Standing on the armies of NATO, after its establishment, main battle tanks M48 and M-60 though possessing taktikalise characteristics that are consistent with the requirements imposed on them, but were not able to fully resist the new Soviet tanks of the first post-war generation of T-54, T-55, T-62 and it-1.

Standing on the armies of NATO, after its establishment, main battle tanks M48 and M-60 though possessing taktikalise characteristics that are consistent with the requirements imposed on them, but were not able to fully resist the new Soviet tanks of the first post-war generation of T-54, T-55, T-62 and it-1.

A planned modernization of M-48 and M-60, according to the forecasts of Western experts, could not fully compensate for the lag of the Western armored vehicles.

To overcome the backlog in 1963 between the United States and Germany began negotiations aimed at an agreement on the joint development of the project and the production of prototypes of the main battle tank, able to become in the 70-ies of the twentieth century a single tank of NATO.

The Americans believed that participation in the project of the German experts will create a tank, fully fit for combat in Europe and thus fully meet the requirements set by the countries of the Old world to main battle tanks.

August 1, 1963, this agreement was reached. The project managers main battle tank of 70-years (MW-70) was appointed: from the American side — General-major J. Welborn. Dolvin, with the German Dr. Fritz Engelman.

In the same year was formed the joint Committee, whose task included making decisions on all matters relating to the establishment of a new tank. At the direction of the Committee of military and civilian experts of both countries proposed to formulate tactical and technical requirements, which, in their opinion, had to have a new combat vehicle.

Such requirements were submitted to the Committee in early 1964. To conduct a feasibility study of the main parameters of the new tank and their economic effectiveness, the Committee chose the American company “Lockheed missiles and space company.” Specialists of the company used for that purpose computation devices, which, in modern terminology, are called computers. This was the first attempt of its kind in the world tank building.

The technology of carrying out of similar works in brief were: all the tactical and technical requirements for the new tank expressed 69 criteria. As a reference sample, which was carried out a comparison of the MBT-70, chose an American tank M-60. According to Western military experts, it best met the requirements at that time.

Was conducted comprehensive field tests of the tank on a specially designed American and West German designers to the program. Their goal was identifying and fixing all the positive and negative sides of M-60. The results obtained were processed and placed in scenerelease car. After resolving any identified negative aspects were the so-called “upgraded theoretical” tank M-60, which was also subjected to tests, only this time with the help of computing machines.

The most important parameters of the new tank, such as traction, speed, protection, management methods, and many other, expressed in mathematical symbols, introduced in computer. Mathematical models have described, and various tactical situations in which could be the reference tank. All this allowed to assess in detail all of the stated requirements for the new tank in order to begin production of the first production batch of vehicles they were able to accomplish, and at the same time to morally outdated.

In parallel, the project management selected the candidates for the role of the main manufacturers.

After the contest, chose the American company “General motors” and “German research society” (DES).

Research (OR) and development (s) work decided to conduct in two stages. Started in Germany in Augsburg. The second phase was conducted in the USA (Michigan, Warren). When the program is run in Germany by the heads of the working groups was the American specialists, and their deputies — German engineers, After the transfer of works into the U.S. the situation changed to the opposite. This order, according to the leaders of the project, was to speed up decision-making on controversial issues at a higher level. For ease of understanding prepared and released a two-volume dictionary, German-English and English-German terminology which meet the requirements of ongoing joint activities. So, I did everything that issues were resolved in working order.

