Passenger car GAZ-A. Many people know the famous saying of the Patriarch of the American car industry Henry Ford — “the Buyer is entitled to choose a car of any colour provided that its color will be black.” However, not everyone knows that the Ford-T was painted black not because of the aesthetic preferences of the Ford to the Kohler. The reason for this was purely technological — Assembly-line production with its rigid rhythm were taken for drying the body after painting a certain, very short time, which in the early XX century was granted only black Japanese quick-drying enamel…

Passenger car GAZ-A. Many people know the famous saying of the Patriarch of the American car industry Henry Ford — “the Buyer is entitled to choose a car of any colour provided that its color will be black.” However, not everyone knows that the Ford-T was painted black not because of the aesthetic preferences of the Ford to the Kohler. The reason for this was purely technological — Assembly-line production with its rigid rhythm were taken for drying the body after painting a certain, very short time, which in the early XX century was granted only black Japanese quick-drying enamel…

The idea of the Assembly line came to Henry Ford with the development of the car to high demand Ford-T, which, as conceived by its creators, had all the data to become most popular and the cheapest in the world. However, to provide a low-cost machine using a piece of the Assembly was impossible.

Development of the idea of the Assembly line occurred in mid-1913, a subsidiary of Ford Motor Company in highland Park (PC. mi). Wherein the chassis of the Ford-T was dragged on ropes by the Assembly of posts, providing work during short pauses in the movement of the rope “conveyor” to set the machine sub-assemblies and assemblies. Even such a primitive model demonstrated the main advantage of the pipeline with the build time of the car significantly decreased.

A year later started mass production of “Tin Lizzie” (the so-called Ford-T the Americans), and soon improved the production line every ten seconds started to go a completely finished car.

About 20 years of continued production of the Ford-T is the total amount of production of this machine has exceeded 15 million copies. However, by 1927 it had become clear that the number of buyers “Tin Lizzie” is significantly diminished. In the same year the factories of the company was for a few months closed for refurbishment for the launch of a new model, called the Ford-A — the same as in the first car of Henry Ford’s model 1903.

The coincidence of the names was hardly accidental — apparently, the head of the company intended to open a car with the index “A” new era in the history of the Ford Motor Company.

Ford-A, the exterior of which has largely been created Absalom Ford, son of the founder, was a very ergonomic (of course, compared to the “Tin Lizzie”) the car is in good proportion with the geometrical parameters of the driver and passengers. When you create a Ford-A before the designers were tasked to make it so that the car can be had in the process of operation, to periodically upgrade, replacing her worn-out or outdated parts and components more modern.

