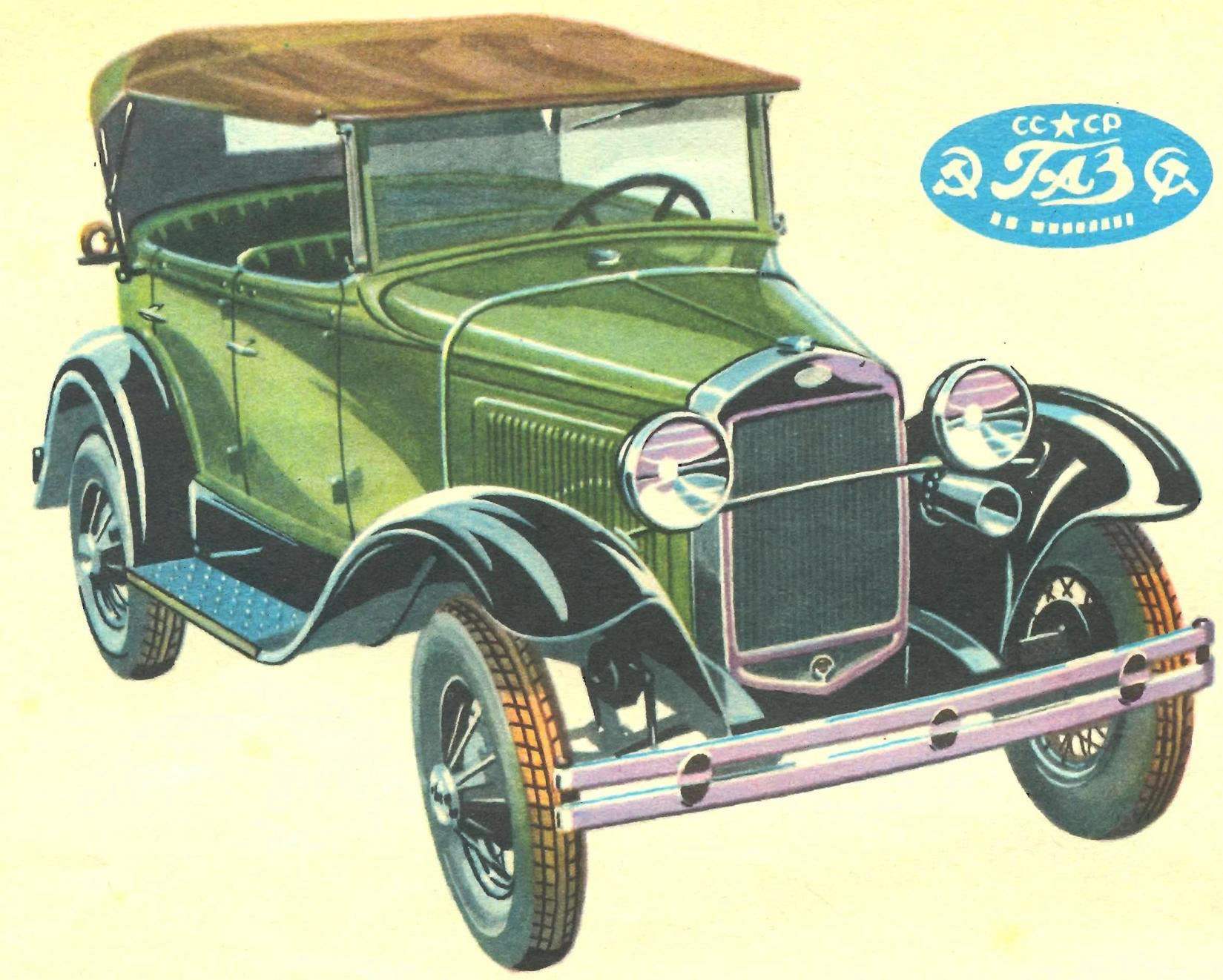

On the sixth of December, 1932, eleven months after the start of the Gorky automobile plant, with its conveyor descended first cars GAZ-A. Cars these, very simple and unpretentious, quickly won the hearts of drivers. In fact, their distant relatives were already well known in our country.

On the sixth of December, 1932, eleven months after the start of the Gorky automobile plant, with its conveyor descended first cars GAZ-A. Cars these, very simple and unpretentious, quickly won the hearts of drivers. In fact, their distant relatives were already well known in our country.