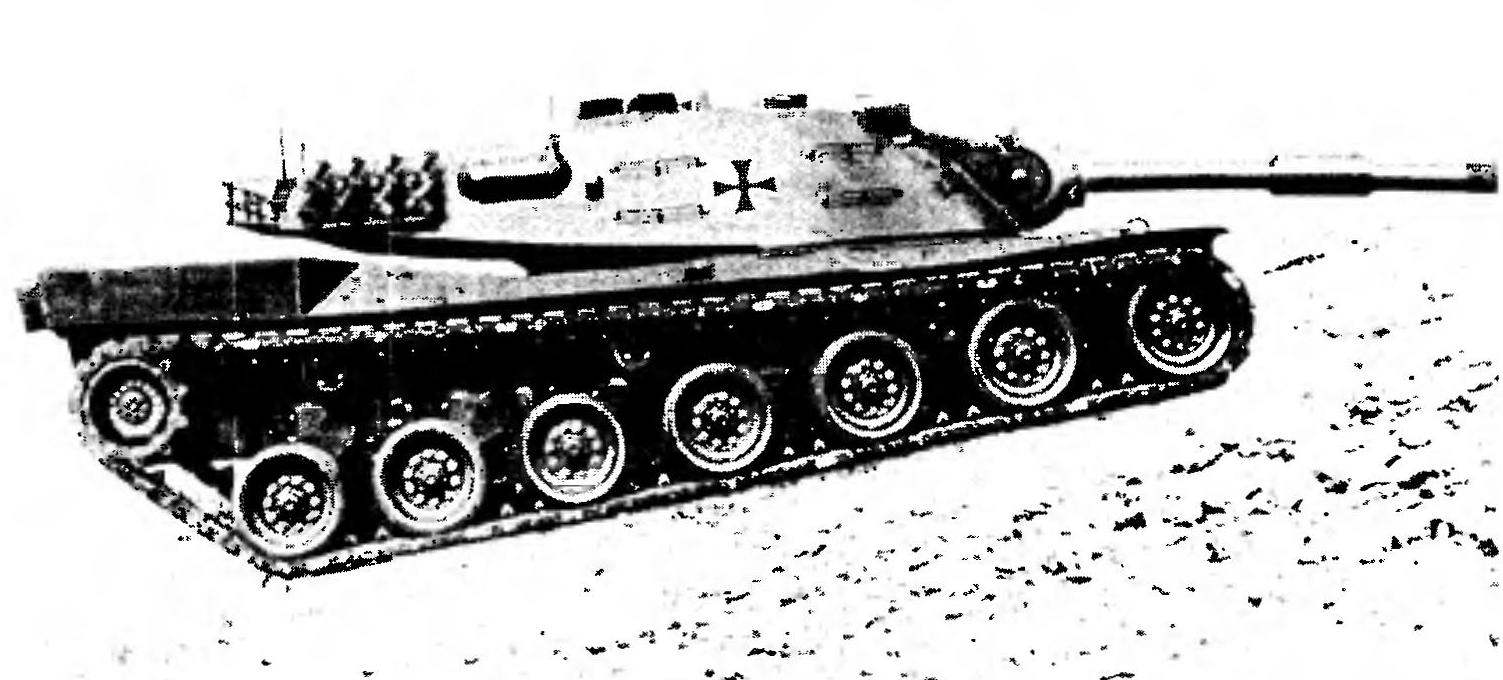

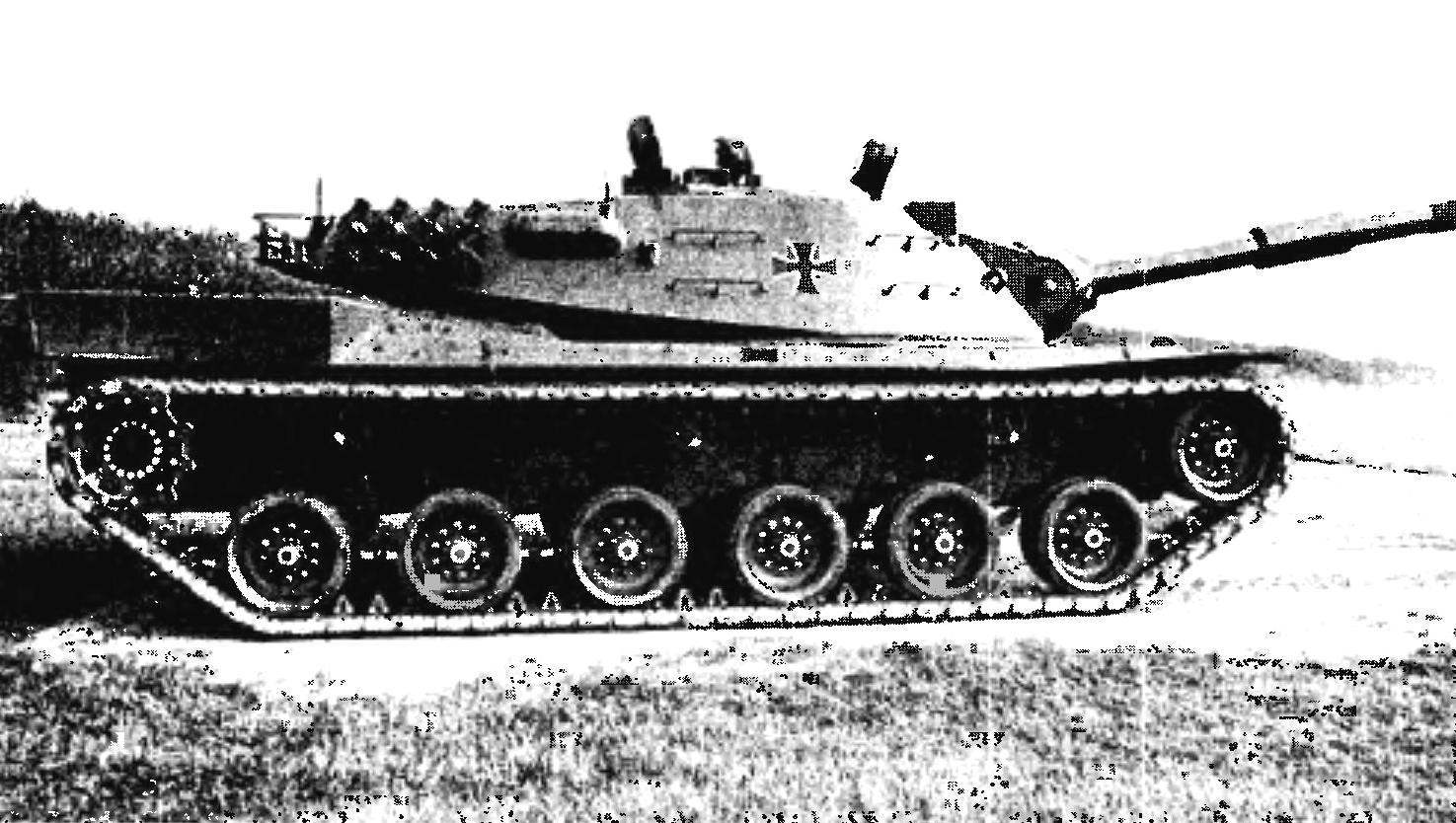

The West German version of the tank MW-70 20-mm automatic anti-aircraft gun in firing position

The West German version of the tank the MBT-70

But sometimes having such problems, the solution of which went beyond the competence of even the leaders of the program and touched on the political and economic spheres

One major issue was which of the two systems to give priority in the new project: European — metric or American inch? West German manufacturers championed the metric system, most of the American firms insisted on using inch.

The dispute reached the level of defence Ministers, where the common Council adopted a compromise solution, whereby all of the Assembly MW-70 must be performed in metric measurement, and the details in the nodes could be performed in both metric and inch dimension, in accordance with the practice of the manufacturer.

During the R & d during 1964 and early 1965 had developed five projects of the new tank, two of them American and three West, which was built of wood, first in 1:10 scale and then in full size.

At this stage, the partners began to have significant differences in views on the main armament for the future tanks that put on the brink of failure, work on the continuation of the joint project.

The essence of the controversy was as follows. According to us, the armament of the new tank was to consist of 152-mm gun-missile system XM-150 to fire conventional 152-mm artillery shells and anti-tank guided missiles (ATGM) “Shillelagh”.

HMM-150 — an analog of the complex XM-81 mounted on the us light tank M-551 Sheridan and medium tank M-60А2, and was its further modernization, during which, inter alia, increased the length of the barrel. This allowed the fire of him not only high-explosive and cumulative, but also armor-piercing projectiles with a detachable tray.

This opinion is not shared in military circles of Germany. The Germans were firmly convinced that, first, the distance for tank battles on the Central European theater of military operations, not so great to use the advantage of the ATGM “Shillelagh” in a relatively high probability of hitting at long range shooting; second, embarrassed by the high cost of the missile, which was between 2,500 to 3,000 dollars, while the cost of a standard 105-mm projectile was equal to about 200 dollars. The Germans insisted on using a specially designed 120-mm rifled gun company “Rheinmetall” with high muzzle velocity, and allowing it to fire the same types of artillery shells that the American complex, but having a higher armor penetration: 40% apcr, and 10 percent shells.