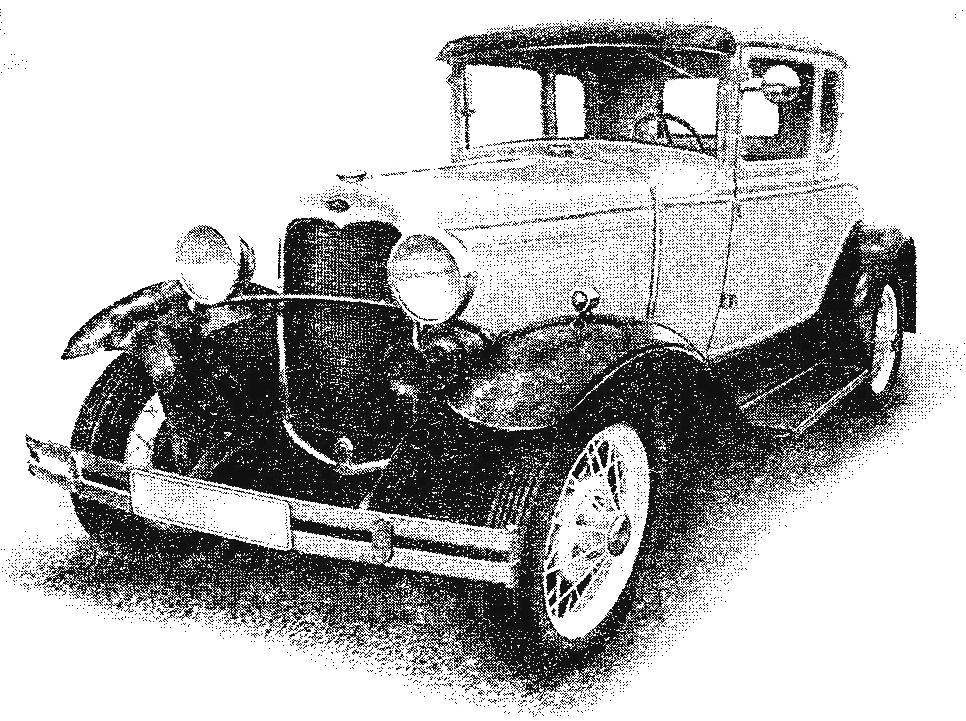

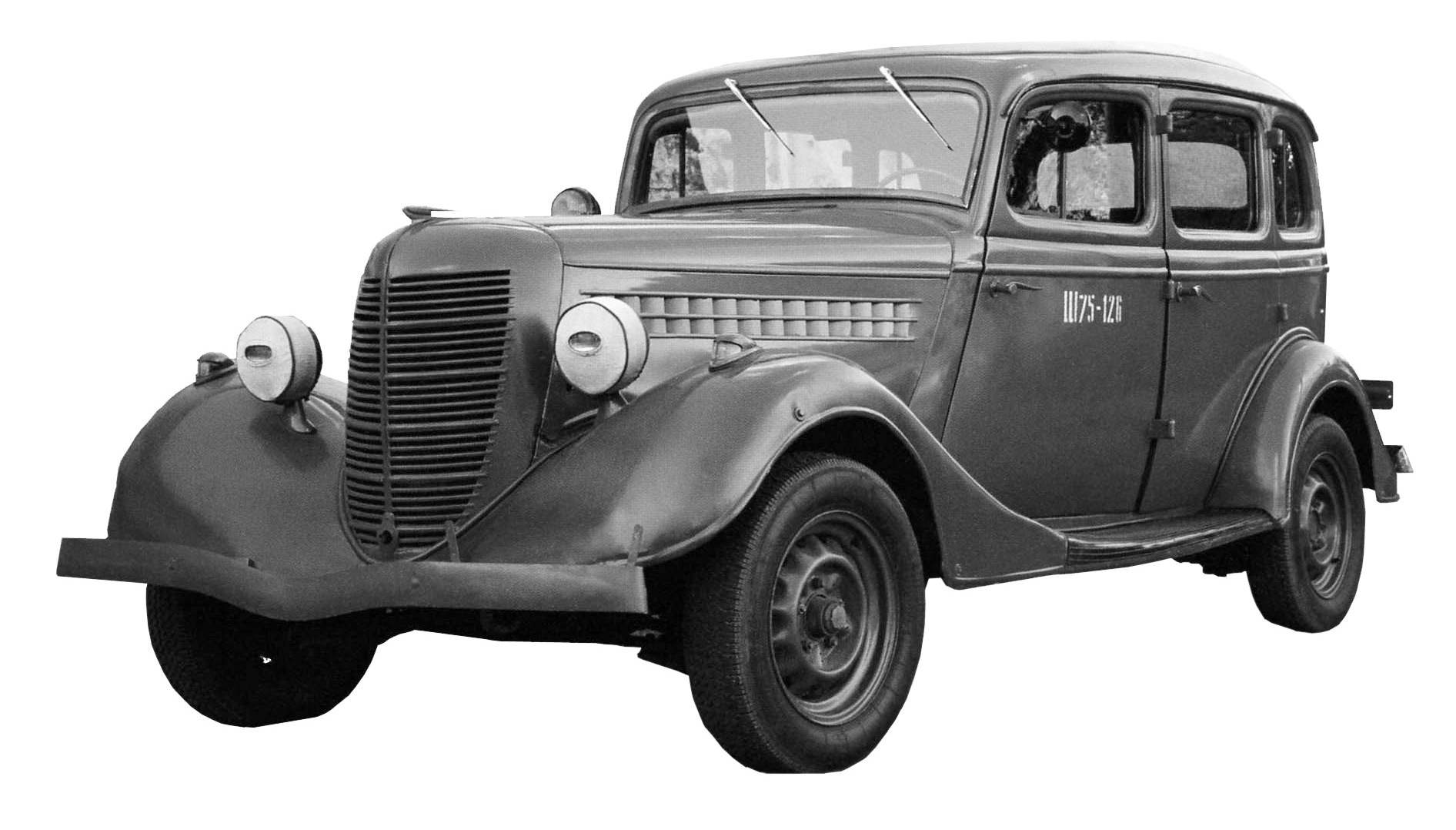

Ford is A Sedan edition of 1931

The front of the cabin Ford A Sedan

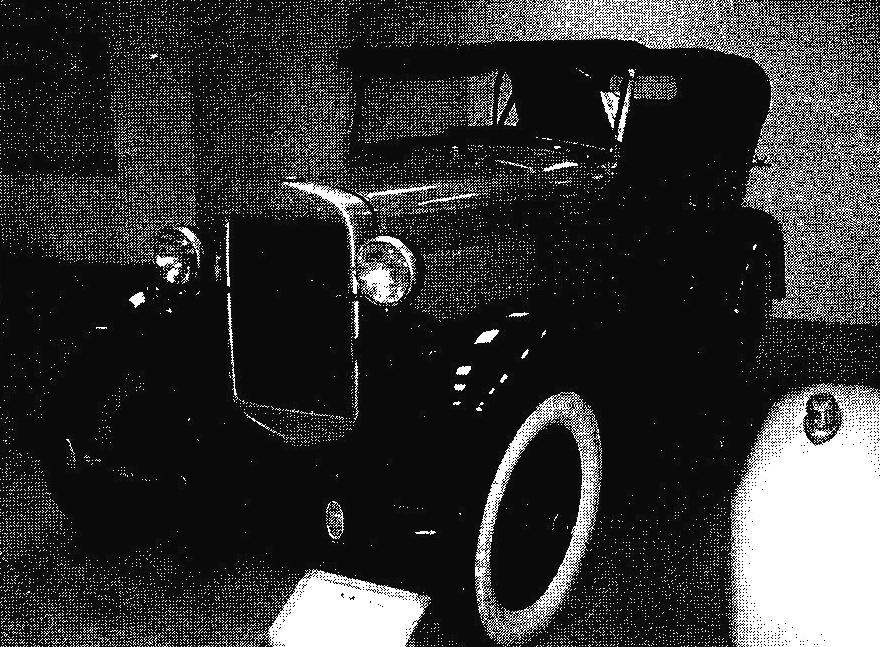

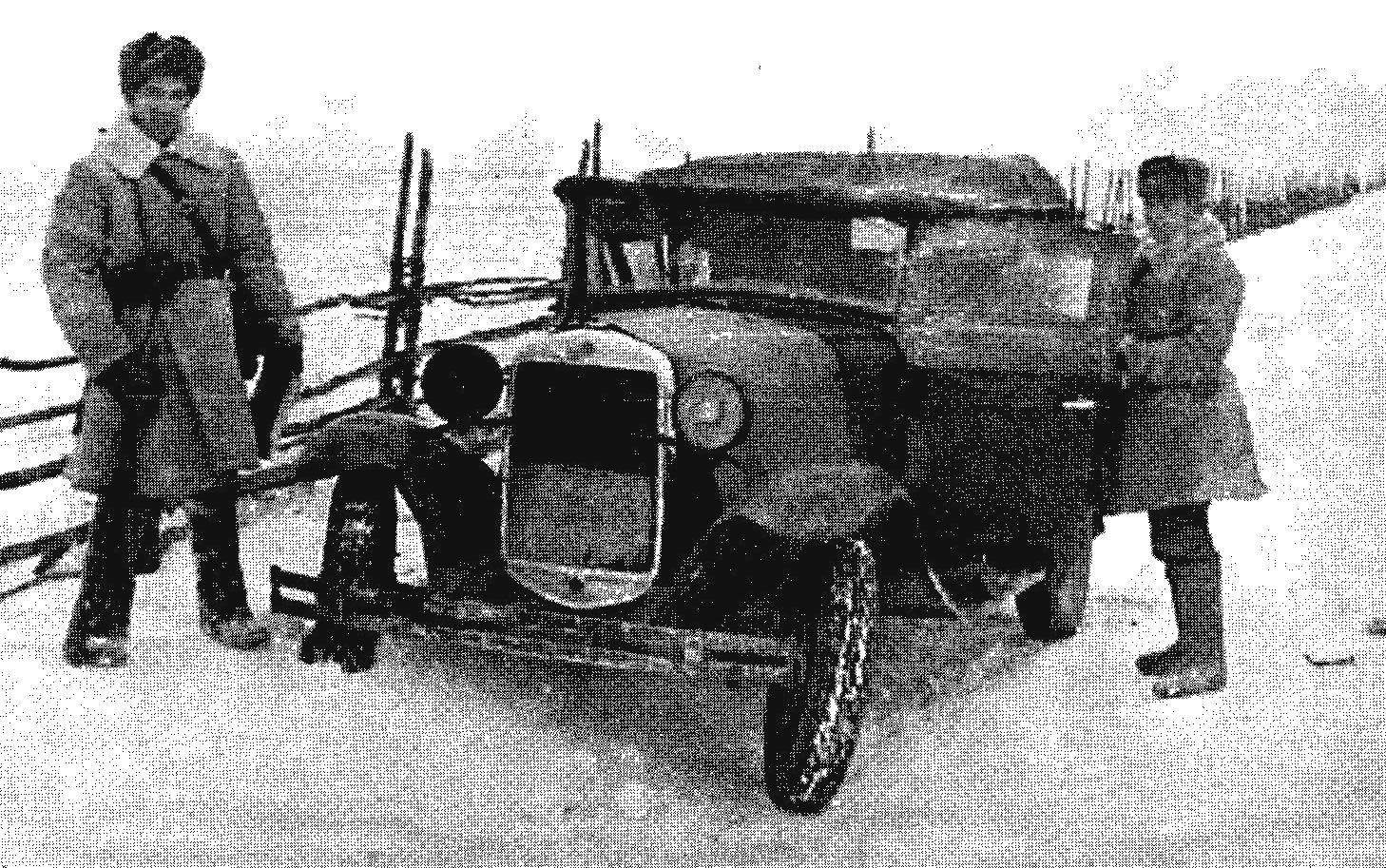

The first GAZ-A, assembled at the Gorky automobile plant on 2 January 1932

The column Karakum rally. Lead the GAZ-a

The car GAZ-a (front 3/4 and side)

The design of the Ford-A was simple and technological. The basis of the car was spar frame on which was mounted the engine, transmission, axles and the body. The power unit was a 4-cylinder engine with cylinder capacity 3285 cm3, power 40 HP, mated to a three-stage gearbox. Bridges with rigid axles, suspension — transverse semi-elliptic leaf springs. Wheels — wire non-adjustable spokes, brakes — mechanical drum. By the way, when Edsel suggested the father to equip Ford-A more modern hydraulic brakes, he flatly refused — in this case, would have had to pay a considerable amount to the firm Lockheed is the sole holder of the patent for this device.

The wheelbase of the car was 2629 mm track — 1422 mm; total weight — 1100 — 1300 kg; the maximum speed reached 100 km/h, fuel consumption — 12 — 15 litres per 100 km. Interestingly, Рогс1-And became the first car company, equipped with a shatterproof windshield.

The audience friendly met Ford-A for the first 16 months of sales it was purchased more than a million cars. But only for a period of four years the production was released more than 4.5 million cars.

* * *

In the middle of 1920-ies the party and state leaders far from the America of Soviet Russia began to realize that the dynamic industrial development is such a huge country is impossible without its mass motorization. Judge for yourself — in 1928, America was 23.2 million cars, and in the USSR — only 20.6 thousand cars and buses.

The most promising way to quickly create a new car industry was recognized as the acquisition abroad of modern plant and licenses for the production of freight and passenger cars. For this purpose was of the company of Ford Motor Company and General Motors, who had considerable experience of the mass production.

The agreement between the government Commission headed by Deputy Chairman of the VSNKh of the USSR V. I. Milowka and the leadership of the Ford Motor Company on the granting of licenses for the production of Ford-A and Ford-AA was signed on 31 may 1929. To participate in the development of technical project and working drawings of architectural and construction part of the plant was attracted by the American joint-stock company Austin & Co.

Only it took three years for the country to create in Nizhny Novgorod is quite a modern plant, which received the name “Nizhny Novgorod automobile plant named after Molotov” (NAB). However, the release of the first domestic “fords” was held long before the end of its construction in the factory “Gudok Oktyabrya” (also at the Bottom) 1 Feb 1930 began screwdriver Assembly of cars Ford-A, and polutoratonny trucks Ford-AA of 72 thousand purchased in America of Ford’s kits. Going to these machines and in Moscow, at the car Assembly plant named KIM.

The car GAZ-a with a body “Phaeton”

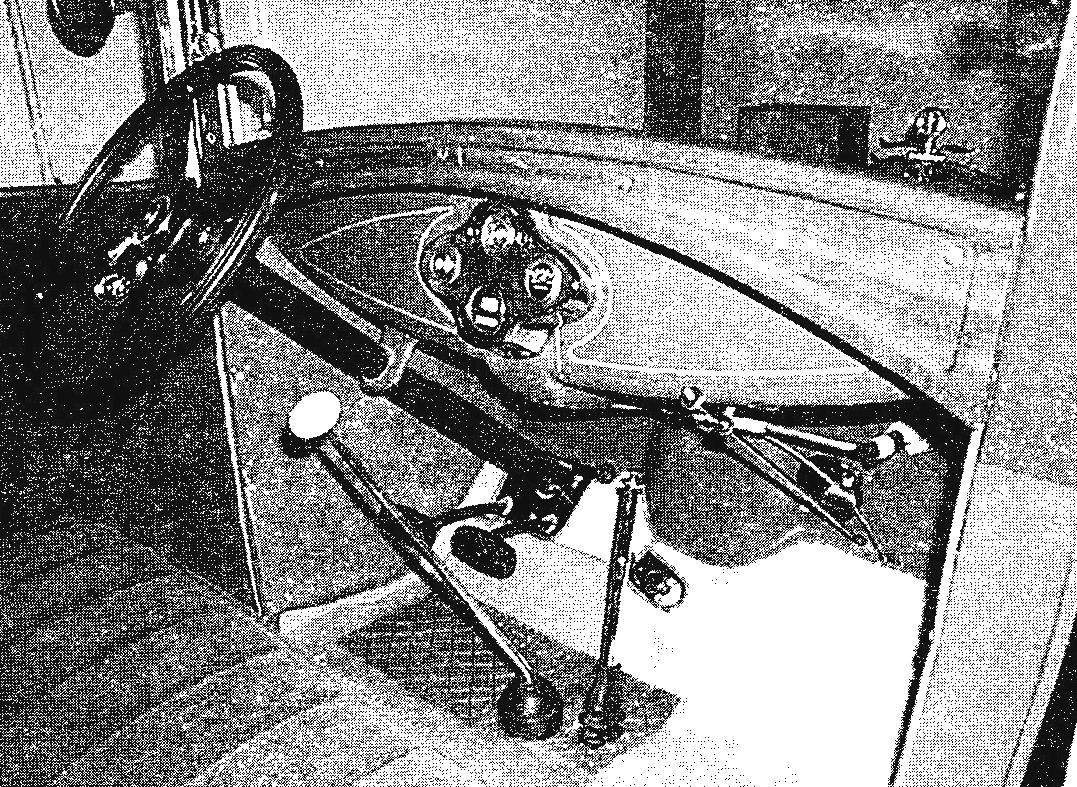

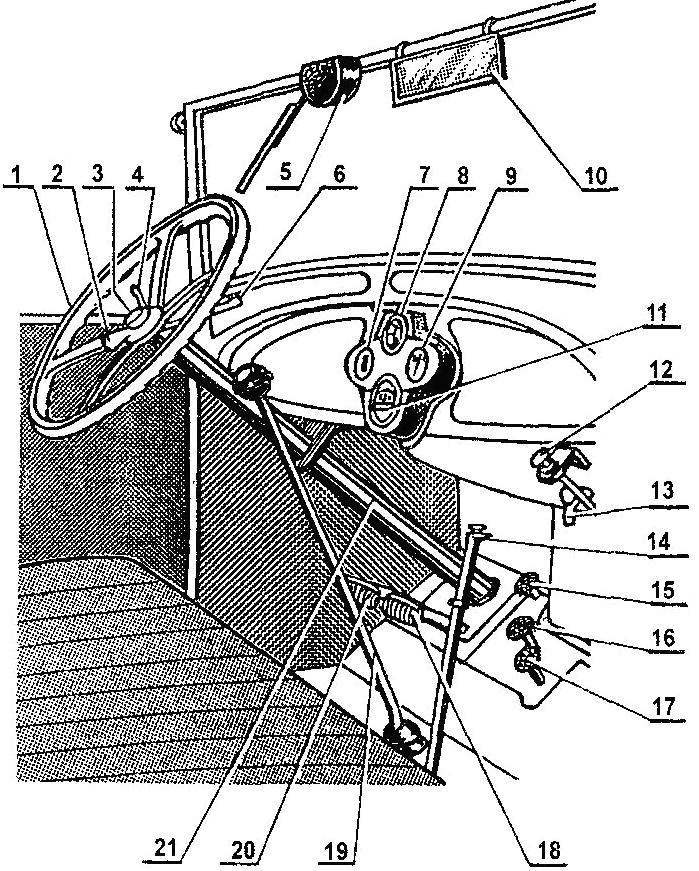

The interior of the driver’s seat:

1 — steering wheel; 2 — lighting switch; 3 — horn button; 4 — the lever of the ignition control; 5 — the mechanism of the wiper; 6 — the lever of a permanent gas; 7 — the ignition lock; 8 — the gauge of fuel in the tank; 9 — ammeter; 10 — rear view mirror; 11 — speedometer; 12 — button adjustment of the carburettor; 13 — fuel valve; 14 — brake lever; 15 — pedal starter; 16 — gas pedal; 17 — a support for feet of the driver; 18 — a brake pedal; 19 — the lever of the gearbox; 20 — clutch pedal; 21 — steering column

Openwork design specianova wheels GAZ-a was a very tough and durable

The only tail light had two functions — brake and the left “envelope”

The first trucks of domestic production came off the Assembly line of Naza 29 January 1932 and cars — 8 Dec. Let me remind you that in the same year the city was named Gorky, and the factory produced vehicles — the acronym GAS.

The passenger car GAZ-a were greeted by Russian drivers and mechanics on автостандарт33.Russia repair and maintenance work in the operation of reliable, low-maintenance and repairable cars can be even in our garages. In addition, the GAS-AND were very undemanding to as fuel — it can equally well have consumed any low-octane fuel and even, if necessary, — kerosene.

When you start the car in production the design was slightly modified — it has been reinforced clutch case and steering mechanism, and air filter is installed.

The machine cost a minimum of devices and assemblies in the electrical system there was only one relay, and on the dashboard was located only three instruments — speedometer, ammeter and fuel gauge. The last one was purely mechanical — the arrow pointer was kinematically connected with the float in the fuel tank.

The design of the car was used only 21 of the rolling bearing (on modern machines more than two hundred!), in the lubrication system was no oil filter in the cooling system thermostat, and the fuel system — the fuel pump! The latter was unnecessary — the fuel flowed to the carburetor by gravity from a tank located under the engine hood, near the windshield.

Mention should also be made single wiper blade, clearing a small sector in front of the driver’s head — this unit was pneumatic, with vacuum operated from the intake manifold. Best of all he acted when the engine is idling and with increasing engine speed movement of the brush slowed.

Lubrication of the cylinder group of the engine was carried out by the method of spraying that in the absence of the oil filter significantly reduced the resource of the motor. And babbit crankshaft bearings of the crankshaft are not reliable. For those who have not heard about babbit, let me remind you that it is a antifriction alloy based on tin or lead with additions of antimony, copper, and other metals — the temperature of its melting point is 400 — 500 degrees. Worn babbit bearings were made right on the spot — melt was filled with a “bed” for the bearing directly to the cylinder block of the engine.

You were lucky if the engine nursed overhaul 40 thousand km! By the way, modern drivers, this mileage I think just running the motor…

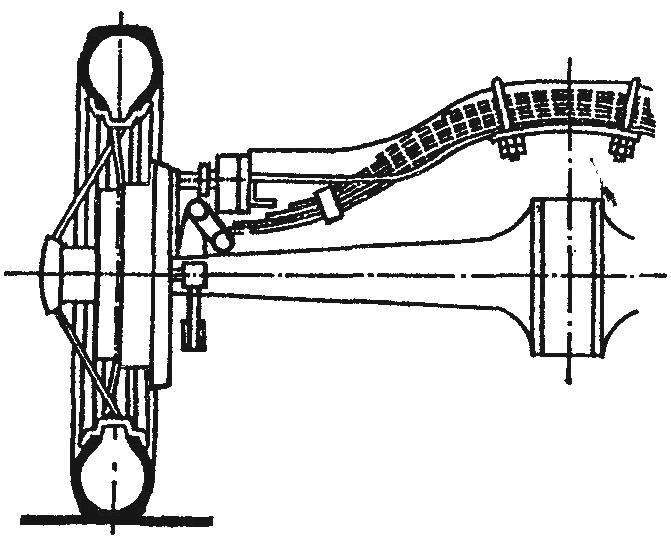

GAZ-a, as well as its American prototype, had the suspension on two semi-elliptic transverse-mounted leaf springs with hydraulic shock absorbers rotary lobe type. By the way, the GAZ-A was the first Russian car with such shock absorbers.

