The training model “air combat”. The emergence in recent years of specialized model stores are relatively inexpensive and fairly powerful electric motors allow to transfer a number of classes of models to electric drive. The result was the appearance of the model aircraft new fans that previously stopped the need to get model engines internal combustion with all its attendant problems — their high cost, short lifespan, low reliability, problems with the acquisition of fuel components, the complexities of starting, running and operating.

The training model “air combat”. The emergence in recent years of specialized model stores are relatively inexpensive and fairly powerful electric motors allow to transfer a number of classes of models to electric drive. The result was the appearance of the model aircraft new fans that previously stopped the need to get model engines internal combustion with all its attendant problems — their high cost, short lifespan, low reliability, problems with the acquisition of fuel components, the complexities of starting, running and operating.

We offer our readers a model of air combat with an electric motor Graupner Speed 400, the operating voltage which is 7.2 V. To power the motor more convenient to use a motorcycle battery, at 12 V: taking into account the voltage drop on the current-carrying cords on the motor terminals should be a voltage close to the working. At startup, the battery is most convenient to place inside a bag with a shoulder strap or in a small school backpack. Toggle switch start engine is located on the control handle “bouzouki”.

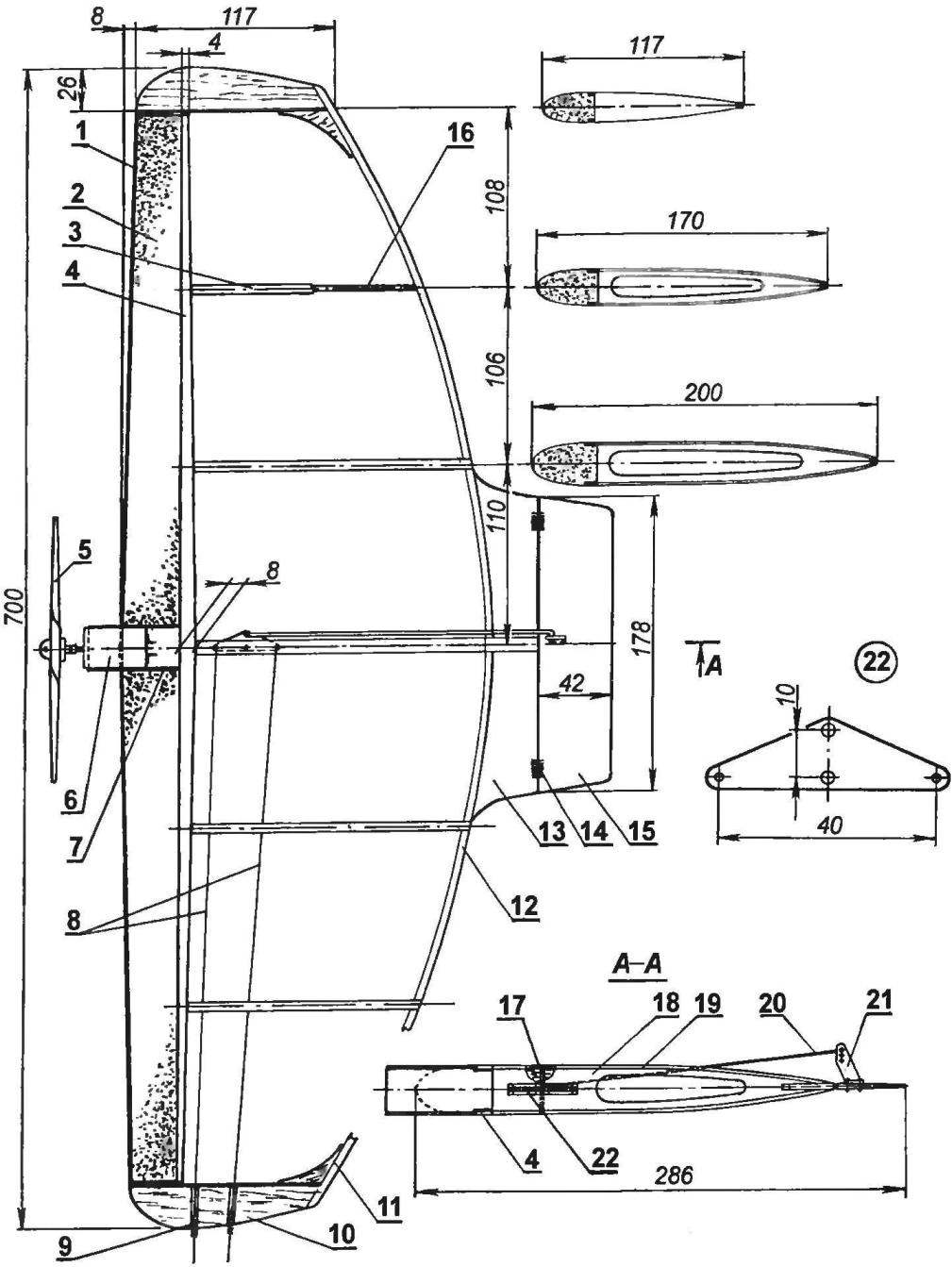

Model design is not very different from those created under the ice, it is only slightly reduced. Pine beam flange, tapered — 8×3 mm in the center and 4×3 mm at the ends, the wall is made of plywood with a thickness of 1 mm. the Forehead of the wing — from the packing foam; cut electrotermometria made of stanochek luchkovoj saws, which instead of steel stretched canvas glow by an electric current nichrome filament.

The leading edge — from pine strips with a section of 2×10 mm, rear — pine slats 5×5 mm. Central rib cut from the balsa plate with a thickness of 5 mm, and the rest of the plates 3 mm thick ribs All along the perimeter is edged with strips of balsa section 8×2 mm — it increases the stiffness and strength of the model as a whole. Fins — balsa, plate thickness of 5 mm. At the outer tip is fixed a lead weight weighing 15 — 20 g.

