Resolution of the State Defense Committee (GKO) on the seventh of May 1944 No. 5822 by the Red Army was adopted 100-mm field gun of the sample of 1944 with the assigned name of the BS-3. Among domestic ground forces artillery systems wartime weapon has a special status, defined in terms of “first” and “only” a number of technical and historical circumstances. BS-3 – the most powerful anti-tank gun of World War II.

Resolution of the State Defense Committee (GKO) on the seventh of May 1944 No. 5822 by the Red Army was adopted 100-mm field gun of the sample of 1944 with the assigned name of the BS-3. Among domestic ground forces artillery systems wartime weapon has a special status, defined in terms of “first” and “only” a number of technical and historical circumstances. BS-3 – the most powerful anti-tank gun of World War II.

This is the first and remains the only one of the accepted adopt towed 100-mm rifled gun, designed primarily to deal with heavily armored moving targets. BS-3 is the only field gun that has taken a significant part in the hostilities. Its production began during the war and continued long after its completion. And the characteristics inherent in the structure allowed it to remain in service for several decades after the end of production, despite the turbulent evolution of reactive anti-tank weapons and does not stop working on creating more advanced rifled and smoothbore antitank artillery systems (D-60, “Sting”, ” Rapier “,” Octopus “and others.).

This is the only almost completely original constructive Large series field artillery system: all other received if adopted, represented a deep modernization of the previously created or successful combination of elements already existing instruments. For BS-3 is characterized by the absence of direct predecessors, and the extent of borrowing is limited to the use of ballistic solutions and devices partially barrel ammunition. Although, of course, when it is taken into account the development of the potential of the earlier works.

Combining a unitary loading and hydropneumatic balancing mechanism, torsion bar suspension of the wheel speed and possibility besperedkovoy towing with high transport speeds at neottyanutom trunk was a novelty in the domestic similar caliber artillery systems for

The abundance of innovative solutions and ultimately their successful implementation have demonstrated a high level of design training and professional maturity of the team of the Central Bureau of artillery konstruktorkogo (TsAKB), headed by Lieutenant General V. G. technical Grabinym troops, despite the fact that the actual TsAKB formed in the system-People’s Commissariat of arms (IEC) in just a year and a half before putting the BS-3. This is the second attempt in the Soviet period, the formation of the brain center of the industry in the defense industry, based on carrying out a variety of research and development work in the interests of all Russian artillery, (history of the organization still requires a fundamental study and lighting). Elimination of CRI-58 (as he was known in the last years of its existence) in 1959, if we evaluate this fact from the point of subsequent history, it is a mistake. Convincing proof of this can be considered as the creation of eleven years the same institution – CRI “Petrel”.

In fairness it should be noted that the period was marked in the history of Soviet artillery in general, as very unfavorable due to over-emphasize the political and military leadership in the jet (since then called rocket technology) category. This, in turn, has led to significant degradation of design and production base artpromyshlennosti country and irrational spending. To justify such a development can only be lack of proper understanding and a certain euphoria, characteristic of the early period of the formation of a fundamentally new military technology. Then, of course, everything fell into place. But that was much later.

