Winter fishing — an occupation for the most persistent. Try-ka in the cold to spend the whole day at the wells — there will not save any coat, no tent, no “forty degrees warmer”. However, indulge in a favorite hobby can be and in a comfortable environment. You only need to get a special all-terrain vehicle on low pressure tires with a closed heated cabin, in which all fit for his beloved winter fishing.

Winter fishing — an occupation for the most persistent. Try-ka in the cold to spend the whole day at the wells — there will not save any coat, no tent, no “forty degrees warmer”. However, indulge in a favorite hobby can be and in a comfortable environment. You only need to get a special all-terrain vehicle on low pressure tires with a closed heated cabin, in which all fit for his beloved winter fishing.

The Rover, dubbed “comfy” was developed on the basis of the engine from a cargo scooter TG-200M. Experience shows that this motor is one of the most reliable among domestic two-stroke engines equipped with dynastream and forced air cooling. The front and rear axles, main gear (reverse gear with differential), brakes and steering systems used on motorized wheelchairs С3Д. The transmission of torque from the engine to the wheels is through roller chain on the reverse gear (main gear from motorized С3Д), and then through elastic shafts with u-joints from С3Д sidecar — wheel.

Rear axle of the vehicle designed on the basis of a modified front axle from motorized С3Д — to do this, the wheel hubs were cut off the pipes and welded the brackets with the holes for the fingers attaching to the arms of the bridge. Besides hydraulic shock absorbers rear axle was replaced by a spring motor-hydraulic, allowing staff to unload the torsion bars and increase the capacity of the machine. Well, front axle is also borrowed from motorized С3Д, was mounted on the frame of the vehicle with virtually no modifications. The only replacement is a regular shock absorbers on the spring-hydraulic.

For “comfy” was constructed of a welded tubular frame, insulated double cabin mixed construction with steel tubular frame, the inner lining of hardboard, foam padding and outer shell of fiberglass and epoxy resin.

