Large-scale work on designing a new main battle tank began in the USA after the termination in 1970 of the joint with Germany development of a promising tank МВТ70. In February 1972, the United States was formed the operative group, composed of military and representatives of the companies-developers. Their task was the formulation of a concept of the future tank ХМ1. The result of the work of this group was “Requirements for the material,” published in August 1972. A new tank was developed on a competitive basis. To participate in the competition, the Pentagon chose two companies: Chrysler and “GM”. 18 July 1974 was signed with them the contract to develop and manufacture prototypes of a new tank. Under the terms of the contract, prototypes were to be presented for testing by early 1976.

Large-scale work on designing a new main battle tank began in the USA after the termination in 1970 of the joint with Germany development of a promising tank МВТ70. In February 1972, the United States was formed the operative group, composed of military and representatives of the companies-developers. Their task was the formulation of a concept of the future tank ХМ1. The result of the work of this group was “Requirements for the material,” published in August 1972. A new tank was developed on a competitive basis. To participate in the competition, the Pentagon chose two companies: Chrysler and “GM”. 18 July 1974 was signed with them the contract to develop and manufacture prototypes of a new tank. Under the terms of the contract, prototypes were to be presented for testing by early 1976.

In July 1973 the US and Britain signed an agreement on the transfer of Americans of the production technology of multilayer armor “Cobham”, latest at the time. In the US, this armor was called “the Burlington”.

After three years of hard work in January 1976 at Aberdeen proving ground began comparative testing of prototypes, which continued until April 30. Firm “General motors” presented a tank equipped with 12-cylinder diesel engine with variable compression ratio A/CR-1360-2 the company “Teledyne continental motors”. The machine had a combined suspension: hydro-pneumatic on 1-, 2-m and 6-m of the supporting rollers and the torsion 3-, 4 -, and 5 m. the Simplified fire control system (FCS) was borrowed from the experimental tank ХМ803. Yes, and the whole car “General motors” was a profound modernization of the latter.

As for the sample firms Chrysler, the situation was fundamentally different. Retaining the classic layout, the designers of this firm offered a much more progressive pattern. And in everything — in relation to powertrain, chassis, fire control system, etc.

In July 1976 the Commission for the procurement of the U.S. Congress adopted the decision on the conclusion of the contract with the firm-winner, which, however, has not yet been named. The final decision was delayed because of another attempt to create a single tank of NATO. On grounds of the United States were tested West German tank Leopard 2AV, there were negotiations about the production of its nodes, about installing them on XM1 and even mass production “Leopard” in the United States. However, all ended in nothing. In the US, however, in the process of unification has developed a new tower-“the hybrid” for the XM1 tank. It was done in such a way that it could in the future with minimal changes to install 120-mm gun.

Only 12 November 1976 the Chrysler firm was announced the winner of the competition for a new tank for the US army. However, before mass production was still far the New contract involved the manufacture within three years 11 prototypes of the tank and elements of the booking for the test firing, as well as the restoration of two cars that participated in the initial testing phase.

M1A1 tank ON one of the American bases in Germany. 1990-ies

Serial production of the new tank, known officially as the M1 “General Abrams” began on 28 February 1980, when the pipeline state plant Lima Tank Plant down the tank Its name the car is named after General Creighton Abrams, who commanded during the Second world war, a tank battalion, and subsequently led the operations of American troops in Vietnam and personally engaged in the issues of the project ХМ1 during his tenure as chief of the main staff of the land forces of the US army.

Tank “Abram” has a classic layout with a front compartment and aft engine compartment. It was the first since 1930-ies the American tank, which has the driving wheels located on the rear.

The hull and turret are atypical for the American post-war tank of welded construction using in their frontal parts of the multi-layered armor. In the image and likeness of British tanks “chieftain” the driver at the closed hatch position reclining. This allowed positioning the upper front hull plates at a large angle of inclination (82°) to the vertical and thus to reduce its vulnerability. The driver controls the tank via a T-shaped steering wheel motorcycle type. For convenience of the driver in the semi-prone position his seat is made of three elements — cushions, lumbar support and backrest, are located in such a way that they fit the arched back of the driver.