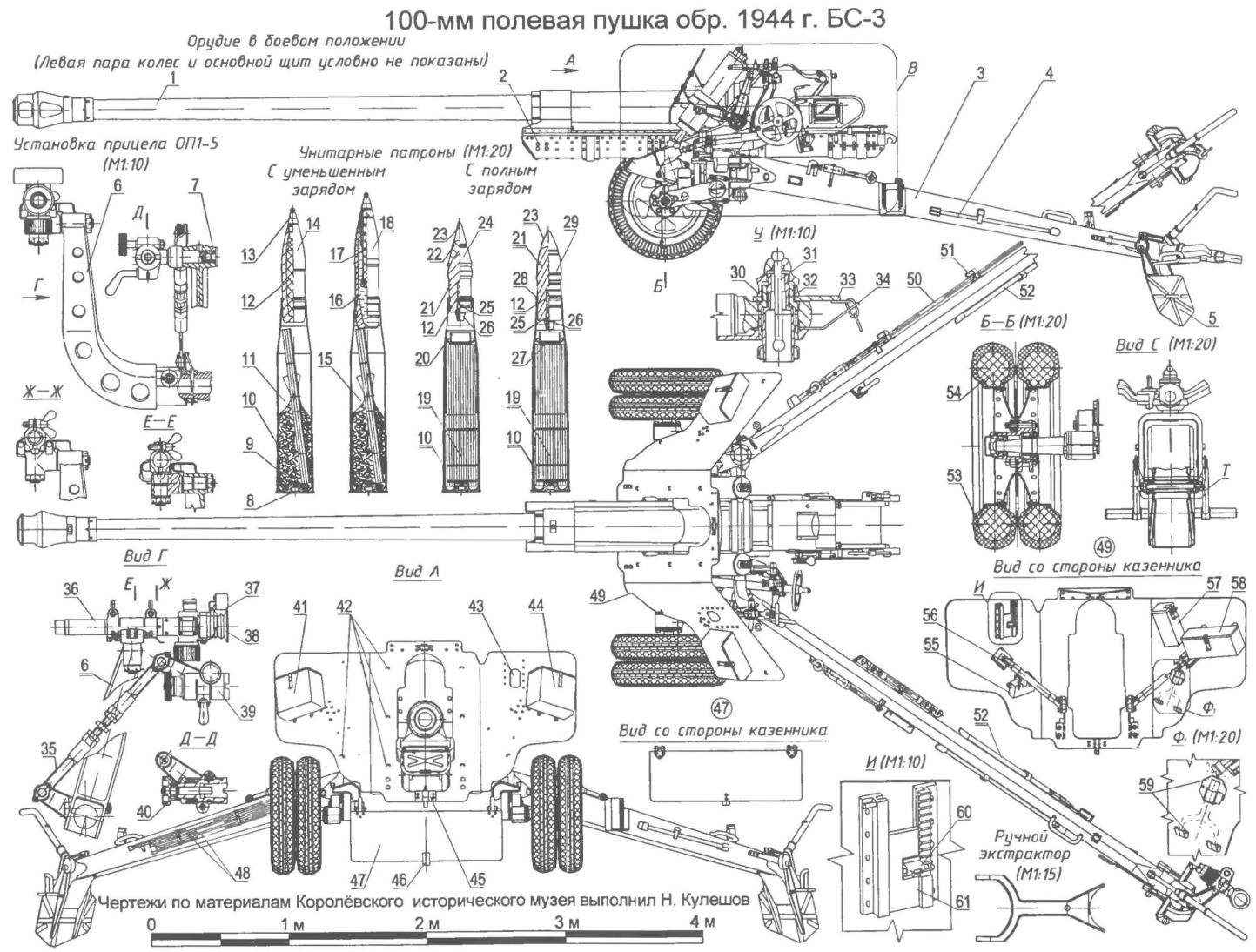

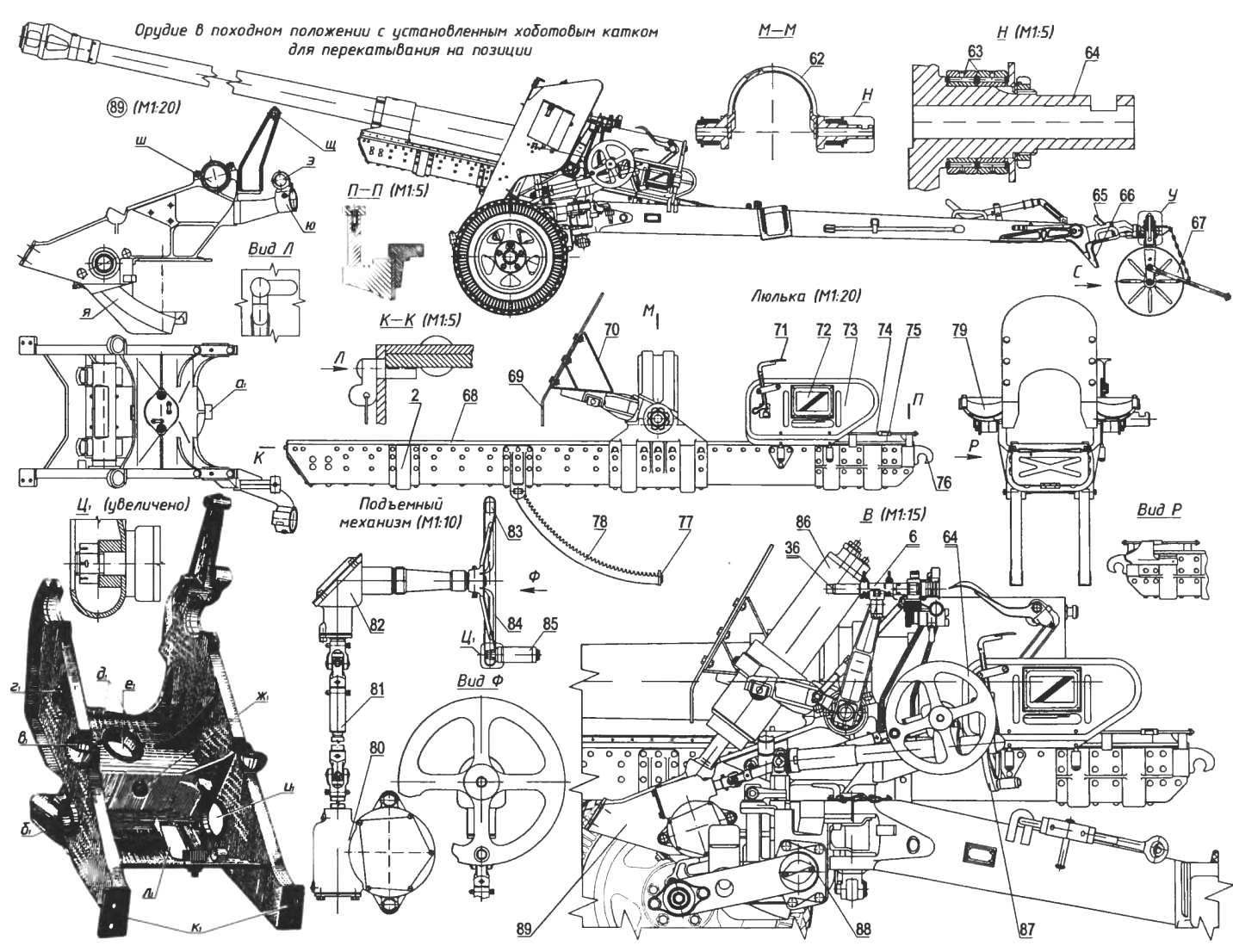

