3 . Extremely simple, but thought out to the last detail, the design speed has allowed its Creator, student of the Kharkiv school of Constantine Chistova three times to climb on the highest step of the podium at the “high” competition in this class. It should be noted that reached the championship of the USSR 204,731 speed km/h was actually a record and at the same time… unattainable. K. Chistov, the result not only exceeded to date, but even the barrier of 200 km/h is not yet amenable to young athletes.

A distinctive feature of race is its high adaptability. Of machinery is enough to have a drill press which with success can be replaced, even the hand drill. And yet — only the usual sets of bench tools. All this makes the model a scalable in even the most unprepared conditions of school clubs. The simplicity of it allows under the guidance of experienced kruzhkovtsev to recommend a model for the construction guys, starting with 3rd grade.

All six parts racing “vartuli” are made of common, readily available materials — no “spaces” and sophisticated technologies. But despite this (which only increases the class developer as a designer!), model lightest. Its weight is 300 to 320 g in different versions. And this, together with the engine KMD-2,5, own weight which is equal to 180 g.

Engine mount, which is, in fact, the basis of all models, has a rational and at the same time providing a light weight form. Her blank-sheet aluminum alloy D16T or Д1Т thickness 2.5—3 mm. by the Way, from the same material and the strap is made of cord and bracket for mounting straps on Motorama. The lower part of the motor is simultaneously stand, gradually turning into a skate model.

Work on the main part of the race begins with perennate drawing in full scale on tracing paper. Need to move carefully not only the contours, but all the Windows and the centers of the future holes. Cut out from the tracing paper pattern, paste it on a metal workpiece and produce machining of the part. Large Windows can be performed by drilling on the contour with the subsequent cutting heights of lintels and simple cutting heights using a chisel. To cut the groove the engine is set, and then by marking on the legs of Carter nutriveda, drilled and cut holes M3.

The finishing processing operations of the motor are finishing the form of the ridge, rounding the corners at the front, deburring, cleaning and polishing of lateral surfaces.

The hull is carved from a well-dried block of straight-grained; it does not have knots lime. Basic dimensions are taken from the General arrangement drawing of the model. Initially, the bar is brought to the section 20Х46 mm, and then formed perpendicular to the plane carry the “side view” and “top view”. Only after cutting the contours using a knife, begin to round corners. Niche under the tank and the crankcase can be performed with chisels and bormashenko. Boarding the plane proshlifovat for Motorama and carefully Alesgerov metal surface, fasten both parts ia epoxy resin. For reliability through the holes duralumin parts in the wood screws screws or bolts. Final processing of the outer surfaces of the housing should be only now.

To increase the stiffness and strength, as well as the exclusion of impregnation of wood fuel needed after finishing to fit the hull fiberglass thickness is 0.05—0.1 mm epoxy resin. If you need fiberglass no, you can get coverage from one “epoxy”. The external effect will be the same, but the strength of the tail section will be reduced.

A few words about the length of the “beam”. A avtomodelisty made short machines. However, the experience of the young citizens of Kharkov and Tyumen and Omsk says: the longer the model (more precisely, the farther from the engine stabilizer), the less possibility of tipping “vartuli” at startup. Although in principle it is possible to prevent shortening of “beams”, but for the sustainability of the run will need to simultaneously increase the area of the stabilizer.

The stabilizer option in the main — sheet duralumin. Although it’s permissible to “tail” and made of fiberglass or other plastic. Metal is good because to simplify its edges can be folded down, thus forming a ski; then do not have to bother separately with their manufacture and installation on the model. The finished stabilizer is fixed after the grinding and polishing with two screws.

Work on the fairing is quite time-consuming. From basswood or foam will have to cut out the exact model of the piece is reduced in external size of 2 mm. Its surface is polished and coated with a thin layer of epoxy. From the motor model on the fixed angle for which the disc is clamped in a vise. Outside cause and raspolirovyvayut layer “Edeluxe” or with a shaving brush and soap foam. After drying, a separation layer model fairing covered with several layers of fiberglass with a thickness of 0,1—0,2 mm, impregnated with epoxy resin. When the binder has hardened, a hacksaw cut off the excess fairing, removed from inside the model and dabravata item received. On a sheet of sandpaper laid on a flat surface, proshlifovat end to plane. This operation can be considered complete when the fitting between the fairing and the engine mount will not be gaps. And at the end of the grind detail from the outside; cut a window for the exhaust adjustment screw compression ratio, the carb needles and a small air intake in the front for engine cooling. For mounting the fairing at the back is pasted a small bar. With the screws M3 “hood” is captured in the Assembly model at the head of the engine, the third screw back on the housing.

After fabrication all parts are covered with microprotocol and, if necessary, scratches and nicks zashpaklevyvajutsja. When you finish racing synthetic enamels they are dried in a heat chamber. However, in order not to break the epoxy coating, the heating temperature will have to limit 65-70°C.

The fuel tank soldered from tinned sheet metal. Dimensions are taken of the actual, by the opening in Motorama. In the direction of the cords (i.e., in the direction of centrifugal force) height of the tank should be in the range of 12-15 mm. Than the smaller, the less will be the pressure drop of fuel in its formulation, the more stable will be the operation of the engine.

The model is ready. Shown in figure spinner borrowed from the motor CSTOM or “Talka-2,5”; while lathe is not as difficult and grind it themselves. For successful performance at competitions you will now be taken for the crossing of motor and selection of the propeller.