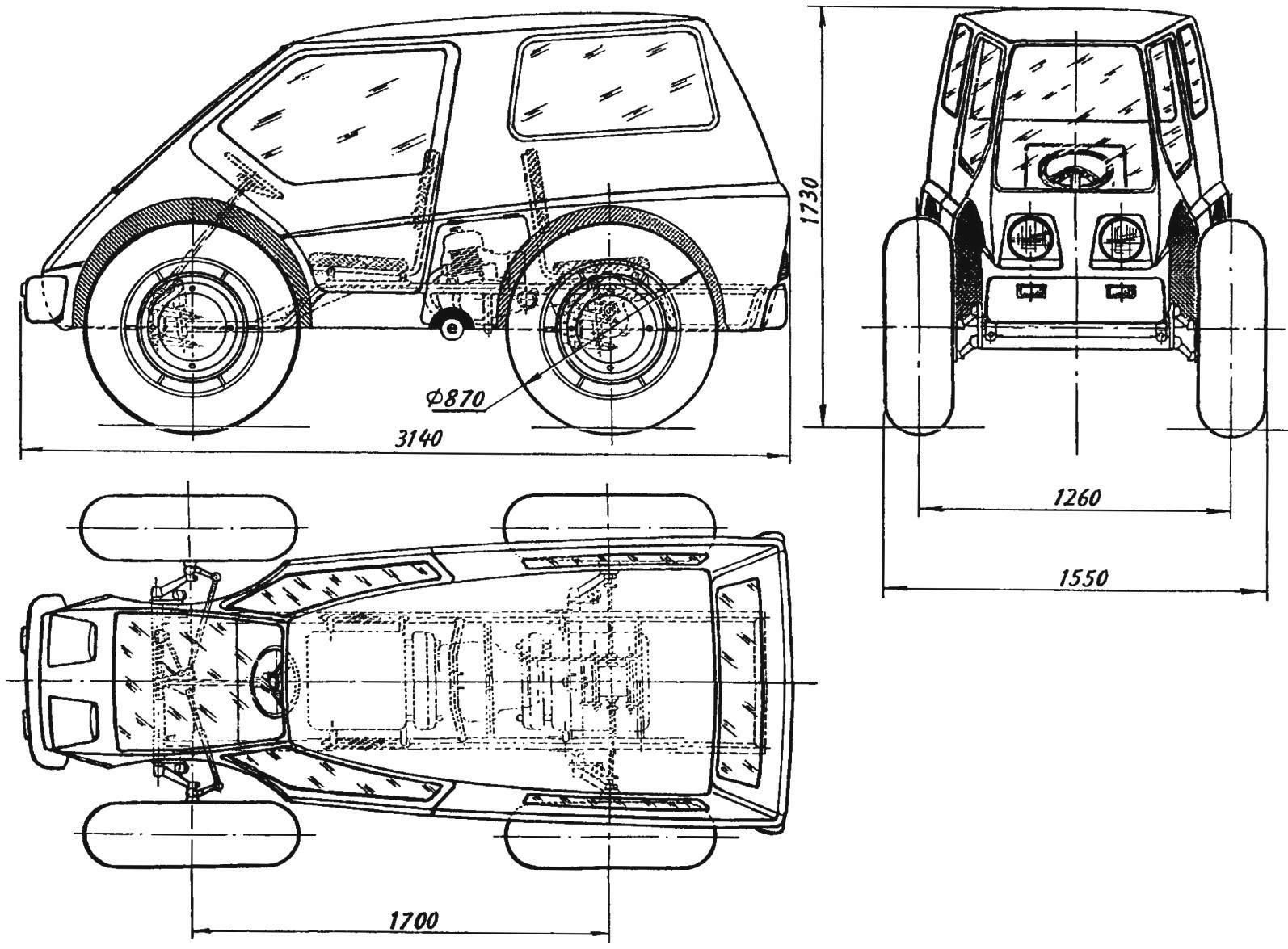

Fig. 1. Comfortable all-terrain vehicle of the fisherman “comfy”

The base of the frame of the vehicle consists of two longitudinal steel pipes with diameter of 40 mm with a wall thickness of 3 mm. For fastening the front axle in front of each of the spars is welded to the shoes, well, rear axle is mounted to is welded to the frame brackets cut from steel sheet of thickness 3 mm. the bridges are fixed at the points of fastening is exactly the same as on the scooter С3Д — bolts with nuts and split lock washers.

The Assembly of the frame to produce a level floor or on a simple bench, built from a pair of three-meter boards in the thickness 40— 50 mm and three or four crossbars. Once installed on the slipway ready longerons future frame must be inspected for symmetry, absence of distortions and compliance to its size, after which the side members are welded to a tubular crossmember and the attachment points of the body. The rear cross member pipe with a diameter of 40 mm. Two cross-members made of pipes with a diameter of 30 mm represent the engine mount of the engine, and one also with a diameter of 30 mm, is the backbone of the main transmission (reverse gear). As can be seen from the drawings, the reverse gear is mounted vertically, with a star up, the lever of switching reverse in front of the fly.