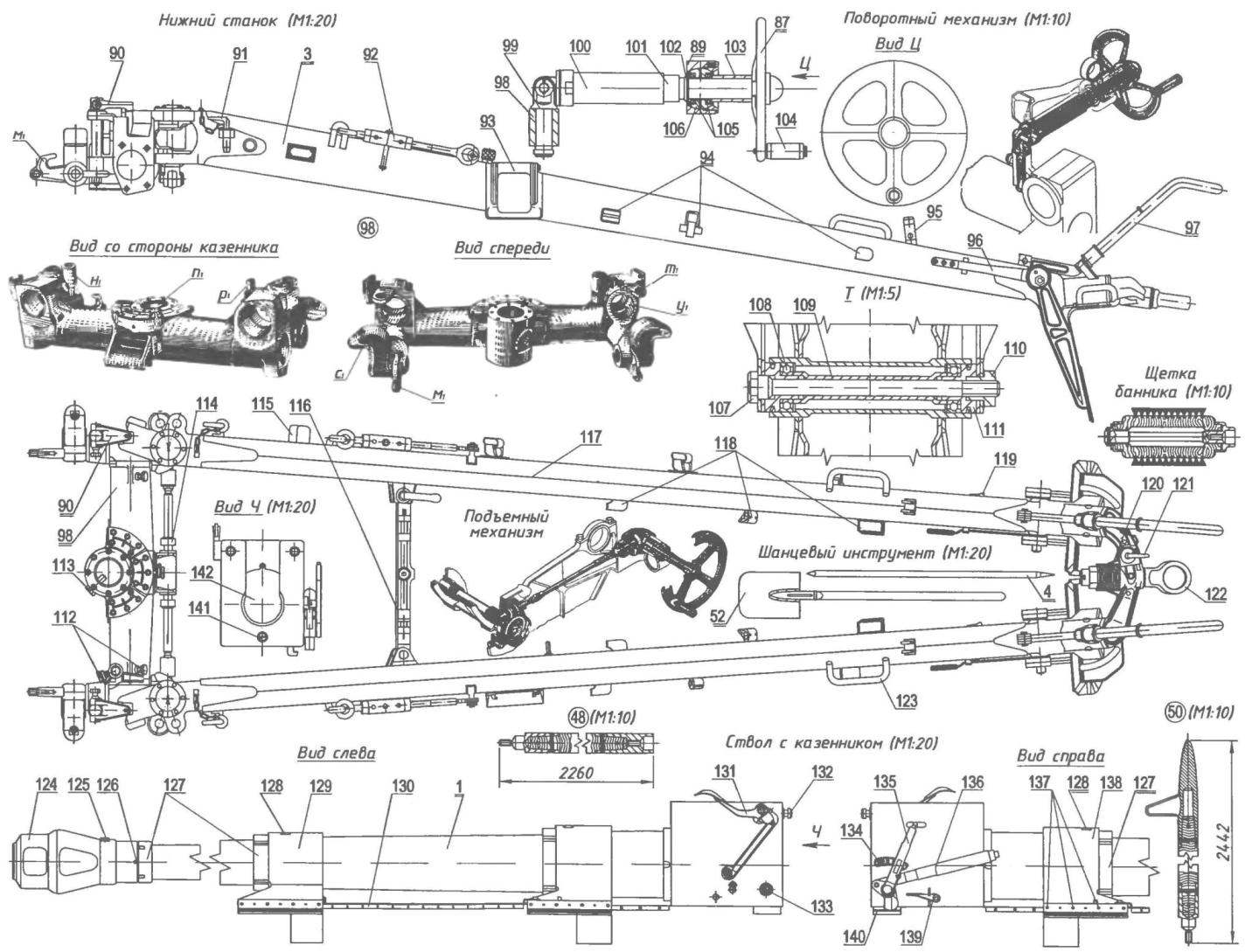

100-mm field gun BS-3 mod. 1944:

1 – stem pipe; 2 – cradle casing; 3 – left frame; 4-scrap; 5 – year-old opener; 6 bracket; 7 – an arm of the upper sight of the machine; 8 – capsule sleeve; 9.19 – charges; 10 – sleeve; 11: 15 a.m. 21 – Case; 12.17 – explosive charges; 13 – head fuse; 14 – high-explosive grenade OF-412; 16 – smoke composition; 18 – Smoke steel shell D-412; 20 – seal; 22 – armor-piercing tip 23 – ballistic tip; 24 – armor-piercing tracer BR-412D; 25 – the bottom fuse; 26-tracer; 27 – razmednitel; 28 – Lead belt; 29 – armor-piercing tracer BR-412B; 30 – a nut; 31 – roll; 32 – an arm; 33 – washer; 34 – the handle; 35 – Rod parallelogram mechanism; 36 – direct fire telescopic sight OP1-5; 37 – nalobnik; 38 – eyecup; 39 – mount panoramic sight 52-C-412; 40 – handwheel protracted roller; 41 – a box for the brush and Bannik arrester; 42 – ears; 43 – observation window in sight direct fire; 44-box straps and іuskovogo cord and documentation; 45 – lock the bottom panel in its stowed position; 46 – lath; 47 – the bottom panel; 48 – rod; 49 – the main board; 50 – vehg; 51 – the holder; 52 – a shovel; 53 – GK car wheels reinforced tire type GAZ-AA; 54 – airless tire; 55 – pocket for the battery; 56 – an arm; 57 – a box for the panorama; 58 – sight direct fire box; 59 – Mount a manual extractor; 60 – with the latch handle 61 – shutter armor; 62 – Bracket; 63 – the needle bearing; 64 – the left pin; 65 – the rules of the holder; 66 – Winter opener; 67 – Khobotova rink; 68 – skid; 69 – sliding panel; 70 – gon; 71 – the handle of descent; 72 – plate with the schedule to determine the amount of fluid in the recuperator; 73 – the trigger guard; 74 – rack; 75 – rollback pointer; 76 – capture; 77 – Felt seal; 78 – sector; 79 – an arm of the balancing mechanism; 80 – the case of the worm gear; 81 – articulated telescopic drive; 82 – bevel gear, 83 – a counterweight; 84 – flywheel hoist; 85, 104 – wooden handle; 86 – a balancing mechanism; 87 – a flywheel rotating mechanism; 88 – Semi torsion bar suspension; 89 – upper machine; 90 – an arm of the mechanism of inclusion and turn off the suspension; 91 – stop the trails in the firing position; 92 – buckle fastening the breech in its stowed position; 93 – – bracket installation of air-hydraulic pump; 94 – Mount scrap; 95 – SIRC; 96 – the rules of the holder; 97 – a rule; 98 – head-box; 99 – fork, 100 and 101 – shrouds; 102 – the uterus; 103 – sleeve, 105 – thrust bearings; 106 – spherical liner; 107-axis; 108 – bearing; 109 – spacer; 110 – nut; 111 – the gland; 112,137 – nipples; 113 – locking bolt pin top of the machine; 114 – draft; 115 – Block; 116 – fixing cradle bar is in its stowed position; 117 – right frame; 118 – fixing shovels; 119 – the seizure of opener; 120 – Belleville springs; 121 – stopper in its stowed position; 122 – Earrings; 123 – handrail; 124 – muzzle brake, 125 – a bolt; 126 – a lock ring; 127 – nut; 128 – cylindrical pin; 129 – front clip; 130 – panel 131 of the lever mechanism re-cocking the hammer; 132 – fixing bolt breech in its stowed position; 133 – crank bolt axis; 134 – directing the arc; 135 – handle o.kryvaniya shutter; 136 – Semi-automatic; 138 – rear collar; 139 – ejector lever; 140 – Pick-up; 141 – tube; 142 – wedge gate; sh – hole for a pin of the cradle; the u – hole for the mount panoramic sight; e – hole for the lifting mechanism; w – hole for the rotating mechanism; I – the housing sector of the lifting mechanism; a1 and x1 – limiters vertical lay; 61 and u1 – holes for fitting the worm gear; B1 – Ball slot toe balancing mechanism; r1 – a platform for mounting the shield bracket; D1 – hole cover bolts; e1 – the hole for the pin; k1 – a platform for mounting the main board; n1 – window sector for the hoist m1-kryuk; H1-bobyshka a rotating mechanism; n1 retention adapter to the pin; p1 – the right focus; c1 – the right-hand box; T1 – hole stopper for the trails; U1 opening for the pin fixing the trails

And in early 1943, long before the summer, the most violent in the history of war fighting with the use of large armored corps, the most far-sighted experts of the industry and the Main Artillery Directorate (GAU) of the Red Army clearly felt the threat of appearance of the German army tanks and assault tolstobronnyh artsamohodov, equipped with long-range. guns.

Existed in the army during this period, the field artillery could try to fight with the enemy only on terms largely bordered on suicide.

Regular army antitank means are outdated already reached the limit of their technical capacity, 45-mm cannon (manufacture powerful 57 mm gun ZIS-2 samples in 1941 after the release of several hundred articles had to be discontinued in the same year). Anti-tank guns ammunition divisional and regimental level in the current situation lost only required efficiency corps artillery meet the changing requirements, but was heavy, cumbersome and therefore malomanevrenna and vulnerable. And not so numerous.

