During the Second world war in the West, fighters, modified to destroy ground targets, became known as fighter-bombers. After the war they were further developed. This contributed to a widespread adoption of leading aviation powers on a much more expensive jet technology, the emergence of tactical nuclear weapons and the reduction of the fleet of combat aircraft. For nuclear strikes from low altitudes in fighter-bombers practiced bombing kupirovaniya, and cars equipped with special sights In this period, the fighter-bombers became the basis of tactical aircraft of NATO countries.

During the Second world war in the West, fighters, modified to destroy ground targets, became known as fighter-bombers. After the war they were further developed. This contributed to a widespread adoption of leading aviation powers on a much more expensive jet technology, the emergence of tactical nuclear weapons and the reduction of the fleet of combat aircraft. For nuclear strikes from low altitudes in fighter-bombers practiced bombing kupirovaniya, and cars equipped with special sights In this period, the fighter-bombers became the basis of tactical aircraft of NATO countries.

In may 1957 came the Directive of the General staff of the Soviet Army on the establishment of the air force fighter-bombers (IBA). Original shelves IBA manned subsonic MiG-17 and MiG-15. Simultaneously, the air force was given the OKB-51 led P. O. Dry technical specification for a supersonic fighter-bomber, backed up by the resolution of Council of Ministers of the USSR, adopted in July 1958.

To reduce the development time for new machines it has modified front-line fighter su-7, has successfully passed state tests and running in production at an aircraft factory number 126 in Komsomolsk-on-Amur In the first prototype of the su-7B (Cypher OKB-22-1) at the Moscow plant № 51 remade a second plane, the 4-series (serial No. 02-04), built by the aircraft factory № 126. On it in the fall of 1958 until February of 1959 replaced the engine AL-7F for AL-7F-1 with a thrust brought to 9600 kgs. Due to the increased diameter of the afterburner of the new engine is a modified aft fuselage became bloated.

Factory flight tests of C-22-1 of the 50 flights were performed from 24 April to 4 December 1959 test pilot OKB-51 E. S. Soloviev. At this stage assessed the key performance characteristics. 7 Dec 1959-22-1 was transferred to NII VVS for state tests; at the same time factory No. 126 commenced the production of su-7B and collected in December of 1959 with the first two production vehicles.

The second prototype C-22-2 entered the joint state tests on 6 February 1960 They were held on the airfields Chkalovsky, Engels and Vladimirovka. Test team GK NII VVS at the stage of joint tests of the su-7B was headed by Colonel-engineer J. M. Kalachev. Under his leadership, the leading test pilots majors, Y. I. Rogachev and V. G. hoarder until may 3, performed the main volume of flights under the program. Only during the tests on two machines made 157 flights, including 10 flights performed according to a special program of state tests unguided missiles (NAR) the ARS-240. In accordance with the program of the plane also flew test pilots N. Zakharov, V. Ivanov, P. Kochergin, Sergei Mikoyan, Chipcom and Shane.

C-22-2 were checked for completeness compliance with the technical requirements of the air force and was significantly different from the production su-7:

— increased to 3380 l capacity fuel system with two wing tanks (1090 l). In addition, provided under the fuselage, two external fuel tanks (PTB) 600 l;

— in the rear fuselage housed the drogue parachute was increased to 15 m2 dome;

— in addition to the two guns NR-30 with ammunition for 65 cartridges per set 4 removable beam holder (two under the fuselage and two under the wing), which could be suspended: 4 bombs from 100 to 500 kg; 4 incendiary tank BZ-360; 4 missiles ARS-240 or ARS 212 to ПУ12-40; 28 missiles KARS-160 4 UBA-14, 64 57mm rockets ARS-57M or KARS-57 meters in 4 blocks of UB-16-57. For firing the guns and rockets used a modified sight ASP-5 NM, working in conjunction with DME SRD-5M, located in the radio waves cone air intake;

— to make full use of maximum takeoff angles and ensuring the departure from the land at minimum speed on the C-22-2 set a higher main landing gear and wheels CT-69 (880×230 mm) with disc brakes.

Basic flight data airplanes C-22 received during the state tests, meet the tactical-technical task, with the exception of the range (80 and 87% from the target at low and high altitudes, respectively).

