In accordance with the state program of creation of artillery weapons in the postwar period in 1946 in the Department of “200” HZTM resumed work on heavy truck, this time on the basis of the latest tank T-54. It was to meet the following requirements: the towing of artillery systems and trailers weighing up to 25 tons (203-mm howitzer B-4, 130-mm anti-aircraft gun KS-30, guns especially large power) at speeds up to 35 km/h in any conditions, the platform capacity 5 tons, winch with a pulling force of at least 25 t of the tractor Chassis must have the possibility of installation on it of excavation technology and equipment and ensure that it is the drive.

With the aim of improving the reliability and mobility of the chassis in its construction were introduced synchronized gear shift (transmission), two-stage planetary rotation mechanisms (MPP-2), the torsion elastic suspension elements, cycloid gearing leading stars convenient metal cabin.

Work on the new “item 401” (it started at the factory post-war numbering of tracked vehicles) under sustained attention and effective support of GAU and TAUTU, headed by chief designer HZTM M. N. Shchukin, who has moved staff from the city of Kirov tank factory No. 38, and his Deputy, F. A. Pavement. Assemble product A. I. Avtonomov (since 1954 the head designer for the trucks), a leading on the car was V. M. Doroshenko, he, together with V. M. Krichevsky engaged in the transmission, the frame was led by the chief of the Bureau A. K. Arkhi-POV, control system, I. A. Borschevsky, equipment — A. F. Gorbatov. winch — A. D. Motrych. In designing the new tractor was also attended by the designers of the nodes Koulikovskaya E. K., M. I. Kotov, D. I. Krolenko, Y. M. Medvedev, V. E. Moiseenko.

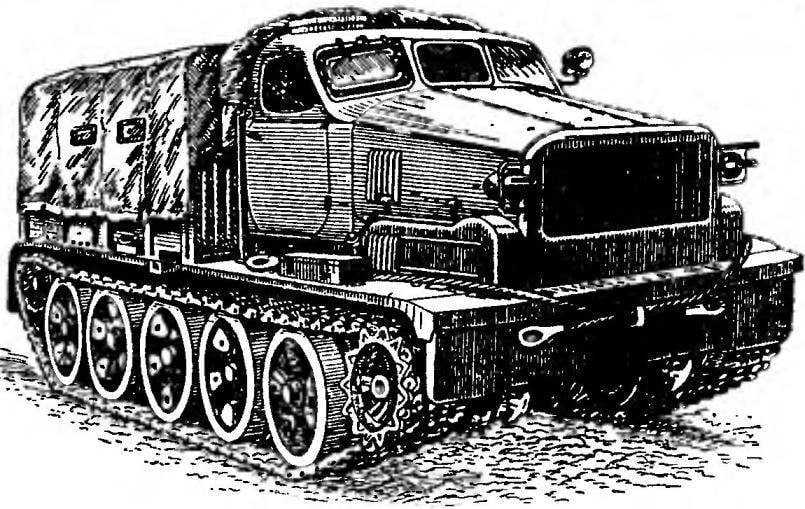

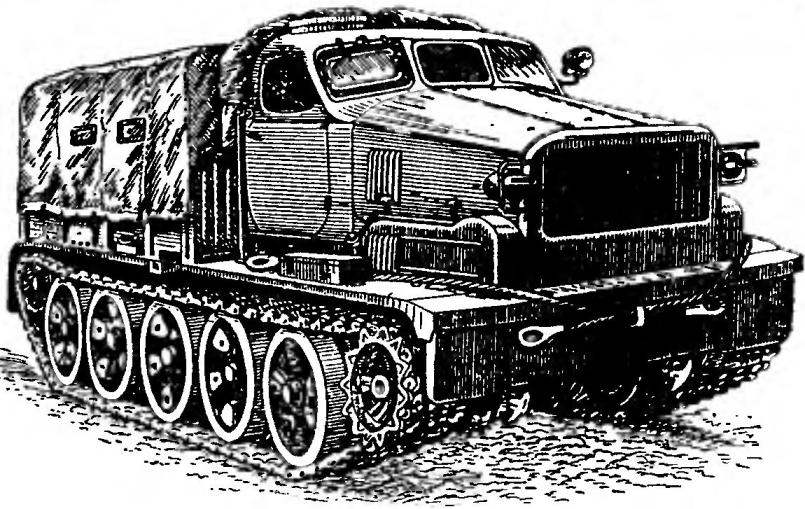

Artillery tractor at-T:

1 — star the leading 2 — box of ZIP; 3 — headlight; 4 — hood; 5 the cockpit; 6 — awning removable; 7 — device traction; 8 — wheel driven; 9 — supporting the rink; 10 — hook towing; 11 — seat folding; 12— the awning in the rolled up position; 13 — arc of the awning in the retracted position; 14 Luc; 15— shovel; 16 — ropes towing; 17— spotlight search.