The tank is armed with a M1 105-mm rifled gun М68А1 (English L7А1 gun, produced in USA under license), is equipped with an ejector and is stabilized in two planes. For a quick change barrel provided a quick disconnect coupling it with the breech made in the form of a sector of multistart threads. To the right of the guns in the turret are the commander and gunner left, loader. Ammunition gun consists of 55 shots. 44 of them are in a niche of the tower in two compartments, 22 rounds each. The compartments are isolated from the fighting compartment with armored shutters with a thickness of 20 mm. above the compartments is equipped with three lifting plates for pressure relief in the explosion of ammunition. The rest of the shots are stored in armored containers, placed in the enclosure under the tower (8) and police tower under the gun (3).

In gun ammunition consisted of first shots with armor-piercing projectiles with a detachable tray М735 with the core from tungsten, and later М774 with a core of depleted uranium.

Along with the gun the tank is fitted with 7.62-mm machine gun М240, 12.7 mm machine gun М2НВ open pin header front commander’s turret and one 7.62-mm machine gun М240 on the rack, pinned Luke loader. Ammunition machine guns consists of 11 400 rounds of 7.62 mm rounds and 1,000 12.7-mm. On the side of the turret is equipped with two six-barreled smoke grenade launchers М239.

Main battle tank M1A2

Tank M1 “Abrams” has a fairly advanced system of fire control. It has a periscope combo sight-rangefinder GPS with ocular otvodki for the commander.

The sight-rangefinder is the day branch (channel) with a magnification of 3 to 10 and the field of view, respectively, 18° and 6.5°, night vision and thermal imaging branch, the receiver of the laser range finder and gyroscopic stabilizer of the line of sight in the vertical plane. The composition of the FCS includes a digital ballistic computer M21 which continuously controls the position of reticle and simultaneously controls the operation of all subsystems of complex weapon control.

Besides the main gunner’s sight equipped with an auxiliary tank commander’s monocular sight М919. It is installed in the roof part and is intended for targeting a 12.7 mm machine gun like you’re shooting air and ground targets. Auxiliary monocular telescopic gunner’s sight М920 with 10x magnification used for aiming the main armament in case of failure of sight GPS.