From the point of view of today’s driver, driving a car was not easy. The steering column mounted three lever manual gas control ignition timing and the light switch. When starting the motor the throttle lever coaches would simply be fitted to a three prong down (increased gas), and lever adjustment the ignition timing is transferred to the position of “later”. Only then was it possible to turn the starter by pressing the right foot button on pedal for such a tiny gas pedal. After warming up the engine the driver was set to normal ignition timing and idle speed, after which the movement began.

A very serious drawback of the car was his utter inability to Russian weather conditions. Unfortunately, the leaders of the Soviet automobile industry of VSNKh of the USSR when you purchase a license stopped his choice on the chaise with fabric uppers — very cheap and technologically simple car modifications, not on the sedan with all-metal body, this variant has also been released by the Company Ford Motor Company.

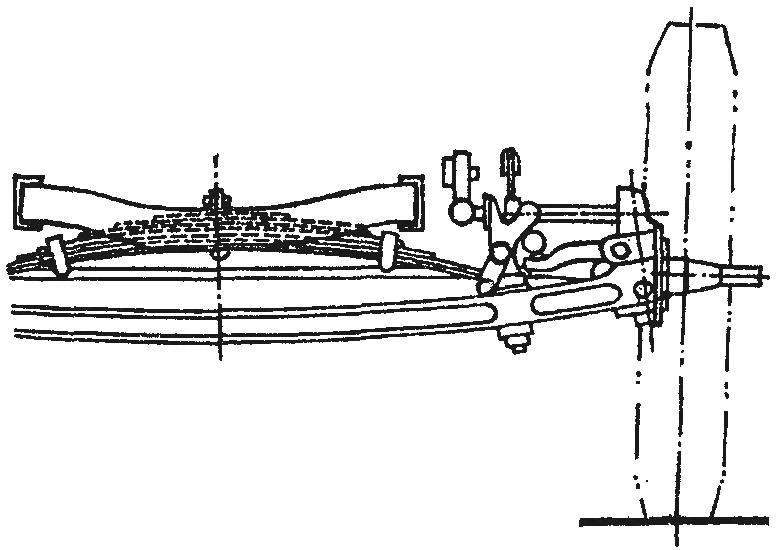

The chassis of the car GAZ-a

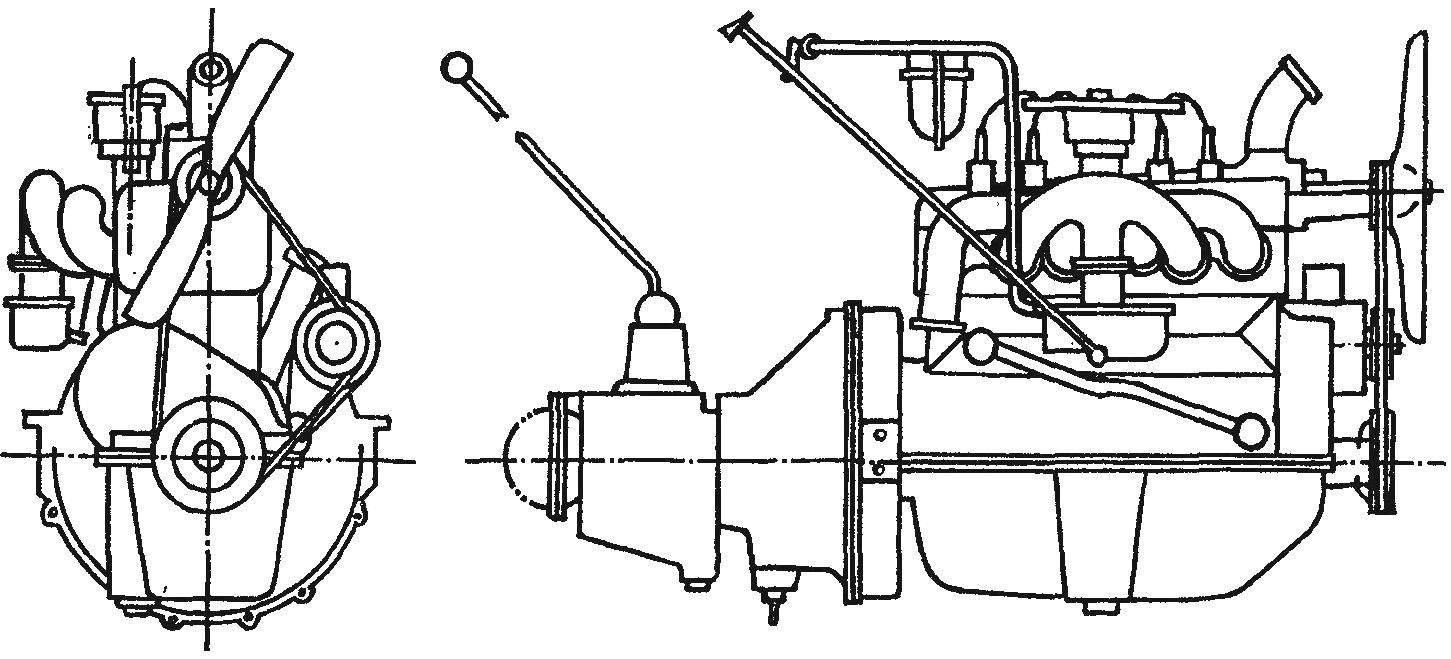

Rear axle of the vehicle

The front axle of the car

The car engine GAZ-a

Summer conditions in the Phaeton was more or less tolerable, but in winter… Even with a raised canopy and fastened to the sides of the canvas curtains with celluloid Windows in the car it was impossible to ride without boots and coat. Besides from the breath of the driver and passengers are constantly freezing windshield — to avoid this, drivers had to periodically wipe it with a sack of salt.