Location of hatches in the bottom (bottom view):

1 —hatch access to the drain hole of the gearbox; 2 — access hole to drain the water from the frame; 3 — access holes for draining the fuel from the tanks; 4 — hatch for the oil drain from the sump; 5 — access hole for draining liquid from the cooling system; 6 — access hatch to the oil and water pumps, and fuel priming pump; 7 — access hatch to fuel tanks; 8 — hatch for draining oil from the crankcase of a reducer of the winch; 9 — access door to the winch; 10 hood for venting of the air reservoirs.

The frame of the tractor body (back right):

1 — the crankcase side transmission; 2 deck; 3 — boxes of batteries; 4 — neck of fuel tanks; 5 — cover over air cleaner; 6 — latch mount spare truck; 7 — hatch cover over the fuel tanks; 8 — lock mounting extension of the cleats; 9 — front seats; 10 — rail; 11 — tow hooks; 12 — cover over the winch; 13 — sheet feed; 14 — Carter traction and outstanding tether devices; 15 — step; 16 — Board rear hinged; 17 — arm awning; 18 — box ZIP.

Tent:

1 — piece rear awning, side; 2,8 — window; 3 — the rear panel, hinged; 4,5,6,10,11,12—belts; 7 — part of side awning; 9 — arc; 13 — the valve of the front Windows; 14,17 — hole; 15,16 of the tent, the front and top.

PERFORMANCE CHARACTERISTICS OF ARTILLERY TRACTOR AT-T

The mass in running order unladen, kg………………..20 000

Platform capacity, kg…………………………………… 5000

Weight of towed trailer, kg……………………………………25 000

Seats in the cabin……………………………………………………………………….4

Seats in the back seat…………………………………………………… 16

Dimensions, mm:

length……………………………………………………………………………. 7043

width of crawler…………………………………………………….3154

width on removable flaps………………………………………….3170

cab height………………………………………………………….. 2845

the height of the hatch of the cockpit………………………………………………… 3000

Base rollers, mm………………………………………………… 3748

Track (by means of caterpillars), mm……………………………………. 2640

Ground clearance, mm………………………………………………………425

Average specific ground pressure with the load on the platform, kg/cm2…………………………………………………….0,652

The width of the tracks caterpillars, mm ………………………………………………500

The maximum power of the engine at frequency

rotation 1600 rpm, HP……………………………………………….415

Speed, km/h:

maximum loaded highway……………………………………….38

average with the cargo and trailer weight of 25 tons on the highway……………32

on dry ground………………………………………………………………24

on a snowy road……………………………………………………… 16

in the deep mud……………………………………………………………..14

Cruising on the highway with the trailer, km………………………………… 1100

Limit gradeability on hard ground with load, deg.:

without a trailer……………………………………………………………………….40

trailer………………………………………………………………………..30

The fording depth, m……………………………………. 1,1

Width of overcome ditch, m ……………………………………….. 1,8

At the end of 1947 was made the first prototypes of the “401-go”, and they successfully accomplished the run Kharkov — Moscow.

The car turned out very workable, powerful, tough, mobile, with excellent traction properties and is easy to operate. The range of indicators it was the most successful among all models of artillery tractors of the first post-war generation. Its creators marked the Stalin prize. Due to the large need for heavy trucks to the factory and tests the new product combined, thereby speeding up the development machine.

In mid-1949 at HZTM began mass production “item 401”, and in third quarter it was commissioned the first fifty trucks, received the army index at-T (heavy).

They are successfully operated in tuloksellisuus, tank and engineer units, aided by the unification of a number of critical components (gears, rollers, leading and guiding wheels, tracks caterpillars) with the main tank T-54, also produced at HZTM.