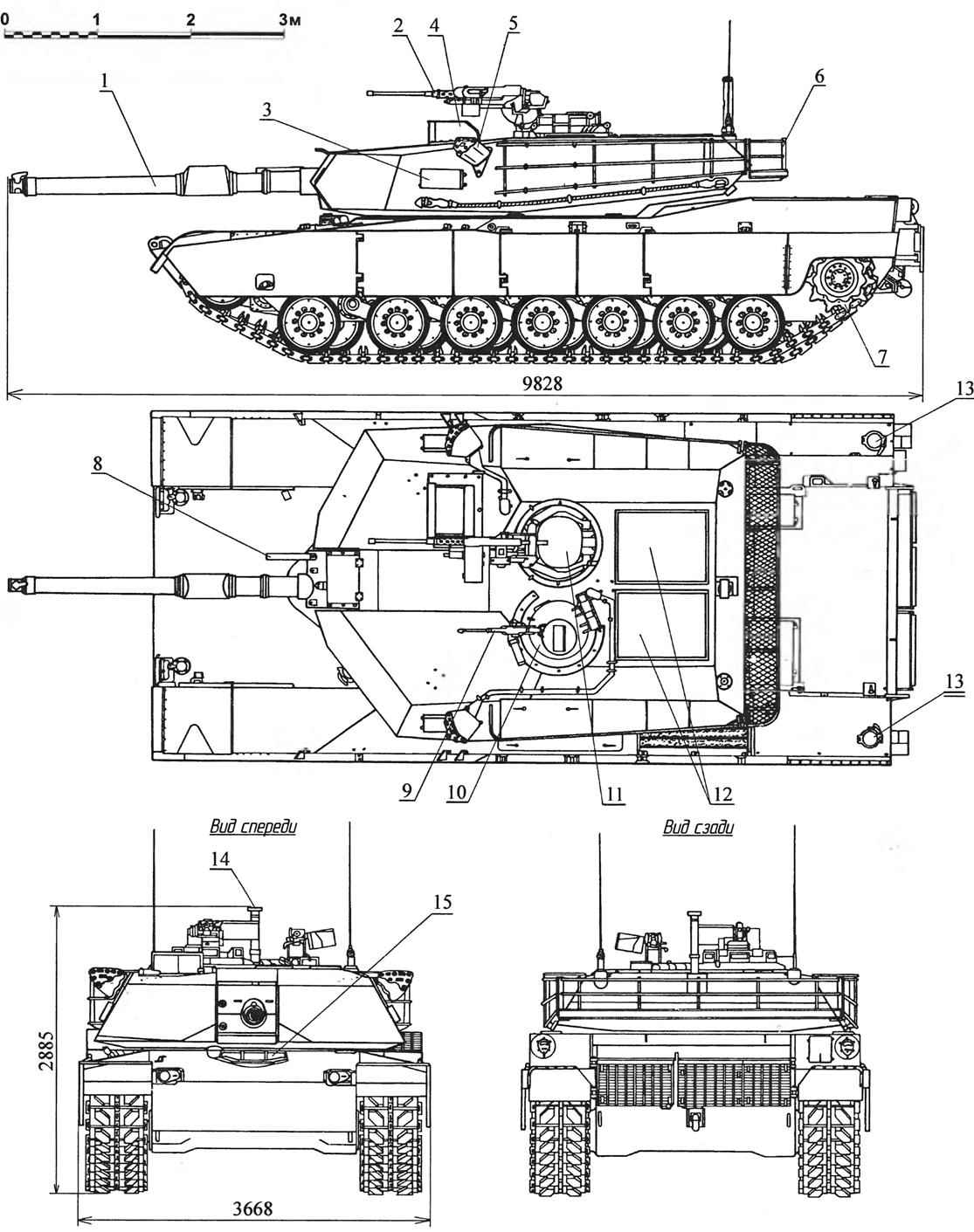

Main battle tank M1A1:

1 — 120-mm gun;

2 — 12.7 mm machine gun;

3 — a box of tea smoke grenade launchers;

4 — armor cap of the gunner’s sight;

5-6-barrel smoke grenade launcher;

6 — basket for ammunition and equipment;

7 — drive wheel;

8 — armor casing coaxial machine gun;

9 — 7.62-mm machine gun;

10 — Luke loader;

11—hatch commander’s;

12 — lifting of the panel;

13 — the filler neck of fuel tanks;

14 — wind speed sensor;

15 — observation devices of the driver.

In a single unit with the transmission and service systems installed on the tank gas turbine engine “Avko laiko-Ming” (Avco-Lycoming) AGT-1500 with a capacity of 1,500 HP (1104 kW) at 3,000 rpm, dual-stage compression, free power turbine and a stationary heat exchanger.

Double-flow hydromechanical transmission the Allison X-1100-THIS includes a one-pot comprehensive hydraulic transmission with lock-up clutch, four-speed planetary gearbox, dual flow differential rotation mechanism with hydrostatic drive and two final drives.

Suspension for one Board consists of seven rubber rollers on Board, the two rubber support rollers, drive wheel at the rear with a removable ring gear (cycloid gear) and idler wheel. Suspension —personal torsion. Hydraulic dampers are installed on the 1st, 2nd and 7th suspension units. Caterpillar Т142 — rubber RMS and removable rubber cushions in each track 78 trucks with a width of 635 mm, step truck—193 mm..

