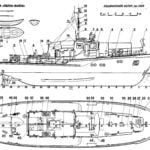

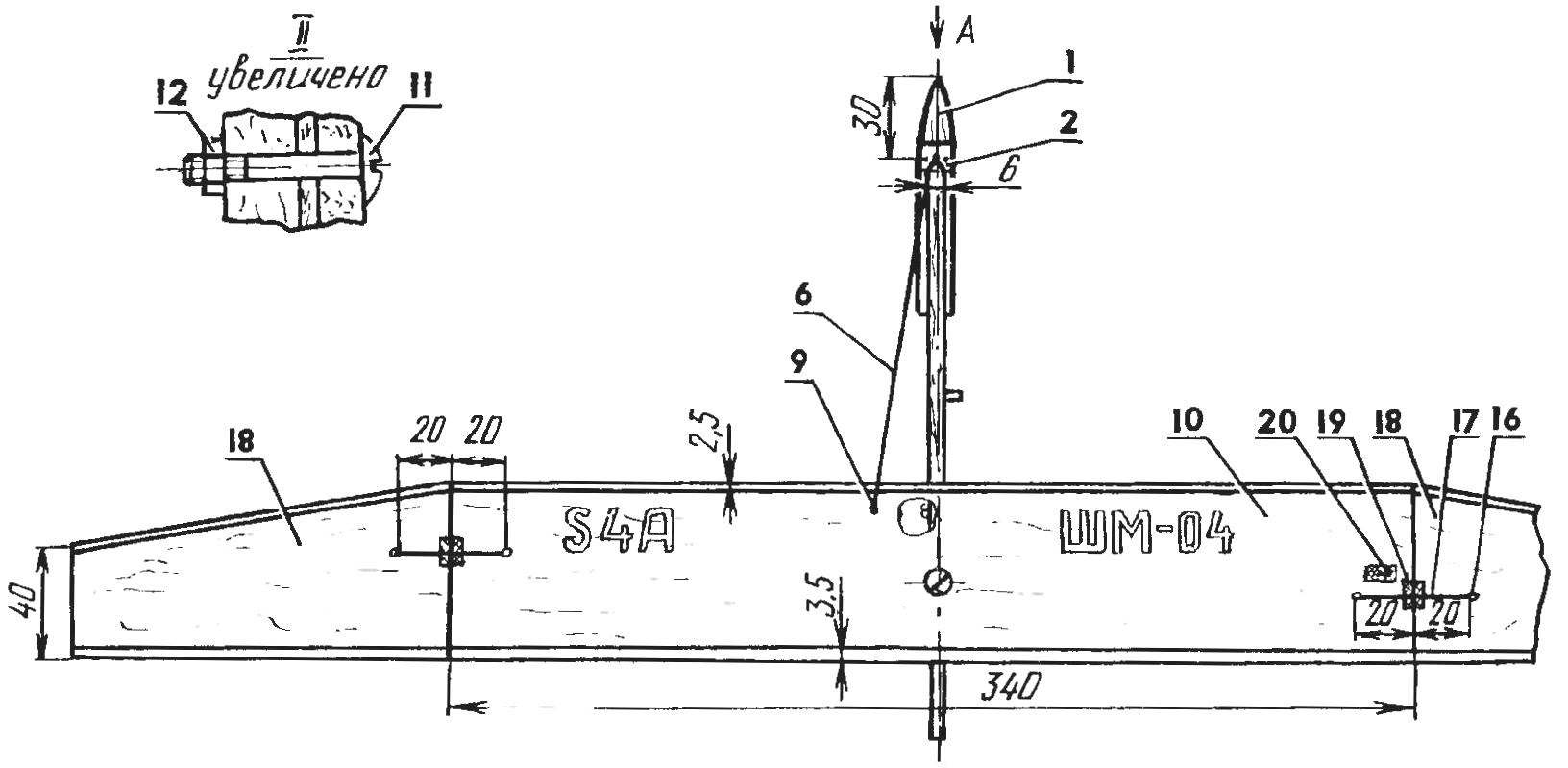

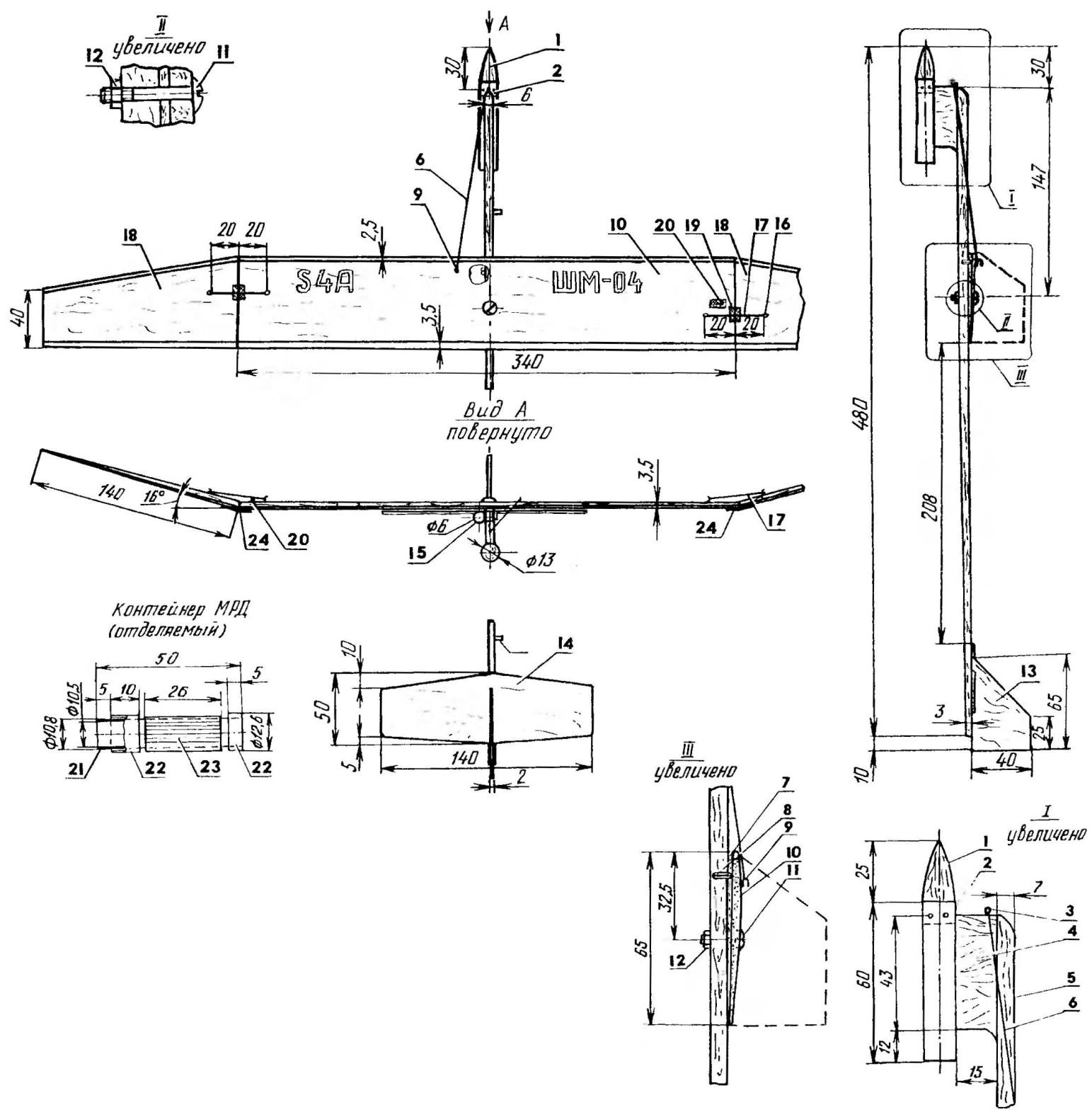

The proposed model is made by the known, so-called “Moscow” scheme. Its main feature is folding the rotary wing. It is made of balsa plate with a thickness of 3.5 mm. the Center section — size 340×65 mm, ears length 140 mm — trapezoidal shape. All three elements of the wing shaped and edged for rigidity along the contour of the fake rails. The width of the front edge of 2.5 mm, the rear is 3.5. The connection of the center section and “ears” swivel, silk strips of 12 mm width, glued on the bottom. From the top, at a distance of 20 mm from the axis of rotation, affixed the hooks, wire, allied with a diameter of 0.5 mm for hanging rubber bands return “ears”. Where you touch the rubber bands to the plane of the wing are reinforced with celluloid overlays. On the center section of the fixed back two hooks. One, closer to the center, the left half for the elastic return of the wing, the other on the right, closer to the edge— thread for the fixing of the wing during takeoff.

