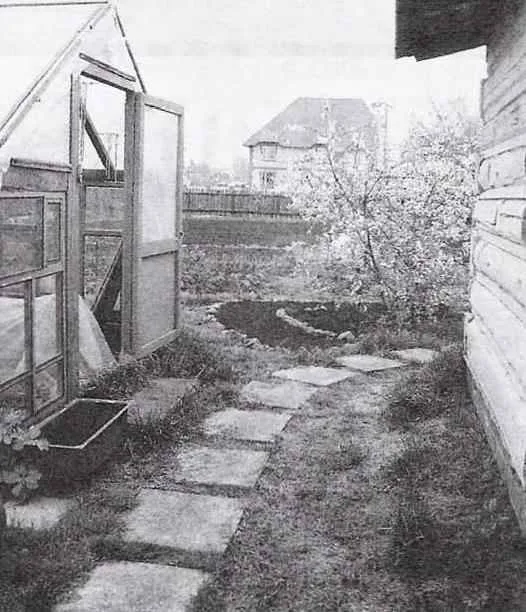

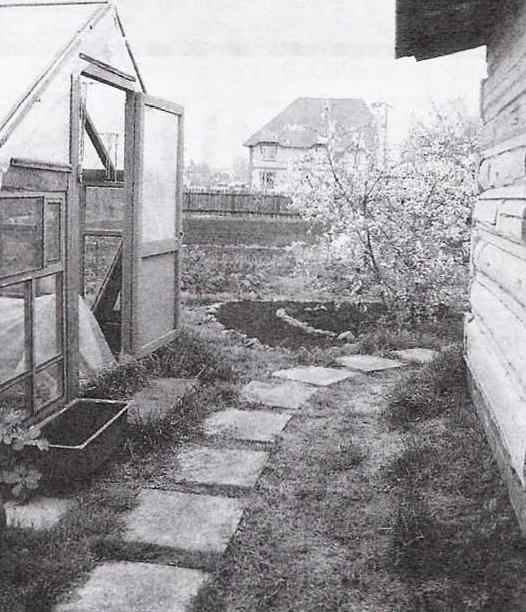

Garden paths at the cottage or the mansion was just as necessary and sidewalks in the city. As a rule, these tracks build from individual concrete slabs with sizes of 400×400 mm and 800×800 mm and a thickness of from 50 to 200 mm And these boards are offered to buyers such as large factories of reinforced concrete structures, as well as small firms. Preliminary calculations showed that the cost of all materials necessary for the production of one tile, four times less than the price of the finished product in trade organizations. So isn’t it better to make them yourself, especially not so this work is difficult. DIY garden paths— more work for the soul than just physical labor. Besides the economic benefits gives strength and promotes creative thinking. Well, if you feel tired, take a break (even for a few days) on any plate.

Garden paths at the cottage or the mansion was just as necessary and sidewalks in the city. As a rule, these tracks build from individual concrete slabs with sizes of 400×400 mm and 800×800 mm and a thickness of from 50 to 200 mm And these boards are offered to buyers such as large factories of reinforced concrete structures, as well as small firms. Preliminary calculations showed that the cost of all materials necessary for the production of one tile, four times less than the price of the finished product in trade organizations. So isn’t it better to make them yourself, especially not so this work is difficult. DIY garden paths— more work for the soul than just physical labor. Besides the economic benefits gives strength and promotes creative thinking. Well, if you feel tired, take a break (even for a few days) on any plate.

For the manufacture of concrete slabs as a binder used Portland cement grades of 300, 400. The filler applicable to pure (without inclusions of clay) sand with additions of clay, gravel, brick, terracotta, or simply a large river sand with pebbles. The concrete mix is: 1 part cement, 2 parts sand and 1 to 2 parts filler.

To increase the resistance to fracture, it is desirable to attach the reinforcing mesh of steel wire and even metal waste: steel pipe, strip, etc add to the mixture a small amount of silicate glue.

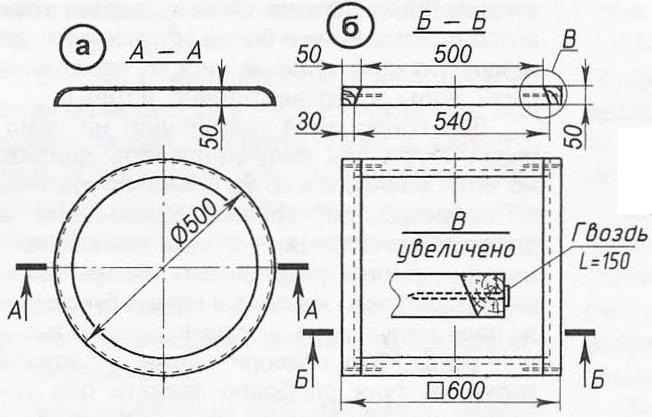

To give the concrete mixture a specific shape of its preservation will require formwork. The most acceptable two ways of its production: from the old tires and wooden bars.

The lateral surface of the tire can be cut ordinary kitchen knife, sharpened it a bit sharper and spraying the cut with water. If tires with steel cord, it is necessary to use an electric cutting machine (angle grinder).