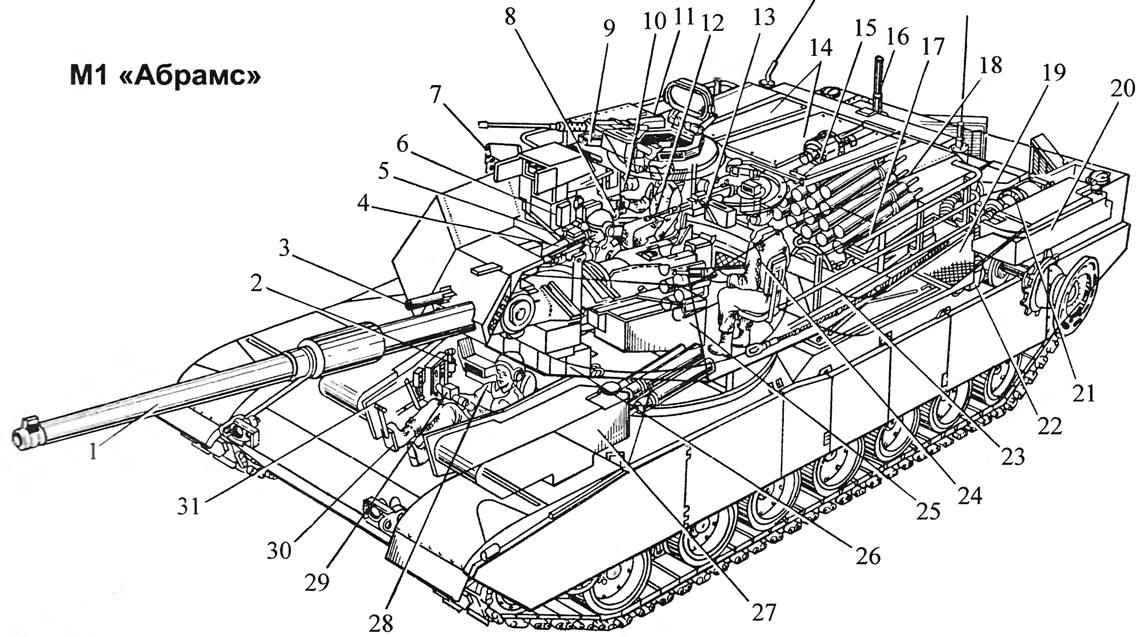

M1 “Abrams”. Arrangement:

1 — 105-mm gun;

2 — periscopic device driver;

3 — 7.62 mm coaxial machine gun;

4 — telescopic sight;

5 — gunner;

6 — the main gunner’s sight;

7 — smoke grenade;

8 — remote control commander;

9 — 12.7-mm machine gun;

10 — the main commander’s sight;

11— the commander’s sight for firing from a machine gun;

12 — the commander of the tank;

13 — 7.62-mm machine gun;

14 — expelling panel;

15 — auxiliary fan;

16 — the wind sensor;

17 — compartment for ammunition;

18 — gas turbine engine АGТ1500;

19 — air filter;

20 — feed fuel tank;

21 —main fan;

22 — transmission;

23, the air intake of the engine;

24 — loading;

25 — cartridge box coaxial machine gun;

26 units of electronic equipment;

27 — front of the fuel tank;

28 — a driver;

29 — steering column;

30 —the brake pedal;

31 — instrument panel.

Overcoming obstacles: angle of elevation is 31°; trench width—2,743 m; wall height -1,244 m; fording depth -1,22 m (OPVT—2.4 m).

Engine, transmission and suspension enable the car combat weight of 57 tonnes to reach a maximum speed of 72,4 km/h. cruising on the highway is 394-440 km. the Crew consists of four people.

Main battle tank M1 “Abrams” during maneuvers in Germany. 1980-ies.

It is interesting to note that the rate of Assembly of new tanks lagged far behind scheduled. So, for November 5, 1981, the army has received 203 machine of the 352 ordered. One reason for this gap delivery plan was the lack of preparedness of suppliers for mass production of engines and electronics, mainly due to the lack of skilled workers necessary for expansion of production. As a result, the pace of the engine Assembly 30 in a month — was achieved only by July 1981. But even at the end of 1981, when the firm “Lycoming” already made 30 engines a month, they arrived at the Assembly tank factory spasmodic, not one day, as envisioned, and closer to the end of the month. To eliminate these disadvantages by the production of “Abrams” had to bring a giant of American industry—the company “General dynamics”. Its subsidiary Land Systems Division in March 1982, has acquired the tank production and all rights on further modernization of the tank “Abram”. In the end, the pace of production of tanks by November 1982, increased to 60 units, and in January 1985, reached its peak—90 cars a month. All in all, until January 1985 was made 2374 M1 tanks.

Tank “Abrams” destroyed by internal explosion in Iraq.

The first in July 1981, Abrams got units stationed in Germany, the 1st cavalry and 2nd armored division 3rd army corps. Special problems with the development of the new material the crew does not arise, because many of them were trained at Fort hood during army trials. In late 1982, M1 participated in the annual NATO exercise “Reforger 82” and competitions of tank crews of the unit for the prize of the canadian army. The debut was successful—Americans took first place.