Thirteenth in April 1943 the People’s Commissar Dmitry Ustinov sent a Deputy Chairman of the GKO Beria list of the IEC proposals on measures to strengthen the fight against anti-tank means. Among the most important was part of the production recovery of the ZIS-2, the use of existing developments on the application of the modified 85-mm anti-aircraft guns, increasing the output of a 122-mm cannon A-19 1931/37 sample, at the creation of new cumulative and piercing projectiles. But the most promising and promising are the 100-mm gun (the possibility of establishing grounded VG Grabin this system) using ballistics development of production of the pre-war period, the marine anti-aircraft B-34 guns. Of fundamental importance in this case was the presence of her mature technology and established industrial base release elements shots unitary loading (this part is only required to further develop armor-piercing shell, absent in the nomenclature of the B-34 ammunition).

The calculations showed that the new instrument will have armor-piercing up to 125 mm at a distance of 1000 meters at an angle of 98 degrees in the meeting from the normal. Also provides for the possibility of organizing its production in two species – both towed and installed at KV or artsamohod. To implement the second option proposed to use developments on previously created the 107-mm tank gun ZIS-6.

Already on 15 April 1943 the GKO goes Resolution number 3187 on measures to strengthen the anti-tank defense. Basically it contains decisions on works on already prepared for production systems, but the IEC were instructed to submit by April 25 GAU proposals for the development of tools based on the M-60 and B-34, the new cabinet gun, possessing qualities of anti.

Option of using the M-60 – 107 mm gun with separate loading, the approval is not received. GKO decree number 3290 of May 5, 1943 sanctioned the work on “duplex” hull guns on a single gun carriage: 100 mm – the ballistics of the B-34 and 122 mm, the ballistics of the A-19. Their development and production (one copy of the prototypes) put, respectively, and Motovilikhinsky TsAKB plant number 172 to them. Molotov IEC – the only one capable of fulfilling such an order at that time. Dates were set hard: TsAKB ought to apply to the production of drawings: 100 mm system – by 30 May, according to the 122 mm by 10 June, the plant number 172 to produce two prototypes by 15 July and 1 August to submit them to the GAC for field tests. This TsAKB received additional funds to improve the working conditions and housing staff and both organizations to devote substantial prize fund.

In order not to exceed the specified weight (less than 3.5 tons) 100-mm guns, while creating the C-3 (this index is obtained in TsAKB) team has used all the experience of the design team of the plant number 92 im.Stalina IEC, formed the core of the formation of TsAKB . These engineers have recently passed into service later became the legendary famous divisional gun ZIS-W and the already mentioned ZIS-2.

The general layout of the implemented system A. E. Hvorostin. Barrel-monobpok vertical wedge gate and a powerful muzzle brake designed I. S. Griban. COT F. B. G. Las-man. The recoil device and the balancing mechanism developed F. F. Kaleganov. Upper machine – A. P. Shishkin, lower – E. A. Sankin. For sights meet Muravev P. F., B. G. Pogosyants and Yu.V.Tizengauzen.

Fourth June documentation sent to the factory. Responsible representative of TsAKB seconded P. A. Tyurina, personally carried out the main part of the transportation of classified material to the Urals plane. Drawings on the trunk, which had marked “Top Secret”, sent separately through the appropriate channels.

The director of one of the oldest and most distinguished in the history of Russian artillery companies – the famous “Motovilikha” – A. I. Byhovsky on arrival Tyurin took it, and post-operative discussion of the task team of the company has started to implement the order. Despite extensive experience TsAKB designers, the site had to process documentation for specific possibilities existing production required the development of new materials and technologies. Here Permiaks made many valuable suggestions. So, together overcoming the inevitable “wet” experimental drawings and production problems, a little over three months came to light in the metal of the first gun test. And on September 14, even without the small factory control tests, she was sent to the landfill for the shooting. Incidentally, the decree number 3290 was originally contemplated in paragraph obliges the People’s Commissariat of Railways to provide urgent transportation of weapons and ammunition.

In this regard, September 15 Grabin signed a decree № 245 on TsAKB the appointment of the commission * for acceptance, otledki and factory testing prototypes of the C-3 and C-4 (option overlay on standardized machine from the C-3 of the barrel with the ballistics of A 122mm cannon obr.1931 19 / ’37).

The first shooting at the suburban Sofrinsky range revealed, along with a number of small natural disadvantages, two fundamentally serious. Firstly, the structure failed attachment cast muzzle brake using the sleeve: it shot off after a few shots, and had to quickly change to the extruded version. Second, by firing a weapon highly hopped, making unsafe work gunner and shoot down sighting installations. This, in turn, led to a decrease in the rate of firing range practice – the quality for the field of anti-tank guns is very important. Besides the gun samozakalyvalas bad after the first shot.

Tests showed congestion of carriage wheels (in KB traditions was the use of standard automotive wheels, and here it was necessary to use not previously used in domestic practice, the pair of wheels installation on GAZ-AA truck with SC bus).

