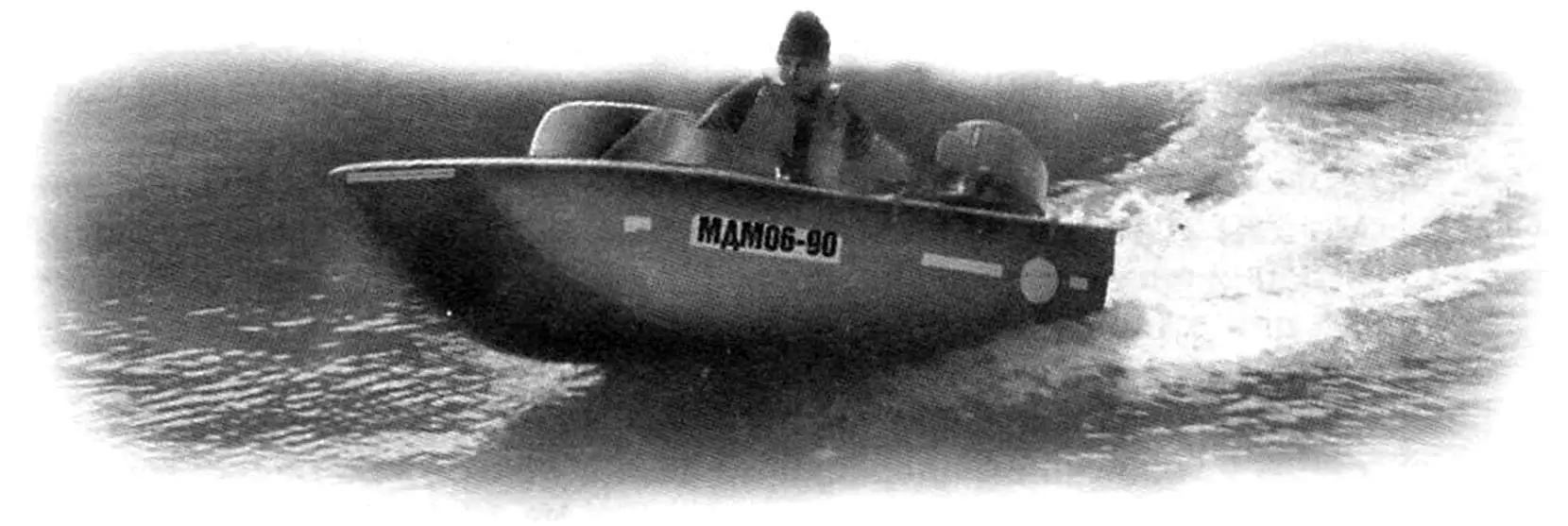

Back in pre-reform and even pre-perestroika times, on my birthday, one of my milestone dates, the management of the enterprise where I worked and my colleagues, knowing about my passionate hobby of small vessels (boats, motorboats, hydrofoils), gave me an outboard motor “Vikhr-30R”. I didn’t even dream of such a thing then: it cost a lot of money, and besides, it was in great short supply.

The watercraft produced by industry at that time and sold only in specialized stores in large cities (it’s hard to call these boats and motorboats anything else) were, in my opinion, poorly suited for such a motor: either too bulky and clumsy, or very light and low-capacity.

And so I decided to make a boat myself, one that would at least match the motor: stable, capable of decent speed, and able to accommodate several people when necessary.

I made the boat, so to speak, impromptu, relying more on intuition and speculation than on calculations and shipbuilding canons. But it turned out, all in all, not bad.