The basis of the at-T was a closed box-shaped frame with a bottom welded from steel sheets with a thickness of 5-30 mm. In front of the vehicle under the cabin floor, forward flywheel was placed 4-stroke 12-cylinder /-shaped diesel tank engine And-401 type-2, derated with the aim of increasing engine life and fit for work on this tractor. He was equipped which has already become a regular on the post-war military tracked vehicle units: the emergency system of air launch (compressed air cylinders), a two-stage hybrid air cleaners, automotive air brake compressor, pre-makasaysayan prodynamics pump and heater, which ensures the engine start at temperatures down to -45°C. a Powerful radiator with full width hood with adjustable louvers and two 12-blade fans with independent belt drives guarantee the work of the motor with the maximum load in hot weather without overheating.

Before the engine was placed dry multi-plate main clutch (GF) with spring system and 5-speed gearbox (power range 6,606) with two transverse shafts constant mesh all the gears and synchronizers enable transmission. In the case of CAT was built in reversing the PTO to drive a winch or other attachments.

Side two-stage planetary rotation mechanism (PMP-2) steady rectilinear motion and two fixed turning radius of 2.64 and 6.3 m. They made a short plane improve traction on tracks 1.42 times without breaking the flow of power. In this case, the total power range of the transmission is increased to 9.38.

The front wheels of propulsion had two removable (for replacement when worn) of the ring gear pushing type with a cycloid gearing. On melkopilchatye tracks track chains could put additional lugs. Since February 1962, each circuit was completed with 75 cogging trucks and 18 bezgrebelny, and before that, they alternated through one.

Double rollers with rubber tires with a diameter of 830 mm had individual torsion-bar suspension without hydraulic shock absorbers. Their presence would increase the average speed on the road, but production capability dictate more.

All-metal 4-seater cabin ZIS-160 was located over the engine. At its core were reduced in height and considerably expanded at the expense of the middle insert of the cabin of the car ZIS-150.

Spacious metal body with an area of 10.55 m2 was with platform and side rails one. The platform had fold-down rear seat and interior, and the top was closed with awning.

Absolutely unique, which ultimately numerous imitation, was the design of the traction winch with a maximum force of 25.5 t and the working cable length of 100 m Placed under the platform in the rear of the frame, it is possible without driver intervention force issue (“push”) the cable back and pull it through trochochaetidae with kinematically connected between two feed rollers and drum, equipped with crookedstar. In the drive system of the winch also includes: dual-mode gearbox (direct and delayed transmission) with the interposition of a friction clutch, automatic brake with electromagnetic control and the mechanism of disconnection of the winch in case of overload and at the end of the issue cable. The rotary delivery device installed at the rear of the frame, allowed to reject the cable in any direction without vanishing him from the streams of the traction rollers.

Elastic traction device can pivot in a horizontal plane and move back to connect with any artillery system, and tow tanks used by the eyelet.

The truck was equipped with on-Board pneumatic system to actuate the brakes of their own and the trailer, and accessories.

Five fuel Bacoa with a total capacity of 1364 litres (later 1415 liters) was sufficient for continuous daily mileage with a load and trailer in the most difficult conditions.

Idler:

1 —cap; 2 — crank; 3 — idler wheel.

Track roller:

1 — cap; 2 — axle; 3 — drive of the rink; 4 — bandage 5 — tire rubber; 6 see — saw.

Driving wheel with the cleaner:

1 — hub; 2 — tube; 3 — gear; 4 — shaft driven; 5 — cleaner.

Cabin equipment:

1 — driver seat; 2 — control lever winch, removable; 3,4 — arm turn; 5 — mirror; 6,7 — indicating the air pressure in the lines; 8 — the gauge of pressure of air in the cylinders to start the engine, 9 — canopy with light filter; 10 — a speedometer; 11 — oil-pressure indicator; 12 — wipers 13 — tachometer; 14 — temperature gauge-oil; 15 — window demister; 16 — hour meter; 17 — the index of temperature of a cooling liquid; 18 — lamp; 19 — horn button; 20,22 — lamp position of the winch cable, signal; 21—headlamp switch; 23 — a box for valuables; 24 — first aid kit; 25 — cylinder air-start engine; 26 — fuel filler flap lid; 27 — a box of ZIP; 28 — cap fuse; 29 — lever vent cover of the hatch of the cabin; 30 — voltammeter; 31—button switch of the starter; 32 — shift lever; 33 — throttle; 34 — arm fuel; 35 — crank fuel pump; 36 — arm junction valve; 37 – crane air start pressure reducing; 38 — the brake pedal; the 39 — arm of blinds; 40 — foot pedal control the main clutch.

Traction and outstanding the cable device:

1 — polispast; 2 — device to the tractor hitch; 3 — the device permitting the cable; 4 — winch; 5 — thimble cable; 6 — wire.