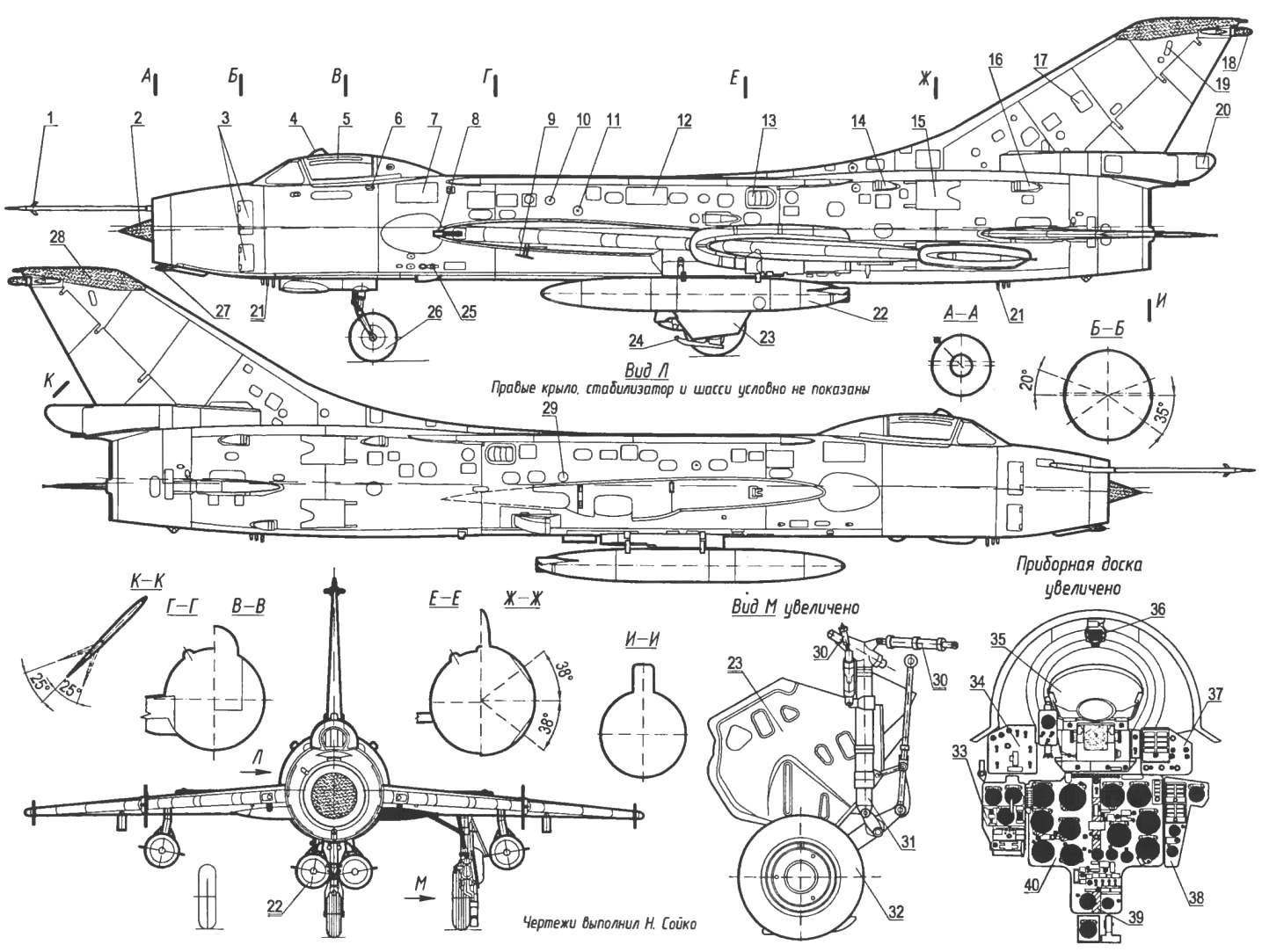