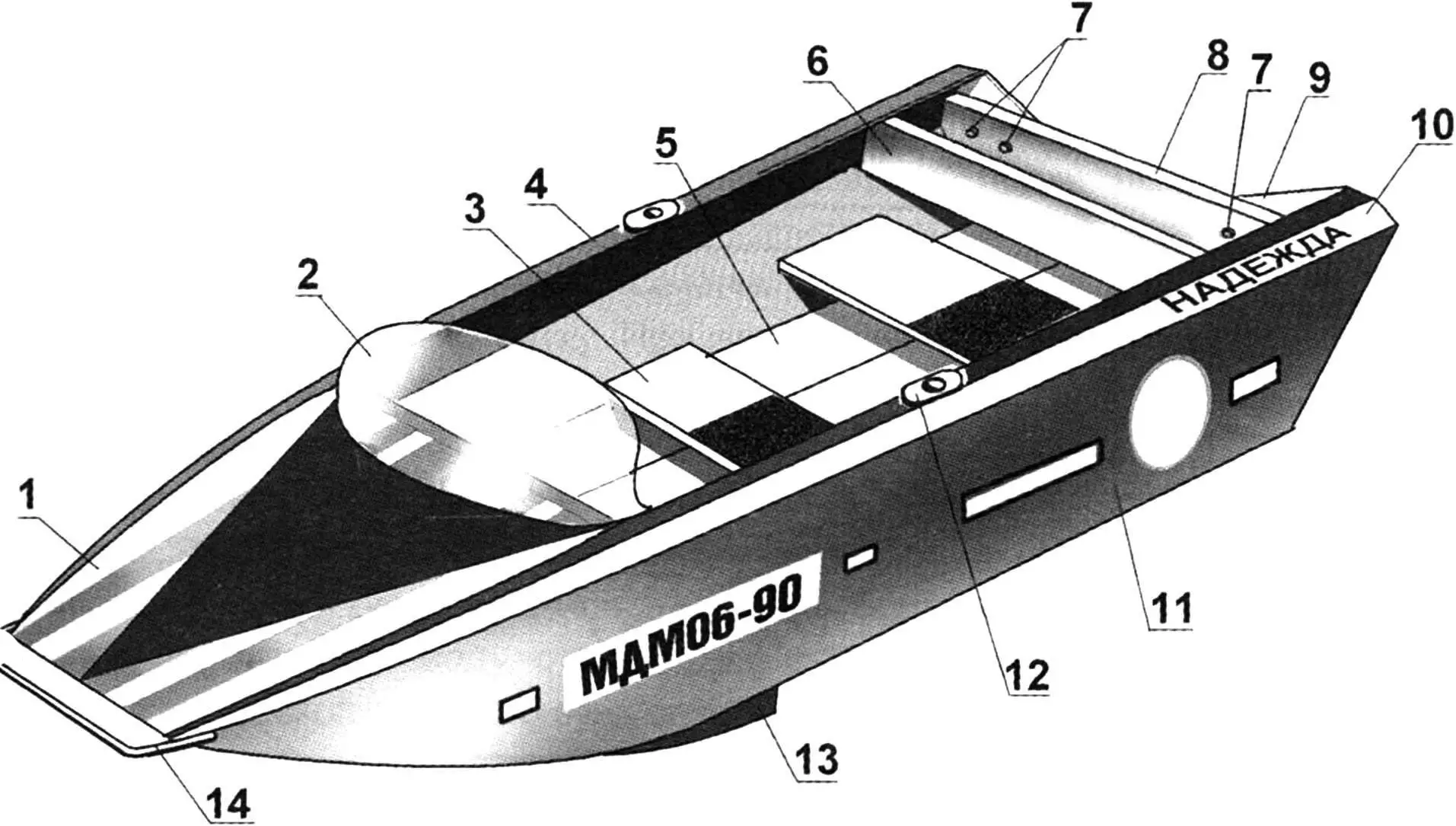

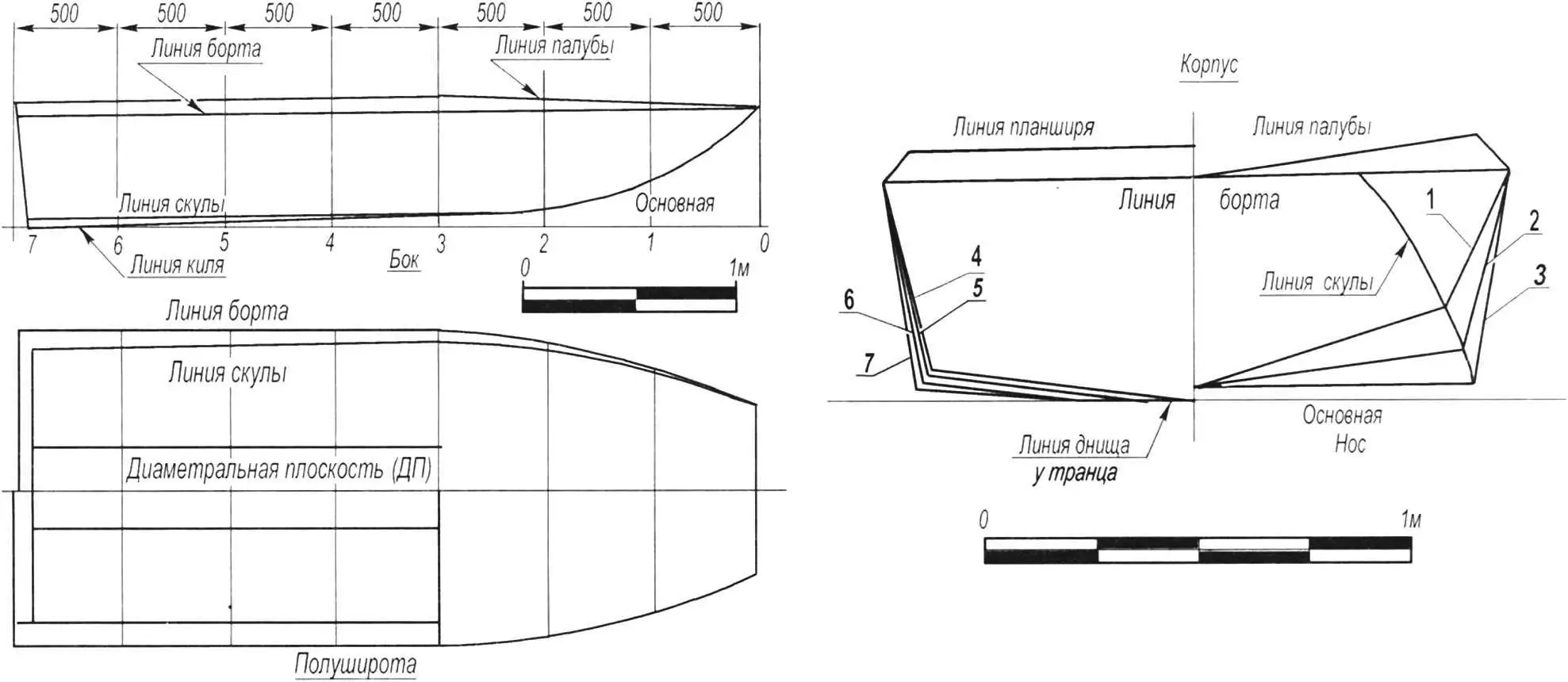

1 — deck planking; 2 — windshield (plexiglass s5); 3 — seat-bench (birch board s30, 2 pcs.); 4 — gunwale (2 pcs.); 5 — bottom (a — center section, b — left section, c — right section); 6 — seat back (birch board s30); 7 — M8 nuts for bracket handles (4 pcs.); 8 — transom board (birch s30); 9 — transom; 10 — bulwark (2 pcs.); 11 — side (2 pcs.); 12 — oarlock socket plate (St3, sheet s5, 2 pcs.); 13 — runner (2 pcs.); 14 — handle-railing (duralumin tube 19×2); 15 — heel; 16 — stiffening frame; 17 — stern bracket (duralumin tube 19×2, 2 pcs.)

Material resources and machine base were more than modest, and this also affected the boat’s design — no complex curves.

The material I had at that time was a duralumin sheet 2 mm thick (I didn’t know its grade, but the metal was quite strong, though it bent well even when cold). From it I made almost all the main parts of the hull.

