Labor traditions of the older generation of “Rostselmash” continues young. In creating the “Dona” the active participation of young specialists of the design Bureau, their peers in the experimental shop. Komsomol organization of the Association is a patron of the production of prototypes of the new machine. Nineteen youth teams of CB working to improve its parts. Komsomol members together with their older colleagues developed the original steering column, Domracheva device, threshing drum and other mechanisms.

The need to create a new family of cars has arisen due to the fact that the harvesters “Niva” is not always able to cope with the volume of harvesting, which falls to their share. In small fields “field” shows perfectly, but when it is necessary to remove thousands of hectares of grain, it restrains the pace of the harvest. In addition, cleaning is often carried out in difficult weather conditions, during the lodging of crops. To harvest huge areas of grain lands of our country on time and without loss only a powerful modern technology. Significantly increase output per shift of grain cars and will help harvesters “don-1200” and “don-1500” width grind 1200 and 1500 mm. They will be the basic designs on the basis of which will create modifications to the black earth and the harvest on the slopes. Created devices through which the “don” can get not only bread, but corn, sunflower, soy, cereals.

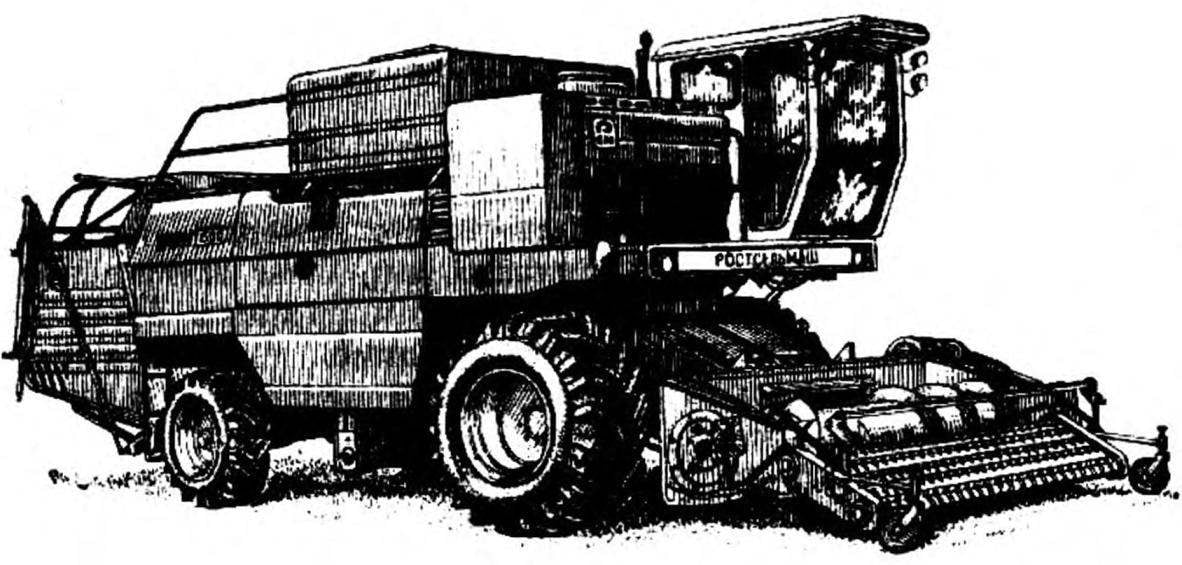

Self-propelled combine harvester “don” (simplified layout):

1 — reel, 2 — conveyor, 3 — threshing cylinder, 4 — engine, 5 — bounce-flail, 6 — vibrator, 7 — distribution screw, 8 — bunker, 9 — straw Walker, 10 — solomonashvili, 11 — rod, 12 — stacker differently, 13 the fingers of the stacker differently, 14 — demolicious device 15, and the upper and lower cleaning sieve, 16 — fan 17 — auger, 18 — grain weight, 19 — AA-bitter, 20 — auger header, 21 — cutting machine.

A distinctive feature of the new combine — harvester wide-cut to the same fit for low bread. If cleaning is carried out using split method, the harvesters are equipped with a wider sphere of rolls. These devices increase the efficiency of grain harvesting per shift.

For processing of large amounts of bread weight of “Dona” increased size of drum up to 800 mm in diameter. It can clean up to 9 kg mass and the second. “Niva” during this time, handles only 5 kg.

An important part of any combine hopper of grain. It is the size of the new machine 6 m3 which is two times more than the “Field”. Thanks to the hopper increased capacity “don” rarely stops for unloading grain into a truck body.

Engine “Dona” — diesel with a capacity of either 160 or 220 HP, the Chassis can be equipped with mechanical or hydraulic drive. The latter increases the efficiency of the motor, providing variable speed control.

Important feature of “the don”, which will be appreciated by the operators, is increased in comparison with the “Kolos” and “Niva” permeability. Tires, specially designed for combine harvester, can be cleaned in any weather, on the sticky soils. On the highway they kept speed to 20 km/h.

