To get started give examples of calculations of the main design elements.

Thus, the diameter of the rotor of AV-1 is selected from the condition of the load per unit area of the sweeping disk (Ps) in the range of 6-7 kg/m2. This value is taken according to the results of processing statistical data flying light gyroplanes, helicopters, with a specific load (p) in the range of 6— 8 kg/HP In my case, based on anticipated flight weight (t) unit 180-200 kg (empty weight 100-120 kg) and a positioning engine (N) 34 HP, two of which were spent on the drive of the tail rotor, we obtain the following values of load per unit of power, area, sweeping drive NV (Som ) and the diameter of NV (D):

The diameter of 6.04 m NV very close to the size NV of the gyroplane Benzene with engine 40 HP and weighing 190 kg. With such initial data it was hoped that the helicopter will fly. But in order that he could fly as vehicle, you need to pull HB (T) was much greater than the mass of the spacecraft (at least 1.4 times). This provides sufficient vertical climb rate and the altitude of flight.

Now define a calculation of the maximum T on the hover in normal atmosphere (760 mm Hg. article, 18°C). In this case we used the empirical formula:

T= (33,25 N Dn)2/3,

where: p=0,6…0,7 is a coefficient.

In the end, the pull turned out 244,8 kg, which is very close to the actually obtained in the tests of AV-1. (On the basis of these ratios

1,4, in our opinion, poletni. the weight of the apparatus must not exceed 175 kg. — Ed.)

Description for helicopter construction will begin with the so-called fuselage parts.

Compartment the cabin has a truss in the form of a quadrangular pyramid, a vertical side (the main frame) as it separates the cab compartment from the engine. It is made of duralumin (D16T) pipes: vertical and lower—40×1,5 mm, and the front — 30×1,5 mm. Above the cab there is a power connecting element — frame under the main gear, the bottom of the same horizontal cross member engine mounts. The second power rail (seat back) is of duralumin tubes of rectangular section 30x25x1 5 mm; it serves for attachment of the intermediate gear, backrest and assemblies of the main landing gear.

The layout of the helicopter AV-1:

1 — tube receiver air pressure, 2 — control arm of the swashplate, 3 — arm clutch release lever 4 — the instrument panel (tachometer, temperature of the cylinder heads of the engine, speed indicator, variometer), 5 — main gear box, 6 — swash plate, 7 — rotor hub, 8 — control rod swashplate l-shaped, 9 — intermediate shaft 10, the intermediate gear 11— drive chain steering screw, 12—oil tank 13 — belt drive tail rotor, 14 — tail boom braces (D16T, pipe 40x 1,5), 15 — struts (D16T, pipe 20×1), 16 — tail rotor, 17 — prop tail, 18 — beam tail, 19 — electronic unit, 20 — engine, 21 — arm collective pitch control (the”step-gas”), a 22 — strut main landing gear shock-absorbing, 23 — pull collective pitch control, 24 — pulley intermediate, 25 – trimmer, 26 — rod stabilizing goods 27 — pedal unit pitch control of the tail rotor.

Transmission helicopter:

1 — the main rotor hub, 2 — gear main, 3 lever release bearing, 4 — shaft clutch release slotted Cup. 5 — the leading gear of the intermediate gear 6 — shaft drive gear, 7 — Cup, friction-ratchet clutch. 8 — lock release shaft ball bearing, 9 — shaft-spring, 10 — inboard engine, 11 — engine, 12 — flywheel 13 — oil pump, 14— oil tank, 15 — gear driven, 16 — overrunning clutch ratchet, 17 — shaft intermediate, 18—speed sensor rotor, 19 — blade rotor.