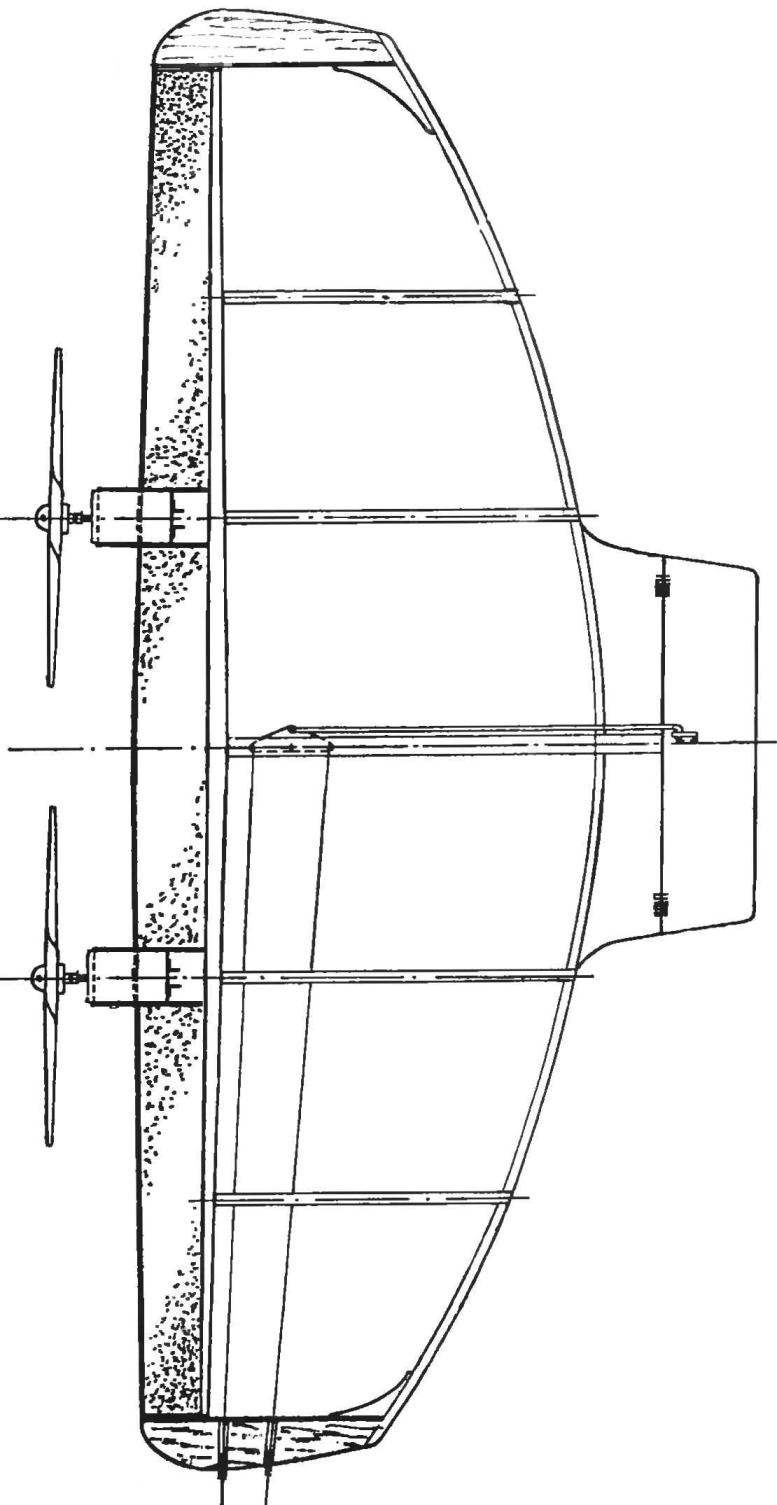

The model of “air fight” with the motor Speed-400:

1 — front edge of the wing (pine, strip 2×10 mm); 2 — the forehead of the wing (packing foam); 3 — trim the ribs (balsa, strip 2×8 mm); 4 — shelf side member (pine, rail 3×8 mm); 5 — propeller Ø170 mm; 6 — motor type Graupner Speed-400; 7 — cage motor (Vileika of fiberglass and epoxy|, 8 — transverse traction (cables from copper wire); 9 — guides for the transverse rods (spring steel wire); 10 — ending (balsa plate s5); 11 — Klondike (plywood s3); 12 — rear flange (pine, rack 5×5 mm); 13 — shank (balsa plate s3); 14 — hinge-hinge (nylon thread); 15 — the Elevator (balsa plate s3); 16— rib (balsa plate s3); 17 — the axis of rocking of the control (aluminum, wire Ø2. 5); 18 — the Central rib (balsa plate s5); 19 — trim rib (balsa, strip 2×10 mm); 20 — control rod Elevator (dural needle Ø2. 5 mm); 21—pylon rudder (aluminum, sheet s2); 22 — the chair of management (fiberglass, sheet s2)

