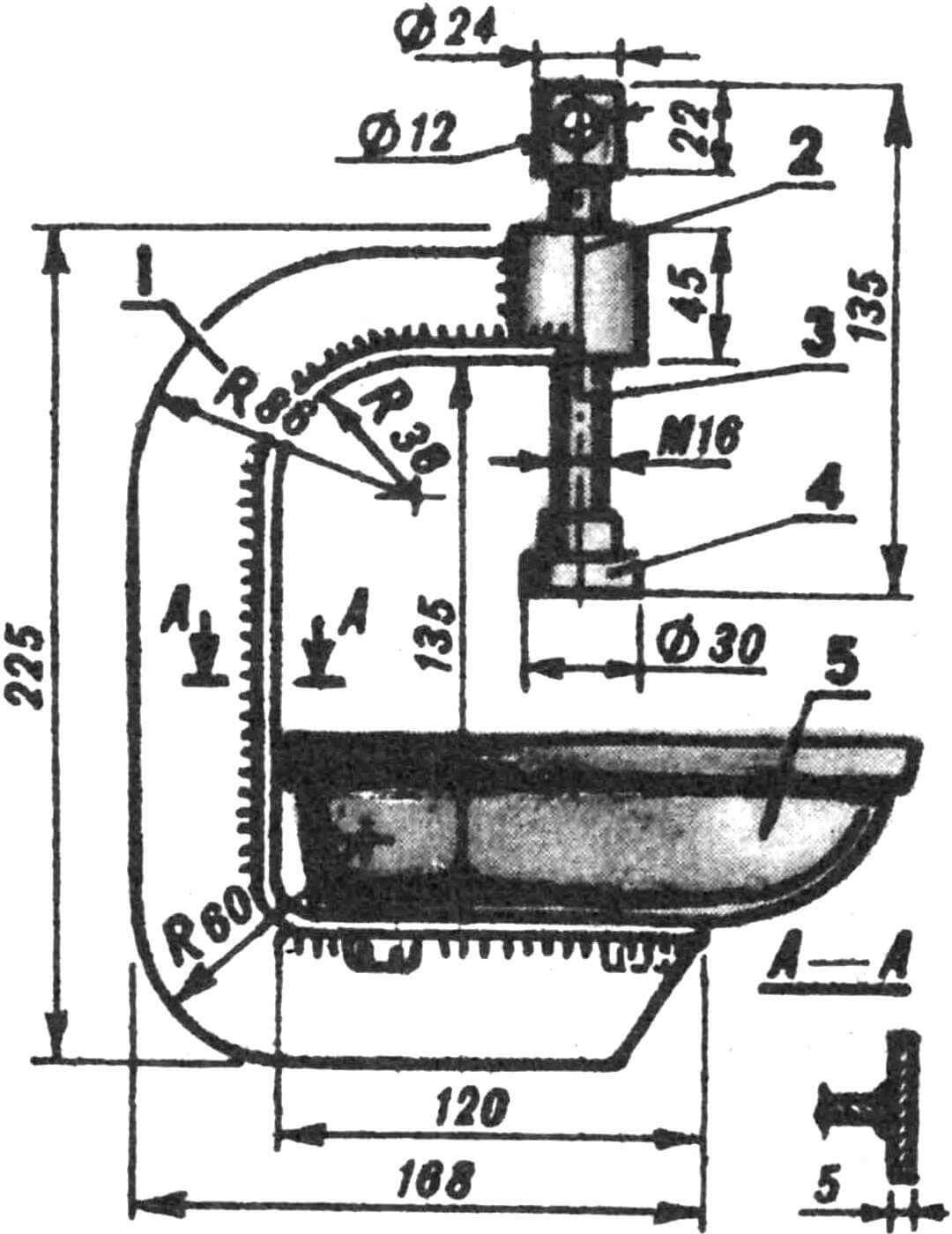

If the electric iron has served its purpose, but the heater in it is still working, use it in a new role – a vulcanizer. It’s not at all difficult to do this. Cut a bracket from five-millimeter steel (see figure), weld a cylindrical boss to it on top, and a strip of metal 50 mm wide along the inside. The cross-section of the resulting clamp should be T-shaped. Drill a hole along the axis of the boss and cut a thread in it for the clamping screw. Then bolt the iron body to the bottom of the clamp – and the vulcanizer is almost ready.

Vulcanizing iron:

1 – clamp bracket, 2 – boss, 3 – clamping screw, 4 – clamping heel, 5 – electric iron.

Now about the technology of work. Let’s say you need to repair a puncture in the inner tube from a motorcycle. Preheat the iron. Wash the prepared puncture site and the raw rubber patch with clean gasoline, connect it, place a sheet of paper (slightly larger than the size of the patch) between the surface of the iron and the raw rubber, and press the whole thing with a screw to the heating surface. After waiting for 7-8 minutes, unplug the iron, and after another 7-10 minutes, release the clamping screw. The patch is ready.

I have been using this device for 15 years now, repairing cameras from cars, motorcycles, and even thin ones from bicycles. I also bake simple gaskets, cuffs and rings, for which I made special molds. Simple devices also allow you to vulcanize a deformed or torn fitting from the chamber.

V. SYSOLOV, Petropavlovsk, Kazakhstan