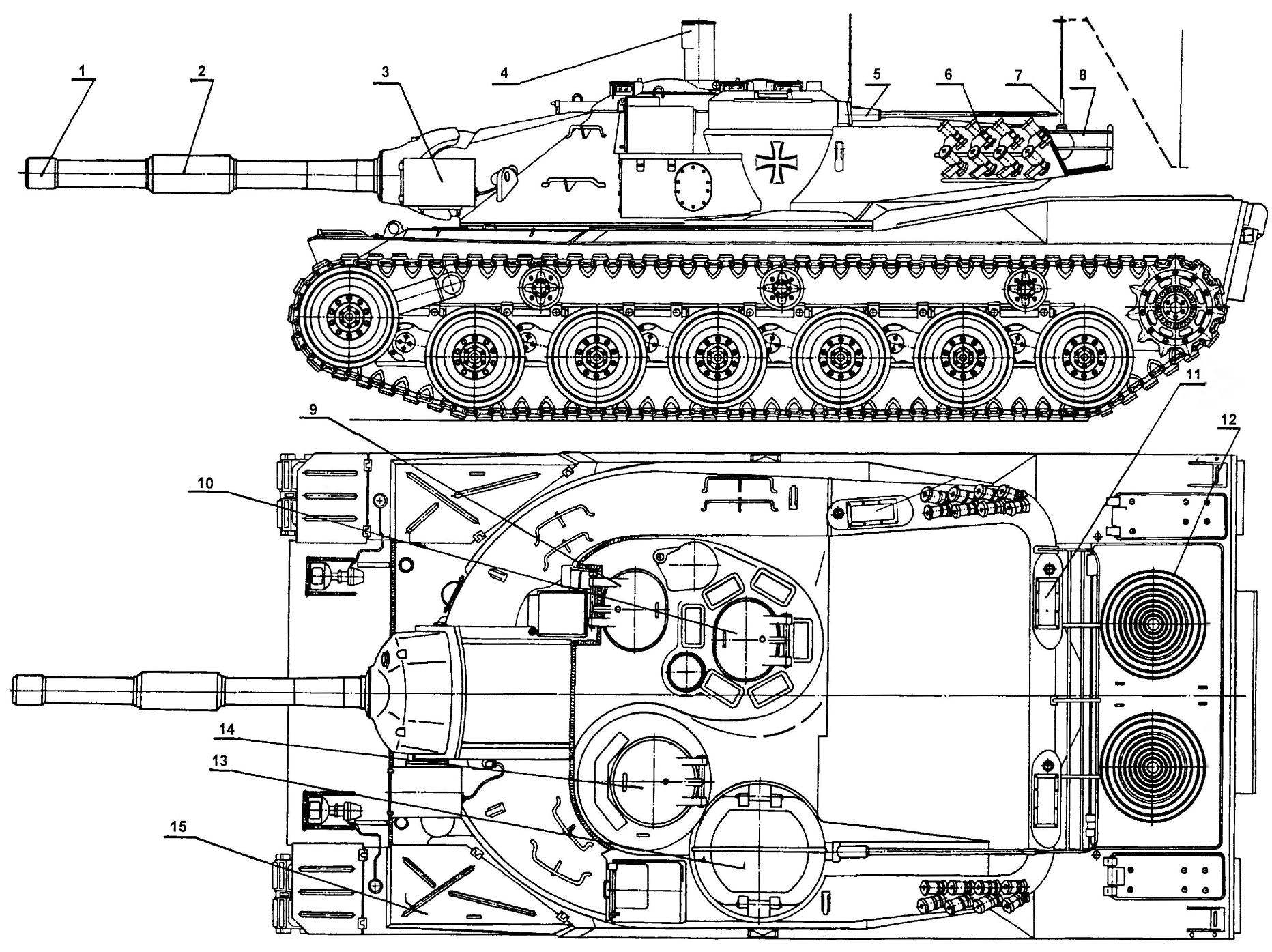

MW-70 20-mm automatic anti-aircraft gun (West German version):