Since 1930, the Moscow plant named KIM and Gorky’s “the Whistle of October” was assembled from American parts cars “Ford-A”, the machine proved to be the most suitable for use in our country. The factories of steel for the Soviet specialists the preparatory classes in mastering the art of conveyor assemblies. Of course, everyone was waiting for the time when we ourselves, with his own hands from beginning to end we make cars.

And in the history of domestic car industry opened a new page mastered the mass production of cars.

In 1933, the country received 10 thousand cars “Gazovik” as they were called at that time. The following year, output reached 17 and in 1935 -19 thousand. Only from 1932 to 1936 the plant was built more than 50 thousand cars GAZ-A. They were so reliable and durable that even today, forty years later (a long time from the point of view of “life” of the car), individual instances can be found in Chita and Kazan, Yaroslavl and Sverdlovsk. Three such machines are carefully preserved in museums: one in the factory Museum Gas, the other on AZLK (in the past the plant named KIM), the third is exhibited in the Department of automotive engineering of the Polytechnic Museum in Moscow.

We will enter into the hall, where there is a faint smell of gasoline, oil, even some strange, typically the Museum’s a taste of antiquity. Here it is, the GAS-AND, looking at us looking a little yellow reflectors of the headlights, a friendly stretch towards black wings, paint them — a sign of age — covered already visible web of small cracks.