Design and Technology Group under the leadership of TsAKB P. M. Nazarova has proposed a set of measures to eliminate detected flaws (and the question “jumping” was the subject of a special discussion at the technical council of the IEC) with a corresponding alteration drawings.

At the Leningrad plant “Bolshevik” for drawings modified prototype began production of the first series of five guns. In November 1943 Turin sent again (now the factory number 232 in Leningrad) for the issue of guns experimental series, taking into account the adjustment of the Panel of Nazarov. In the context of not finished fighting for unblocking he had to get in a roundabout way. Set new drawings entered the plant in December 1943,

The prototype gun was subjected to repeated tests already Gorokhovetsky range between 17 – 31 December 1943. During the 22 – 29 January 1944, after the new completions, testing continued. And again, without much success for the previously noted shortcomings in.

Four guns of the experimental series during the period from 5 to 15 February 1944 have been tested at the Leningrad site. Artillery Committee GAC in its report noted that two major drawbacks – for stability when firing guns at small angles of elevation of the barrel and on the strength of the muzzle brake fixing – preserved. In addition, we discovered manufacturing defects caused by inadequate equipment of the plant and the initial degree of development of their production. But, given the urgent need for the army in such a gun, the conclusion Artkoma SAU, its release was necessary to begin immediately provided to eliminate questions on the muzzle brake and Technological omissions. Others considered it possible to work in the manufacturing process of the first 30 – 40 guns.

Twenty-fourth of February, while on a routine of shooting accuracy, at gun number 1, issued by the number 232, on the 89th shot, shot off the back of the breech. There were no victims – chip hit the wall of one of the polygon structures. The reason for The incident was unclear, since the prototype for which the documents produced and the breech already endured substantial number of shots without comment to the strength of the assembly. Metallographic analysis showed no errors in the applied steel grade and violations of the metal structure. The performed recalculation confirmed the details for this fourfold safety margin. Attempt TsAKB accused of deviations from the requirements of the design documentation manufacturers factory arguments appealed.

Due to uncertainty of the situation March 16, 1944 at a joint meeting of representatives of the GAC, and TsAKB plant number 232 decided to breech hardening by increasing the thickness of its walls and the replacement of the steel grade, although the plant reiterated their objections, considering the use of higher strength steel sufficient measure gain whereas increasing the size of the breech require substantial processing interacting parts and processes. And, as shown by the development of events, this position was correct. Back in late February, there was an assumption expressed the director A. I. Zaharinym plant, the possibility of appearance of the breech during the production of the stress concentration zones in the corners of the gate slot.

Subsequent analysis confirmed that he was right – in the end it turned out that this method results in a manual fine-tuning parts after machining. The drawings made by the mandatory implementation of the radius in the area of coupling planes, and the problem with the broadening of the walls of the breech has been solved (but the last word in this story had to tell the chairman of the technical council of the IEC E. A. Satelyu).

Work continued on the alteration of the structure and the muzzle brake. In early January TsAKB agreed to manufacture it, and some other parts are not forging and casting. This is very satisfied with the factory, have difficulty stamping equipment, and there quickly designed a cast muzzle brake previously spent in the factory of stainless steel brand “BRO”. In March 1944, he began his trial. And while the first sample broke into 149-m shot now we coped with the situation quickly.

GKO decree number 5509 dated March 29, identified priorities for the restoration of production at the Leningrad plant. Including the plant number 232 were instructed to focus on the development of BS-3 gun. Login To her release and plant number 7 “Arsenal” Frunze IEC in cooperation with other enterprises of Leningrad.

In the period from 15 April to 2 May 1944 in accordance with Directive artillery commander of the Red Army Chief Marshal of Artillery NN Voronov, in Gorokhovets Artillery training camp conducted military tests a battery of four guns-3 series production plant number 232. Their main objectives were to test the technical and performance tools, determination of compliance requirements for heavy anti-tank systems, and issue conclusions about the possibility of adoption of the C-3 is adopted as a cabinet or anti-gun. Fire tests included, and full-scale shooting of captured armor Heavy tank T-V1 “Tiger” and assault guns “Ferdinand” (so called while we have a German self-propelled “Elephant”). Their results and general mood test says an excerpt from a telegram sent by April 26 Grabin chief of the 18th Division TsAKB K. K. Renne “Vasily Gavrilovich! Reporting briefly. By moving targets the results are good. According to the “Tiger” from 500 – 1000 meters and 1300 meters and an angle of 30 degrees and 60 degrees forehead prokolachivaem board easily. Accuracy and precision are now not allowed to doubt … “

For the record (as specified in the test material) – frontal sheet body at the “Tiger” has a thickness of 110 mm. And further. To telegraph the text is not entered into an involuntary confusion – German trophies could not move and they were used only as a stationary target.