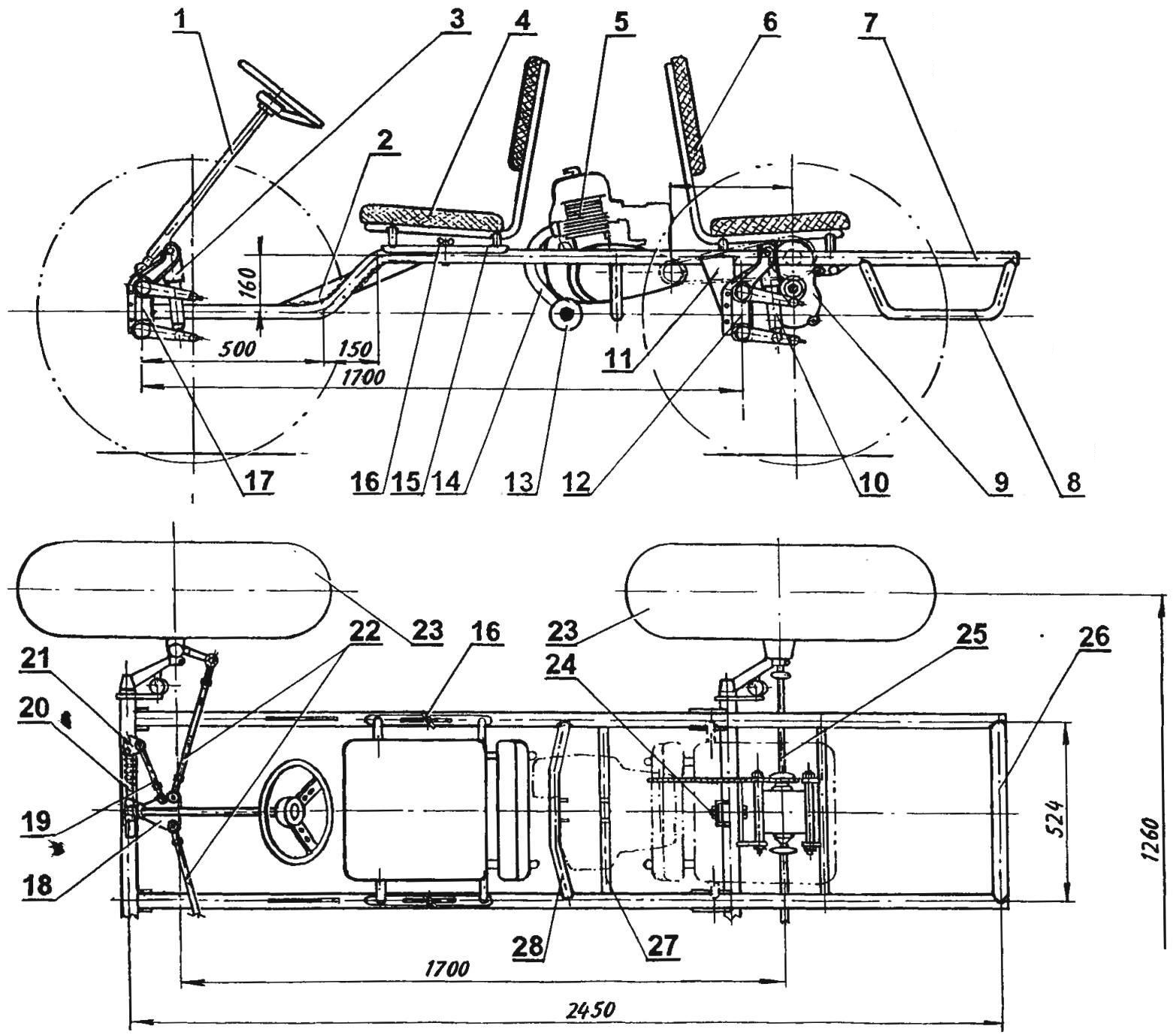

Fig. 2. The design of the chassis of the Rover:

1 — steering column (motorized С3Д); 2 — reinforcing the gusset plate (steel, sheet s3, 4 PCs.); 3,10 — spring-hydraulic shock absorbers (from a motorcycle “Voskhod”); 4—driver’s seat; 5—engine TG-200M; 6 — passenger’s seat; 7 — spar frame (steel, pipe 40×3); 8 — additional frame (steel, pipe 30×2,5); 9— main gear (motorized С3Д); 11 — bracket axle bracket; 12 — rear axle (modified front axle motorized С3Д); 13 — silencer; 14 — exhaust pipe (from engine TG-200M); 15 — the skids the driver’s seat; 16—nut-lamb M10 mounting seat; 17 — front axle (from sidecar С3Д); 18 — pendulum steering; 19 — intermediate steering rod; 20— steering rack(sidecar С3Д); 21 — adapter, 22 — track rods (motorized С3Д); 23 — wheel-pneumatic; 24 — Shoe mount main gear (steel, channel 60x40x3); 25 — the elastic shaft with u-joints (from sidecar С3Д); 26 — rear cross member (steel, pipe 40×3); 27, 28 — crossmember for the engine mounts (steel, pipe 30×2,5)

Mounting the engine on the frame for the bottom and front mounting units (plugs) that provides a reliable fixation. To mount the plug for mounting the motor on the frame, it’s best to first hook them on the engine, then using clamps and mild steel or copper wire with maximum precision to fix the engine on the frame, and then grab the nodes by welding. Latest finally are welded to the frame after dismantling of the engine. Similarly fixed to the frame and the attachment points of the main gear.

The exhaust tube from TG-200M, silencer — homemade, it is a hollow cylinder, inside of which is twisted into a tight roll of fine steel mesh.

Steering — motorized С3Д remade for vehicles and, accordingly, the steering column in the middle of the cabin. For this steering gear rack is installed, the adapter is made of a triangular swing arm, and a regular tie rod end is made shorter, the intermediate connecting adapter Reiki and pendulum.

The cabin of the vehicle is made by technology, the essence of which is contained in publications of the journal “modelist-Konstruktor”, but the offer below is more simple and feasible.

The Foundation of the cabin is a frame, welded from thin steel tubes with a diameter 16 and 18 mm. Rigidity it is no different, and this is understandable — a function it rather formative. The frame is fixed by welding the frame front and rear side panes and the frame of the doorway. By the way, the doors on the vehicle just two front left (driver) and back end (passenger). Finished glass for vehicle pick up failed, so all they are cut from plexiglass.

