A true master of creativity will suffice even in the bathroom. If your intention is to close the bottom of the bath screen – not in a hurry for him to shop. It’s a simple device if you want you can do it yourself. What matters is that you had minimal DIY skills and the desire to spend a few hours of free time. However, in this case, you do not get to do without going to the store and extra expenses but something can still be saved.

A true master of creativity will suffice even in the bathroom. If your intention is to close the bottom of the bath screen – not in a hurry for him to shop. It’s a simple device if you want you can do it yourself. What matters is that you had minimal DIY skills and the desire to spend a few hours of free time. However, in this case, you do not get to do without going to the store and extra expenses but something can still be saved.

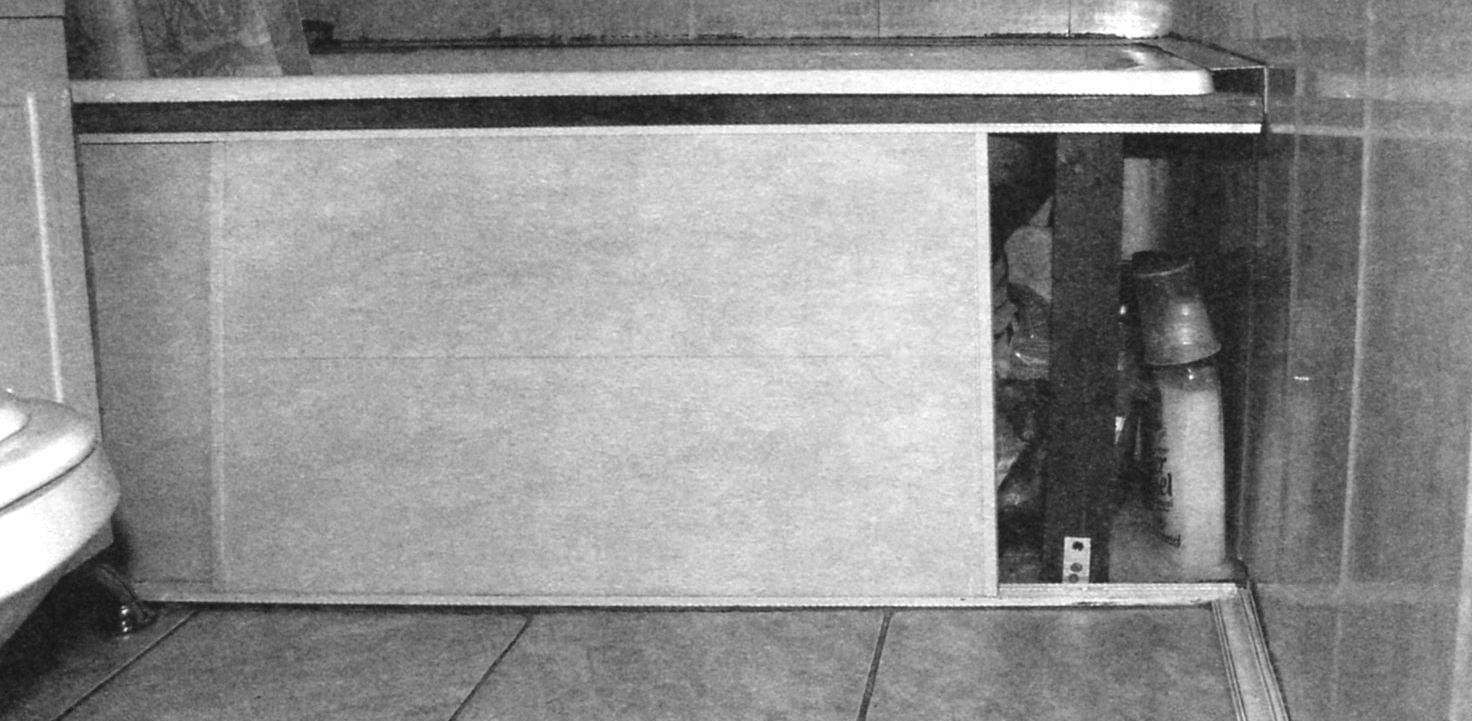

The manufacture of the frame of the screen I had two pieces of wood equal to the length of the bath and the section of about 30×40 mm and two short bars of the same cross section equal to the height of the bath. The bar to acquire had him back on the farm. For making sliding screen doors a perfect fit PVC panels, remaining after repair. For connecting doors at the ends I modified a plastic box for open wiring with a width equal to the thickness of the PVC panels. Purchase had plastic rails, originally designed for sliding glass book shelves. Only used the top – they are more profound.

Cutting the size of the wooden beams, I chose the lower parts of the uprights and the lower horizontal bar of the grooves for the corners, they will be stapled. Having finished that task, impregnated with antiseptic and bars to both the horizontal planks nailed plastic rails (two in parallel).

Since the production of the screen I have in mind during the renovation of the entire room bathroom, the lower timber used as formwork during casting of the floor screed.

The lower horizontal bar “drowned” in the screed bathroom floor and fastened to the rack using the area

The upper horizontal timber fastened to the rack by a screw on the inner side

Movable bar screen Assembly. The ends of the doors fixed plastic boxes for outdoor wiring

