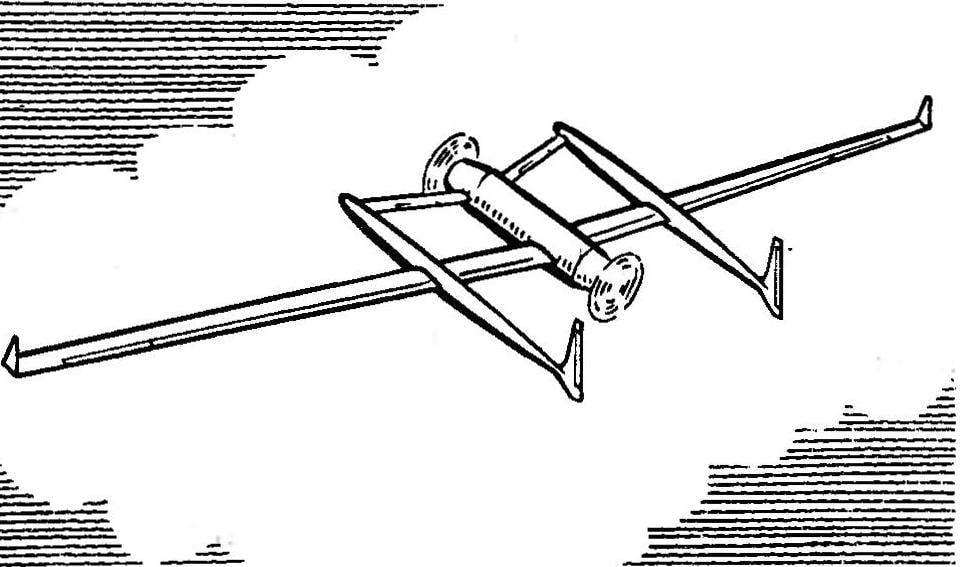

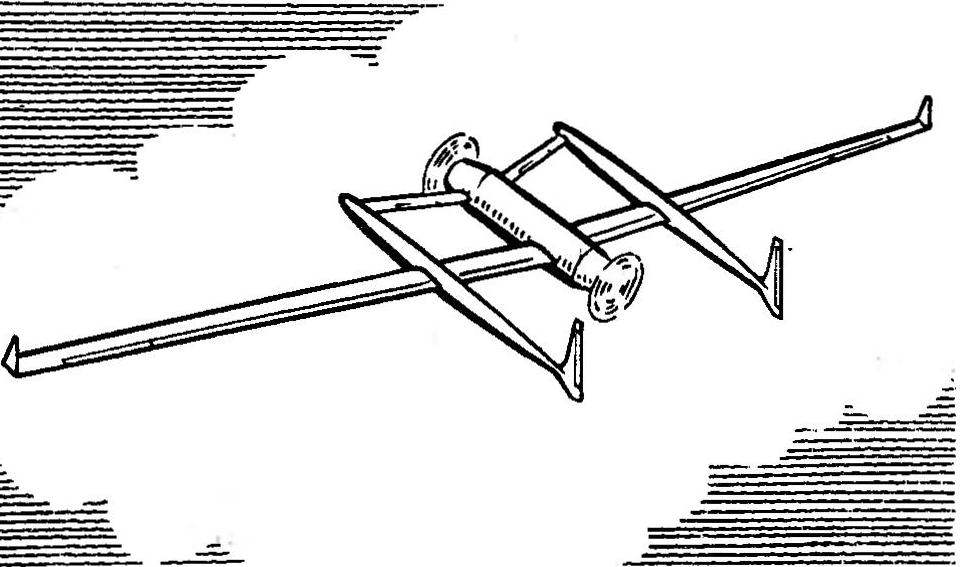

The figures show the most complex version of the design model based on partial use of balsa in the power circuit of the wing and stabilizer. Now this former scarce wood became available. The design of the fuselage and the beams can be monolithic. The Central fuselage vystragivaetsja from a piece of Linden or aspen with a thickness of about 5 mm, and after processing the workpiece in the sub zones glued 1 mm overlapped plywood. Beams are also cut from 3 to 4 mm Lastin Linden or aspen. All load-bearing plane (wing and stabilizer) vystragivaetsja from solid billets of the same wood, and without first selecting the mechanization of the wing and control surfaces of the stabilizer. In this performance polyopia after finish the Assembly will be indicated in the table the maximum mass.

The easier option alnobetula design with the same lining of the ends of the fuselage 1 mm plywood (the thickness of the blank of the fuselage should be equal to 8-10 mm, and the beams – 5 mm). However, then have trouble with the exterior model because the pores of the wood somewhat complicate the processing of the surface. Although, if you are able to buy the balsa in the right quantity, will not be big problems to stock up on a special film for covering a mini Voyager, in balsa and with a tight wrap

dry weight Prokopii in take-off condition is equal to approximately 800 — 900 g.

In all cases, the wing is split. To make the nodes of the connector, you can easily, therefore we do not give recommendations. Management — external simple type, with wiring cords under the front edge of the wing. Alignment is a fully equipped model should be in 10 — 15 mm in front of the Central section of the wing.

The new machine is equipped with engines MK-17, which cut off the excess weighty cooling jacket of a cylinder (shaped like a triangle with the corners in areas of mounting screws). In addition, in accordance with earlier publications in the “Modeller-designer” modificeres node of the carb and fixing the axis of the spool (the nozzle is made through and is used just like the MC-12B or”Rhythm”). Power —gas pressure taken from the crankcase through the set in his sock from the bottom fitting of the valve facing the cavity in front of the native bearing of the crankshaft. Propellers can be modified brand of the plastic (due to the increased weight they will provide easier starting), or homemade wood (these are more efficient in the air if done correctly). In any case, you need to check what will happen with the crankshaft rear pusher engine in its vietii into the crankcase, and if necessary, put wheel bearing, Besides, it is better to provide a propeller with a slightly increased pitch.

In conclusion, I would like to appeal to those who mastered the technology of making models from foam, followed by their tight tight wetmanski paper. Think about — perhaps this prototype and offer a copy for your hands?

V. TIKHOMIROV

Today we continue the theme begun with the publication of non-traditional polyopia supersonic fighter-interceptor MiG-25, the New development even more unusual in the choice of the prototype for the copy and overall design of the model. Today, it is about the reproduction in miniature of a legendary airplane “Voyager”, made in 1986 by flying non-stop around the globe. I hope that ego of publications will contribute to the revival of some extinct interest to the class “school” sports polycopy. It should again be noted that Voyager, like the MiG-25, only a single instance of a large number of interesting prototypes, giving modelistica up at any level.

Today we continue the theme begun with the publication of non-traditional polyopia supersonic fighter-interceptor MiG-25, the New development even more unusual in the choice of the prototype for the copy and overall design of the model. Today, it is about the reproduction in miniature of a legendary airplane “Voyager”, made in 1986 by flying non-stop around the globe. I hope that ego of publications will contribute to the revival of some extinct interest to the class “school” sports polycopy. It should again be noted that Voyager, like the MiG-25, only a single instance of a large number of interesting prototypes, giving modelistica up at any level.