Further, the frame inside lined with hardboard; panel cut from this material, are attached to the pipe frame with M4 screws. Hardboard is also sewn on the inside both doors. The thus prepared frame on the outside are covered with construction foam. The actually shaping of the cab and doors was carried out integral. Surface of the cabin is first leveled a homemade instrument consisting of a machine from luchkovoj saws, which is a serrated leaf was fixed nichrome wire glow by an electric current; powering the heating element was carried out through Latr Then the foam was treated with long, razor-sharp knife, and then using glued on strips of plywood coarse sandpaper.

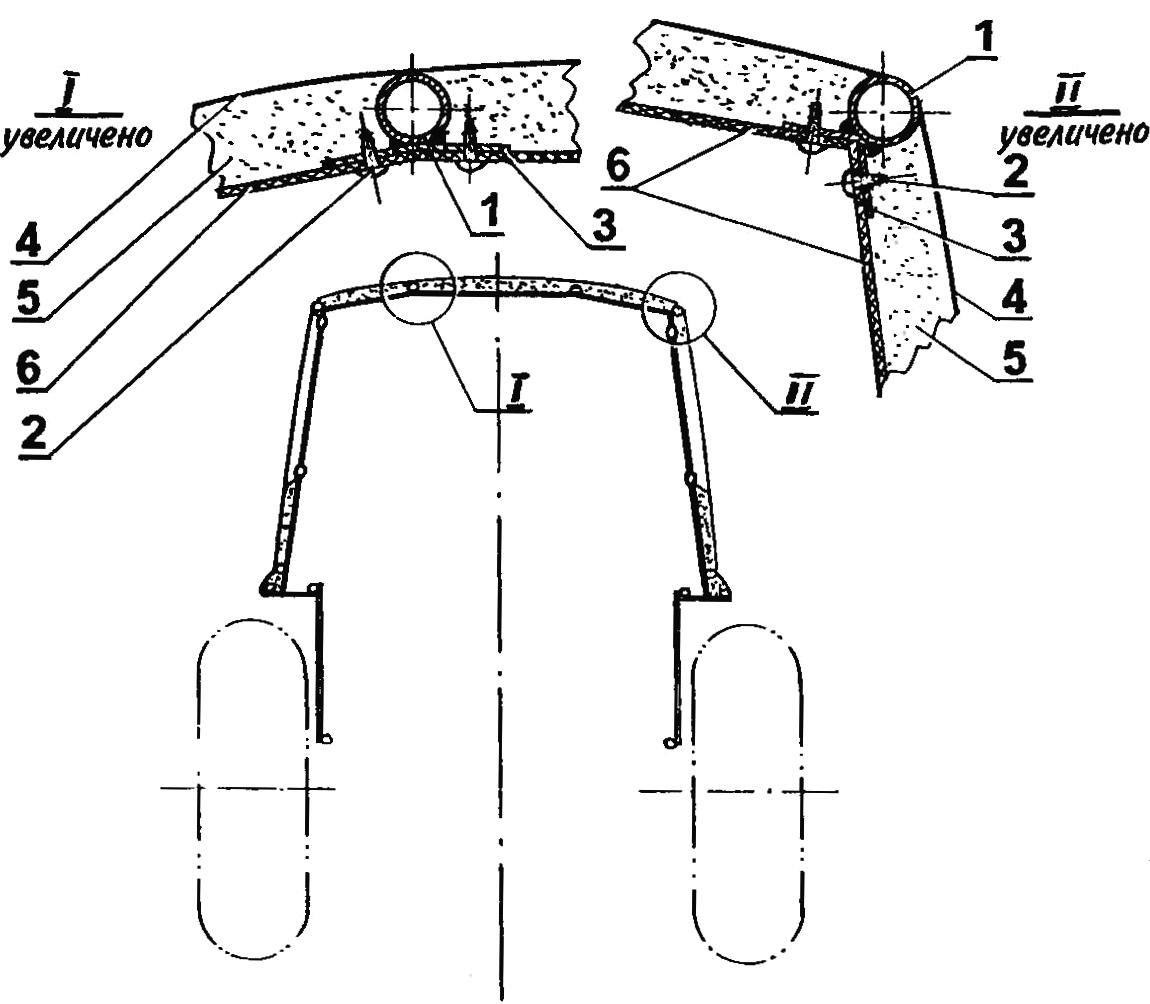

Fig. 3. The cockpit design:

1 — frame (steel, pipe 16×2, 18×2); 2 — self-tapping screw; 3 — mounting plate (steel, sheet s1,5); 4 — casing (3 layers of fiberglass and epoxy resin); 5 — filling (construction foam); 6— panel interior cladding (hardboard s4)

Thus prepared surface of the cabin are covered with three layers of fiberglass cloth on the epoxy binder. After polymerization of the resin shell viskazalas, podsalivanii two-component autosplice and painted — first with a layer of the pound, and then two layers of enamel. Inside the cabin are covered with artificial leather.

Cabin floor made of 8 mm plywood panels, cut from her twice was soaked with hot linseed oil and screws were fixed on the frame. Wheel arches trimmed with a 5 mm plywood, also impregnated with hot linseed oil.

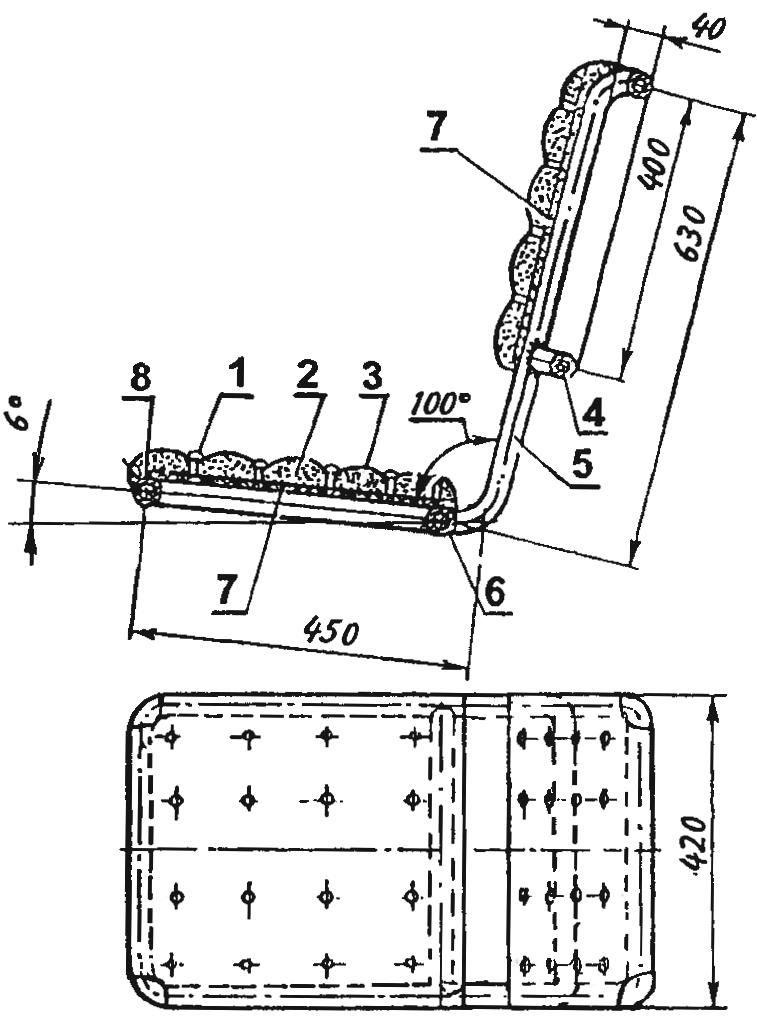

The driver’s seat and passenger’s homemade. Steel pipes are welded to their frames. On the last places in the seat and back stretched rubber rings, cut from the camera wheels of the truck. On top of this elastic framework fixed foam cushion, then the seat and seat backs were covered with artificial leather.

Control Rover — car type. Brake system hydraulic, motorized С3Д. Drives gas and clutch cable. The pedal unit consisting of a gas pedal, brake and clutch mounted on the hinge nodes, welded to the frame rails. The transmission is carried out using a hard thrust and the intermediate lever. It carried the lever located under the right hand of the driver. With the right hand and arm set enable reverse (reverse).