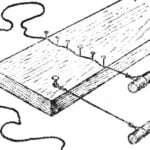

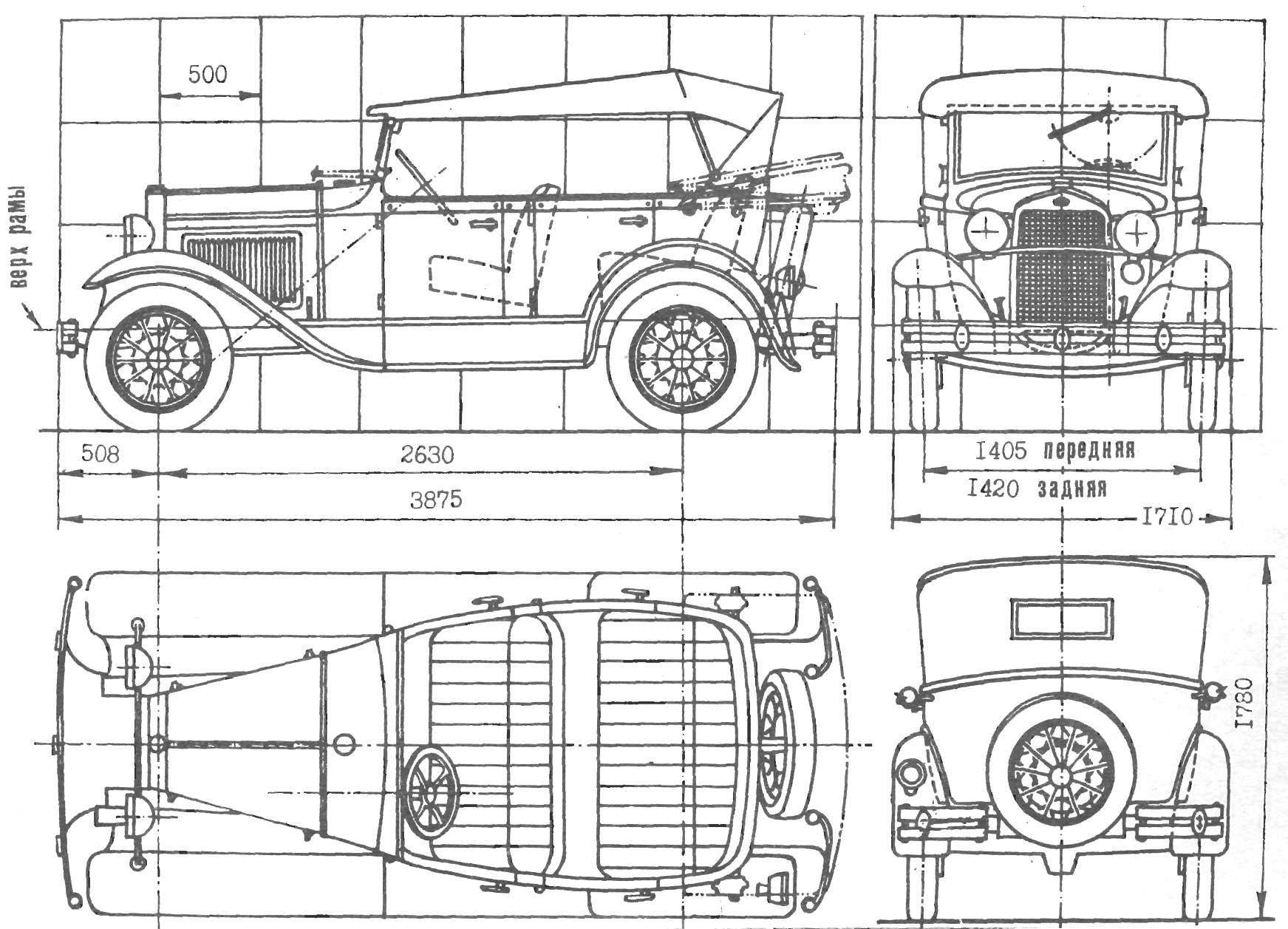

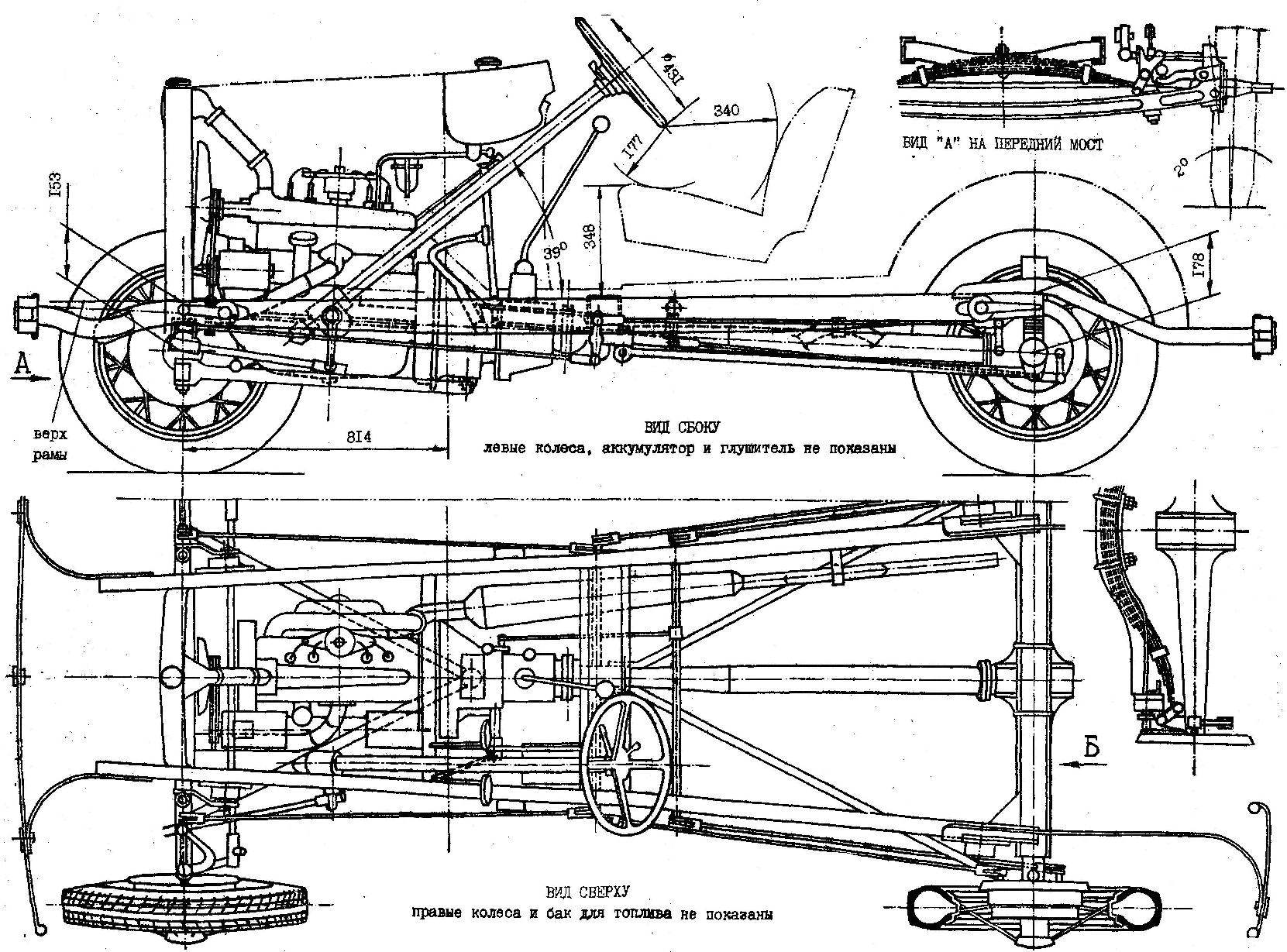

Fig. 1. The chassis of the GAZ-A.