Modernization “Abrams” was carried out shortly after the start of serial production in the framework of the so-called program of “Block I”. The impetus for its implementation was the Lebanon war in 1982 and information received from the Israelis, about the new Soviet piercing projectiles. The result of the first phase of the program began to tank M1 IP (IP— Improved Product—improved) that appeared in 1984 and received increased booking the frontal part of the hull and turret, improved suspension, improved transmission, new caterpillar Т156 and an additional basket for the property in the rear of the turret. The combat weight of the machine is made up 55,55 so Only from October 1984 to may 1986 was made 894 IP M1 tank.

In August 1984 it has been adopted a M1A1 tank. The main difference was the 120 mm M256 smoothbore cannon made by the German license. Her ammunition was reduced to 40 rounds, a coaxial machine gun ammunition allowance of up to 2800 rounds. On the roof of the tower mounted two shaped panels of the same size instead of three. In addition to the existing individual protection from weapons of mass destruction established the system of collective security with HLF М43А1. In connection with the increased mass of the tank changes in the suspension. Since 1988, some tanks in the composition of the frontal armor hull and turret introduced depleted uranium (M1A1 ON Heavy Armor). Combat weight machines — 57,155 tons (M1A1) and 62.2 per ton (M1A1). By the end of 1993 was manufactured 4802 tank M1A1 and M1A1. In December 1985, the Assembly line plant in Detroit got the first two series of tanks M1A1. With the growth of issue they are primarily reported in the part located in West Germany. The first 10 tanks received a training center in Wilsele, where they were used for training instructors. First Union, which was sent to the M1A1, was the 1 armoured division 5th army corps. In 1986, deliveries began 221 M1A1 tanks to the marine corps of the United States. Version of the tank for the marine corps differed from the army, mainly in terms of meeting the requirements of the units involved in the landing operations.

In 1988, between Egypt and the U.S. signed a contract for the supply of 555 M1A1 tanks “Abrams”, of which 25 were released in the US and the rest of 530 to 1998 were collected for licenses for constructed under this order tank plant in Cairo. In the period from 2000 to 2004, with the U.S. side was completed a number of agreements for the supply of 325 Assembly kits. In total the end of 2008 the total number of collected tanks had to reach 880. In addition to this, it was supposed to buy another 125 sets (2009-2011). Thus, the amount collected in Egypt M1A1 tanks “Abrams” for the national armed forces will be 1005 units. American technology is designed to gradually replace the obsolete tanks of Soviet production of the T-54/-55, T-62.

Baptism of fire “Abrams” received during the “Gulf War” operation of the multinational forces against Iraq, seized in 1990, Kuwait. The first “Abrams” modifications M1 and M1 IP arrived in Saudi Arabia from Europe to the 24th mechanized infantry division in August 1990. By November, the number reached: 580 units — 123 and M1—M1A1. However, the tanks of early modifications had limited ability to provide crew protection from weapons of mass destruction (expected use by the Iraqis of chemical weapons). In addition, there was concern low affecting the properties of the 105-mm guns with a possible meeting with the elite units of the Iraqi army, equipped with tanks of Soviet production of the T-72M and T-72M1. So command had decided to use M1 tanks and M1 IP in the second tier. In the first tier was to be used cars ON the M1A1 and the M1A1, which had a collective overpressure system, effective 120-mm gun, and a stronger reservation. Part of the 7th army corps and units of the expeditionary forces of the US Marines involved in the operation “desert Storm”, urgently were equipped with such tanks. By February 1991, the us troops in Saudi Arabia was 1223 ON 733 M1A1 and M1A1.

M1A1 tank on the ground in Iraq.

In 1993, four “Abrams” (M1A1) in the framework of the UN peacekeeping operation “restore hope” was taken to Somalia. In the battle for the duration of operation, tanks were used only once—January 7, 1994. They fire and armor supported the attack on the fortified post of separatists Michel Aideed.

Tanks “Abram” ON the M1A1 and M1A1 were involved in the composition of peacekeeping forces on the territory of the former Yugoslavia.

22 Sep 2006 the first tanks M1A1 entered service with the 1st tank regiment of the Australian army. Until March 2007, Australia was delivered 59 units. Work on the Australian ordering began in June 2005 when the selected Australian military tanks arrived at the base storage of the US army in Anniston (Alabama). Here they are fully disassembled and assembled again, citing the “zero” status: “mileage: 0 km, maintenance — 0 hours”. After that, the tanks were shipped to the customer.