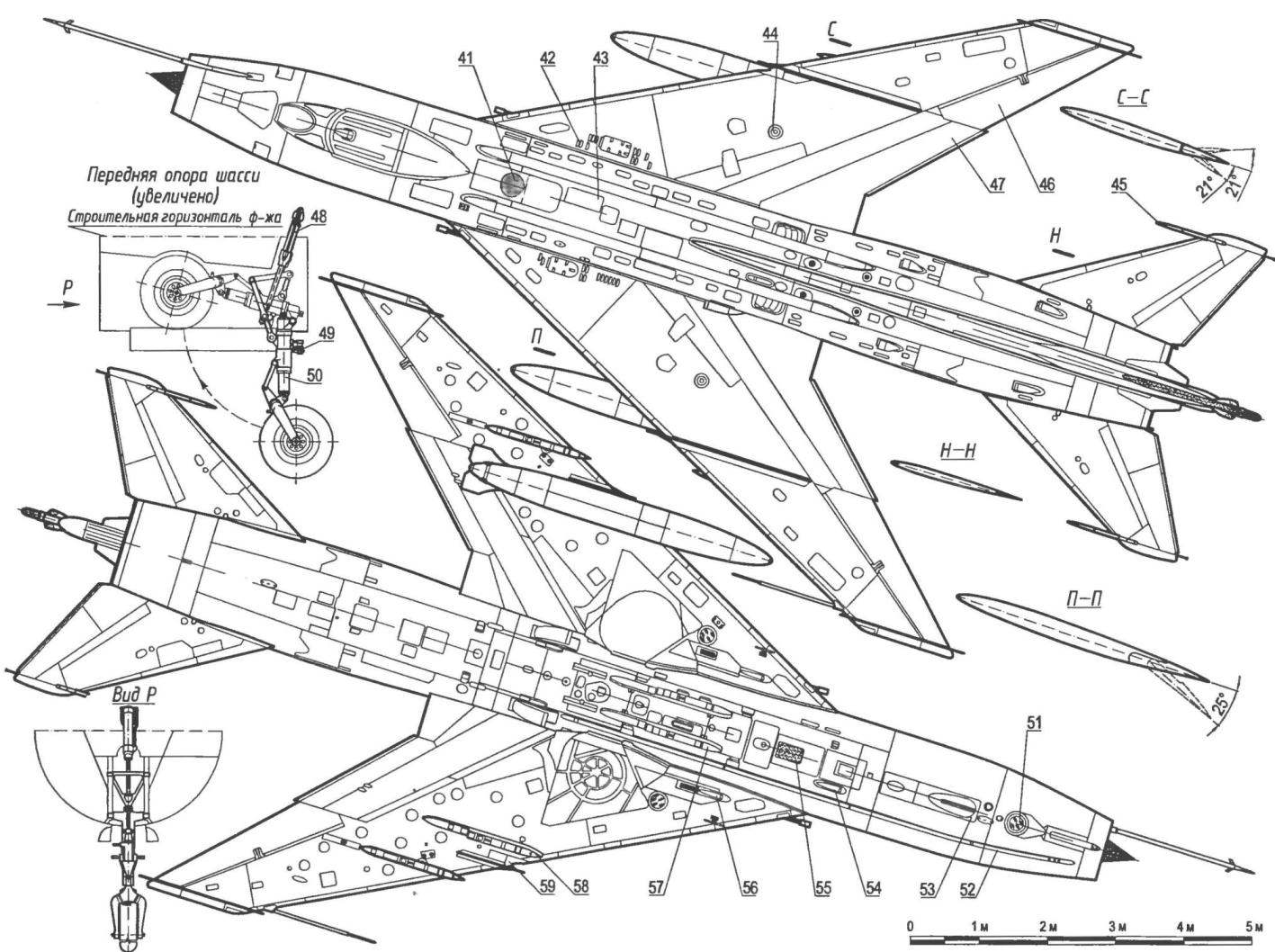

Fighter-bomber su-7БКЛ:

1 — rod LDPE; 2 — movable cone air intake; 3 — anti-surge sash; 4 — periscope TS-27AMSH; 5 — omnidirectional antenna ARC-10; 6 – thermocouple; 7 — cover of electrical equipment; 8 — gun HP-30; 9 — antenna radio altimeter RV-UM; 10 – filler neck fuel tank; 11 — filler neck-fuel turbine starter, 12 hatch cover maintenance units turbojet AL-7F-1-250; 13 — window bypass; 14 — intake air cooling-chamber and the afterburner; 15 — brake flap; 16 — vozduhotehnika cooling of jet nozzles; 17 — cover CAD; 18 — antenna SOD-57M and “Sirena-2”; 19 — antenna of the SOD-57M (1st range); 20 — fold drag parachute container; 21 — antenna SRO-2 (3rd range); 22 — 600-litre PTB; 23 — shield main landing gear; 24 — lyanok; 25 connectors airfield networks; 26 — wheel K2-106A (660×200 mm); 27 antenna SRO-2 (1st & 2nd bands); 28 — fairing antenna RSIU-5; 29 — fuel filler oil system of a turbojet engine AL-7F-1-250; 30 — cylinders of the landing gear; 31: nitrogen-hydraulic shock absorber of the main stand; a 32—wheel CT-69 (880×230 mm); 33—left panel; 34 — sight PBK-2; 35 — sight ASP-5НД-7 -; 36 — a liquid magnetic compass KI-13; 37 — right alarm panel with alarm signal Board; 38 — right panel with the normal signal Board; 39 white lane; 40 — Central panel; 41 — antenna ark-10; 42 — fissure vent-chamber HP-30; 43 hatch cover of the charging guns; 44 — fuel filler wing fuel tank; 45 — anti-flatter cargo; 46 — Aileron; 47 — flap; 48 — the cylinder release and cleaning of the front landing gear; 49 — damper “shimmy”; 50 — nitric-hydraulic shock absorber front; 51 — boarding-taxi-headlight; 52 – the duct systems of KS-1; 53 wing front landing gear; 54 — air intake cooling compartment radio equipment; 55 antenna MCI-56П; 56 — cooling air intake compartment NR-30; 57 — beam holder БД3-57ФР; 58 — beam holder BDZ-57КР; 59 — cover fotokinopulemeta AKS-5-57

Fly in the ointment to the obvious advantages of the new aircraft speed, twice the speed of sound, large range of payload of 2 tons and features the development of combatant plane pilots of average skill — were the deficiencies identified during the tests. Some of them were required to liquidate in the next three months, the rest had to be eliminated according to the program agreed by the State Committee on aviation technology (GKAT) and the Soviet air force.

The establishment of the first domestic fighter-bomber proved to be more difficult than seemed at first Combat use of the su-7B as a fighter-bomber in the brought to the test the limit the following disadvantages.

Shooting NAR was allowed to conduct only when the engine is idling because of the risk that it will stall.

Navigation equipment of the aircraft did not provide accurate output in the target area at low altitude. Air force Institute proposed to establish a course system of KSI instead of the gyro compass GIK-1, the errors of which after perform turns with roll more than 30° and change the speed of the flight reached 15 — 20°. Distorted information sent to the navigation indicator NI-50ИМ. Of error and big the graduation NO-50ИМ were not allowed to enter the goal: side the error was 5 — 6 km. In some cases, the aircraft flying at an altitude of 300 — 500 m, it was possible to direct on a target at a distance of 70 km, using ground-based radar P-30.

Flying at a low altitude test of the Institute revealed that the limited forward visibility is getting worse and optical effects — interaction of the reflector sight and the windshield glass due to the diffraction of light to the front of the plane viewed through the bright circular spot, which hinders the orientation and target detection. When flying in the direction of the sun review was practically absent. Height detection and recognition is an overlook of the guidelines was carried out through the side cockpit glass.

The state tests of the aircraft showed no stipulated technical requirements of the devices that bombing from horizontal flight and kupirovaniya. The sight ASP-5 NM was allowed to bomb only with a gentle dive, maintaining a pre-specified conditions of bombing (height, speed, and dive angle) the Angle of pre-emption was not to exceed 7.5° (otherwise the brand of sight was applied to LDPE and at an angle of more than 9° precision bombing is practically excluded). The very sight of the test did not work: their contribution to it made the sensor angles of attack and slip DUAS-133 DME and SRD-5.