Main gear:

1 — the stabilizing rod, 2 —nut M18, 3 — sleeve first fork blade, 4 male couplings NV, 5 —seal, 6 — bearing gimbal ring AP 80018Ю, 7 — ear 8 — AP outer ring 9 — bearing 76-112820Б, 10 — ring propeller (30KHGSA), 11 — AP inner ring (30KHGSA), 12 — bearing 205, 13—shaft-gear lead, 14 — bearing 106, 15 cuff, 16 — ring split, 17—bushing thrust (30KHGSA), 18 — pump screw-oil, 19 stock drive mechanism common step 20 — pull collective pitch control, 21 — nut 22 —homemade thrust bearing, 23 —bearing housing, 24 — rod o, 25 — o-cover, 26 — gear driven, 27 main gear 28, the bearing 109, 29 — main shaft, 30 — spline-drive joints of the outer ring AP, 31 connector sleeve of the second blade 32 — finger couplings NV (30KHGSA, rod Ø 18), 33 — bearing needle self-made, 34 — pull leash of the blade, 35 — fork stem, a 36 — rocker mechanism common step and AP, a 37 — thrust.

The main rotor hub Assembly:

1 —safety pin, 2 — hinge blade, 3 — fork stem mechanism common step, 4 — arm, 5 — pull up, 6 — the stabilizing rod, 7 — thrust, 8 — leash, 9 — outer ring AP.

Sleeve bearing vnta:

1 — leash, 2 — finger, 3 — fork bushing blade, 4 — fork hinge of the blade.

Swash:

1 — main gear box, 2 — thrust, l-shaped (made in concert with POS.8), 3 — ears 4 – slot-drive joints of the outer ring, 5 — bearing housings, gimbal rings, 6 — sleeve coupling the outer ring, 7 — ring gimbal, 8 — ring inner, 9 outer ring, 10 — opposed slot-joint.

The drive mechanism of the tail rotor:

1 — plug coupling tail rotor, 2 — cross, 3 — finger, 4 — way leash from the hinge axis, 5 – thrust, 6 poljushka mechanism pitch control, 7 — axle drive poloski, 8 — pin (45 steel, rod Ø4), 9 — bearing 7000105, 10 — gear case (D16T), 11 — bearing 7000102, 12 — Cup (30KHGSA), 13 — a pulley of the screw.

Bushing steering screw:

1 d — pad (18KH2N4MA), 2 — pin (30KHGSA), 3 — bushing (bronze), 4 — finger thrust, 5 — leash from the hinge axis (30KHGSA), 6 — blade, 7 — Cup blades (30KHGSA), 8 — a sealing rubber ring, 9 — ring retainer.

The blade rotor is:

1,2— draki side rail outer (larch, Northern pine, ash, beech density 0.8 g/cm3), 3 — coat (fiberglass s0,1, two layers), 4 — gorse medium (wedge “in there”), 5 element of the spar (the wedge “in there”) medium, 6 —elements of the outer spar (southern pine, spruce density of 0.25—0.42 g/cm3), 7 — polystyrene (PS, density 0.15 g/cm3) 8 — coating (fiberglass s0,05, two layers, the second layer at an angle of 45° to the axis), 9 — cargo (lead), 10 — coating (fiberglass s0,1, two layers, one layer at an angle to the axis 45е), 11 — rivet, 12 — trimmer.

Blade tail rotor (linear twist):

1 — spar (larch, ash, beech, Nordic pine, density 0.8 g/cm3), 2 — the shank (foam PS), 3 — tube (pine) 4 — balancing weights (lead, Ø8 mm).

“Compartment” of the engine in the form of a trihedral pyramid made of steel pipes (steel 20) section 30x30x1,2 mm. the bottom face has the attachment under the engine, struts, chassis and tail boom.