In 1934, Gorky attempted to create a modification with a closed metal body. The plant was produced a pilot batch of such machines, known as GAS-6, but engineers are unable to build a fairly complex Assembly of body nodes in the waste and smooth operation of the conveyor, and from the production of GAS-6 had to be abandoned. His contribution to the creation of the sedan made, and Moskovskiy Zavod Aremkuz, organized in 1935, the issue on the basis of GAZ-a private car-taxi. Strictly speaking, this body was not metal and was a wooden frame, which is attached to a steel panel. The mass of such a machine was 1350 kg — nearly 270 pounds more than the Phaeton GAZ-A.

A very interesting modification of the GAZ-a was a car-pickup GAZ-4 with a cab of the lorry GAZ-AA and all-metal truck body. The car was designed to carry 500 kg of cargo. A characteristic feature of a pickup truck was the spare wheel attached in back not as in the GAZ-a, and in a niche on its left front fender.

A curious feature of the design of six cars GAZ-a, participated in the experimental (Karakum) mileage 1933 length is about 10 thousand km, began an experimental wide-tire “sorbello” — their width was twice that of a standard, which significantly reduces the specific load on the ground. Machine with Serbelloni to easily overcome the Sands of the Karakum desert and withstood an 86-day trial the hardest RAID.

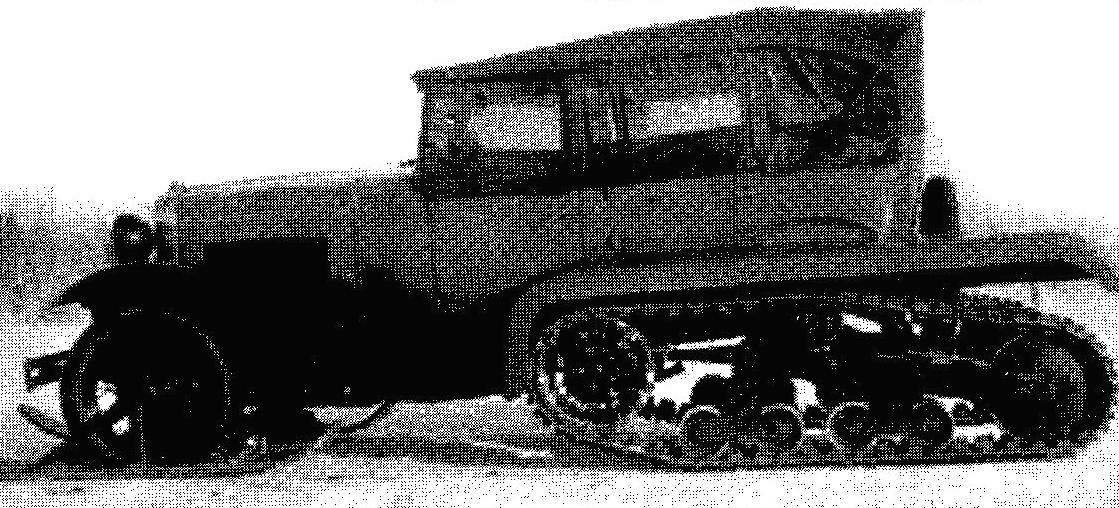

Gas was created a very unusual version of the GAS-AND — in 1934 there were collected a few hundred copies of a three-axis polugratsii GAS-TC terrain. Some of these machines were in the Red Army — they mounted recoilless guns of Kurchevsky. Tested at the factory and winter ski-track version of the GAZ-A.

Known to another vehicle on the basis of car GAZ-a — it was created in 1934 poda adjunct of the Department of armored vehicles of the Military Academy of mechanization and motorization of the red army (now the Academy of armored forces) A. N. Nikitin. The topic of his doctoral dissertation was related to the problems of aerodynamics — as a result of the research scientist was created very unusual for that time experimental streamlined car GAZ-a-AERO. As shown by purge and test runs, the coefficient of drag CX was twice less than that of serial GAZ-A. the body of the GAZ-a-AERO had a wooden frame and metal casing, the windshield was V-shaped (as in “Victory”), lights half utaplivanii in the body, and the rear wheels were completely closed fairing. To improve aerodynamics the car was stripped as usual for cars of the 1930-ies of the foot pegs, bumpers and fixed outside the spare wheel.

GAZ-a-Aero body streamlined shape, designed by A. N. Nikitin

The car-a taxi with a body “sedan” GAS-A-Aremkuz

GAZ-TK — triaxial modification of GAZ-a with the gun of Kurchevsky

GAS-AND on the roads of the great Patriotic…

Ski-track version of the GAZ-A

GAZ-a-AERO was equipped with uprated to 48 HP the engine with aluminium head, to disperse the car up to 106 km/h (remember, the GAS AND top speed was 90 km/h).