Walk around the car. Its buffer is made of two elastic steel strips. Nickel plated radiator the first is decorated with the emblem of the Gorky plant — black oval with the letters “GAS”. Wheel with wire spokes without threaded nipples to adjust the tension — the kind of strength and reliability possessed design. Similar wheels on modern cars almost never meet — except on a sports car. But in those years spellbane wheel was used quite widely.

Slightly yellowish color of the windscreen suggests that it is laminated — two layers of glass with a padded third elastic film, the once transparent but yellowed. Upon impact, laminated glass was covered with a thick layer of cracked but not scattered in one crystal, as later invented tempered glass. In front of the windscreen sticking out of the tube tank. It is located at the rear of the engine compartment: fuel flowed to the carburetor by gravity. Thus, eliminated the need to pump in those years is still a very imperfect instrument. Tank of GAS-AND almost hung over the knees of the driver and passenger. At the bottom of the tank was tap, which the driver, before leaving, blocked. The tap is often leaking from the point of view of fire safety posed a serious threat. Black ebony steering wheel near the horn button, there are two lever. One is to manually control the spark advance (today this work is done by machine) and another to install a constant supply of “gas”. The speedometer is not the usual hands — in the window of the moving device applied to the drum the numbers indicating the speed. The numbers on the pointer of gasoline deposited on the scale, connected directly with the float in the gas tank.

Just below the tiny, round pedal “gas” I had heel feet — oblong pedal appeared on the later cars.

If we were able to disassemble the whole car to the last bolt, we would see only 21 of the bearing (in a modern car about two hundred), seven of which are roller, and the rollers are wound from thick steel strip. But the crankshaft bearings were sleeve bearings, not like now, with thin-walled bimetallic quick-change liners that serve 80-100 thousand km Material was provided by alloy, called Babbitt, which is poured a “bed” for the bearing directly to the cylinder block or connecting rod. To fit the surface of the bearing to sakam crankshaft, a layer of babbit was sabriel. But even the most careful adjustment is not saved from the fact that in 30-40 thousand kilometers had to re-pour the bearings.