In preparation for the state tests on the main landing gear C22-2 installed wheels with the air pressure in the tire 13 ATM — the biggest at that time in the domestic fighters. Due to low performance on earth the airfield for take-off the aircraft required special training runway. In addition, the su-7B was able to operate from airfields with a runway length of not less than 2.2 km away. During takeoff (the engine of the aircraft at takeoff and at the beginning of the run) fully compresses the shock absorber of the nose landing gear, and the distance from bottom of intake to the soil amounted to 930 mm on clay airfield would lead to entrainment of foreign objects and engine damage.

The engine AL-7F-1 due to design limitations and the lack of the automatic maximum speed limiter after the launch required constant attention, reducing the possibility of combat maneuvering of the aircraft and complicating the work of the pilot.

Stability and handling of the su-7B without-and with all brought to the test weapons were assessed as satisfactory. The disadvantages of the aircraft carried small quantities of efforts and deviation control knobs to create overload at subsonic speeds (in some flight regimes to increase the overload on a single unit of the handle was 3 mm), which could lead to dangerous consequences in combat. Because of this, experienced test pilots in some cases exceeded the specified maximum overload. There is increased sensitivity of the aircraft to deflection of the rudder and the large easy foot control with the lack of effectiveness of the ailerons. These deficiencies in piloting failed to clear in the future. The well-known military test pilot E. M. Groves assessed the flying of the su-7U in one sentence: “the awl”.

Of the five types of RS stipulated in the technical specifications, the state tests showed only two ARS-240 (later C-24) and KARS-57 (P-5K). In the Arsenal of the fighter was absent guided missiles “air — air”, so air force Institute proposed to rearm aircraft missiles K-13. The aircraft is stipulated in the technical specifications the 30 mm gun TKB-515 left cannon NR-30. Vitality cannon be below the established air force standards: front mount left gun collapsed after performing half of the required shots.

A flight with a set of practical ceiling in one direction was unsafe: deleting from the airfield up to 200 km remaining fuel in 600 — 800 kg are not guaranteed return to their base. Air force Institute proposed to further increase the capacity of the fuel system through the installation of two PTB under the wing.

Depending on take off weight speed of lift-off, the su-7B was 330 — 380 km/h. due to the large time of the landing gear (12 — 15) climb performed with increased angle of attack, to avoid exceeding the limit speed (< 600 km/h) to complete the landing gear.

In addition, the su-7B was proposed to set the autopilot to consider issues of suspension under the aircraft increased the number of NAR and aerial bombs of calibre of 100 and 250 kg. to increase the flight range of the aircraft ferry PTB increased capacity; to create on the basis of the su-7B training and combat aircraft. Lapping plane to the level of requirements that meet the air force took several years.

Fighter-bomber su-7B was adopted on 24 January 1961 and asked the development of modifications with improved landing performance and combat training. By this time in Komsomolsk-on-Amur was built 107 production su-7B.

First to the development of the su-7B began in June 1960 the pilots of the Voronezh regiment of the 4th Center for combat training and retraining of pilots of tactical aviation (tsbp and PLS). For the Voronezh production su-7B armed regiments IBA in the European part of the USSR: 642-y OAPI 48th VA Odessa military district, 274-th Proskurov APIB 9th IAP, VVS Moscow military district. From January to October 1961 in the 4th tsbp and PLS conducted combat tests of the su-7B, and 9 Jul 1961 21 serial fighter-bomber flew in the parade in Tushino.

To improve the landing characteristics of one of the su-7B (Cypher OKB-25) equipped with a control system pornsleep UPS-2M hardpoints boosters, 2-ku-dipole parachute system and automatic cleaning of the flaps, combined with the production of braking parachutes. December 2, 1961 test pilot OKB S. V. Ilyushin made the first flight on this machine.

In early 1962 s-25 modified: moved the drag chute container in the upper part of the fuselage and improve the system of blowing boundary layer.

Tests-25 system UPS-2M in early 1963 showed that the UPS does not provide the necessary reduction of the landing speed of the aircraft, increases the weight and complicates the operation and driving technique. The application of the system oops on the su-7B was acknowledged unreasonable.