At-T, able to work in extremely harsh conditions, quickly gained universal acceptance and broad use in the army as the most powerful and reliable tow vehicle for towing heavy artillery, later missiles and also as a carrier of earth-moving equipment. This powerful and beautiful machine, starting from 1952 to the early 80-ies, had always been a decoration of military parades on red square.

In operation the tractor is continuously improved. Quickly and increased the number of its modifications, which contributed to the successful layout, allowing convenient to place attachments. So, on the chassis “426” (using elements of the T-55) was mounted a large radar “Circle.” For the same purpose was used the extended 7-track rollers of the chassis “426”. For sparcely there was a variant of the tractor “402” engine V-54 capacity of 520 HP

But especially a lot of army earth moving equipment based on at-T released from the factories of Kiev, Kramatorsk, Dmitrov: heavy bulldozers-puteprokladchik BAT, BAT-1 and BAT-1M (product “405”, “405” and “405 MU”), high-speed rotary trenchers family of BTM (product “409” and its numerous modifications), bucket wheel excavators of the family of MDC-2 with a rear transverse arrangement of the rotor and others.

Their performance even on heavy soils was so high that allowed to solve long-standing problems of mechanization of heavy engineering works, including high-speed isolation deep trenches on the front lines. They have the total mass of 26-28 tons and confidently moved in inoperative position at speeds up to 36 km/h.

In 1957, for towing sled trailers in the Antarctic expeditions were a series of specially trained Arctic trucks the at-TA (“404”) extended, 750 mm tracks tracks that with a curb vehicle weight 24 t reduced specific pressure on the snow to 0.24 kg/cm2. Cabin and engine compartment were insulated, and on the platform was mounted residential house. Engine power was increased to 520 HP, but to work with confidence in specific and severe conditions of Antarctica, especially the mountainous part, it was not enough. So soon on the basis of at-T has created the famous “Kharkov” (“404”) — 35-ton snow cruiser with seven road wheels and tracks tracks width of 1 m, capable of Luge trailer weighing 70 tons to cross over to 1500 km at ultra-low temperatures, reaching a maximum speed of 30 km/h While the forced engine with drive supercharger retains its maximum power 995 HP up to an altitude of 3000 m above sea level and could work nonstop for days. On the “Kharkov” engine-transmission compartment, control modules, housing and the cargo consisted of a single insulated enclosure size 8,5x4x3,5 m, equipped with a duplicated life-support systems. This allowed us to make long crossings, if necessary, to make repairs up to replacement of powertrain without departing crew out. Tractors “‘Kharkovchanka” is well established when working in the harsh conditions of Antarctica and left a good memory, though without a break (mainly because of ladolescence materials) were not treated.

Manufacture of tractor at-T lasted for 30 years (in 1962, the daily production reached 2 to 3 machines) until mid-1979, when the conveyor it was replaced by a multi-purpose heavy tractor MT-T (“429”) created on the basis of fundamentally different engine, transmission and chassis.

E. PROCHKO

Recommend to read ANCHOR — FROM ANCIENT TIMES TO THE PRESENT DAY Oddly enough, but we tend to think of Ancient Rus agrarian power, traded mainly salt, hemp, wax, fur goods, linen. Meanwhile our ancestors were taken abroad and iron, and iron, famous... SKI FOR MOTORCYCLE… No steep turns on groomed winter road or spring ice is not terrible motorcycle with the original device, made by G. Konyaev from the village of Il'insk Perm region. The hinge side of the... Scroll back to top

The designers of the Department of track-laying tractors (known as the Department of “200”) of the Kharkiv locomotive plant them. The Komintern (KhPZ) built in 1936 heavy artillery tractor “Voroshilovets” on the basis of the original, but irrational in the scheme, laborious to manufacture and maintain chassis. Later, in the design process of the T-34, they came to the conclusion that because of the proximity of the traction-weights, power, and mobility it is advisable to develop heavy trucks based on the chassis of a modern medium tanks. This unification was beneficial and production.

The designers of the Department of track-laying tractors (known as the Department of “200”) of the Kharkiv locomotive plant them. The Komintern (KhPZ) built in 1936 heavy artillery tractor “Voroshilovets” on the basis of the original, but irrational in the scheme, laborious to manufacture and maintain chassis. Later, in the design process of the T-34, they came to the conclusion that because of the proximity of the traction-weights, power, and mobility it is advisable to develop heavy trucks based on the chassis of a modern medium tanks. This unification was beneficial and production.