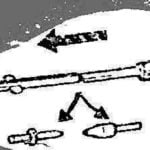

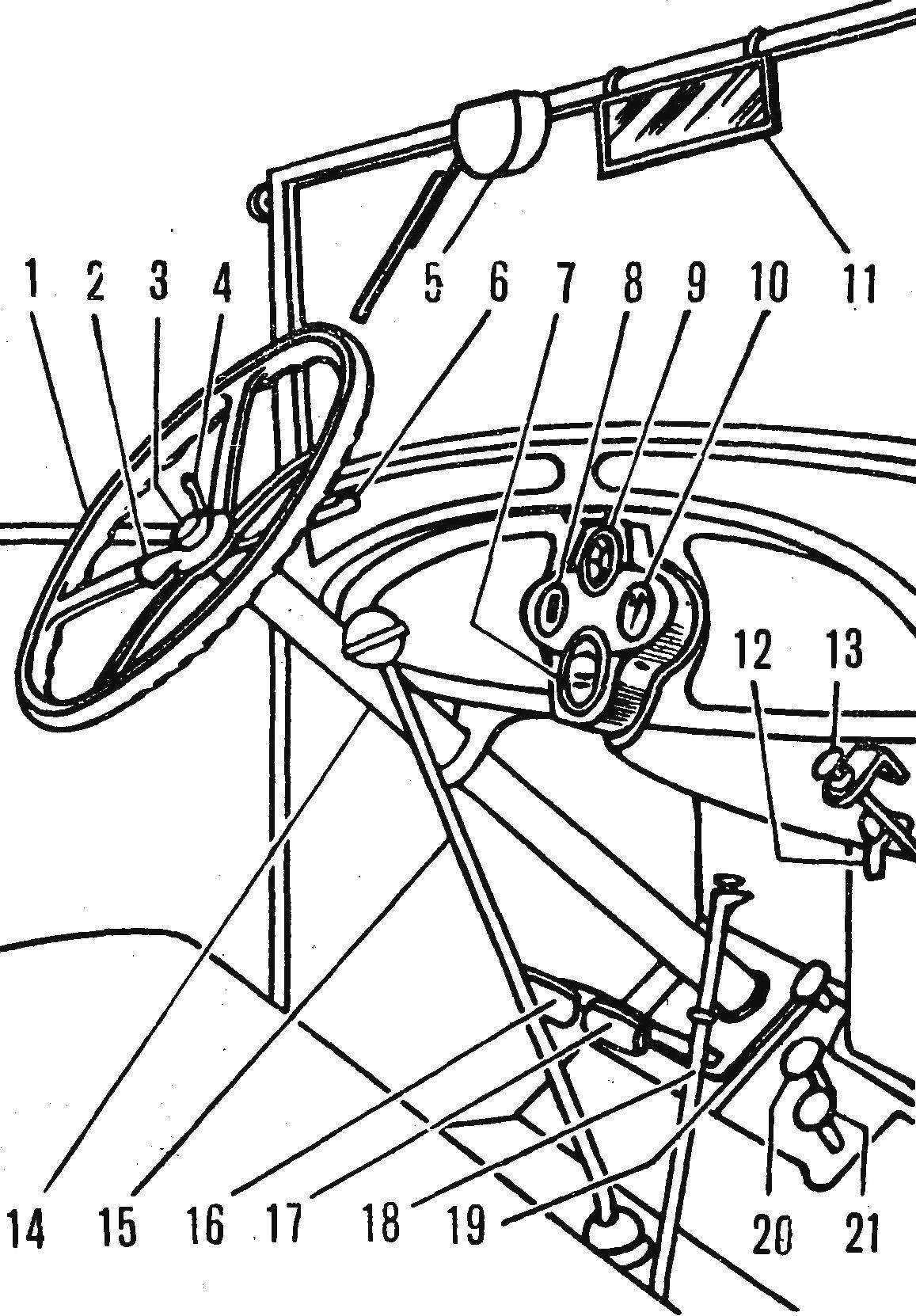

Fig. 2. Controls and instruments:

1 — steering wheel 2 — arm, light switch, 3 — button signal, 4 — lever, ignition control, 5 — wiper 6 — gas lever, 7 — speedometer, 8 — ignition switch 9 — index of level of gasoline in the tank, 10 — ammeter, 11 — rearview mirror 12 — petrol tap, 13 — regulating pull the carb, 14 — steering column, 15 — gear lever, 16 — clutch 17 — foot pedal brake, 18 — Parking brake lever, 19 — pedal starter, 20 — accelerator pedal 21 — bearing foot to the accelerator.