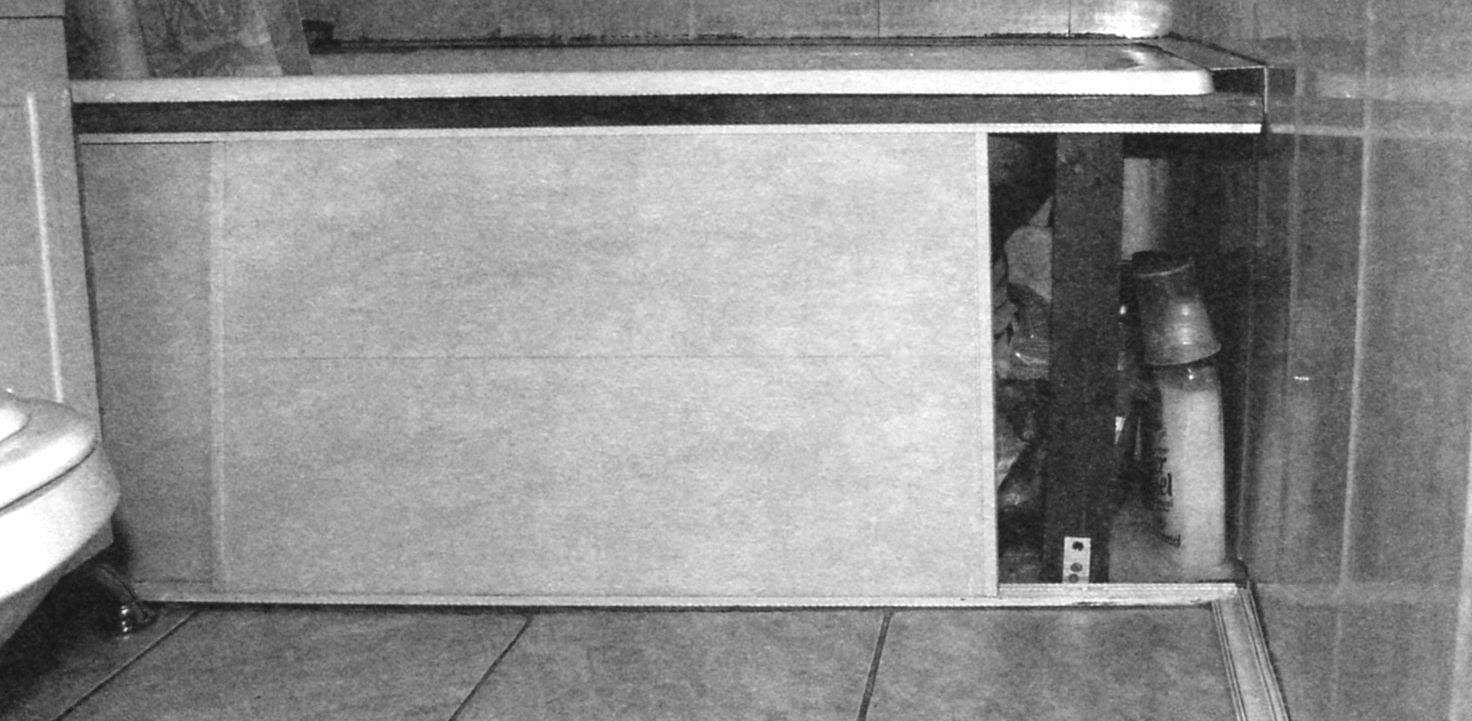

Setting a new tub with drain and specifying the size of the uprights of the frame of the screen, connected with upper beam (the inner side) directly with screws, and the bottom with aluminum angle (it is less susceptible to corrosion than steel). Wooden frame to frame is “hung”, when fixing the top bar pressed to the bathroom with little effort.

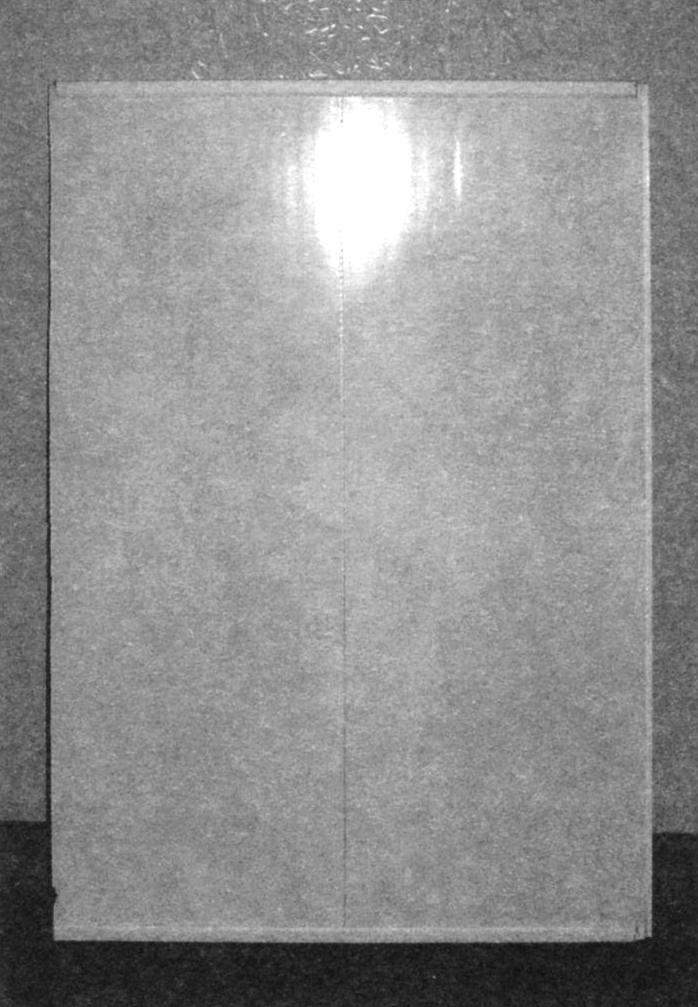

Had to make a last – sawing PVC panels for the manufacture of doors. Length it is better to pick up so that the door in the closed position a little gush each other. Every door I went at the height of two panels. Cementing them in parallel (at the edges they are special ridges and grooves), for rigidity on the ends of a piece of duct for electrical wiring. Since the width of the boxes were exactly matched, then landing them was tight, and glue the boxes to the plates of PVC did not.

After the installation of the doors came out quite good screen, to close the space under the bath, which stores a sufficient amount of detergent and other household stuff.

N. YAKUBOVICH