Many readers, after the editorial board asked them what amateur constructions (for water, land, and air) they were interested in, sent hundreds of letters to the editorial office requesting the publication of drawings and a description of a light foldable boat for amateur fishermen, tourists traveling on blue roads, for all those who love nature and their native land. We are fulfilling your request.

Who doesn’t know about the remarkable deeds of Sergey Sugrobin, one of the heroes of Galina Nikolayeva’s novel “Battle on the Way” and the eponymous film based on this novel, a craftsman, rationalizer, inventor? But Sergey Sugrobin is a collective image. And how many young rationalizers and inventors, home designers live among us. Hundreds, thousands, millions.

Here, our correspondent met one of such Sugrobins — Vladimir Komzolov — in Izhevsk. At the factory where he works, he is rightfully considered one of the best rationalizers. But not only production successes enrich the biography of this guy with a characteristic Vyatka accent. You could meet him at all-Union automobile competitions and among tourists discovering the expanses of the Siberian taiga and the beauty of Lake Baikal. But most often you can catch Volodya in his home “workshop,” where he creates curious things. With one of them, a collapsible boat — a tourist’s dream — we want to introduce you in this article.

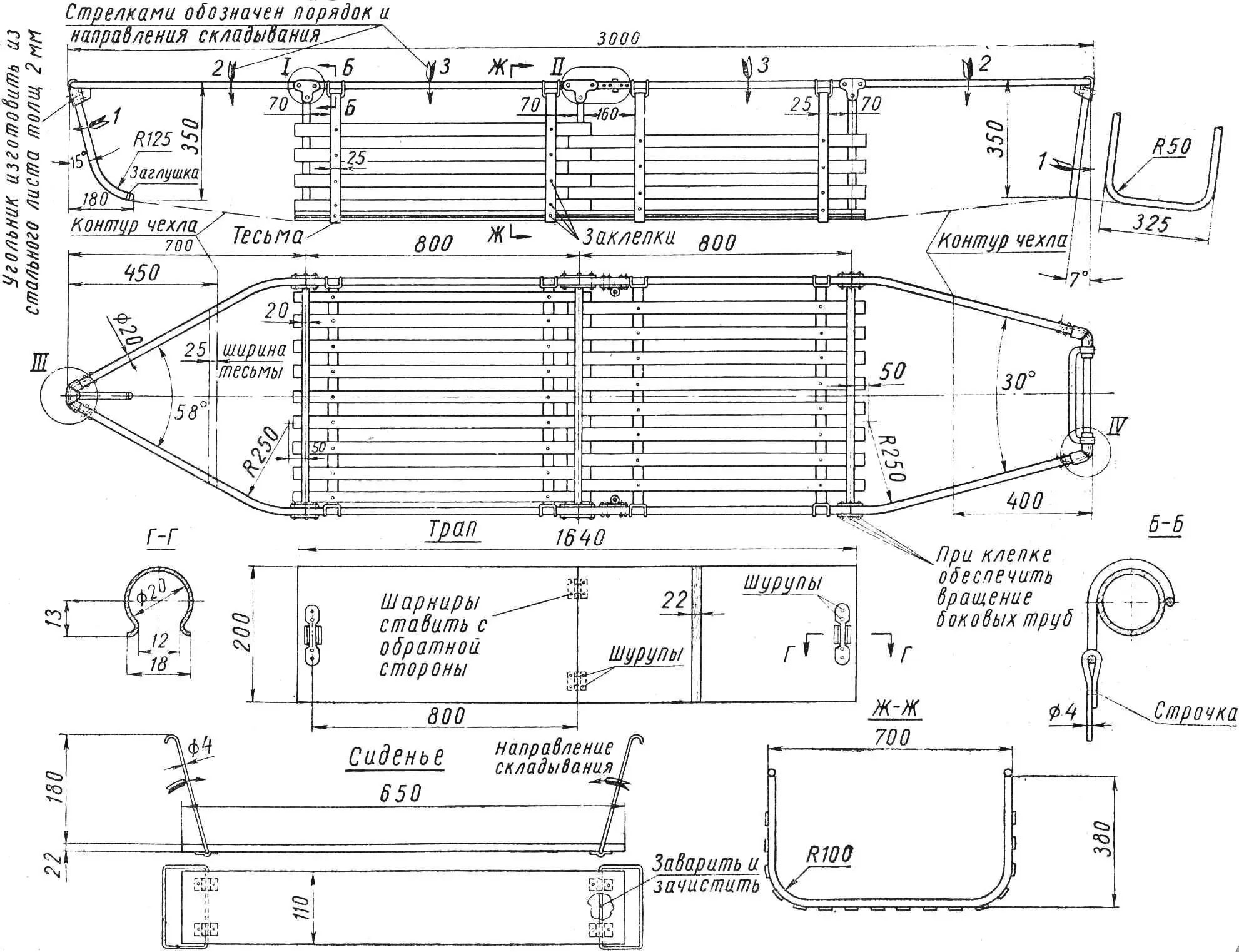

The frame boat (Fig. 1) is designed for two people and a load of 50—60 kg. When folded, it occupies a volume of 150 X 700 X 800 mm and fits freely in a car trunk or on a tourist’s back. All additional equipment: ladder, oars, benches — no longer than 800 mm. Assembly and disassembly of the boat takes no more than five minutes, much less than inflatable rubber boats. It has no rigid longitudinal elements, except for the load-bearing sides. The profile of the covering is created by a set of planks fastened with webbing, which are installed between the frame and the hull.

The design of individual units and their dimensions can be changed based on capabilities, materials, and the intended method of transportation.