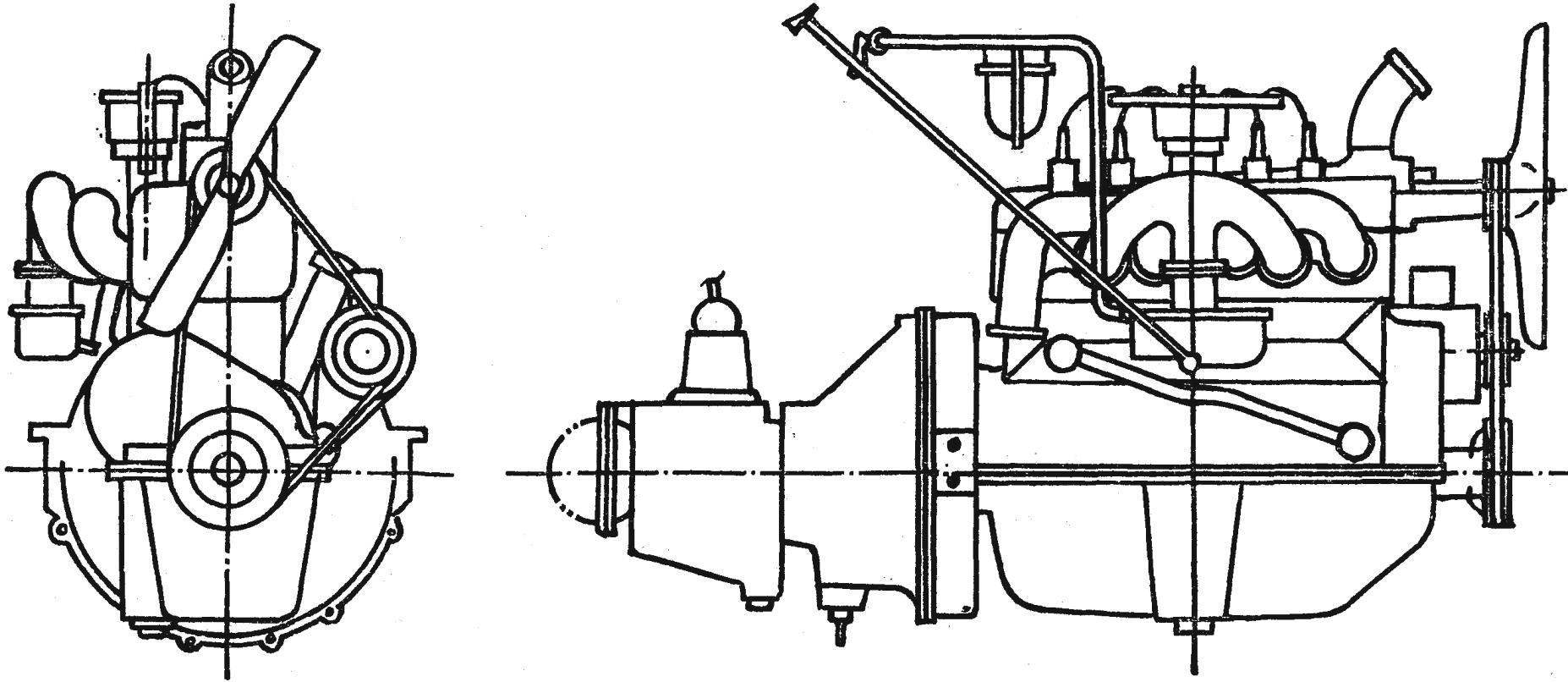

Fig. 3. The engine of the GAZ-A.

Much of the design of GAS-AS it seems in our days amazing: belt hand brake the rear wheels, the lack of a device to adjust the valves (if necessary, the valve stem slightly cut down), very small (4,2) compression, so that in hot weather, when the conditions for evaporation of the liquid is favorable, the engine could even run on kerosene.

For suspension he served two transverse leaf springs, the rear had an unusual form of highly stretched “written” the letters L.

The GAS-produced mainly five-seater four-door open body “Phaeton”. In case of bad weather it was possible to raise a canvas tent and fasten over the door canvas sides with celluloid Windows. In 1934 it was produced a pilot batch of cars (they had an index of GAS-6) equipped with a closed body of type “sedan”. Assembly on the conveyor of such body requiring the mutual adjustment of many complex shape, and most importantly, easily deformable parts, was very slow, and they refused. But the demand for closed cars existed to satisfy him, Moskovskiy Zavod Aremkuz (now he is engaged in repair of buses) began to mount on the chassis of the GAZ-a closed four-door body for the Moscow taxi.