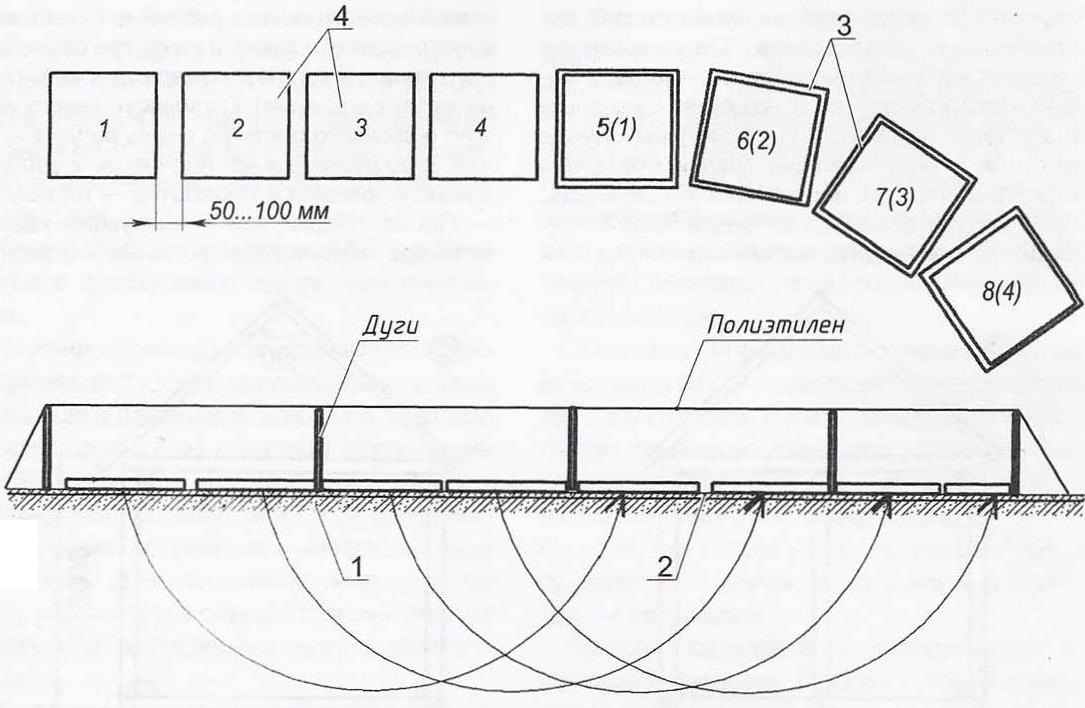

The options of formwork for concrete slabs:

and from of tires;

b — from wooden bars.

The size best suited to the tires of cars “Lada”, “Volga”, UAZ (diameter slabs of this concrete form is 500 — 600 mm), but the hardness more suitable tires from trucks. Having four tires, you can start the process of casting concrete in them. This formwork system is, of course, has its advantages: simplicity of manufacture and maintenance, low cost. But round form of the plates may not be arranged, then arranged for me to go it was convenient for them only strictly in the middle. Therefore, making a few of these boards, decided to move to a square, roughly the same as “squaring the circle” — size 500×500 mm.

For the variant forms produced from pine bruskov by section 50×50 mm. Giving one party a slight slope on a planer and Napili blanks to size and made them a square formwork frame so that the bottom of the inner lower frame size the angle was a bit over the top. This facilitated later removal of forms with barely his concrete slab.

Of course, you can vary the size to meet your needs. Example: 500×600 mm 600×600, 400×600 mm.

Four form-the formwork must be impregnated with oil (can be used) and dry.

Before molding of the track from a homemade boards need to try to level the soil surface, sprinkle on sand cushion thickness of at least 30 mm and compacted.

The technology of laying tracks from monolithic concrete slabs:

1 — soil;

2 — spreading a levelling layer (sand);

3 — formwork (wood 50×50;

4 — slab (monolithic concrete).

Then put all four forms in place, put them on the line and level and begin in order to fill concrete mixture. Completing the last, gently tapping on the form, remove the first and move on the fifth place, to fill with concrete and level. And so on.

One weeknight this technology can make 4 — 8 plates,and if you use a day off — all the 16 — 20!

Upon completion of this “change” form should be well cleaned from the remnants of cement and to wash! The dirty form of dried residues should not be removed from not even a frozen plate without damaging it!

To obtain a smooth (and more durable) slabs can be “salesnet”: sprinkle with cement, if necessary, lightly sprinkle with water and smooth down kelmoj or steel Falcon.

Worn part of the track (already filled with concrete plates) must cover up wrap polyethylene film for protection from accidental stepping from rain or from drying out.

In the following week and wrap should be removed and fresh concrete need to be watered, not letting it dry out, which prevents cracking.

For the final finish of the panels is sanding coarse sandpaper or a rasp treatment acute their outer edges, the crust to the plates of sand to half height.

For the final finish of the panels is sanding coarse sandpaper or a rasp treatment acute their outer edges, the crust to the plates of sand to half height.

The strength of concrete obtained is sufficiently high, and the plate is durable. First like tracks of them for about 15 years!

A creative person there are no obstacles to the production of new, exotic forms!

As for the track pad tracks, I first have arranged them straight, with sharply defined angles of rotation, but then it seemed to me not so comfortable for walking. Therefore, in the future began to design them in the “English style” — on well-trodden paths. By the way, earlier made a round plate gently moved (or rather moved) along the tracks — they now serve as the basis for large flower beds-planters with perennial flowers, which in winter we keep in the cellar.

We wish to work with advantage and I envy you, because we know that, taking us as an example and going to work creatively, you’ll do it much better and more beautiful!

A. MATVEICHUK, Zavodoukovsk