“The rocketeer” in Belgorod region more than five years are among the strongest in Russia. In the team competition they are equal “butt” on the leaders rakatomalala Moscow and Chelyabinsk regions, in turn becoming the winners. Over the years, no competitions, no matter where they have been Champions in any class of models of missiles. So, at the last national championship winners in two categories — S6 and S9 become athletes Belgorod team, which was represented by rocketmodeler. The station of young technicians Novy Oskol Anastasia Mayboroda and Vlasta Yagupov. And, it should be noted that their names appear consistently among the winners of Russian and international competitions in recent years. Our magazine has repeatedly published drawings and descriptions of models young “rocket scientists” of Belgorod region. Today we offer our readers to familiarize with the model of rotachute (class Ѕ9А) champion of Russia 2007 Power Yagupov.

“The rocketeer” in Belgorod region more than five years are among the strongest in Russia. In the team competition they are equal “butt” on the leaders rakatomalala Moscow and Chelyabinsk regions, in turn becoming the winners. Over the years, no competitions, no matter where they have been Champions in any class of models of missiles. So, at the last national championship winners in two categories — S6 and S9 become athletes Belgorod team, which was represented by rocketmodeler. The station of young technicians Novy Oskol Anastasia Mayboroda and Vlasta Yagupov. And, it should be noted that their names appear consistently among the winners of Russian and international competitions in recent years. Our magazine has repeatedly published drawings and descriptions of models young “rocket scientists” of Belgorod region. Today we offer our readers to familiarize with the model of rotachute (class Ѕ9А) champion of Russia 2007 Power Yagupov.

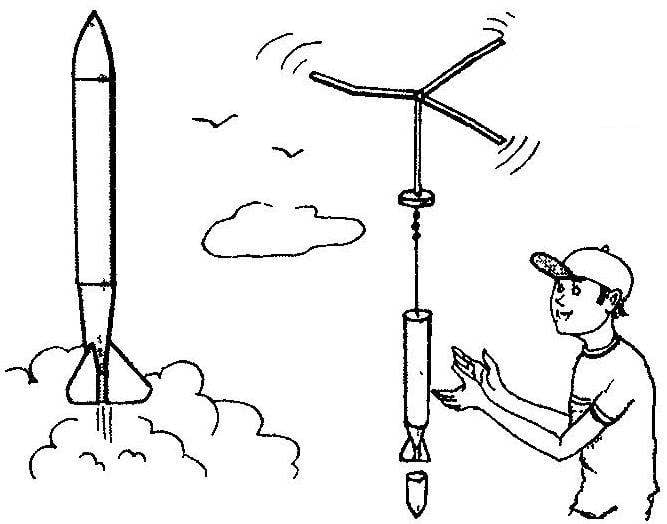

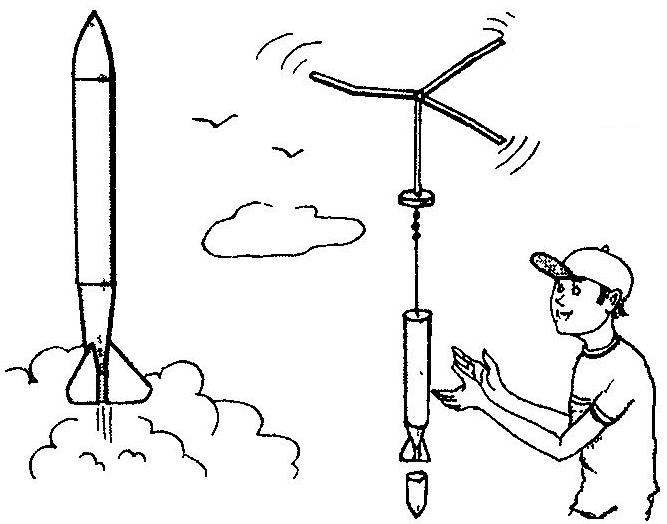

No matter how corny that sounds, but I want to focus on what’s really proposed design rotachute differs from the known and published on our pages for its simplicity, availability to repeat and, in my opinion, originality of technical solutions One of them is the absence of the head fairing of the rocket on rotor (bearing screws on the stage of the descent), He is separated from the body at the time of ejection of the rotor and held it with a rubber band damper.

I can not mention that in the presented design, Rotorua the role of the creative teacher — Director syut Vitaliy Maiboroda.

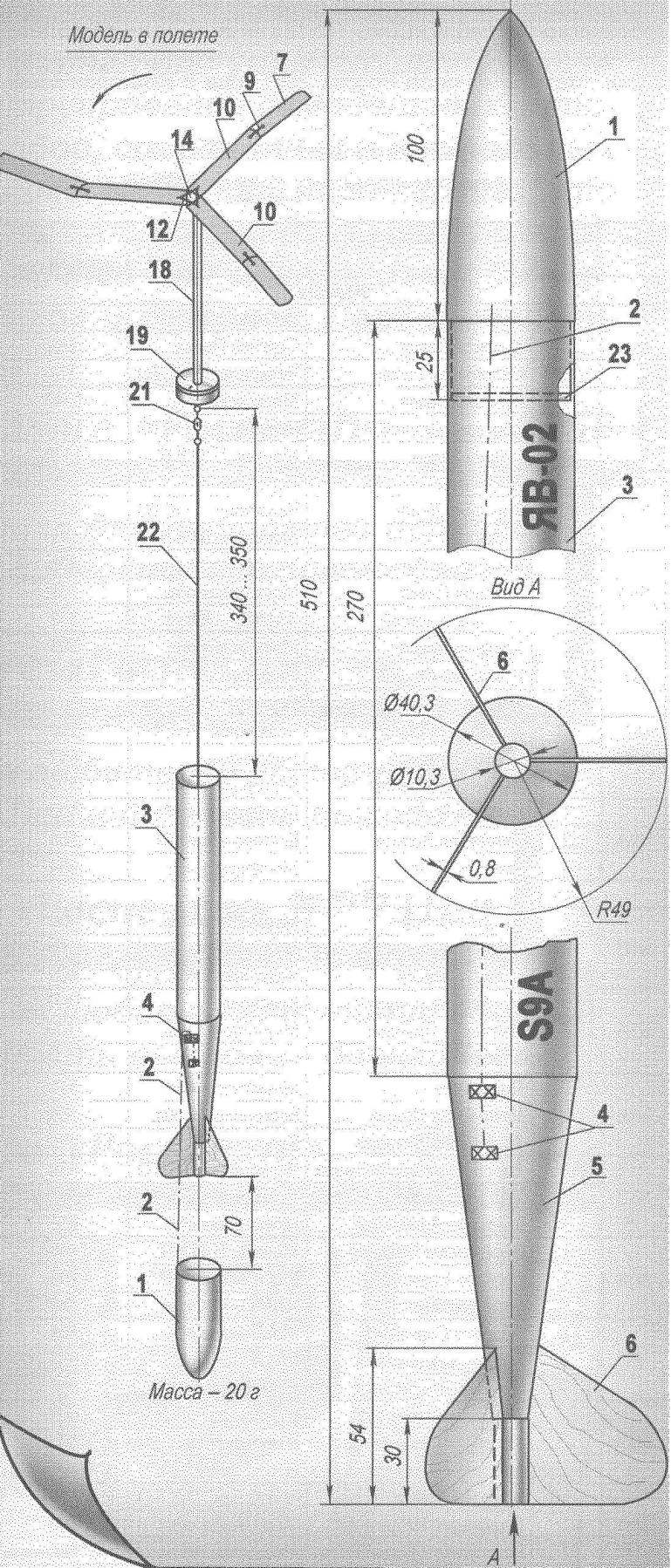

Bearing element of the model class Ѕ9А, creating a lifting force, is a three-bladed rotor, Each blade — folding, consists of two elements, the root — length of 195 mm with a thickness of 3 mm and a cantilever length of 180 mm and the same thickness, the Width of the blades is 30 mm, the profile is PLANO-convex, the angle “V” blades — 5° When viewed from above the rotor blades are straight, with hinged wingtips, sweep 68° mounting angle of the blades have negative 5°.

The blades are cut from the balsa plate with a thickness of 3 to 3.2 mm and length 380 mm, handle in form in the package Then profiles, bring their thickness up to 3 mm and coated with two layers of nitrocellulose lacquer Then cut across each blade, i.e. in the middle of the Handle end face at an angle of 79° and a swivel connecting them, pasting bottom a strip of fabric with a width of 12 mm At a distance of 9 mm from the edge, along the longitudinal axis in each half, drill a hole with a diameter of 3 mm at the Bottom mounted on epoxy two staples (pins) from a steel wire in diameter 0.5 mm having them parallel to the line of folding in the future, They are the holders elastic bands return the console, Its threaded through holes on top and tie knot, making a loop After Assembly, these holes are sealed with tape.

To the free end of the root element of the blade is glued bottom “biscuit” — the balsa wedge with a length of 30 mm and a width of 7 mm and a maximum thickness of about 4 mm It serves to align the plane of the attaching of the blades to the rotor hub, the Root part of the blade should be stitched with thread to strengthen the Top, a distance of 12 mm from the edge of the blades glued hooks On them, put on a loop of elastic with a diameter of 1 mm, necessary for unfolding the blades of Its length, and therefore tension, is selected in a practical way At a certain tension of the elastic blade should be disclosed without impact loading Otherwise possible destruction of the structure.

The rotor hub includes the lens and rod prism is an equilateral triangle with a side of 30 mm made of balsa 4 mm thick, scored and glued veneer on Top, in touch gum disclosure make small holes with a width of 2.5 mm, in which “lies” rubber band when folded the blades.