1 — 120-mm gun: 2 — ejector; 3 — infrared illuminator; 4 — panoramic device of the commander; 5 — 20-mm automatic anti-aircraft gun; 6 — smoke grenade launchers; 7 — antenna radios; 8 — shopping for property; 9 — Luke gunner; 10 —the hatch of the tank commander; 11 — insertion of antenna; 12 — ventilation grid 13 — fold hatch 20-mm automatic anti-aircraft gun; 14 — driver’s hatch; 15 — yashik ZIP; 16 — headlights; 17 — viewing device commander; 18— viewing device gunner: 19—recess coaxial machine gun; 20—hole for the gun sight; 21 — viewing device of the driver; 22 — towing eye: 23 — exhaust hole

The belief in the correctness of each party forced the leadership to adopt “a two-tower solution,” which gave the ability to selectively install on the chassis of the MBT-70 tower is a complex of HM-150, and a turret armed with a 120 mm tank gun West German production. In order to simplify the logistics of parts and components of both towers are maximally standardized. Such a solution allows in the future to have in the tank connection tanks with missile and cannon armament, and thus better match the expected conditions of warfare in Europe. It was also agreed that each side will produce their prototypes: American — in a tank factory of the company “Dzheneral the motor” in the city of Cleveland, the German plant of the company “Krauss Maffei” in Munich. The German version of the tank received the name “Skyler” (boar).

In 1966, the successes achieved in the process of work on the project, helped to create chassis layouts and test them. On the layout worked out adjustable hydropneumatic suspension, allowing the tank to gradually change the value of clearance in a wide range.

In October 1967 at the same time in the US and Germany military experts have demonstrated the first prototypes of the tank MBT-70, completing, thus, the four-year phase of the program.

The layout of the tank differed significantly from the classical, previously used in the tanks of the NATO countries. Instead of the usual location of the compartment in the bow of the tank in the car it was located in the fighting compartment near the main armament in the turret on his left. Such a decision the designers made, in an effort to reduce the overall height of the tank. To preserve the position of the driver always face forward in the course of the machine independently of the rotation of the tower he was placed in a special cabin that when the turret is turned in the opposite direction. All the controls of the tank complied with the remote, keypad, electric. The cab driver was located to the left of the main armament on the right side were the gunner and behind him is the tank commander.

Placing the entire crew in the tower made it possible to substantially facilitate the solution of problems related to the creation of the system ensuring its vital functions. This system was developed in Germany, where intensive work in this direction was conducted in the period of the Second world war.

The system consisted of a filter-ventilation unit (HLF) of the company “Dragerpark company”, purifying the air in the crew compartment from contaminated dust, chemical and bacteriological weapons, the installation of air conditioning company “brown, Boveri & C” and the heater of the firm “Webasto company.” This system allowed the tank crew to operate in contaminated areas for a long time without leaving the tank.