The tail boom is of riveted duralumin sheet thickness of 1 mm. it Consists of three parts: two cones (diameter at top 57 mm) and a cylinder between them (diameter 130 mm) with outer fins, which serve as reinforcing stringer and the area of the riveting of the shell elements. The attachment points of the braces vkladani reinforcing frames.

tion engine with a working volume of 750 cm3. The crankcase and crankshaft are taken from the motorcycle K-750; pistons, cylinders and heads from the MT-10. Carter’s light weight and adapted for use with a vertical shaft (modified oil system). It is possible to use other engines, gross weight not exceeding 40 kg and a capacity of at least 35 HP

Special mention should be made of the stabilization system of the apparatus. On the AV-1 applied type system “BELL”, but with a higher stabilization factor (0,85), which almost completely relieves the pilot of concern about balancing the helicopter in hover mode. Moreover, it limits the angular velocity in curves, protecting the helicopter from overloads. Handling is thus ensured by the shape of the goods in the form of flat disks (chosen experimentally). The length of the rods is chosen from the condition that the goods in the form of flat disks should have a good “sit” in the flow. Therefore, the circumferential speed of the goods selected 70 m/s, and at 600 rpm this corresponds to the length (radius) core, close to 1 m. the Mass of the load was chosen from the condition that when the deviation of the plane of rotation of the stabilizing rods from the plane of NV 1.5°-2° should be the point which when passing through the lever mechanism to the axial hinge of the blade is equal to NV (or more) the friction torque in the bearings of the hinge axis under working axial loads.

The main gearbox is designed to transmit torque to the shaft of the rotor. Inside it is the stock collective pitch control mechanism of NV. He ends with a plug that its lateral projections included in engagement with the plugs of the plugs of the blades, the rotating mechanism of the stabilization system. During vertical movement of the rod (arm) using the leverage mechanism of collective pitch changes the angle of installation of blades (and therefore its pitch). On the top cover of the gearbox housing includes a swash plate (AP), used to change the position of the plane (actually a cone) of rotation of the LC relative to the vertical axis of the apparatus (the axis of the main shaft of the gearbox) due to the opposite signs of changes in the angle of attack of the blades: the angle of attack of the blade going down, decreases going up and increases. Thus there is a change in the magnitude and direction of the horizontal component of the thrust vector NV.

The gear case split on the plane perpendicular to the axis of the shaft is welded of sheet steel 30KHGSA with a thickness of 1.3 mm. bearing housings also machined from steel 30KHGSA welded to the cover, and then produced by heat treatment (“tempering”, the high holidays), to relieve stresses and increase strength. Then progressirovanii flanges, assembled the cover and the machined seats of the bearings and the holes on the coordinate machine. The bottom cover is made of alloy D16T.

Main shaft is made of steel 40HNMA, peel plies are treated to Gвр -110 kg/mm2. Shaft diameter -45 mm, diameter of inner hole is 39 mm, the wall thickness in the area of the splines of the hub HB — 5 mm. shaft Surface is polished, slots and landing bearings madnani.

The driven gear and drive shaft gear — steel 14ХГСН2МА-W and have respectively 47 and 12 teeth with module 3 and an angle of 28°. Teeth cemented to a depth of 0.8—1.2 mm and termoobrabotannyj to hardness HRC = 59 to 61.

The outer ring of the swashplate split (as a collar), made of alloy D16T (milled from a sheet thickness of 35 mm) and the inner ring and the propeller — steel 30KHGSA. Bearings gimbal ring — 8001 OCCUPIES 8. Bearing-warp machine — 76-112820Б.

Module tail rotor (PB) collected on the glass, telescopically connected to the tip of the tail boom. He can be nominated for

The front landing gear svobodnovihrevye, without depreciation, has a wheel 250×50 mm (from skis). The main landing gear is made of steel tubing and is equipped with pneumatic shock absorbers. Wheel main landing — 300×100 mm with cut protector (map). This “haircut” is to reduce weight, improve aerodynamics and ease of movement “skidded” on the grass during training or in case of unsuccessful plantings. Lower chassis bracing — steel pipe 20×1 mm.