The proposed model is made by the known, so-called “Moscow” scheme. Its main feature is folding the rotary wing. It is made of balsa plate with a thickness of 3.5 mm. the Center section — size 340×65 mm, ears length 140 mm — trapezoidal shape. All three elements of the wing shaped and edged for rigidity along the contour of the fake rails. The width of the front edge of 2.5 mm, the rear is 3.5. The connection of the center section and “ears” swivel, silk strips of 12 mm width, glued on the bottom. From the top, at a distance of 20 mm from the axis of rotation, affixed the hooks, wire, allied with a diameter of 0.5 mm for hanging rubber bands return “ears”. Where you touch the rubber bands to the plane of the wing are reinforced with celluloid overlays. On the center section of the fixed back two hooks. One, closer to the center, the left half for the elastic return of the wing, the other on the right, closer to the edge— thread for the fixing of the wing during takeoff.

To the lower surface of the wing, in the middle of the center section glued the pylon balsa plate with variable thickness (maximum 2.5 mm), a width of 5.5 mm and a length of 65 mm. by Changing the thickness of the pylon at the ends, you can adjust the installation angle of the wing, what is necessary to do when debugging gliding flight.

At a distance of 10 mm from the front edge, the side of the pylon glued the emphasis of the rotation wing is an l-shaped hook, soldered from two curved steel wires with a diameter of 0.5 mm. In the middle of the center section and in the rack and the fuselage at the distance of 147 mm from the front edge of the drilled hole with a diameter of 2.5 mm, the inside is reinforced with epoxy. It is inserted in the bolt with a wide head, who is simultaneously the fastening element of the wing and the axis of its rotation. The finished wing is carefully crafted and double-coated with nitrocellulose lacquer.

Fuselage — lime rail length 450 mm variable section: front — 7×6 mm, rear— 3×2 mm. To the nasal part of the bottom slats glued the pylon propulsion unit — the balsa plate with a thickness of 6 mm and a size 43×15 mm. To her, in turn, also bottom attached propulsion unit consisting of housing and fairing. The body — tube is made of fiberglass with a length of 60 mm, is laminated on the mandrel with a diameter of 12.7 mm. Cone carved from basswood, inside the bore and is fixed in the housing. In the rear fairing (belt width 10 mm) drilled four radial holes with a diameter of 1 mm for bleed of gases from the expelling charge mrad. Through two of them passes the thread of the fixing wing in take-off mode.

To the rear fuselage top is attached to the stabilizer and fin. Both elements of the tail are made of balsa veneers of 1.5 mm thickness and slightly rounded contour. Before installing on the fuselage they are double-coated with nitrocellulose lacquer.

Model rocket modeling class S4A:

1 — fairing (Linden); 2—housing of the motor unit (glass); 3 — hook elastic return of the wing; 4 — pole MRD (balsa s6); 5 — fuselage (Linden, rack 6×4, L450); 6 — Resita return wing; 7 — pylon wing (balsa); 8 — focus wing; 9 — hook of the elastic return; 10 — wing (balsa s3,5); 11 — the axis of rotation of the wing (bolt M3); 12 — nut M3; 13 — keel (balsa, veneers s1,5); 14 — stabilizer (balsa, veneers s1,5); 15 — guide rings (tin s0,3); 16 hook; 17 — gum return “tabs”; 18—wing — ears (balsa s3,5); 19 — reinforcing pad (celluloid); 20—the hook threads of the fixation wing for takeoff; 21 container MRD (GRP): 22 — boarding sleeve (paper); 23 — brake feed container MRD; 24— joints of the consoles (silk); details 3,9,16,20— wire OVS Ø0,5

In the right side of the rod of the fuselage glued two guide rings to start the rocket. They are curved strips of sheet 0.3 mm thick and fixed with epoxy.

In accordance with the new technical requirements of the missile models in this category, they must be equipped with a detachable with MRD recovery system — expanded brake band minimum sizes 300×25 mm or a parachute with an area of more than 4 dm2. This rocket uses a detachable container mounted before you start together with MRD in the engine block. The container is made from fibreglass tube with a length of 50 mm and an inner diameter of 10.5 mm. is wound on Top of it with glue two paper rings which serve as mounting bushings. Their outer diameter is slightly (0.1 mm) smaller than the diameter of the mandrel of the motor unit. Before installing the container in the engine block it was wound brake band, and the end of the pre-glued between the rings.

The procedure for preparation of the rocket for launch to the scheme; console folded down to the center section and turn folded thus the wing 90 degrees counter-clockwise. It lies along the fuselage. Using a hook fixing the wing in the right side of the center section and the holes in the fairing propulsion unit thread and knotted it. Then insert into the unit detachable container mrad.

Flies the model with ordinary (simple) agnostinelli installation. After firing the lifting charge burns the thread MRD fixing the wing. Under the action of the gum is returned to the position for planning. At the same time shot detachable container MRD and its brake band unfolds.

The mass of the model rocket plane without a container and MRD — about 30 g.

V. ROZHKOV, master of sports