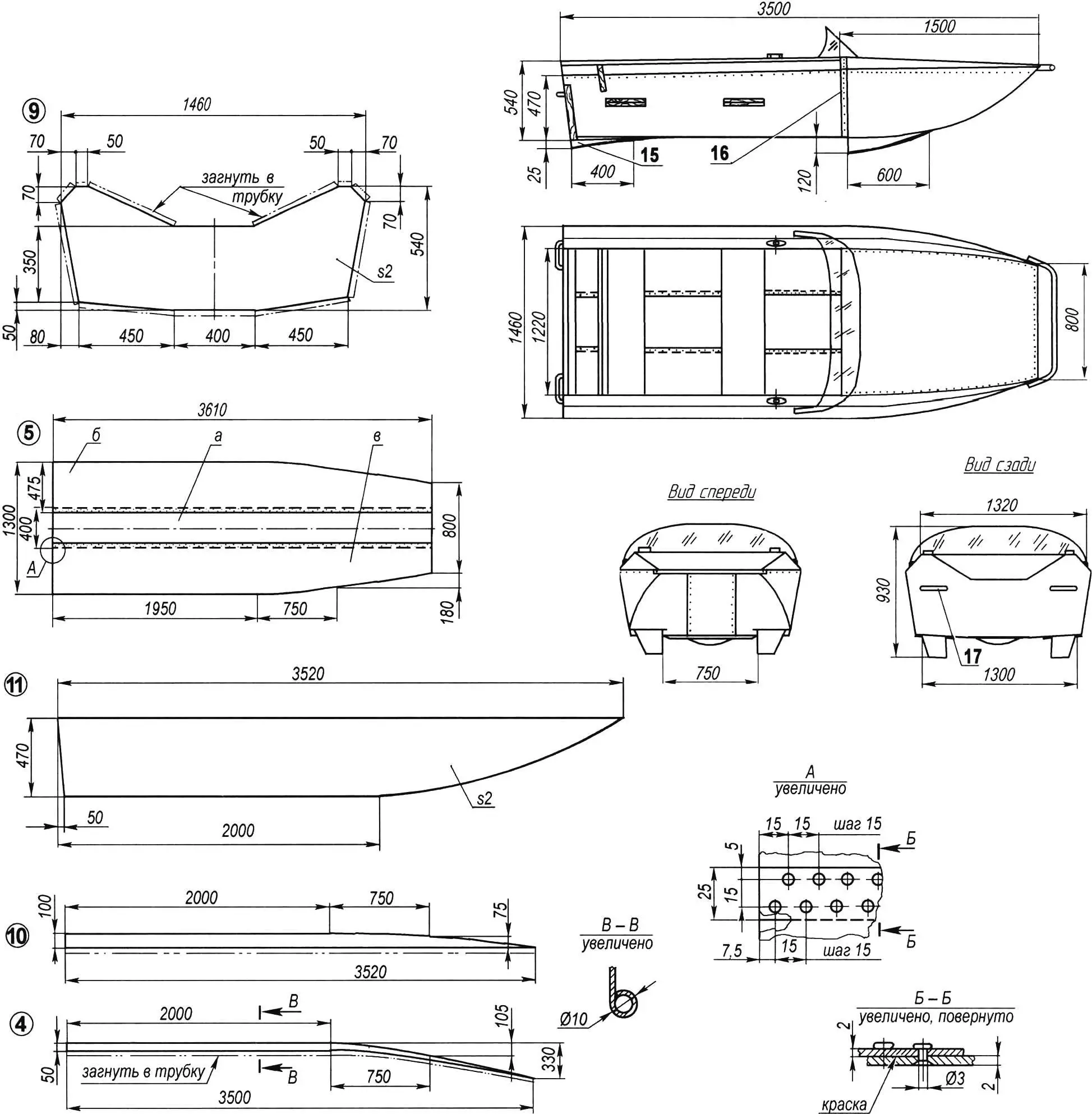

I made the boat’s bottom composite, from three strips. The center strip is 400 mm wide and 3610 mm long, that is, slightly more than the overall length of the boat (3500 mm). This size was chosen because at a distance of 1500 mm from the front edge, the bottom smoothly, along a template curve, bends upward to the height of the side — 470 mm. The latter in the design is defined conditionally: as the height from the bottom to the bulwark.

On both sides, I joined one more strip of the same length to the center strip in an overlap, but slightly wider (475 mm). The overlap was 25 mm for each joint (same for all other joined elements in the structure). I positioned the edges of the side sheets on top (bent inward). I riveted the joints with aluminum rivets 3 mm in diameter (with countersunk heads — on the outside), arranged them in a staggered pattern with a pitch of 15 mm and the same distance between rows. The offset from the edges of the joined parts was 5 mm; before joining, I coated them with thick oil paint.

I cut the front edges of the bottom along a length of 1660 mm along smooth symmetrical template curves, leaving a width of 800 mm at the front (400 mm from the axis of symmetry). As a result, the bottom took on the shape of a large ski.

To avoid returning to the question of joints each time, I note that they are all made the same type.

The sides and bulwarks with gunwales are made of the same duralumin sheet as the bottom. The latter elements are made as one part, and the names of its parts are determined only by their location on the hull and purpose. Although, probably, it’s easier to make these parts from different blanks (exactly as shown in the drawing) — then you wouldn’t have to bend and hammer out the curved front parts to fit them more tightly to the sides.