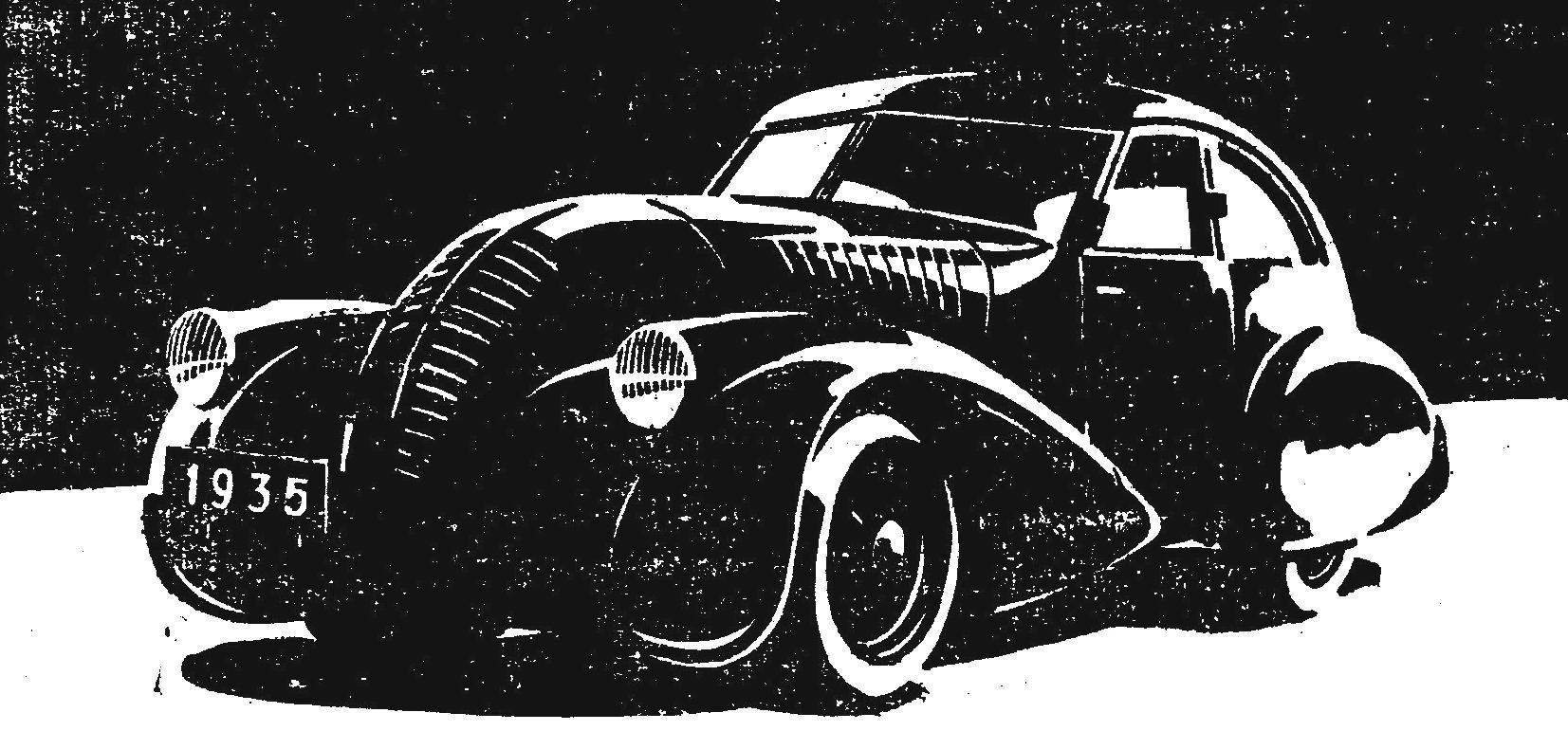

Very interesting, although the only sample GAS BUT the saloon was built in 1934, the Moscow engineer Alexei Nikitin. He gave the car a two-door streamlined body, which would significantly reduce aerodynamic losses and to increase by 20 km/h maximum speed. With the same purpose, a separate Moscow and Leningrad sportsmeny put homemade outdoor double body on the chassis of the GAZ-A.

From 1934 to 1937, GAZ produced “pickups” GAS-4. They used double cab of the truck GAZ-AA, which has a metal body 0.5 tonnes of cargo. In the back of the body (for loading mail products, small consignments of industrial goods} has been made door. Therefore, the spare wheel moved to the front pocket of the left wing. By the way, post “pickups” GAS-4 met in the streets of Moscow, even in the late forties.

In 1934, Gorky made a batch of a few hundred cars GAZ-TK (not to be confused with the GAZ-AAA), three-axle vehicles based on the GAZ-A. Here we should pay attention to the bus GAZ-A. Their width is equal to 120 mm, that is was almost the same as a modern motorcycle with a sidecar. But with a full load of GAS, AND weighed three times more of this bike and hence its narrow tires provided the soil is much more pressure. So when driving on sand, mud, snow wheels easily failed, and the car was stuck. Such a narrow tire then applied to all passenger car and the GAZ-A was no exception. However, during the famous Karakum mileage of 1933, which was tested and six GAS-AND, they were equipped with experimental tires “sorbello” with a width of 250 mm and an outer diameter of 800 mm. They provided a very low ground pressure and, in fact, was the predecessor of today’s wide-base tires used on road vehicles.

I must say that the chassis of the GAZ-a was used not only for “pickups” or taxi. It was body mounted armored D-6 and D-12 that were on the armament of the red Army.