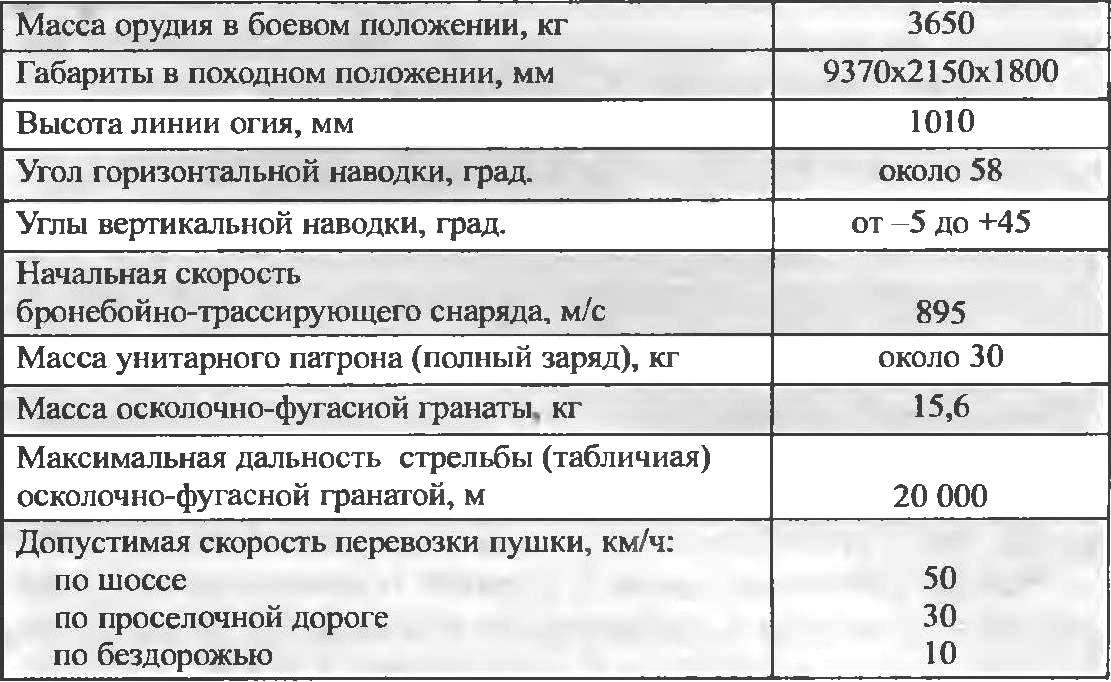

Specifications 100 mm BS-3 field gun mod. 1944

It should be borne in mind that a squad formed battery skomplektovat of personnel training artillery regiment, relegating to the introduction of new technology in all three days. However, the selection of artillerymen paid special attention to the gunner.

As a result, it is determined that the C-3 is capable of hitting a tank T-V1 over the entire area of the frontal projection at ranges up to 2,000 meters from any angle and from a distance of up to 500 meters to cause appreciable damage to the frontal armor assault weapon (through penetration of 200 mm “forehead” of the “Elephant” is not even able to reach such a cannon). The board of both representatives of the German “zoo” were amazed at all the sighting distances. To hit a moving target required, with an average consumption rate of 2.2 projectile at 4.5 shots per minute.

Still proved to organic defects of the system. Jump when fired at low elevations are not allowed the gunner to constantly keep the eye at the sight of the eyepiece (in troops and persist to this vice gunners had to adapt in time dodging the jumping optics). The presence of a powerful muzzle brake at low altitude line of fire and grazing paths, typical for shooting bronetselyam, led to the formation of significant dymopylevogo clouds, blinding and unmasking position calculation. But it was inevitable price to achieve the desired weight: Still muzzle brake absorbs 60% of the retracement of energy.

General conclusion. Gun-3 can be recommended as a heavy anti-tank gun for the acquisition of the individual divisions and regiments in the composition of certain anti-artillery brigades. However, it can be used as tools of the body in addition to the systems of the A-19. The output resolution of acceptance into service to determine the time and volume of production.

It should also be mentioned that the 19 October 1944 D. D. Ustinov signed a decree No. 477 on awarding the leading participants work at C-3 with a large list of personal TsAKB employees, number of plants 172, 232, 7, and 40-GSPKI. To encourage other designers, engineers, employees of shops and departments have been actively involved in developing and putting into production a new gun for this order, make available Grabin – 80 thousand virtually any, Bykhov -30 thousand.. virtually any, Zakharyin -.. 100 thousand . virtually any, Yevdokimov (director of the plant № 7.) – 50 thousand virtually any.. and Kaganovich (Head GSPKI-40) – 30 thousand.. virtually any The order ended with the words: “I am confident that in the future design organizations and factories friendly IEC joint work on creation of new weapons will provide the Red Army and Navy even more sophisticated types of weapons.”

Since May 1944 the plant number 232 started the planned supply BS-3 (a designation received after adopting gun), having until the end of the year to make 275 guns. Since August, they began to release the plant “Arsenal” Frunze. The total annual output amounted to 335 copies. Production of the plant “Bolshevik” lasted three years, and the plant number 7 did BS-3 to 1953, which eventually gave the military almost four thousand systems. And until the service in the early 1960s of new smoothbore guns gun BS-3 tank and its analogue D-10 (by the way, almost the same age, owes its existence to the same IEC proposals in April 1943) formed the basis of means of combating anti-Land troops.