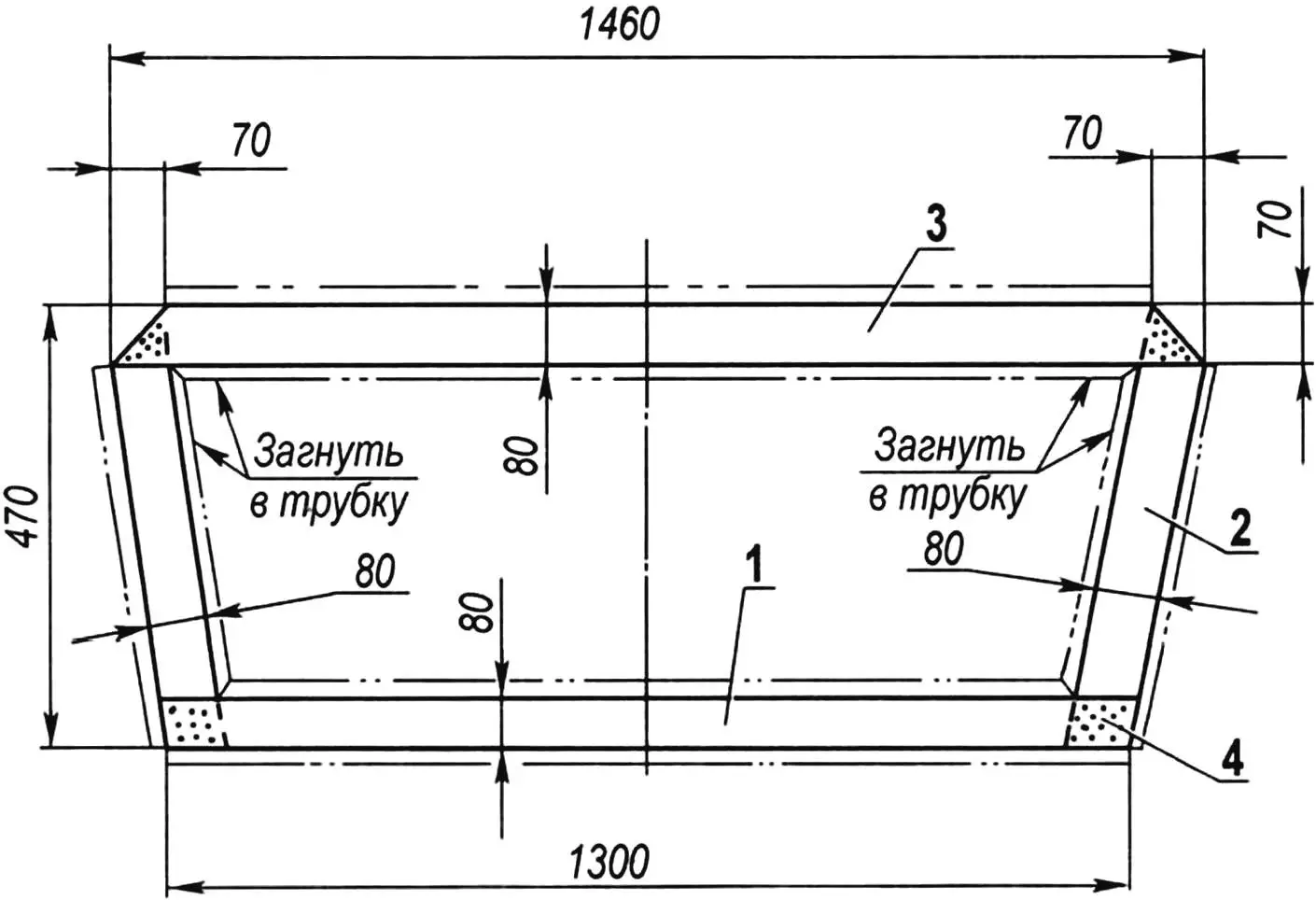

1 — floor; 2 — frame (2 pcs.); 3 — beam; 4 — rivets (as required)

At the edges of the gunwales in the cockpit, bends in the form of tubes are made, which increase the rigidity of the sides and the hull as a whole, and also prevent accidental cuts on sharp edges.