The machine is equipped with four-stroke two-cylinder boxer engine with a working volume of 750 cm3. The crankcase and crankshaft are taken from the motorcycle K-750; pistons, cylinders and heads from the MT-10. Carter’s light weight and adapted for use with a vertical shaft (modified oil system). It is possible to use other engines, gross weight not exceeding 40 kg and a capacity of at least 35 HP

Special mention should be made of the stabilization system of the apparatus. On the AV-1 applied type system “BELL”, but with a higher stabilization factor (0,85), which almost completely relieves the pilot of concern about balancing the helicopter in hover mode. Moreover, it limits the angular velocity in curves, protecting the helicopter from overloads. Handling is thus ensured by the shape of the goods in the form of flat disks (chosen experimentally). The length of the rods is chosen from the condition that the goods in the form of flat disks should have a good “sit” in the flow. Therefore, the circumferential speed of the goods selected 70 m/s, and at 600 rpm this corresponds to the length (radius) core, close to 1 m. the Mass of the load was chosen from the condition that when the deviation of the plane of rotation of the stabilizing rods from the plane of NV 1.5°-2° should be the point which when passing through the lever mechanism to the axial hinge of the blade is equal to NV (or more) the friction torque in the bearings of the hinge axis under working axial loads.

The main gearbox is designed to transmit torque to the shaft of the rotor. Inside it is the stock collective pitch control mechanism of NV. He ends with a plug that its lateral projections included in engagement with the plugs of the plugs of the blades, the rotating mechanism of the stabilization system. During vertical movement of the rod (arm) using the leverage mechanism of collective pitch changes the angle of installation of blades (and therefore its pitch). On the top cover of the gearbox housing includes a swash plate (AP), used to change the position of the plane (actually a cone) of rotation of the LC relative to the vertical axis of the apparatus (the axis of the main shaft of the gearbox) due to the opposite signs of changes in the angle of attack of the blades: the angle of attack of the blade going down, decreases going up and increases. Thus there is a change in the magnitude and direction of the horizontal component of the thrust vector NV.

The gear case split on the plane perpendicular to the axis of the shaft is welded of sheet steel 30KHGSA with a thickness of 1.3 mm. bearing housings also machined from steel 30KHGSA welded to the cover, and then produced by heat treatment (“tempering”, the high holidays), to relieve stresses and increase strength. Then progressirovanii flanges, assembled the cover and the machined seats of the bearings and the holes on the coordinate machine. The bottom cover is made of alloy D16T.

Main shaft is made of steel 40HNMA, peel plies are treated to Gвр -110 kg/mm2. Shaft diameter -45 mm, diameter of inner hole is 39 mm, the wall thickness in the area of the splines of the hub HB — 5 mm. shaft Surface is polished, slots and landing bearings madnani.

The driven gear and drive shaft gear — steel 14ХГСН2МА-W and have respectively 47 and 12 teeth with module 3 and an angle of 28°. Teeth cemented to a depth of 0.8—1.2 mm and termoobrabotannyj to hardness HRC = 59 to 61.

The outer ring of the swashplate split (as a collar), made of alloy D16T (milled from a sheet thickness of 35 mm) and the inner ring and the propeller — steel 30KHGSA. Bearings gimbal ring — 8001 OCCUPIES 8. Bearing-warp machine — 76-112820Б.

Module tail rotor (PB) collected on the glass, telescopically connected to the tip of the tail boom. It can advance to tension the timing belt. In this case, however, you need to rebuild the length of the control cables tail rotor. The drive is carried out from the intermediate gear via a chain and two belt drives.

Steering screw — hinge (has a combined horizontal and axial joints) rotates upwards from front to back. Its diameter is 1.2 m, the number of revolutions per minute is 2500.

Bushing RV consists of the d-pad and two glasses, riveted blades. As axial bearings serve two bronze bushings, centrifugal force takes thread М24х1,5. The seal is a rubber ring which is fixed with washer and spring ring. Leashes the hinge axis offset from the axis of the horizontal hinge (GSH) at 30°. Lubrication oil MS-20 is poured into the glass before Assembly.

A horizontal hinge is assembled with bronze bushings and cemented finger, which is fixed on a fork of GSH from twisting.

During Assembly of the blades with a glass, special attention was paid to the alignment of their axes.

Now a little about the choice of the main parameters of the blades of the propellers.