Of course, in quantitative terms, the BS-3 compared with the family of guns D-10, the period and the scale of production that are worthy of the Guinness Book of Records, it is difficult, but each system has its place in the overall structure of the army artillery equipment. An important factor in this is a complete identity of the nomenclature used for both systems (BS-3 family and guns D-10) ** ammunition, which greatly simplifies the maintenance of such a mass of these weapons in a combat situation.

Field gun BS-3 was transported without Chuck. For its transportation during World War II used three-axle trucks “Studebaker” US-6. At the same time on the machines, had the rear fenders, the latter were taken, as they have limited turning radius and causing damage to the parts Khobotova -stanin guns. After the war, US-6 replaced the domestic cars ZIS-151, ZIL-157 BTR-152 and crawler tractors AT-A, MT-A and MT-LB.

The significance of that at the time the military gave this gun, indirectly evidenced by the fact that published in 1954 (ie after the cessation of production) management service structure describing the BS-3 and its ammunition, still bore marked “Confidential” .

During the service in order to maintain an adequate level of guns were planned overhauls and subjected unimportant refinements, improving their combat and operational quality. In particular, we developed a modification of the BS-3 H, adapted for mounting infrared night sight (this revision was made on existing guns). Subsequently, work continued on the creation and organization of production of various types of ammunition increased efficiency.

Attempts have been made and the more radical upgrades.

For example, the battery NII-88 Ministry of Defense Industry team of designers led by E. V. Charnko engaged artillery equipment of the airborne troops, offered in 1954 to turn towed BS-3 self-propelled. A similar development – creation on the basis of the 57-mm towed gun W-26 self-propelled SD-57 – shortly before it was successful. A similar version of the BS-3 (received index B-76) did not affect the actual swinging of the gun – only needed in addition to place the engine with manual transmission, controls, fuel system and replace wheel.

In the proposed project due to a lack of suitable domestic engine provided for the use of the 55-strong motor cooling air from the car “Tatraplan”. But these works are not received for a number of independent designers from the causes of development.

Reports from the parades, military personnel photos and newsreels preserved for us the scenes, so to speak ‘live’ biographies service BS-3 gun. It happened even be a party to the “extras” in the once popular “Maksim Perepelitsa” feature film (1955). Much later, the “cinematic” biography of BS-3 continued in one of the series of adventure television movie “the Secret Fairway” (1986).

BS-3 gun Service carried outside the country. In 1950-ies. I studied the question of the organization of licensed production in Poland. The system was exported and participated in many local conflicts on the Asian continent and the Middle East. In 2001, the TV report about the actions of the forces of the Northern Alliance in Afghanistan, demonstrated the presence of BS-3 in the number of weapons parts.

As recently became known, in the process of creating the script the parade dedicated to the 60th anniversary of the Victory, held activities in preparation for inclusion in the calculation of the front eight guns BS-3. Later, however, these plans were reviewed

Several viable technical solutions implemented in the design of tools BS-3, as well as some members of the items borrowed in the future for the development of more advanced artillery systems other design teams. For example, the shutter used in the latest anti-rifled cannon, adopted by the Soviet Army – 85 mm D-48 and, with minor changes in the very high-volume post-war period, towed artillery systems of the Ground Forces – 122mm divisional howitzer D-30.

The ninth of May 1985 in the Moscow region of Kaliningrad (1996 – Korolev), where 17 years was CB VG Grabin, opened Memorial in honor of the Kaliningradians-korolevtsev – defenders of the Motherland. And as a symbol of military and labor glory of his decorated the gun BS-3, No. 8334. This was preceded by a very troublesome operation to request, receive, and prepare for the installation of weapons from the arsenal of the Defense Ministry, undertaken on the initiative of grabintsev veterans who worked in the Scientific and Production Association ” Energy “of the Ministry of general Machine Building (now the Rocket and space Corporation” Energia “im.S.P.Koroleva). It is a part of this organization in 1959 (when it was known as OKB-1 GKOT) the will of the state of circumstances included pereprofiliruemy purely rocket theme CRI-58.

As BS-3 and a monument installed in the territory of “Arsenal” plant. Cannon takes a worthy place in the expositions of the Central Museum of the Armed Forces Central Museum of the Great Patriotic War in Moscow and the Central Military-Historical Museum of Artillery, Engineer and Signal Corps in St. Petersburg (where, incidentally, is the system number 316 issue still 1944).

In conclusion, it is worth mentioning that provided GKO Order of May 5, 1943 122-mm gun S-4 is also produced (albeit at a later date) and spent the necessary amount of its tests. But, as D-2 (its competitor set up in plant number 9 CB IEC), in the series she has not got iz-za proximity end of the war, the availability of sufficient quantities of the A-19 systems, the expanded production of BS-3 and a number of disadvantages caused by the desire to achieve the greatest possible harmonization with similar instruments and minimum weight.

A. Britikov