Serial production of su-7B its design has been continuously improved. On the su-7B with the 13th series began to establish a system of KS-1 that, regardless of the position of lever engine control transferred to the latter at low throttle when pressing the pilot button combat with the launch of rockets, after which it automatically outputs the engine to the original mode. 26-series su-7B began to produce the main landing gear, shortened to 113 mm, and the eighth machine 31 series nose strut, complete with improved damping performance. On the rear fuselage with the 28th we came to the intakes blowing the flaps of a jet nozzle. Fighters with 36 series shifted to the starboard side rod LDPE, which significantly expanded the range of angles of dive when bombing and improved visibility from the cockpit forward on takeoff and landing. On the proposal of the technology of the production plant electroplaits put in two small fairing on the upper surface of the fuselage.

In early 1962, he graduated from the factory and have started joint state tests of modified su-7B (S-22-4) with a reduced length of run and run, equipped with wheel-ski gear. Factory tests have shown that the C-22-4 provides the pre-set technical specifications length of run and run.

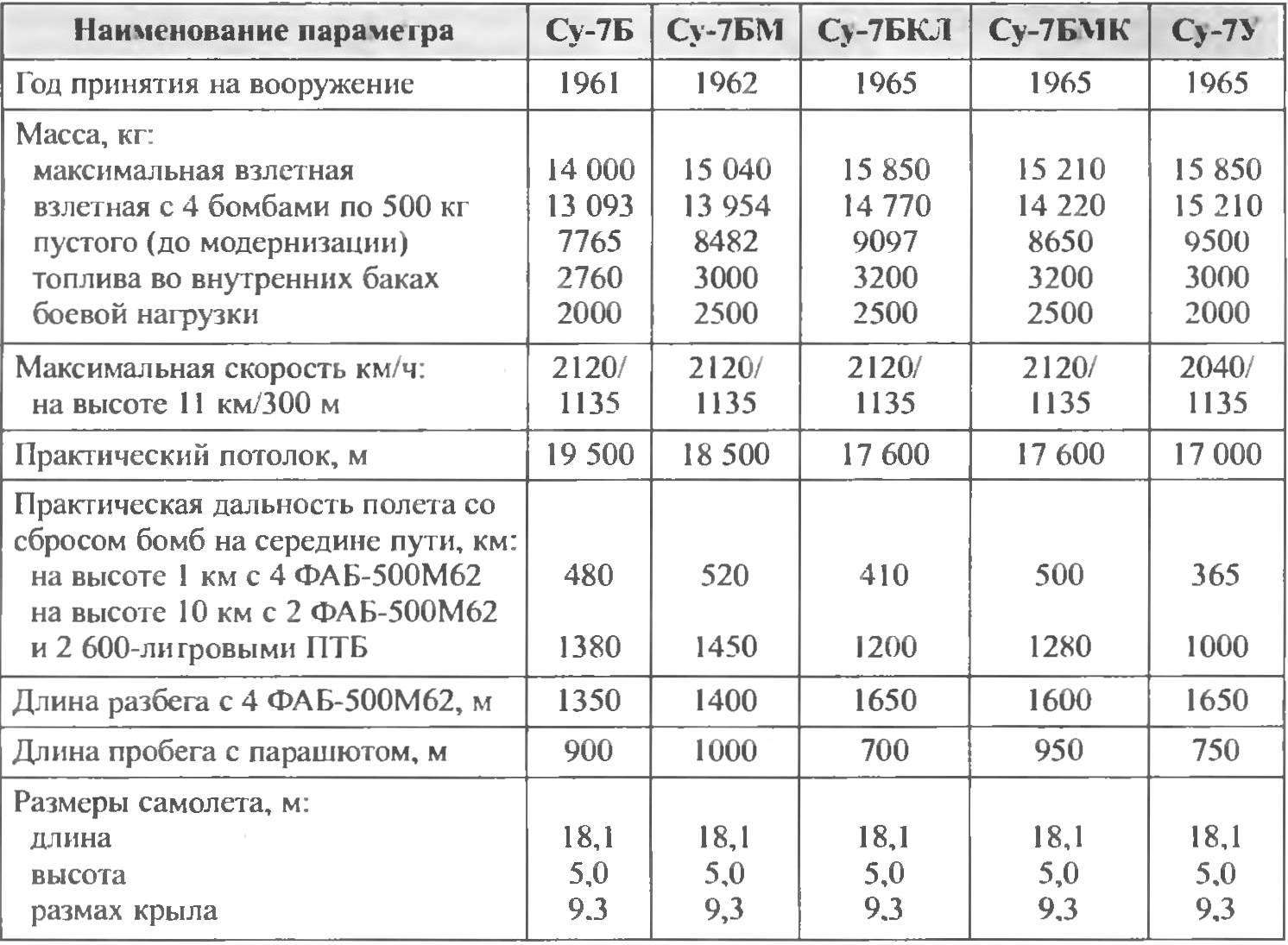

The main characteristics of the aircraft su-7B

Note. Maximum takeoff weight for the given machine after the modernization program, adopted after the exercise “Dnepr-67”.

In July 1962, the Assembly line plant in Komsomolsk-on-Amur rolled out last serial fighter-bomber su-7B 45 series, and in September gathered the first fighter-bomber su-7BM (product-22M). Its production lasted until March 1965 when, after completing a 56 series switched to production of the su-7БКЛ.

For serial su-7BM implemented the main proposals highlighted in the act state testing of C-22 in may 1960:

— installed new equipment: the system of KSI-2, rsiu-5, the autopilot AP-28-T1, dual channel damper Д2К-110, the radio altimeter low altitude RV-UM, remote attitude indicator AGD-1;

— due to the two underwing fuel tanks total capacity of fuel system increased to 6050 l; more powerful pumping station NS-3 has speeded up the cleaning of the landing gear and removed speed restrictions during climb after takeoff: installed new wheels CT-69-4 (880х230В) on the main landing gear and the brake wheel CT-100 (570х140В) with tyre pressure of 9 bar to the front strut:

— equipped aircraft of the bottle system of fire alarm system SSP-2M;

— to protect the engine against ingress of foreign objects equipped with the engine intake system jet protection “blow-off”;