The shank and the Elevator is also made of balsa. The hinges of the Elevator — from nylon yarn braided around a steering wheel and shank “eights”.

The engine is mounted in a fiberglass cage, laminated of fiberglass and epoxy binder in the billet, whose diameter is the same as that of the motor. The length of the clips makes sense to do a stock — this will help in debugging the model to adjust the alignment by moving the motor forward or backward.

Wing clip is secured with epoxy glue. After final adjustment, the clip is trimmed, the engine is wound stripe-other vinyl electrical tape or Scotch tape, that allows reliably to fix it.

Rocking control cut from the fiberglass (you can use other insulation and quite durable sheet material) with a thickness of 2 mm. it is Secured in the slot of the Central rib, between the two washers; axle it is the segment of the dural spokes with a diameter of 2.5 mm.

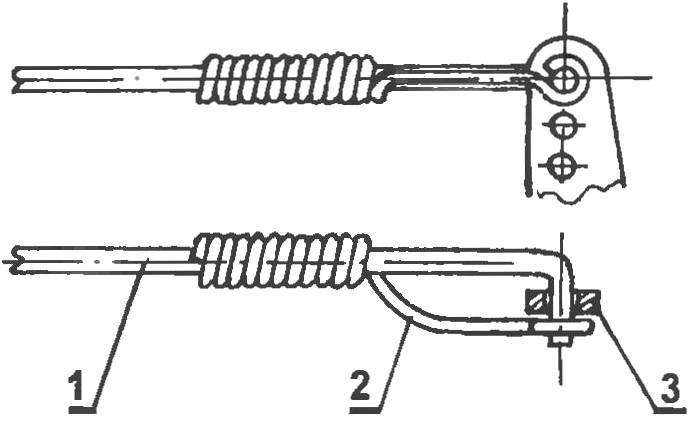

The device lock control rod:

1 — longitudinal thrust; 2 — retainer (steel wire Ø0,8 mm); 3 — horn of the Elevator