Mean aerodynamic chord (MAR) of the blade is calculated from the condition that the fill factor of the sweeping disk (K) will be within 0,025—0,035 (lower value for high peripheral speeds of 200-220 m/s; and large — for smaller, 170-190 m/s), according to the formula:

bmin = (SHB K)/DHB ;

where bmin— the minimum of the SAH.

TECHNICAL CHARACTERISTICS OF THE HELICOPTER AV-1

Weight, kg

empty……………………115

flight…………….200-220

Height, m…………………….2

Length, m……………………5

The diameter of NV, m……………….. 6

The speed of descent

autorotation, m/s…………3

The rate of climb, m/s………..3,5

Speed km/h

maximum………………100

cruising………………..80

Helicopter AV-1 to the rotor value of the coefficient K = 0,028, since the circumferential speed is selected in the range of 190-210 m/s. thus SAH is taken equal to 140 mm.

On the aircraft it is desirable to have all very easy. But with respect to NV, we can talk about the minimum allowable weight, as the weight of the blade depends on the centrifugal force needed to create a cone of rotation of the rotor. It is desirable that the cone was in the range of 1°-3°.

To make the blade with a mass of 2-3 kg is unlikely and even undesirable, as it will be a small amount of kinetic energy in an emergency landing in autorotation with the erosion, as well as during the transition to autorotation motor of the flight. Weight 7-8 kg for the emergency case is good, but at peak revs NV will have a significant centrifugal force.

On the AV-1 applied to the blade mass from 4.6 to 5.2 kg, which provides a maximum load from centrifugal forces up to 3600 kg. The strength of the sleeve HB is designed for this strain (7-fold margin of safety); its mass is 4.5 kg.

The proposed form of the blade twist and plan — the result of experiments with blades of different shapes, twists, and profiles.

HB blades has to satisfy two contradictory requirements: good automotivate (i.e. to ensure a low rate of descent in autorotation with engine failure) and with maximum efficiency to use the engine’s power to the motor flight (climb, top speed and economy).

Consider blades for helicopter and gyroplane.

Good gyro twist about. the inverse, that is, the installation angle of the blade from butt to negative (-5°…-8°), and the terminal segment positive (+2°). Profile PLANO-convex or S-shaped. Currently widely used the airfoil NACA 8-H-12 (S-shaped, 12%). The shape of the blade plan is rectangular.

A good twist of the helicopter video, that is, the butt angle is positive (+8°.. .+12°) towards the end of the plot. The NACA 23012 profile, the relative thickness of which at the end — 12%, and butt — 15%. The shape of the blade plan is trapezoidal, narrowing from 2.4 to 2.7.

Calculations were made of the shape of the blade in terms of the finite element method for the case of flight at a speed of 110 km/h and overload reserve of the blade, “going back” —

1,4. If the rpm is HB 580 rpm, the diameter HB of 6 m and a flight weight of 200 kg turned the blade width at the end of 80 mm, and the butt 270mm (narrowing to 3.4). The extra width of the blade at the end leads to unnecessary loss of engine output to overcome the turbulent resistance profile, and therefore beneficial to minimize wetted surface areas, operating at high speeds.

On the other hand, in order to have the stock lift on the end portions of the blade when stageline NV or when switching to autorotation (the most probable error of piloting by the pilot), it is necessary to have the blades slightly wider than the calculated.

I have made the narrowing of the blade 2, root chord 220 mm, and the limit is 110 mm. in order to reconcile helicopter with gyro in one unit, had to use a blade without twist.

More complicated profiles. The end portion of the blade (Rотн = 1 — 0,73) has a NACA 23012 profile with a relative thickness of 12%. Plot Rотн = 0,73—0,5 — transition profile NACA 23012 to a NACA 8-H-12, ‘ but without the S-shaped tail.