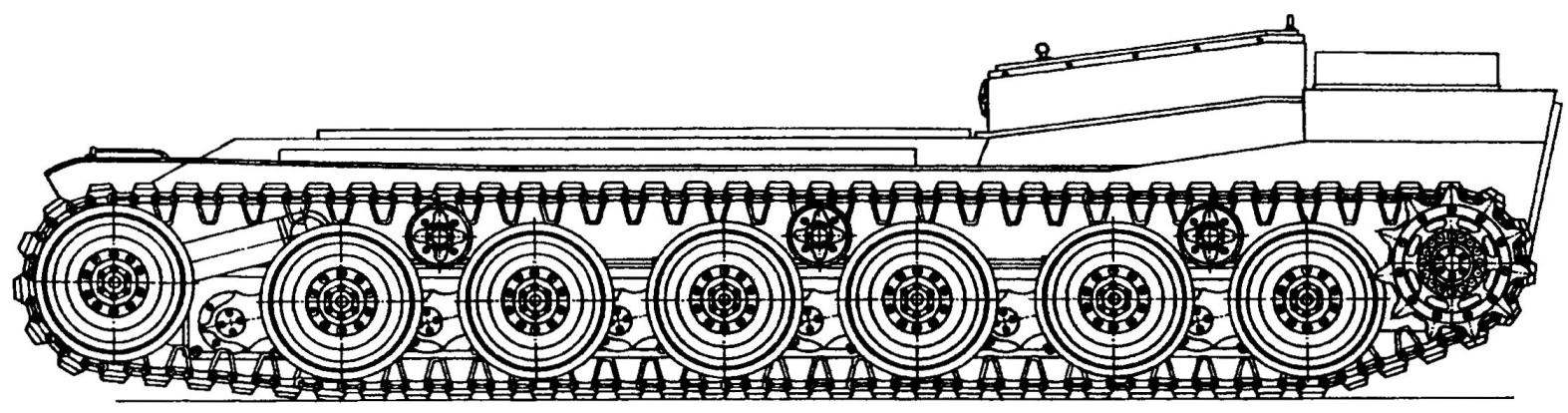

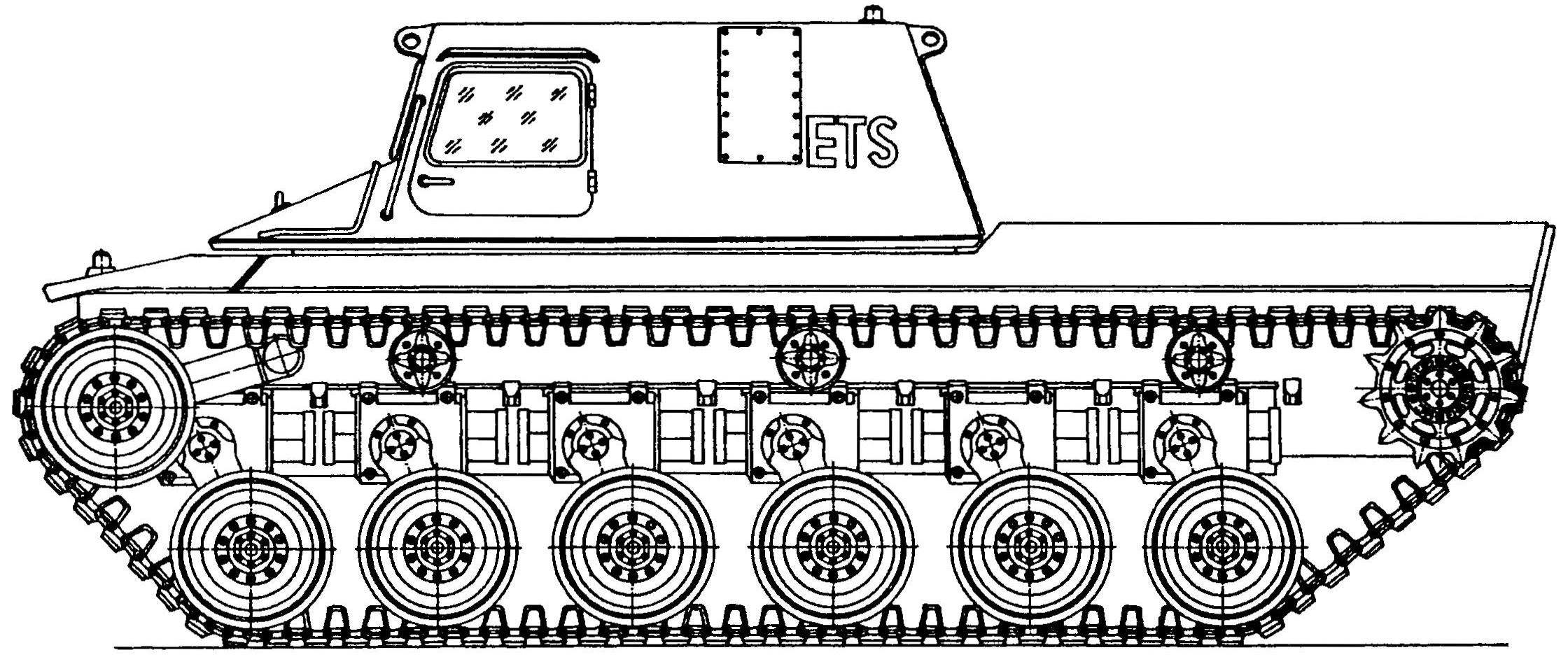

Chassis layout the chassis of the MBT-70 (American version), with a minimum clearance

Chassis layout the chassis of the MBT-70 (West German version) at maximum clearance

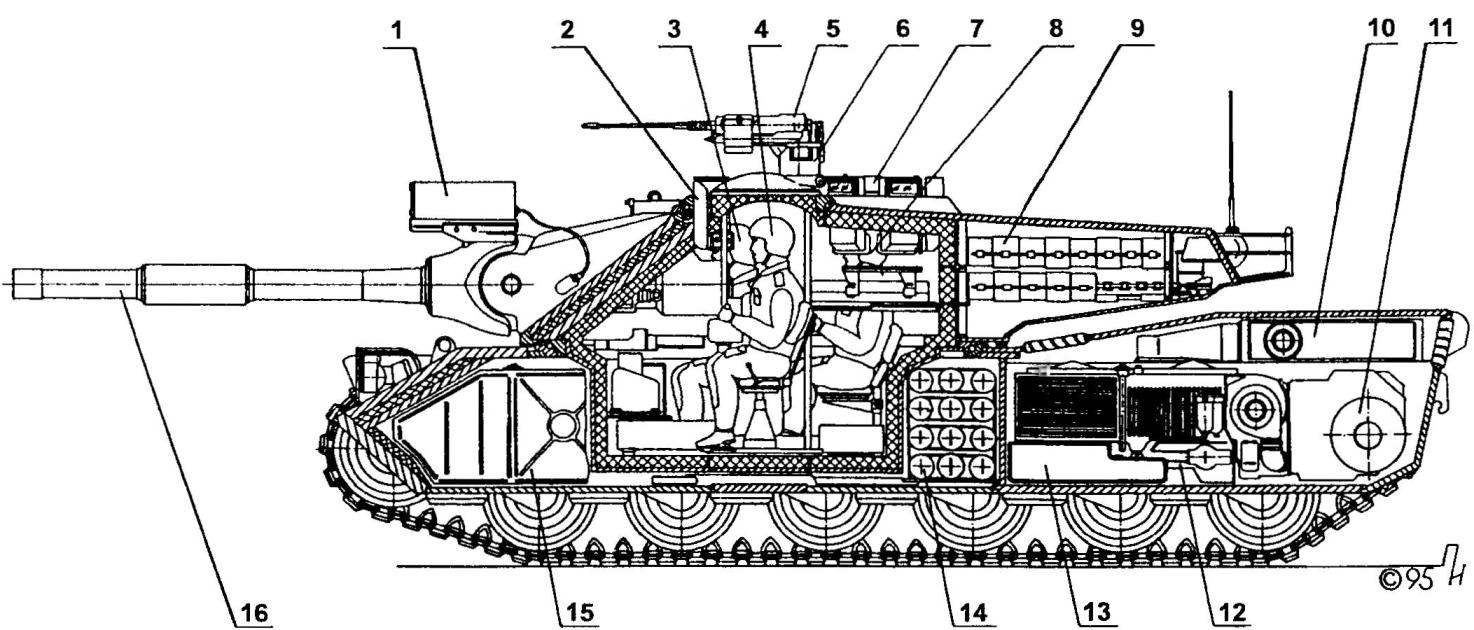

Longitudinal section of the tank XM-803 (simplified American version of the MBT-70):

1 transmitter intensity control ATGM “Shillelagh”; 2— rotating turret of the driver from the observation device; 3 — gunner; 4 — driver; 5 — 12.7 mm anti-aircraft machine gun; 6 — panoramic sight magnification; 7 — hatch commander’s; 8 — commander; 9 — loading mechanism on 25 shots; 10 — air cleaner; 11 — hydromechanical transmission; 12 — diesel engine; 13 — fuel tank; 14 — boeukladki ATGM “Shillelagh”; 15 — main fuel tank; 16 — tool— PU KHM-150 with a rifled barrel

The tower and the body of the tank complied welded from rolled armor plates, and the tower used the bent sheets. This technology was not used since the Second world war, when it was used in the manufacture of “tigers” and “Panthers”.

The commander monitored the area using six still installed periscopes and one stabilized periscope sight rotary type. The commander’s cupola on a tank was absent. All members of the crew had night vision devices. For entry and exit from the tank each crew member was provided a separate hatch.