The last large-scale program of modernization “Abrams” was the program of the Block II. The brainchild of this program, aimed primarily at the improvement of the radio electronic filling of the tank, was the modification of the M1A2 introduced in 1994. The tank received a new stabilized commander’s thermal imaging device is a circular observation CITV, ballistic computer with increased memory, laser rangefinder on carbon dioxide, integrated on-Board information system IVIS imaging surveillance device of the driver. In the case of structures more widely used items of body armor, depleted uranium, anti shaped-charge installed screens on the roof of the tower. The combat weight of the tank made up of 63.1 tons For the US army initially produced only 62 vehicles. 32 tanks was reduced in the test group, and the rest distributed to the training and testing facilities. However, such a small order jeopardize the existence of plants in Detroit and Lima. The order is urgently increased for 44 cars and developed a long-term programme of modernization of the M1A1 tanks. The cost of a newly manufactured tank was approximately $ 4.5 million, and the upgraded 2.5 million dollars.

As a result of the reorientation of the tank program until 2007 with the release for modernization “Abrams” and concluded in 1992 with Saudi Arabia and Kuwait agreements in these countries 315 and 218 M1A2 tanks accordingly allowed, at least until 2010 to leave the current plant in Lima, Ohio, plant in Detroit had to be closed.

However, one plant is quite capable to cope with the implementation of the next modernization program, dubbed SEP and launched in 1999. We are talking about creating a “digital” version of the M1A2 tank. The upgrade included the fitting of tanks and advanced booking third-generation uranium without filler, the new fully digital fire control system, thermal imaging system of the 2nd generation (2nd Gen FLIR) gunner and commander with significantly improved ability to detect targets day and night, auxiliary power unit for the operation of electronic systems in main engine shut-off and thermal control system of air conditioning for the crew and electronic equipment. Also apply the latest information technologies, including color cards, network communication, increased computer memory and processors to increase the efficiency of defeats the purpose. It is believed that the system 2nd Gen FLIR has improved by 70% a definition abbreviated for 45% of the time for shooting and improved accuracy. Improved commander’s thermal imaging device is a circular observation CITV.

Delivery of the first M1A2 SEP was launched in August 1999. The programme included the previously released update 1150 M1A2. To digital also upgraded Saudi M1A2 (contract for the modernization of the first 60 cars were signed in 2006, started ноябрь2007года).

In June 2004, the Agency Forecast International tank Corporation General Dynamics Land Systems M1A2 SEP was named best in the world. Second place was awarded to the Israeli “Merkava” MK.4, the third — Japan Tour 90, the fourth — German “Leopard” 2A6 and the fifth — the British Challenger 2.

However, American experts did not stop there — 6 октября2008 year out of the gate Ennistuskoda Arsenal came first modernized tank M1A2 SEP V2 (Systems Enhancement Package Version 2). This is the latest and most advanced “digital” modification of the American main battle tank M1 “Abram”. Under digital standard SEP V2 updated previously released M1A1. The new machine is different from the previous versions of advanced color displays to show the tactical situation, the sights with electro-optical and infrared channels, improved powertrain and new means of communication, compatible with the networks of infantry units and formations. In addition, the modernization includes the introduction of a number of technologies developed under the program “future Combat systems” (Future Combat Systems).

M1A2 tanks on the streets of Baghdad.

Long-term contract for upgrading M1A1 tanks to the M1A2 SEP V2 standard company “General dynamics” has received in February 2008. It is reported that after the completion of the program the entire tank fleet of the U.S. army will be reduced to “digital” standard. The completion of the modernization is expected in June 2013.

Electronics electronics, but a study of the experience of fighting in Iraq came to light the program of the TUSK (Tank Urban Save Kit — “tank city rescue kit”). In the framework of the contract concluded with the company General Dynamics Land Systems, M1A1 tanks and M1A2 will be installed 2832 armour machine gun shield for loader mounted protivogrippoznye system and curtain sets extra protection.

Strange but true — modernization margin of the tank “Abrams” serial production began in 1980, has not been exhausted.

Atideo: