The power plant includes serial compression motor KMD-2,5 and wooden air traction screw Ø 250 mm, H 75 mm, mount the tank and the counterweight with a software timer mechanism. All the elements combined into a unit which can be easily and quickly replaced, even at the start. Created a console located by the cylinder of the motor a significant imbalance kompensiruet counterbalance, for these purposes the fuel tank and the timer offset in the direction opposite to the engine head.

Timer program: time limitation of the motor and clutch shaft of the main rotor with the fuselage for the forced landing of the model. The timer starts when promoted carrier screw touch of a finger rotating a wire lever, which stop the pendulum of the clock mechanism.

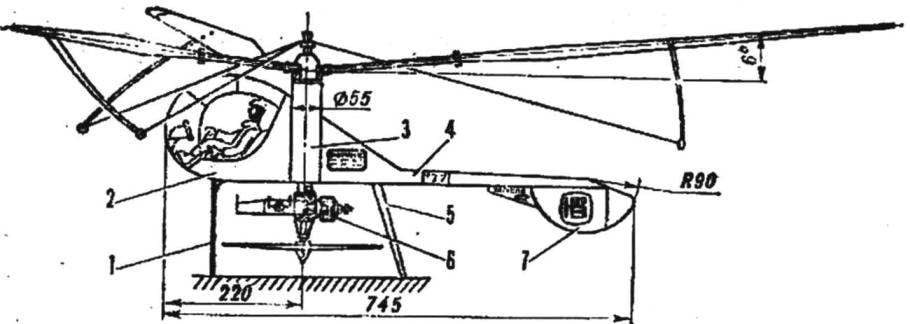

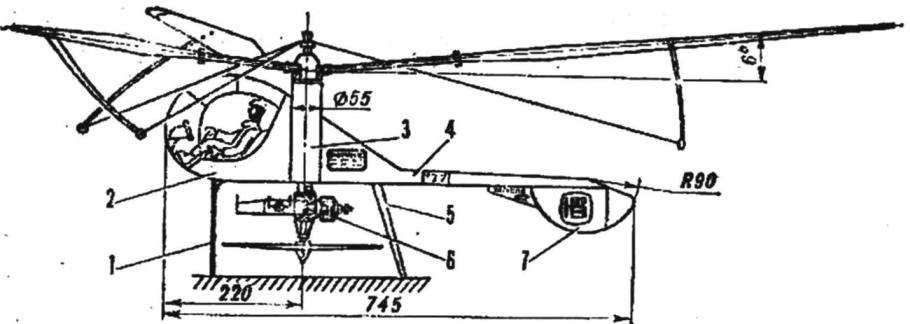

Timer model helicopter HB-39:

1 —front landing gear, 2 — the nose of the fuselage, 3 — cylindrical honour of the fuselage, the 4 — tail boom, 5 — back front chassis 6 — power plant in sbore, 7— Kiel, 8 — stabilizarii weight, 9 — bracket, 10 — stretch, 11 — blade main rotor, 12 — rod, 13 — bushing Assembly.

Propellers for compression of micro-motors:

1 — Ø 250 mm, H 70 mm, material: walnut, maple, hornbeam or birch, 2 — Ø 250 mm, H 75 mm, material: walnut, maple or Stekloplastik, 3 — Ø 250 mm, H 80 mm, material: walnut, Stekloplastik.

Design engine mounts for engine KMD-2,5.

The design of the rotor hub.

The trajectory of the model helicopter:

AB — take-off; BV — climb; W — transition phase; GD — authoritiesi descent; DE parachutisme (forced) descent.

Engine mount with the engine mounted on the lower end of the shaft of the rotor. In the fuselage, the whole Assembly is mounted on two ball bearings, ensuring minimal rolling resistance; only when this condition is met, microventure will not be deployed in flight.

The fuselage. Its lateral projection simulates a single light helicopter with a large glazed cockpit and tail fin. The cross section is lenticular. The external contours of the cabin and the keel is laminated on a mandrel from a set of thin steamed Linden slats. Central (Sideleva) part of the cylindrical fuselage cross-section is pasted Inside its dural shell for ball bearings and in the front lower part mounted aluminum bracket front landing gear. Rear rack is fixed with a tapered pin in an aluminum tube, also glued in the fuselage. All racks are made of D16T sheet thickness of 1.5 mm. the Fuselage is pulled thin fiberglass and covered in bright polyurethane enamel.

The rotor. Mostly parts and components of the rotor design is similar to the model described in “M-K” № 4 for 1980. Compared to her-changed the following.

On the blades applied to two profiles. From the butt To the middle is MVA-301, and from the middle to the end of the blade — Clark-Y. the axis Diameter increased to 5 mm, they are made from silver steel and hardened. The blades are flat and without twist, the stops allow you to change their orientation angles in the range from -10° to +30°. The surface of the blades are painted black.

And still they build these “crazy” dragonflies, looking unusual even against the background of experimental models of Buchvostau! Build them despite the fact that the class unmanageable rotorcraft problems and tasks much more than in any other. However, maybe this “incompleteness” are they attractive?

And still they build these “crazy” dragonflies, looking unusual even against the background of experimental models of Buchvostau! Build them despite the fact that the class unmanageable rotorcraft problems and tasks much more than in any other. However, maybe this “incompleteness” are they attractive?