The next part is the transom. It is made as one piece from the same duralumin sheet. Almost along its entire perimeter (except for the top edge), 25-mm allowances are left for joining with the bottom, sides, and bulwarks. The lower edge of the transom is made with a slight deadrise (more precisely — in the form of an inverted trapezoid).

A wooden board is attached to the transom from the inside across the full width of the boat, significantly increasing its rigidity; the outboard motor is hung on it. On both sides of the transom at the sides, two handles in the form of brackets are attached: thanks to them, the boat is moored to the pier stern-first. One of the handles, after installing the engine in place, is used to attach the safety cable carabiner.

The seats (benches) I made from 30-mm board of hardwood. They rest on duralumin angles riveted to the sides. I also equipped the rear seat with a wooden back, attaching it, like the seats, to angles riveted to the sides. Thus, these parts, providing basic comfort for the helmsman and passengers, also serve to increase the rigidity of the hull. For the same purpose, in the middle part of the boat at a distance of the same 1500 mm from the bow (where the narrowed part transitions into the main hull), a stiffening frame is installed. It is made from strips 70 mm wide, cut from remnants of duralumin sheet. Its external outlines are the same as those of the transom, only without the “deadrise” at the bottom. The upper crossbar of the frame also serves as an instrument panel. Like the transom, the frame has allowances left for joining. Its connection to the hull parts is similar. On the free (inner) edges of the frame, as on the gunwales, I made tubular bends.

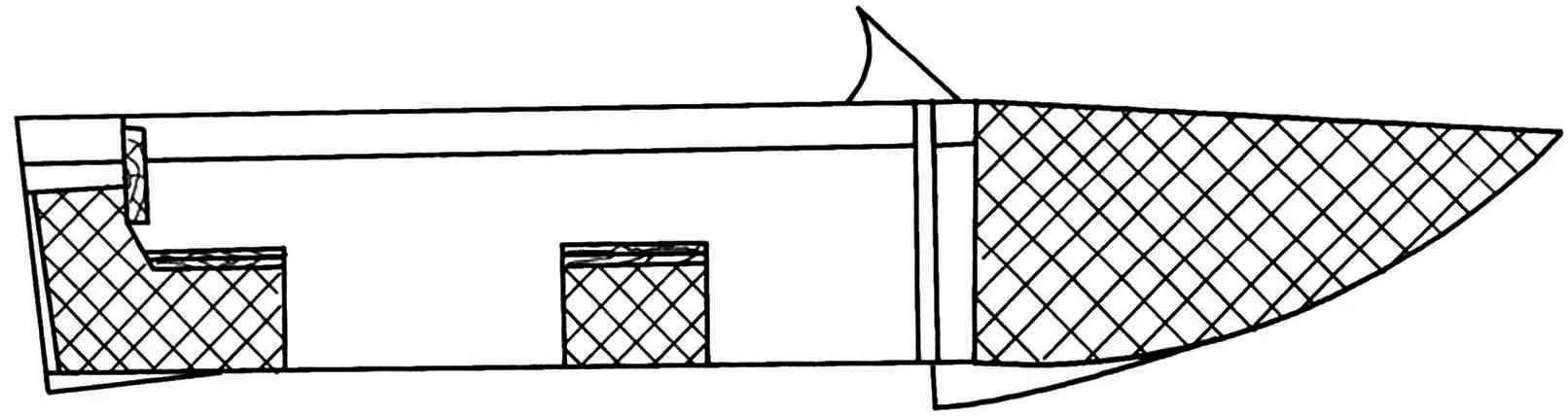

Finally, I closed the front part of the boat (up to the frame) from above with deck planking (all from the same duralumin sheet), and on the bow I secured a handle-railing for mooring or pulling the vessel ashore. With the help of the railing and stern brackets, the boat can be dragged short distances by two people.

Operation showed that in difficult conditions (both weather and others — in significant waves, strong gusts of wind, on waves from oncoming vessels, and simply on sharp turns), the boat at high speed turned out to be difficult to control, and at low speed — it buried its bow in the wave.

