of center consoles and Balance the rocket in order to achieve the centre of gravity. Usually add a bit of lead in fairing or attach it to the rod. After that run a model for planning with hands and then with MRD small pulse, If necessary, make adjustments to the adjustment.

To start a model of its console folded to the lower surface of the center section and rotate it counterclockwise 90°, positioning the folded wing along the fuselage. Ordinary cotton string threaded through the holes (POS. 2) and tie on the hook of the center section located on the right part. Then the same thread is fixed to the loop of decimalization, threaded it through the hole in the pylon and from the right side tied the wick. Then put MRD, and the brake band is placed in the appropriate cavity of the pylon and light the wick.

After the start, at the end of the work of MRD and actuation of the expelling charge blows the thread of the fixing wing and it is under the action of elastic pivots at the planning position. At the same moment the engine fires back. Otletov the allotted time, the smoldering wick burns through the threads of fixation of decimalization, and his sinker is lowered into a vertical position. Changes the alignment of the model (it becomes “back”), and the rocket plane begins to cabriolet and quickly to land.