About the power plants with a pusher propeller at the Amateur designers often gets the wrong opinion that since the obstacles in the air stream, drop screw back, no, its efficiency is higher than that of the apparatus with a tractor propeller and the thrust is correspondingly greater. However, it is not so. Aerodynamically to arrange the air flow to not only the screw, but before him, since “torn”, the distorted structure of the turbulent flow impinging on the blades, can so reduce the efficiency of the propeller that the thrust he expected to develop never will.

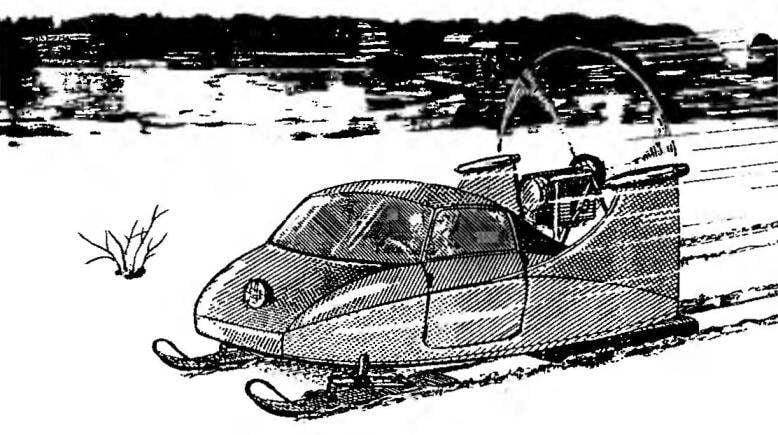

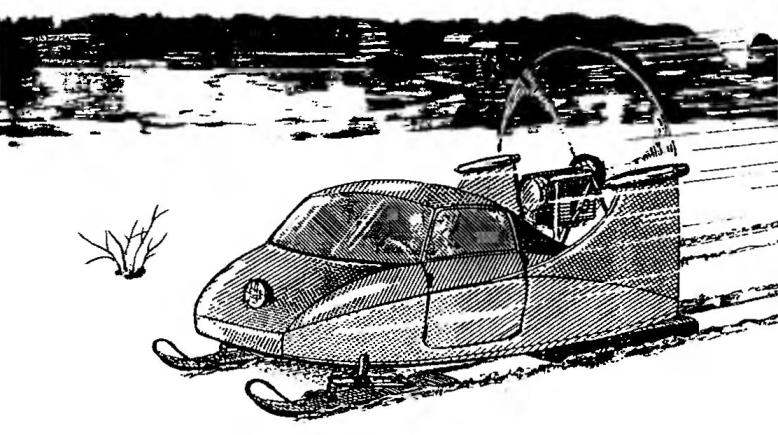

The proposed design attempts to create a comfortable snowmobile, which significantly reduced aerodynamic losses.

The problem is quite complex. I wanted to design a double vehicle with the location of the driver and passenger in the car, and this arrangement has a solid midsection. However, it is preferable to the layout in tandem — the snowmobile was more compact, with the usual proportions of the respective cars.

After drawing of the cabin layout and propeller installation (it was supposed to have it as low as possible to lower the center of gravity of the machine) began suffering with working of body — surface it was necessary to make aerodynamically smooth, with no sharp kinks. The result is a design resembling the domestic post-war car “Pobeda”.

Double snowmobile with engine RMZ-640:

1 — headlight (from the motorcycle IZH); 2 — windshield (ZAZ-968); 3 — side window (plexiglass s4); 4 — engine RMZ-640 and V-belt reducer; 5 — rotor; 6 — marker lamp; 7 — scraper brake; 8 — rear ski; 9— rear window (plexiglass s3); 10—the body of the snowmobile; 11—three-dimensional frame panel; 12 — doors; 13 — rotating blade, the front of the ski; 14 — front ski; 15,16,17—braces, screw-motor mounting (steel, pipe 30х0,5)

Frame-bar snowmobiles:

1 — lower trim panel (plywood s5); 2 — filling (construction foam); 3 — upper trim panel (plywood s5); 4 — rear cross bar (pine, bar 60×50); 5— amplifiers (pine, block 30×30); 6— Central part of the Central cross-beams (pine, bar 60×50); 7 — front beam (pine, bar 50×60); 8,10— spars (pine, boards, s40): 9 — front cross member (pine, boards, s30); 11 — side panel (pine, Board s15); 12 — sidewall average sleepers (pine, bar 60×50,2 PCs.)