Despite the relatively short period of production of GAZ-A (1932 and 1936), the machine is permanently entered into the life of our towns and villages, has received universal recognition. This car is dear to us as the firstborn of mass Soviet passenger automobile industry as a car-worker, a sample of automotive longevity.

Advice to the Modeler

In the manufacture of models-copies of the GAZ-A, as, indeed, any other vehicle manufactured before mid-thirties, it should be borne in mind that the car so many small parts that need to be performed very carefully.

It is tempting to simplify the design of the wheels. But they play an important role in the reconstruction of the correct external appearance of the car-veteran. Don’t forget that external, the longer the spokes should be of 10 pieces on the wheel. Internal, short, which, crossing, connecting the rim with the flange of the brake drum, 10 pairs.

Most GAS AND were black or light green. The color of the cars that took part in the Karakum mileage, blue. On machines of series production of rim, spokes and naves of wheels, lights, steering wheel, suspension parts — were black. Along the waist line deposited color (red or yellow) into thin stripes. Seat upholstered black leatherette.

Exterior chrome-plated decorative parts for GAS-BUT not much: the radiator (after overhaul the machine was painted radiators), headlamp rim, the rim of the stop lamp, radiator and gas tank, hub caps wheels (including spare), front and rear buffers, the exterior door handles.

Fig. 4. Streamlined machine A. Nikitin on the chassis of the GAZ-A.

State license plates had the form of a rectangle with an aspect ratio of about 1:3. On a white background with black thin border black letters was applied to the number of type I-13-31 or I-94-11, and the front license plate or hung to a strap of a headlamp or strengthened over the buffer on the right side of the course. The back room is set on the left from under the stop light.

Now a few words about the details. When the tent body was in the folded position, it wore the case (so that the fabric won’t get dusty), and the arc framework was based on two brackets. The latter was located on the rear corners of the body and was a very short small trays on legs racks.

Audio signal, is installed in all cars GAZ-a and its modifications under the left front headlight, should have a conical trumpet. However, at one time — in 1932 and 1933 — were and are signals having the front part of the socket is shaped like the pioneer horn.

All GAS-AND there is a lid for the hole for the winding handle. It was attached to the axis and easily moved her in any direction.

Some machines were equipped with two flashlights reinforced on both sides slightly in front of the upper hinge of the front doors. Everyone stood at the short curved stem that terminates at an oval flange. Brand marked “GAS” in black oval was only on the radiator and on the caps of the hubs were round shallow podshtampovki.

Tires set of two size: 4,75 — 19 (early) and 5.00 — 19. The first digit indicates the section width of the tyre, and the second is its internal diameter, expressed in inches. Thus, in the construction of the model can be set in one of two sizes depending on the design of the joint of the tire wheel and rim with spokes.

The pattern on the tread of the tyres was such that the sidewall of the tyre (about one-third of its height) came grooves located along the radii. And another important detail: in the front buffer is visible (see drawing) three jumpers oval — the average is almost half at. In addition, two lanes of the front buffer at the ends are connected by a vertical round rod, around which the strip like twists. Similarly decorated and the ends of the two rear polubarinov. Connected the two halves of the steel crosspiece of circular cross section, painted black. It was almost touching the spare wheel.

Fig. 5. Racing car, made in Leningrad athletes on the basis of GAZ-A.

In winter, the body buttons you can fasten a canvas sidewalls with cellulose (yellowish) Windows. The wind didn’t blow out the front under a side panel, it was bent on the bar and was chained six buttons. Door model it is desirable to make the opening, and constipation should be given from the outside door handle. All the hinges on the GAS AND stood outside the body, and the handles of doors “looked” ahead of the fly.

It is very important to run the dashboard, the steering wheel with all the levers, pedals, levers. The windscreen on the GAS AND when folded, the tent can be folded down forward. By the way, about the glass. It was equipped with one electric “janitor” who cleared the piece of glass in front of the driver, and the case was on the inside of the glass. On the side pillars of the windscreen of some cars were turning panes of glass with rounded edges.

Some modelers can tempt the idea of building copies of the GAZ-A, participated in the Karakum mileage. He left to go on the front buffer was a plate with probegom the room, and the radiator cap is a red triangular flag. The cars that were in the mileage numbers 1, 3, 4, 5, 21, were fitted with wide-profile tires and therefore not secovnie, and the disk wheels; the other cars had serial tyres and wheels.

L. SHUGUROV