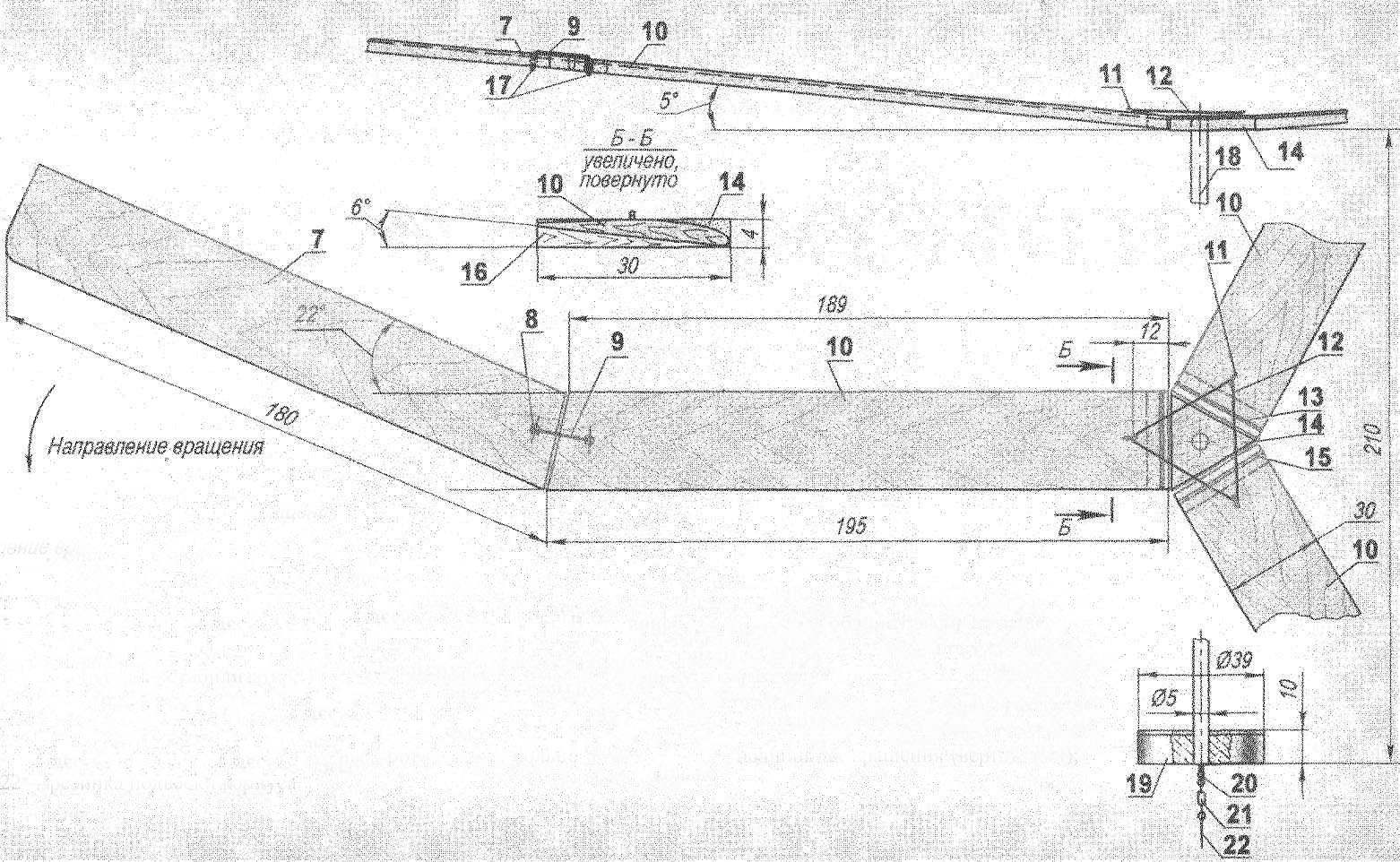

Model rotocut class S9A champion of Russia 2007, V. Yagupov (Belgorod region, Novy Oskol):

1 — fairing; 2 — thread mount fairing; 3 — body; 4 — the place of gluing strands pendants; 5 — tail cone; 6 — stabilizer; 7 — console; 8 — hole for the elastic return console; 9 — elastic return console; 10 — blade; 11 — rack; 12 — elastic return of the blade; 13 — lens; 14 — strengthening the root portion of the blade; 15 blade; 16 — cone (wedge) reinforcing; 17 — pin gum return; 18 — rod (Chia, reed); 19 — wad of the rotor; 20 — ring pendants; 21 — bearing rotation (vertloc); 22 — the elastic suspension of the case

Swivel (mount) of the blades with prism is done by stickers on the bottom with nylon fabric on soprikasalis elements must be provided with the close contact faces of the prism with the ends of the blades.

As stated above, the hub consists of prisms and glued her rod with a length of 214 mm. it is Made of chiy (reed). To the free (lower) end of the rod attached the rear wad with a diameter of 39 mm, made of balsa veneer and soft polyurethane on the end of the glued rod bearing (fishing vertljuzhok) at the end of which suspension cable thread model (thread) represents a segment of a rubber band in a cloth sheath diameter 1,6 — 1,8 mm (also called hat) To the other (lower) end is attached another vertljuzhok, which, in turn, soldered the cut steel wire (holder) with a length of 110 mm and a diameter of 0.4 mm with a curved end to Them, it engages the lower section of the tail cone of the hull.

The bearer of this rotachute — container performed by a known technology is formed of fiberglass. On a slightly heated patterned mandrel layer applied to the separation of the postmark (“edeluxe”) Allowing her to cool down, wrap two layers of fiberglass pre-impregnated with epoxy resin In this case is accomplished as a whole with tail cone and motor block After zatverdzhennia resin workpiece treated on the mandrel in a lathe at low speed (70 — 100 rpm) and cut to length Then lightly heat the mandrel and remove the finished case.

Stabilizers (three of them) are cut from balsa veneer with a thickness of 0.8 mm and reinforced lateral surface of the epoxy resin To the hull they are attached at the butt to skim the surface of the tail drops of superglue, fixing the stabilizers Then miss places of the gluing resin To the tail cone at the point of transition, attach the cut threads, which tie the elastic suspension of the fairing.

Fairing is molded from fiberglass along with the landing skirt. Her face plastered with frames from foam, pre-mounted inside his Kevlar thread for connection to the elastic suspension of the body.

Preparation of Rotorua to spend so start from the Top first, into the housing stack thread pendants, finish (steel holder) hook the curved end over the section of the hull and put the engine (MRD-2,5) He, in turn, due to the tight fit locks the thread suspension poured on Top of a little talcum powder that locks from firing when triggered, expelling charge very thread and the entire model After that put the console of the blades to the root elements and folded blades are placed along the rod. Then insert into the body all folded rotor and close the payload fairing Model is ready to start Mass rotachute V. Yagupov without MRD to about 20 g.

V. ROZHKOV