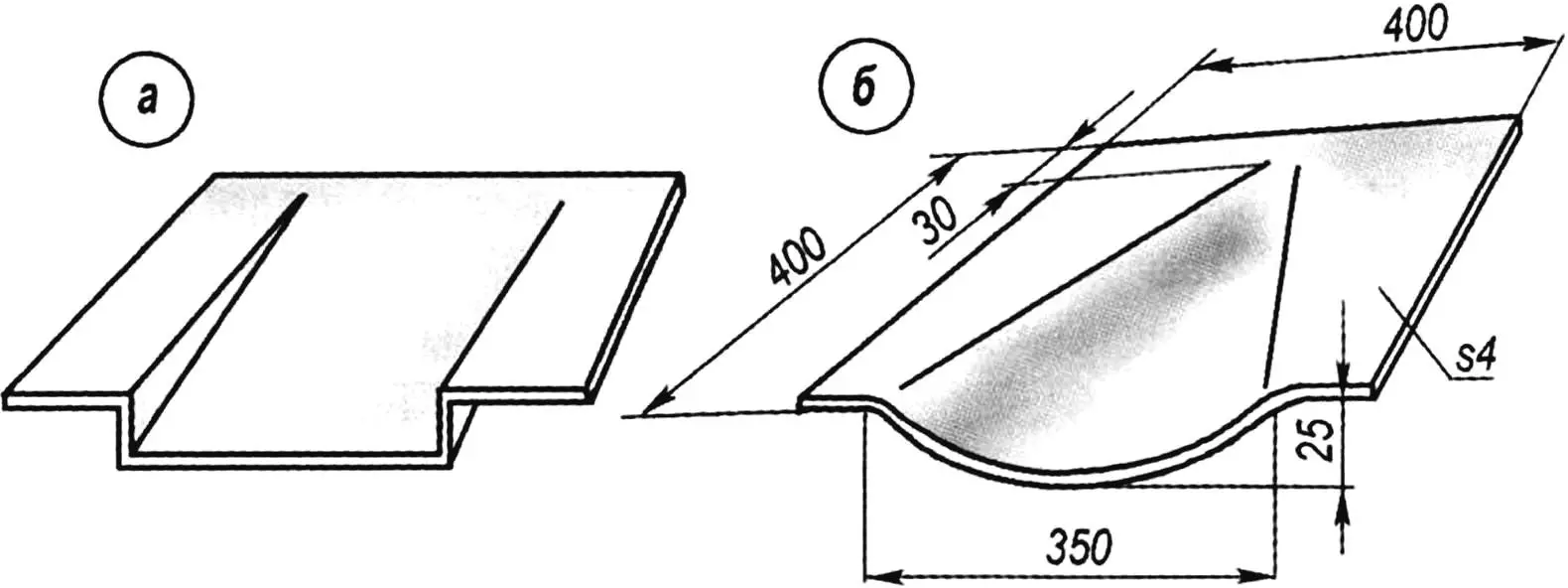

a — initial (unsuccessful) version; b — subsequent, improved

It should be noted that the last drawback disappeared after installing the windshield. It, besides protecting passengers and the helmsman from splashes, played a significant role in ensuring the boat’s aerodynamics. Since the boat’s bow is slightly lowered, at low speed (before planing), it was pressed to the water by the oncoming air flow. And the windshield improved the aerodynamics.

Now about refining the boat’s design. During further operation of the motorboat, other shortcomings also appeared. The first of them — a “delayed” (even difficult) transition to planing when the boat was fully loaded (4 — 5 people). I eliminated this by riveting two rectangular (in cross-section) runners on the sides in front, and a rectangular heel in the rear. At the same time, the boat’s controllability also improved.

However, eliminating this drawback led to another. In planing mode on a wave from an oncoming vessel or when transitioning from rapids to calm water (and vice versa), the boat would sharply heel to one side, hitting the water with its lower chine, bounce off and heel to the other. And so several times. In these cases, it responded poorly to the helm. Once in a similar situation, I was almost thrown overboard.