The main armament of the tank was said earlier, it only remains to add that the use of a clean-burning shells the usual shots of the American complex of the main armament removed the problem of disposing of spent cartridges. To prevent ignition of shots from left after them in coke has been applied to the purge system of the barrel by a jet of carbon dioxide. Tank ammunition for the main armament was 50 shots.

As secondary weapons to engage air and ground lightly armored targets the tank was installed 20-mm automatic cannon Hispano-Suiza with remote control, placing it in a low turret behind of the driver’s hatch. To fire from it could as a commander, and gunner. In addition, the tank is equipped with a coaxial with the main armament 7.62 mm machine gun and smoke and anti-tank rocket launchers mounted on the sides of the tower.

One of the most interesting units of the American version of the tank the MBT-70 was an engine with variable compression ratio, manufactured by the company “Kontinental avian & engineering Corporation”. The ability of the engine to change the compression ratio was based on the principle of hydraulic pistons, first developed by the British research Association for combustion engines (BIGERA). Work on pistons of this type it started in the early 1950-ies. This multi-fuel engine model AVCK-1100-3 with a capacity of 1475 HP 1907 weighed kg.

In Germany, in turn, for their sample MW-70 was developed more difficult, but less difficult multi-fuel engine MW-873 EA-500 liquid cooling capacity of 1500 HP West German company “Daimler-Benz”. The engine in both samples were joined at the flange of the transmission HSWL 354 created by the factory for the manufacture of gears “Renk AG”. The drivetrain consisted of a reversible four-speed transmission with semi-automatic or manual control; hydrodynamic transformer and brake; swing mechanism with a double differential. On a firm level ground in top gear tank developed a speed of over 64 km/h, which in those days was a lot.

Chassis tank had an adjustable hydropneumatic suspension that allows you to raise and lower the body and thereby increase or decrease ground clearance of the tank; raise and lower the stern or bow of the tank and thereby increase the elevation angle main armament in excess of those permitted by the tower; tilt the body of the tank on the right or left side. The first two prototypes of the MBT-70 was set pendant, designed in USA by the “National water lift company (subsidiary of “Pneumo-dynamics korporeyted”), subsequent samples were set pendant, designed in Germany by the company “Frizeke und Hoepfner”. Both systems provided the same course of the hull in a vertical plane to 457 mm, the total height of the tank at a lower position of the suspension was 1976 mm, with the normal position of the suspension — 2280 mm.

The West German version of the tank the MBT-70

The tank was equipped with tracks with rubber-metallic hinge, and removable rubber boots.

The tank had devices for the detection of contamination by radioactive and toxic substances, both inside and outside the tank, the equipment system underwater driving, tanks to overcome water obstacles depth up to 5 meters, emergency kit, navigation equipment and system of identification “friend or foe”.

In the process of project development efforts of experts from both countries was established 34 primary nodes, 10 of them designed by the joint design Bureau, 6 — and 18 American — West German firms.

Serial production of the tank was planned in 1973-1975 when the program is 1500. the Cost of one new sample, according to West German specialists had to make 2.4 million West German marks with a set of XM-150 and 2.2 million West German marks from the 120-mm cannon. Compare with the price being at that time in the Bundeswehr’s tank “Leopard-1”, amounting to 950 thousand West German marks, caused experts cautious attitude to the new miracle tank. So the question is, will the new tank be more effective on the battlefield, in comparison with modern tanks more simple design, from an economic point of view has received a negative response.

The astronomical cost of one sample of the new tank so much effect on the German side, that the latter had unilaterally terminated their participation in further work on the project. The efforts of American experts to save the project and bring it to the end manifested in the further funding of the U.S. Senate under a simplified version of MBT-70, dubbed the XM-803. But senators, frustrated by the lack of triumphant success and exorbitant costs of work done, refused to allocate funds and work on the project is fully turned.

Often such projects end in spectacular displays on military exhibitions and shows. But the expression “negative result — too result” true in all conditions. Tested technical solutions for MW-70 were further used in a purely national projects American tank M-1 and the West German tank “Leopard 2”.

As for such structural solutions as the use of autoloader, guided weapons, and more, Soviet military vehicles, they found a practical embodiment in prototypes and series-produced cars much earlier than their Western counterparts. But this topic deserves a separate discussion.

I. PAVLOV, M. PAVLOV