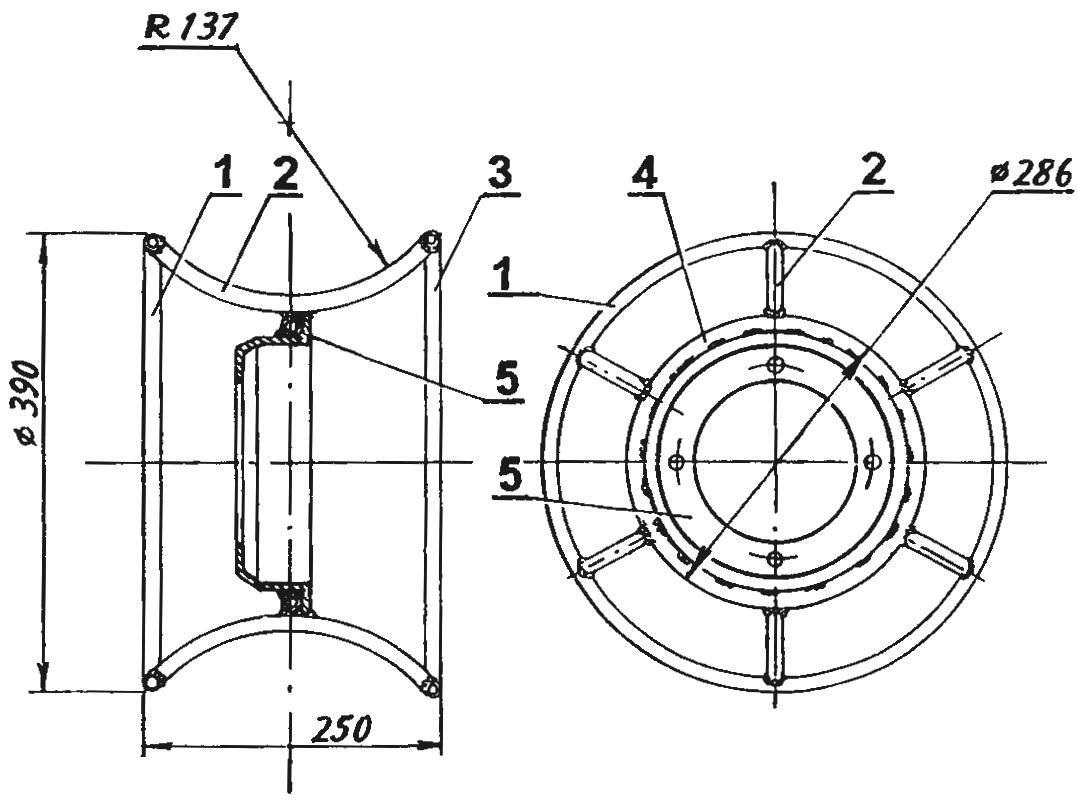

Fig. 4. Wheel of the Rover:

1,3, — outer wheel rim (steel, pipe 18×2); 2 — cradle (steel, pipe 18×2); 4 — the inner rim (steel, pipe 18×2); 5 — drive wheel (from the wheel of the sidecar С3Д)

Fig. 5. Chair:

1 furniture button; 2 — filling (foam); 3 — upholstery (artificial leather); 4,5,6 — frame (steel, pipe 20×2); 7 — elastic support of the back and seat (rubber ring)

Wheel suspension — lightweight, tubular, welded. Procurement of steel pipes with a diameter 18×2 mm bending bent and assembled by welding. Used for assembling the simplest slipway for what is particle Board on the expected circumference of the wheel installed six racks of wooden bars, which were fixed to the prepared rim. After the control their alignment and parallel to each other to privativos rims were welded crossmember. They were welded to the rims finally, only when this operation did not cause tangible leads of the wheel. Also, in two steps, was set in place and the inner ring with welded thereto the inner rim of the wheel sidecar С3Д.

As practice shows, Pneumatics, quite normally kept at the wheels of the vehicle and provide an acceptable quality of coupling with any surface — from snow and sand to arable land and swamps. However, in some cases to improve the patency of the vehicle, you can braid pneumatic nylon rope or synthetic belt slings. It should be noted that Pneumatics although not make the vehicle amphibious, able to overcome the water, unsinkable machine yet provide that you will agree, is important when it exits on the ice.

Another device used solely for winter fishing is a hatch with a removable cover in the floor at the back of the passenger seat; after drilling the hole all-terrain vehicle rolled on her, so that hole was just below the hatch. Frost or strong winds on the hatch is worn frame with sewn to her sleeve windproof synthetic fabric — so the hole is like inside of the cabin of the vehicle. When the heater in the cabin in any frost is quite warm and comfortable.

I. KHOROSHEV