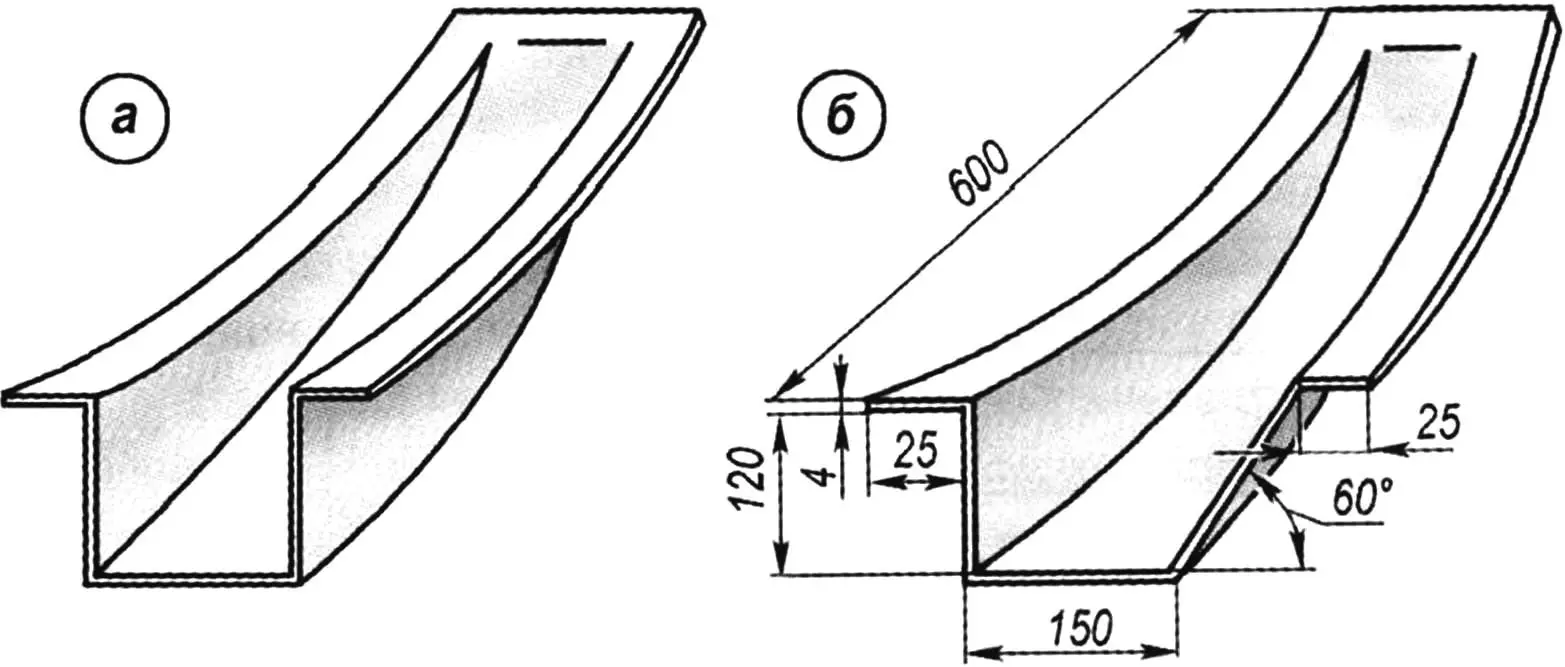

I puzzled over this problem for a long time. But I solved the problem, all in all, simply, at least without major modifications to the boat: I replaced the rectangular heel with a semi-oval one, and made the outer walls of the runners inclined (angle about 60° to vertical). I rounded off the front edges of the runners and heel with a grinder. After that, the boat went as it should.

In the end, the modifications were not so significant. But, since the shortcomings were not all discovered at once, but only in certain situations and at different times, the design refinement continued for almost two years. I eliminated the shortcomings during breaks between navigation seasons.

In the end, I got everything I wanted from the boat. To its capacity, stability, and high speed were added a smooth transition from displacement mode to planing and back; as well as “obedience” in control and good maneuverability, which is important when sailing on small winding rivers.

However, the boat’s fate turned out to be sad due to non-compliance with safe operation measures on the water — it sank. Once I allowed two young guys — my son and nephew — to take a ride on the boat. But when the young people were captivated by speed, then, mesmerized by the water’s rainbow wake behind the stern and forgetting about caution, on one of the bends of a generally narrow and calm river, they lost control, hit a steep bank and… the boat capsized and sank along with the motor. The guys were not injured and safely got ashore. Perhaps avoiding more serious consequences was helped by the fact that they were wearing life jackets (homemade, from foam), which was my mandatory condition for boating.

Perhaps I shouldn’t have told about this, but I want to warn others: the vessel’s unsinkability was not ensured. And it wouldn’t have been much trouble to do this: it would have been enough to fill the free niches with construction foam (plastic bottles from carbonated drinks didn’t exist then).

V. PRONIN