Great attention in the design of “don” our specialists is paid to creation of comfortable working conditions for the driver. Combine behind the wheel of the car, fired scorching rays of the sun and blown by hot winds — an indispensable character in the newsreels of yesteryear. A modern processor without a comfortable driver’s cabin it is impossible to imagine. For example, “don” it is fully sealed and is mounted high above the ground. It reduces its dust. From the heat of the driver save tinted glass lighting and air conditioning. In the cab for the operator is created for maximum comfort. Steering column, changing the angle, soft sprung seat, well-positioned levers and instrument panel significantly increase the productivity of labor.

The first harvesting machine is equipped with an electronic control system for operation of separate units and mechanisms. For example, if you start to slip belt transmission, an electronic sensor will immediately notify the driver in the cab will display a warning display or an alarm will sound. Similarly, the system monitors the technological processes of processing of grain. With its help, the combiner knows in advance about the overload of that particular unit. Changing the mode of operation of the mechanisms, it can prevent them from breakage. In the end, increases machine reliability, reduces the time it repairs.

Prototypes of the harvesters, is being tested under field conditions showed a high efficiency of cleaning of grain crops. “Don” bandwidth by 60-80% more than in the Niva. This significantly reduced loss of grain. The mechanics who worked on the new machine, unanimous in its high productivity and good working conditions of the combine. This year at our laboratory will be collected 25 harvesters “don”.

“Don” is intended for harvesting cereals direct and separate combine harvesting in all zones of our country. For direct combining, it has a header with a width of 6.7 and 8.6 m, with separate used four-meter platform podborski K.

“Don-1200” grind 1200 mm wide, “don-1500” 1500 mm. in addition, they are equipped with a hopper with the device of unloading of grain and devices for cleaning netherne-hand side of the crop. The threshing device is complemented by an automatic mechanism of a tension of a CVT that can handle bread a lot of high humidity without worrying That it will clog the drum.

Motor installation and power transfer drive mechanisms of grain handling and chassis of the harvester. He operated by one man from the cab on the left side of the thresher.

During operation of the harvester reel the harvester brings the stems of oats or wheat to the cutter bar. Cut the ears of corn are served by the screw to the center of the header, and then an inclined conveyor to the threshing drum. During harvest the bulk of the grain together with sexual wakes up through the grate to stryasnuyu Board. The straw with the remaining spikelets is served with a reflex beater straw walkers, where there is a further separation of grain FROM CHAFF.

The keys of the straw walkers moves soy WMD to the exit of the grind, and then it falls into the chamber of the stacker differently with a capacity of 16 m3, where it is pressed or crushed. Grain mixture that got on stryasnuyu Board is transported, and upper grille.

The grain under the action of the air strum of the fan and the oscillating motion of the sieves falls down and the chaff blown out of the thresher through the tray polemoniales enters the stacker differently.

The remaining spikes, moving along the sieve, fall in Kolosova auger, which directs them to the Elevator Domracheva of the device, where they re-oborachivaetsya.

Ready the cleaned grain falls into the grain auger, and then the Elevator rises in the auger hopper. From there it is poured unloading auger in the body of the car. On filling the hopper of the combine signals the flasher mounted on its upper part.

Main unit processor — power plant, consisting of combustion engine and of the systems supporting its work. “Don-1200” engine SMD-23 (160 HP) and “don-1500” SMD-31 (220 HP). This V-shaped four – and six-cylinder diesel with turbocharging and intermediate cooling of air.

From the engine a large part of the flow of power goes to drive the working bodies and the smaller one on the wheel.

A new car, you drive to the front wheels. It can be conventional, mechanical or hydraulic. The latter provides infinitely variable speeds. Their range is from 0.7 to 19.8 km/h meets the requirements of agriculture.

High permeability ensure the tire low pressure c increased the grouser. The rotation of the harvester is carried out with the steered wheels of the rear axle.

I. MESCHERYAKOV, chief designer of the “Rostselmash”

Recommend to read SWEDISH MAIN BATTLE TANK After world war II in tank to establish a relatively strict classification. Steel tanks called armored combat vehicle on tracks with a cannon placed in a rotating turret.... OR ICE For a uniform bending of the tubing, especially thin-walled, usually filled with sand. But it may happen that at the right moment it will not be on hand. In this case, it is possible to...  One of the most important areas of the struggle for increasing productivity and reducing crop losses — improving harvest equipment. Performing Food-ing program of the USSR, adopted at the may (1982) Plenum of the Central Committee of the CPSU, the production Association “Rostselmash” in Rostov-on-don is preparing to release a new model of combine harvesters.

One of the most important areas of the struggle for increasing productivity and reducing crop losses — improving harvest equipment. Performing Food-ing program of the USSR, adopted at the may (1982) Plenum of the Central Committee of the CPSU, the production Association “Rostselmash” in Rostov-on-don is preparing to release a new model of combine harvesters.