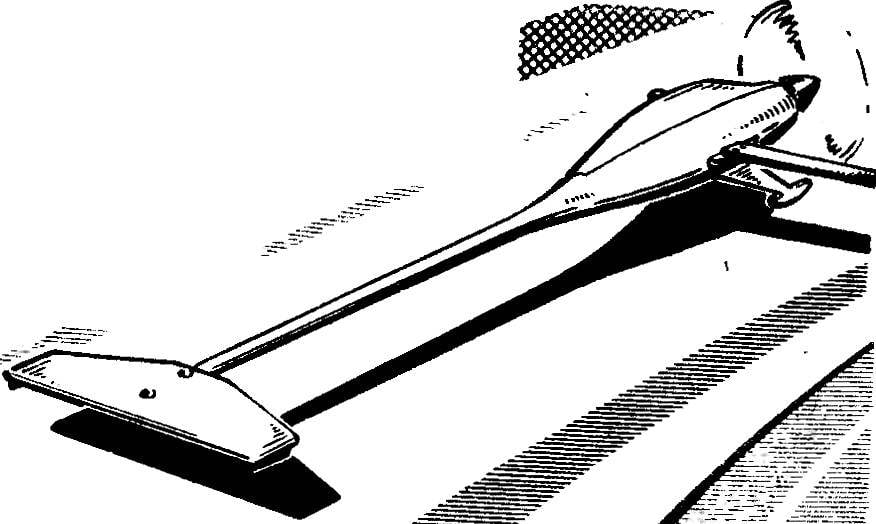

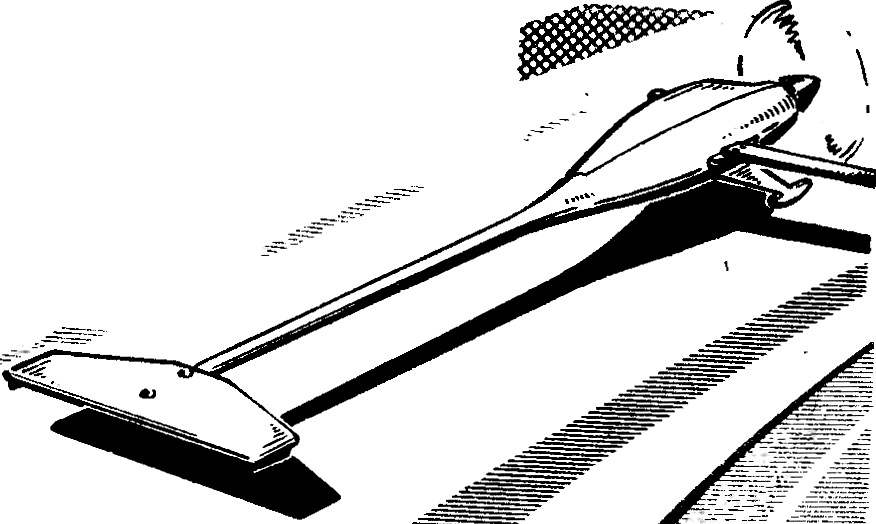

Control line racing car with aerobrigada:

1 — spinner, 2 — blister, 3 — cord strap, 4 bracket cord strap, 5 micromotor KMD-2,5, 6 — fuel tank 7 — housing, 8 — motor, 9 — tail horse, 10 — stabilizer.

FROM the editor: it appears that a good technique is always successful. And so it makes sense to try to apply the proposed model of the snowmobile and on the summer the track Assembly. The more fundamental differences in the traffic conditions on these two types of micromachines are almost there. To rework the model in avtovariant need only to mount at the front of the skate a pair of wheels knife-like type (the entire Assembly can be closed by small fairing) and two micromoles to attach to the ends of the stabilizer. It is important not to forget that at elevated temperature, requires intense cooling of the engine. So, you will have to pick up a cross section of the air intake in the front fairing of the plant.

V. KLIMENKO, head of the self-similar circle of obrzut, Kharkov

Recommend to read “Trainee” radio A radio-controlled model of a racing sailboat yacht can be made from the most accessible materials. And instead of expensive branded equipment, you can use a remote control set that comes... RIVET FRICTION Perhaps one of the most ancient and at the same time, and still most common methods of connecting parts of machinery, parts, tools — mount rivets. Is riveting, as a rule, the percussion...  An example of a creative approach to the creation of modern sports self-similar techniques can be aircar class AC-2 motor with a working volume of 2.5 cm3. Extremely simple, but thought out to the last detail, the design speed has allowed its Creator, student of the Kharkiv school of Constantine Chistova three times to climb on the highest step of the podium at the “high” competition in this class. It should be noted that reached the championship of the USSR 204,731 speed km/h was actually a record and at the same time… unattainable. K. Chistov, the result not only exceeded to date, but even the barrier of 200 km/h is not yet amenable to young athletes.

An example of a creative approach to the creation of modern sports self-similar techniques can be aircar class AC-2 motor with a working volume of 2.5 cm3. Extremely simple, but thought out to the last detail, the design speed has allowed its Creator, student of the Kharkiv school of Constantine Chistova three times to climb on the highest step of the podium at the “high” competition in this class. It should be noted that reached the championship of the USSR 204,731 speed km/h was actually a record and at the same time… unattainable. K. Chistov, the result not only exceeded to date, but even the barrier of 200 km/h is not yet amenable to young athletes.