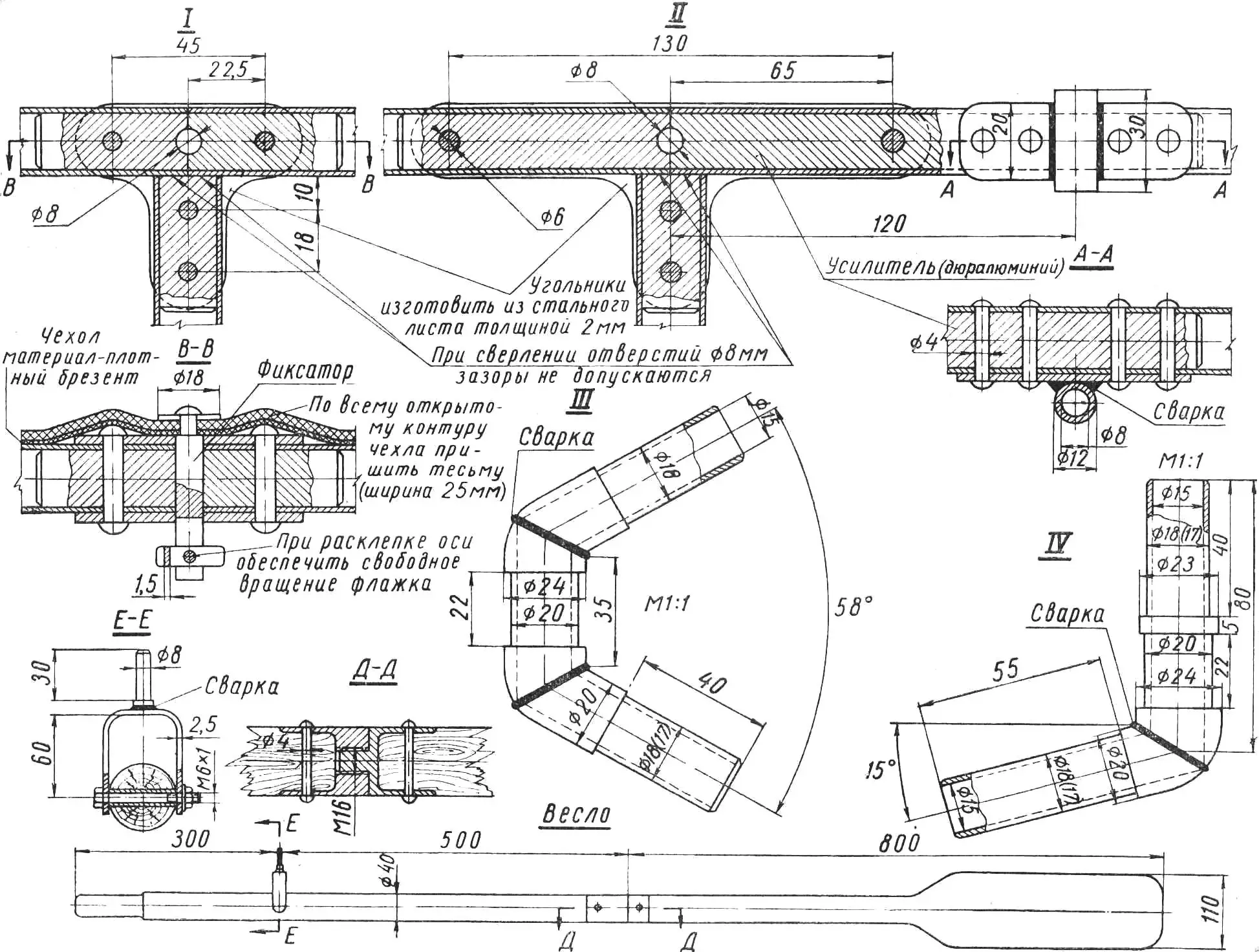

For the frame, use duralumin tubes with an outer diameter of 20 mm and an inner diameter of 17 mm (from an old “folding bed” or folding chair). To prevent them from forming folds when bending, make two wooden plugs, fill the tubes with dry sand, and then bend according to the template. Connecting brackets are made from steel sheet 2 mm thick according to the drawings, end caps on the tubes — from duralumin or any other aluminum alloy.

The bow and stern tubes are connected using elements turned on a lathe and welded, as shown in the drawing. Before welding, cut a template from sheet steel that will allow you to maintain the necessary angle. Connect all parts of the boat frame with steel rivets 4 mm in diameter. They can be selected ready-made.

Drill holes in the tubes in place during assembly, which will significantly simplify the fitting of parts. At the same time, rivet the oarlock eyes, which consist of a base and a turned bushing welded to it. How to make the oarlocks yourself is clear from the drawing.

After assembling the boat frame, drill 8 mm diameter holes at the tube joints for the passage of fasteners. They are riveted directly to the boat cover itself. You can also attach them to the frame with pieces of thin chain and connect them to the cover during assembly.

For the ladder, two boards or sheets of multi-layer plywood will work. The seat is attached with wire loops directly to the boat sides in the most convenient place. Bend the ends of the loops along the outer radius of the tube.

Make profiling planks from wood or plastic and attach them to the webbing with steel rivets. Place washers 1 mm thick and 10—12 mm outer diameter under the rivet heads on both sides. The pitch between rivets equals the width of the plates. They should be arranged so that the ends of one section enter the gaps of another, as shown in the drawing.

Sew wire hooks at the ends of the connecting webbing plank to ensure tension when assembling the boat. Weld the ends of the hooks that go inside the webbing before sewing, then you will get a rigid closed structure.

The oars for the boat are collapsible. How their installation is carried out is visible from the drawing. Another connection of oar parts is also acceptable — in the form of a tenon lock or tubular element.

Make the cover from dense canvas, tent fabric, or other waterproof material. Cut it according to the assembled boat frame. Insert the frame into the bow and stern “pockets” (it is partially folded at this time). When the planks fit tightly into the “pockets,” fully straighten the frame. Sequentially insert the fasteners and smooth out the cover fabric.

After final assembly and fitting, disassemble the boat and paint all parts twice with oil paint.

V. KOMZOLOV