The front ski of the snowmobile:

1 — suspension bracket of a pendulum (steel); 2 — the axis of the pendulum (steel, stud М16х 1); 3 — pendulum suspension (steel, pipe 22×3); 4 — spring-hydraulic shock absorber (from a motorcycle “Ural”); 5— safety arc (steel, pipe 16×2,5); 6— fastening of the pipe (the bolt of M6 with nut and washer); 7 — the base of the ski (s4 plywood, stainless steel, sheet s0,8); 8 — fastening of the safety arc (self-tapping screw d5); 9— the case of the hinge of the pendulum suspension (steel, pipe 30×2); 10— bushing joint (PTFE); 11 — bracket (steel, sheet H4); 12 — mounting for shock absorber (bolt M8 with nut and washer); 13 — undercut (stainless steel, sheet s); 14— shock mount (M8 bolt with nut and washer); 15 — shock absorber bearing (steel)

The desire to reduce aerodynamic losses led to the inlet air channel ending in a semicircle, which also performed the function of the fence propeller. The result was a case fairly complex shape, which, however, was fully justified and aerodynamically, and aesthetically pleasing.

The base of the sled is the bottom frame panel. She glued pine bars-side members, wood cross members, foam padding and plywood working of the hull. The panel with small thickness and low weight with high rigidity as to bending and torsion. For spars matched straight grained boards 40 mm thick, of which planed the curved workpiece with a height of about 50 mm. To sidewalls required Board thickness of 15 mm, and the front cross member, on which are mounted the pivots of the steering gear, took the pine bar 60×50 mm Frame panels assembled on epoxy glue. The same binder are applied in the inset in frame of foam blocks, and the bottom trim panels 5-mm plywood.

The body of the snowmobile performed by the classical to improvised structures technology. It consists of a light frame, welded from thin-walled steel tubes with an external diameter of 15 mm, in which a flexible wire is fixed plywood forming elements — stringers. Windshield — from a ZAZ-968, the frame for it attached to the frame by welding. The space between the stringers are filled with foam blocks; after processing of the foam and putty the surface of the case are covered with two layers of fiberglass. The doors are manufactured using the same technology as the case with tubular frame, plywood stringers and foam filling. Rear window and door Windows from a 4-mm plexiglass.

The sides of the rear body, turning into a Keeley (areas behind the doors), lined with sheets of 4 mm plywood attached to tubular frame with M4 screws followed by pasting external surfaces of two layers of glass. The inner part of plywood sheathing to improve the moisture resistance coated with two layers of varnish parquet.

The basis of propeller installation became very popular with Amateur pilots and good enough exhaust RMZ-640 and V-belt reducer. These engines are equipped with a trikes, gyroplanes and airplanes. By the way, the installation of propeller driven planes practically does not differ from projected at the time a student of Moscow aviation Institute A. Rusak double ultralights. With a propeller with a diameter of 1350 mm power unit develops a static thrust of about 120 kg, which is sufficient for snowmobiles. Propeller installation on the bulk frame panel is fixed by six braces of steel pipes with a diameter 30×1,5 mm. For reducing the aerodynamic drag of the tubes epoxy-glued wooden fairings, giving the braces a teardrop cross-section.

The propeller is made of technology, such as the one that uses the German firm Hoffman. Billet screw pine bars section 60×20 mm glued with epoxy. When gluing the layers of bars of wood were placed symmetrically about the planes of the docking is delivered propeller from possible leash. After gluing the blank was carefully otfugovany in accordance with the screw dimensions.

For the manufacture of templates used theoretical drawing of the screw in 1:1 scale. The templates are cut out of plywood, but it would be better to make them out of aluminum. For work took a planned pattern, pattern side view (from the axis of rotation), as well as the upper and lower templates of the rotor blade profile. The profile of the blade is PLANO-convex, wing.

The workpiece marked using the planning template, fixed a nail in the center for the future of screw: template circled in pencil, rotated 180° and again circled — turned contour of the second blade.

Further in accordance with a marking hatchet, and a plane pre-treated blades. Finally the screw is driven in the stocks. Its base is made of a flat Board with a thickness of 60 mm, it is in accordance with theoretical drawing of the screw are fitted with lower profile templates of the blade and the Central core. The latter is enshrined in the center of the base perpendicular to its surface.

Precision machining of screw was tested with the help of blueprints, which rubbed the bottom of the templates: blank fits over the stud and pressed against him, while on the blade was engraved traces of patterns. After removal of traces of blue rasp next screw is again pressed to the templates, and so as long as the workpiece is pressed against the template, not imprinted the traces of all templates along their entire length.