Plot Rотн = 0,5—0,1 a profile TO|AU 8-N-12 variable relative thickness of 12% on Rотн = 0.5 and 15% on Rотн = 0,3—0,1. This blade pulls well in all flight modes. Autorotation resulting rate of descent of the helicopter 2,5 m/s When the test was performed autorotation landing without detonating, braking is carried out by pitch and vertical speed was suppressed to zero and the mileage was only about 3 m.

An ultralight helicopter in case of engine failure, the transmission of RV is disconnected, since the drive requires the energy generated authorityrules NV that would worsen the autorotation and increased rate of descent. Therefore, for RV no need for symmetrical profile of the blades. It is best to choose a PLANO-convex type R3. To improve efficiency it is desirable to apply the twist (8°). In addition, to improve the efficiency of the screw shape of the blade plan is desirable to have a trapezoid with a contraction equal to 2 and fill factor sweeping drive within 0,08—0,06. Good results are obtained also profile a PASS 64А610-and it was 0.4 with a relative thickness of 12%.

To make the blade possible using different technologies. For example, from solid pine boards. As presets are selected two boards from straight grained, without knots, pine, medium density, cut to the dense layers faces toward a future leading edge and went at a 45° angle. The Board is profiled on the pattern reduced by the thickness of gluing fiberglass and painting (of 0.8—1.0 mm). After finishing the tail portion of the part is facilitated. For this layout stand out spar portion and the trailing edge. Spar part at the butt is 45% of chord, and the limit is 20%.

Then drilled holes with a diameter equal to the distance from the trailing edge to the spar with a step of 40— 50 mm. and then the openings are filled with rigid foam PS or PVC, sanded flush and pasted with fiberglass. The butt part is usually glued in several layers, with a smooth transition to the main canvas.

Another method of manufacturing blades from a few gorse. Billet wikiepedia of three to four gorse, which may be solid or strips glued two strips of different density. Spar part Drake is desirably made of birch or larch. First of the two rails glued billet droki thickness three times more fine. Then she cuts it into two and processed to the desired thickness. While spar part different the broom of the blade is of different widths (10— 15 mm) for binding. You can also glue the spar of 3-4 gorse and tail section — from one or two. After profiling the front edge you need to paste anti-flatter load on length of 0.35 R from the end of the blade, as the flutter affected mostly the end portions of the blades.

The goods are made of lead or soft steel. After gluing it is processed according to the profile and additionally prihvatyvaya to drogam longitudinal strip of fiberglass epoxy resin. After that the whole lobe to paste over the fiberglass.

During manufacture of the blade it is necessary to constantly monitor the weight of the parts in order after Assembly and processing of the mass of the blade as little as possible different from the estimated.