is the cockpit equipped with lighting red light;

— equipped with su-7BM new brake parachute PTZ-7B.

In the summer of 1962 S-22-4 equipped with hardpoints boosters sprd-110 with the system start automatically and the container in the upper part of the fuselage under the two domed brake parachute to increased efficiency.

In the fall of 1962, the state tests of a modified C-22-4 continued in Vladimirovka, on the ground in Osivtsi and in Taganrog. During the tests the aircraft was equipped with front wheel K2-106 terrain and automatic retracting the flaps at the moment of touching the ground the front wheel.

In early 1962 began testing of C-22-6 (serial No. 22-05) sight PBK-2 for bombing kupirovaniya. In addition to sight in refining plant No. 51 mounted on the plane of LDPE 7, DUAS-61-11 and block 458Б (instead 458М). April 9, 1963 in a 58-m flight S-22-6 crashed.

State tests PBK-2 continued in December on a production su-7BM (serial No. 48-15), however it at the factory No. 51. Testing of PBC-2 on this machine successfully completed in June 1964

The vitality of the plants, HP-30, the su-7B was confirmed by testing of prototype C-22-7-22-1 and p-25T with reinforced fixing points of the guns.

In April 1963, ended the state tests of the plane With-22-2 with a wheeled chassis in different climatic conditions from the unpaved airfields. Tests showed that after appropriate training the operation of the su-7B is possible with all versions of suspensions at a soil strength of not less than 8 kg/cm2, and in winter conditions the runway, cleared of snow or having the rolled snow cover with thickness up to 15 cm.

-22-4 after completion of flight tests, the wheel-ski gear in March 1963 he transferred to the plant № 51 for routine maintenance and preparation for future testing to reduce run and run on takeoff and landing.

Until December 1963, the modified C-22-4 at the airfield in Lukhovitsy and LEAH checked the stability and controllability of the aircraft, the braking system, the start and reset accelerators. Aircraft with wheel-ski gear to work with WFP pounder, with boosters sprd-110 to reduce the length of the run and two domed parachute recommended for serial production under the designation su-7БКП (product-22КЛ)

In 1963, the OKB-51 successfully tested ejection seat COP-4. In 1963, the plant № 126 built three prototypes of the su-7U (AT-22), unifying them with the serial model of the su-7BM in 1964 In connection with completion of state tests of the individual systems-22-4 prototypes of the aircraft U-22 equipped with ejection seat COP-4, the upper container of a brake parachute sight PBK-2, managed-pillar and oxygen equipment KKO-5.