It is also interesting to recall another military incarnation of a GAS-AND — his chassis was produced armored cars D-8, D-12 and FAI, in service with the red Army until the great Patriotic war.

* * *

About six years of continued production of GAS-AND — during this time, the plant produced 41 917 of these machines. But life tells the designers that the country will soon need a new car — more powerful, more comfortable, more reliable. And soon after starting GAS-AND in the series, in October 1933 began to develop the “Emochki” GAZ-M1 — the next model of the car, which was destined to become a true legend of the domestic automobile industry.

Mass production of the first Soviet limousine began on 15 March 1936…

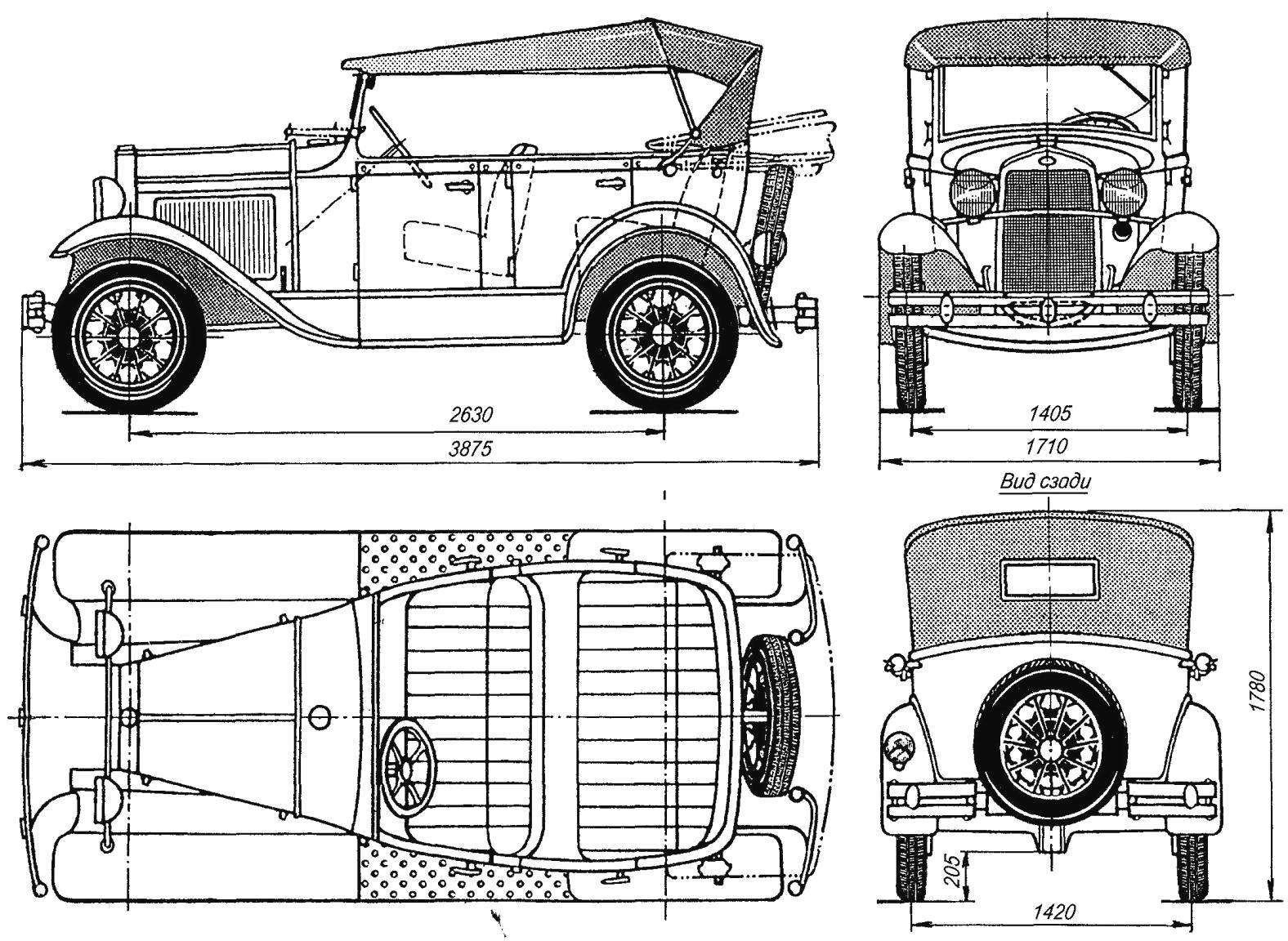

Technical characteristics of the car GAZ-a

Length, mm…………………………………………………….3875

Width, mm………………………………………………….1710

Height, mm…………………………………………………..1780

Base, mm……………………………………………………….2630

Ground clearance, mm………………………………………………….205

The front track of wheels, mm…………………………….1405

Rear track, mm…………………………………1420

Turning radius, mm……………………………………..5500

Engine capacity, cm3……………………….3285

Power, HP 40 Clutch — single-plate, dry

Weight without load, kg…………………………………….1080

Maximum speed, km/h…………………………..90

Fuel tank capacity, l………………………………………40

Fuel consumption, l/100 km………………………………..12

I. EVSTRATOV