V. ARTEMCHUK,

Zhytomyr

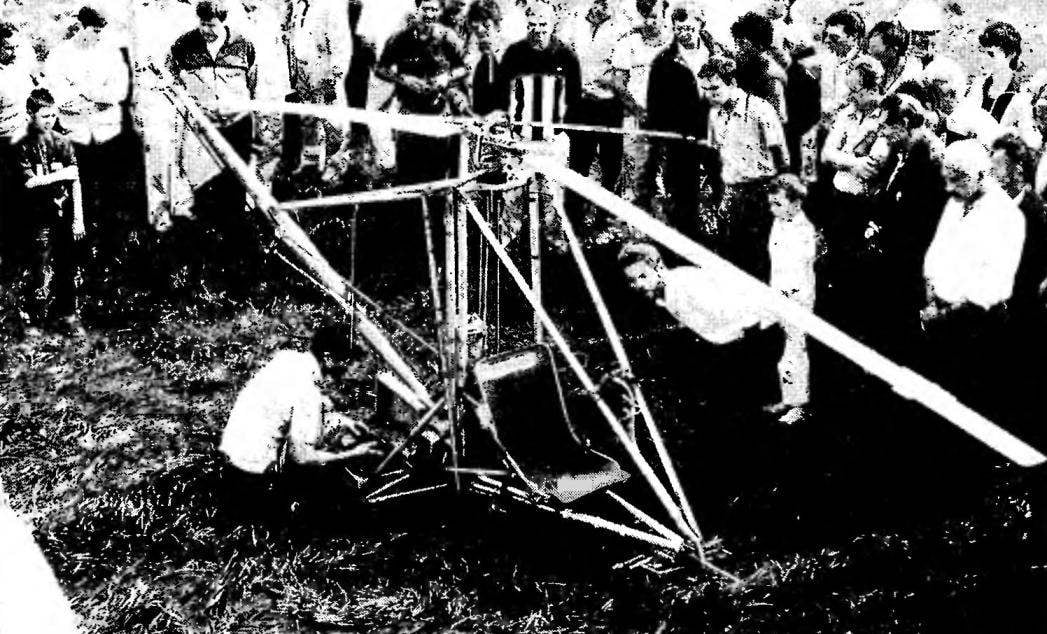

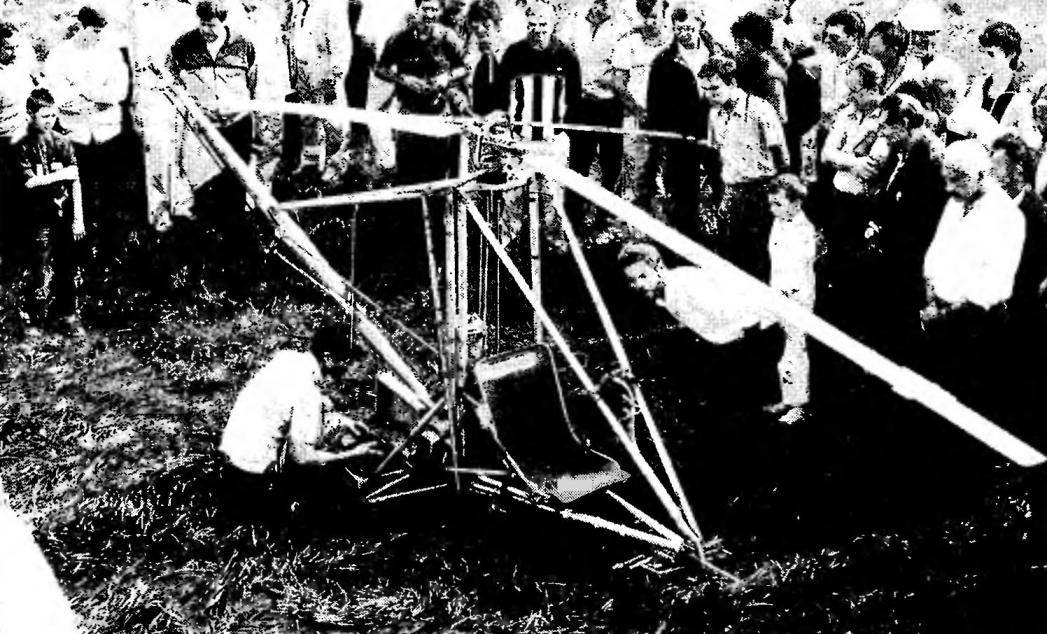

Recommend to read SKI OR CATAMARAN? The boats, which we would like to introduce to the readers, it can be attributed to the category of small vessels. And how else to call a couple of universal self-propelled floats, which... “COMPACT-800” — Engine for UAV Numerous gatherings of amateur aircraft designers brought together hundreds of small aviation enthusiasts, and this clearly showed that interest in designing amateur aircraft is...  Dear fans of aviation! This article may be useful for the development and construction of a light helicopter. Offer – to rotary-wing aircraft (AV-1) is the fruit of a long fascination with aviation, the result of persistent and laborious work for five years, of which two years was spent on construction and the rest for testing, debugging, development piloting, repair, upgrades.

Dear fans of aviation! This article may be useful for the development and construction of a light helicopter. Offer – to rotary-wing aircraft (AV-1) is the fruit of a long fascination with aviation, the result of persistent and laborious work for five years, of which two years was spent on construction and the rest for testing, debugging, development piloting, repair, upgrades.