In 1963, by the decree of the government # 126 replaced on most of the su-7B in combat units of the ejection seat COP-2A for more advanced cs-3 18 APR 1964, during the execution of the flight according to the program correction according to results of tests S-22-4 air force Institute killed the test pilot of Sukhoi design Bureau A. A. Koznov. During takeoff with two bombs FAB-500 with the use of boosters sprd-110 one of Staroverov took off the locking pin from the combustion chamber and force the flames burned the traction control stabilizer When hitting the ground the plane caught fire, and exploded one of the bombs. Completed control tests on modified production su-7B (serial No. 37-06).

OKB-51 continued further development of the su-7B and su-7BM:

— carried out work to ensure the use of the su-7BM nuclear weapons (C-22-10),

— aircraft equipped with altimeter ODI-30 and transferred to the serial plant documentation in the cockpit of the su-7B with improved visibility;

— to facilitate the work of the pilot, to improve the accuracy of maneuver and reduce weather-at least the prototype C-22-11 was equipped with automatic control system SAU-22;

— by plane C-22-8 experienced radio short-range navigation (RSBN) Iskra and antenna-feeder system “Pion”;

— the C-22-9 equipped with a sight ASP-PF and modified beams, the holders BDZ-57M.

In 1965, serial # 126 has mastered the production of four new versions of the fighter-bomber: su-7БКЛ, su-7U and export su-7БКП and su-7УМК.

Su-7БКП differed from its predecessor, the wheel-ski gear, new sight ASP-5 NM-7-HAVE, an ability to reduce takeoff distance of boosters, two domed brake parachute, housed in a container at the base of the keel, the engine with a huge resource AL-7Ф1-250 and a new ejection seat COP-4. In March gathered and the first export version of the aircraft — su-7БМК, who completed a wheeled chassis, modified equipment and system of national recognition.

Following the 1967 exercise “Dnepr” air force leadership approved a comprehensive program to improve the combat effectiveness of fighter-bombers su-7B/BM/BCP.

Has increased not only the number of points of suspension arms. On the ventral wing and near the nodes of the su-7БКЛ suspended blocks UB-32-57 32 Nara C-5, blocks UB-16-57УМ “migrated” to additional nodes. To ensure start-up BUNKS in one run of the UB-32-57 the interval of their descent, compared with the UX-16, is reduced to 0.075 to 0.05 C.

Developed mnogozubkovoy beam holder MBZ-Y6-68 allowed to suspend up to 20 ofab-WAM or 10 ofab-250 M-54 instead of 4 FAB-500M62 or 4 FAB-250M-54. The plane was devouroil more advanced missiles “air — air” R-60 In 1972 at the GK NII VVS su-7БКП tested the gun container UPK-23-250 (lead test pilot V. P. Khomyakov).

To increase the range developed a new overhead bins: PB-PB 950-1150. Flight tests of the su-7БКЛ and su-7U from the PTB revealed serious limitations that were imposed on flying the aircraft. In addition, the PB-950 is poorly separated from the wing of the su-7БКП. For normal offices, they were equipped destabilizers on the nose cone

On the basis of PB-1150 has developed uniform standards that consisted of interchangeable nose and tail pieces, and replacement of the Central, of which it was possible to collect the pot of PB-1150 and PB-800. Many tests of this program was headed by leading engineer of the research Institute of the air force A. I. Marchenko.

Serial production of aircraft of the su-7B was not until 1971 was made All the 1950s cars, most of which was used by the Soviet air force until 1989, more than 700 of the machines set air force Czechoslovakia, Poland, India, Egypt, Algeria, Iraq, Korea, Vietnam and Syria. Fighter-bombers of this type have been used successfully in the Arab-Israeli wars and the Indo-Pakistani conflict, which have proven themselves reliable military vehicles.

N. JAY