The upper part of the screw is processed in the stocks at the upper templates — first in each section with semi-circular rasp blade was priviligies on the respective upper template so that the upper and lower pattern is in contact at the parting line, while embracing the blade. And then it was removed redundant material between the sections — the correctness of this operation was controlled by a metal line applied to the interest points of adjacent cross — processing was carried out until, until it disappeared in the gap between the ruler and the surface of the blade.

Ready screw carefully to balance, for which the Central hole was inserted a metal shaft and a propeller mounted on the balancing line. A lighter blade was loaded with lead — her first glued small strips of this metal and when the screw has balanced out, from the strips was made by casting in the form of a round rod inserted in epoxy adhesive in a hole drilled in the blade where balancing was located strips of lead, and rasklapanje.

Finish the propeller was covered with two layers of thin glass, followed by grinding, final balancing, primer and paint topcoats.

Propeller installation with V-gear:

1 —the engine RMZ-640; 2 — bracket reducer; 3—propeller with a diameter of 1350 mm; 4 — pulley driven reducer; 5—V belt; 6 — drive pulley gear

The theoretical drawing of the propeller

V-belt gear:

1 — bracket nut (duralumin, the area with the wall s5); 2— propeller; 3 — driven pulley (aluminum alloy AK-6); 4 — axis eccentric screw device belt tension reducer (steel 30KHGSA); 5— bearing 36206; 6 — dust ring; 7 — threaded bushing (steel 30KHGSA, 4 items); 8 — axial bushing (steel 30KHGSA); 9 — base plate (steel, sheet s4); 10 — bolt M8 split washer (4 PCs.); 11 — a lock ring; 12— bearing 60205; 13 — drive pulley (caprolon); 14 — bolt M6 split washer (6 PCs); 15 — shank of the crankshaft of the engine; 16— key; 17 — adaptor (steel 30KHGSA); 18—V belt; 19 — bearing 60206; 20 — a sealing bushing (steel 30KHGSA, is pressed into the crankcase); 21 — oil seal; 22 — sealing ring (rubber); 23 — the bearing 206; 24 — bolt M8 with nut and split washer (4 PCs); 25 — pole clamp

The front ski is glued on the epoxy from strips of 4mm plywood and stainless steel band with a thickness of 0.8 mm. the total thickness of the bonding — 30 mm. Front part of a ski equipped with a arc, bent from steel pipe with a diameter of 16 mm. In the middle of the ski fixed guide undercuts, cut from stainless steel sheet 3 mm thick. Ski is equipped with spring-hydraulic shock-absorber of a motorcycle “Ural”.

The back of the ski — box type. Midsole them glued from 4 mm plywood and 0.8 mm stainless steel (total thickness of gluing 20 mm), sides cut from a 25 mm Board. Depreciation the back of the ski do not have.

Steering — rack and pinion mechanism from motorized С3Д. By the way, she used the heater. Brake — scraper type, are mounted on the rear ski. Brakes combo: pedal to the intermediate lever cable from the lever to the scraper — rigid tubular rod. The throttle carb lever under the right hand of the driver. The arm is equipped with button-lock (like on a manual brake car) to stop it in any intermediate position.

I. SOROKIN

Recommend to read MINI-CASE AT THERMOMETER Mercury thermometer, as we know the fragile and the contained mercury is also very dangerous. So if there is no standard paper sheath for it that will help out a makeshift rubber tip.... ACOUSTIC PROBE The magazine "Amaterske Radio" (Czechoslovakia) proposed scheme is a simple audio probe to detect logic levels; low (logic 0) and high (logical 1). The device consists of a bitonal...

Snowmobile has always been one of the most popular homemade vehicles. The reason is the relative ease of fabrication (the snowmobile has no wheels, complex transmission, hydraulic brakes, clutch, etc.) and efficiency (the larger can on a high speed pass there, where it can crawl except crawler tractors). However, the relative simplicity of design of the vehicle with aerodynamic propulsion introduced many homebrew tempted to create a primitive machine. As a result, these sleds though and could move, but the pleasure of driving the Creator never got them. And most often it was of poor aerodynamic configuration.

Snowmobile has always been one of the most popular homemade vehicles. The reason is the relative ease of fabrication (the snowmobile has no wheels, complex transmission, hydraulic brakes, clutch, etc.) and efficiency (the larger can on a high speed pass there, where it can crawl except crawler tractors). However, the relative simplicity of design of the vehicle with aerodynamic propulsion introduced many homebrew tempted to create a primitive machine. As a result, these sleds though and could move, but the pleasure of driving the Creator never got them. And most often it was of poor aerodynamic configuration.