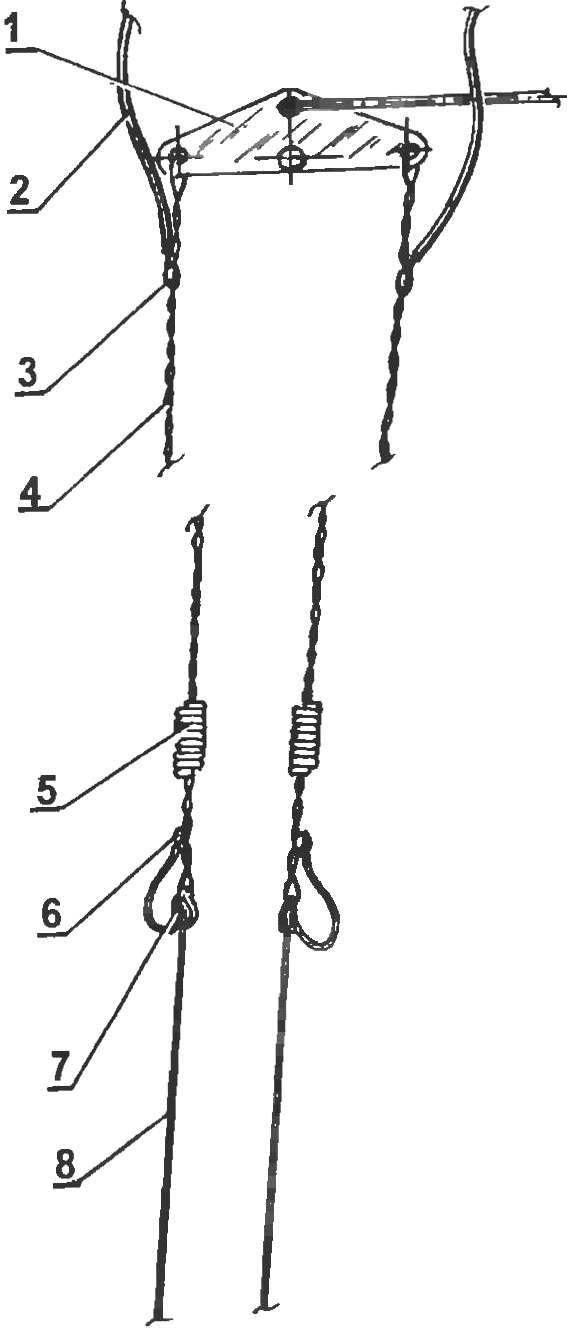

Wiring models:

1 — rocker control; 2 — wire motor supply voltage; 3,6 — spikes; 4 — transverse pull (cable from copper wire); 5 — transverse guide rod (spring steel wire Ø 0,5 mm); 7 — loop fastening cord; 8 — cord (insulated phone wire)

Of the same kind of spokes made and a longitudinal control rod. To secure its connection with the pylon uses a simple detent of a resilient steel wire with a diameter of 0.5 mm (in accordance with the above figure).

Transverse thrust represents wires made of two to four (depending on diameter) copper wires. The conductors coming from the motor, are connected with the transverse rods by soldering a Good cord (length is 8 — 10 m) are obtained from the telephone cable, you only need to isolate from it a pair of insulated stranded provodnichki. With transverse rods they are connected with a loop or knot, the electrical contact is provided by soldering.

After completion of wiring, please connect the battery to Kardam-conductors, start the engine and measure the voltage at its terminals, and the terminals of the battery.

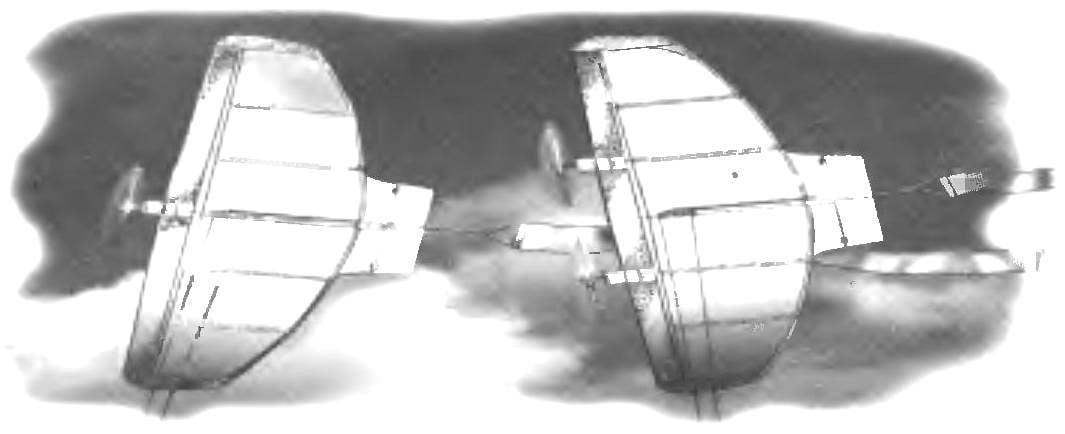

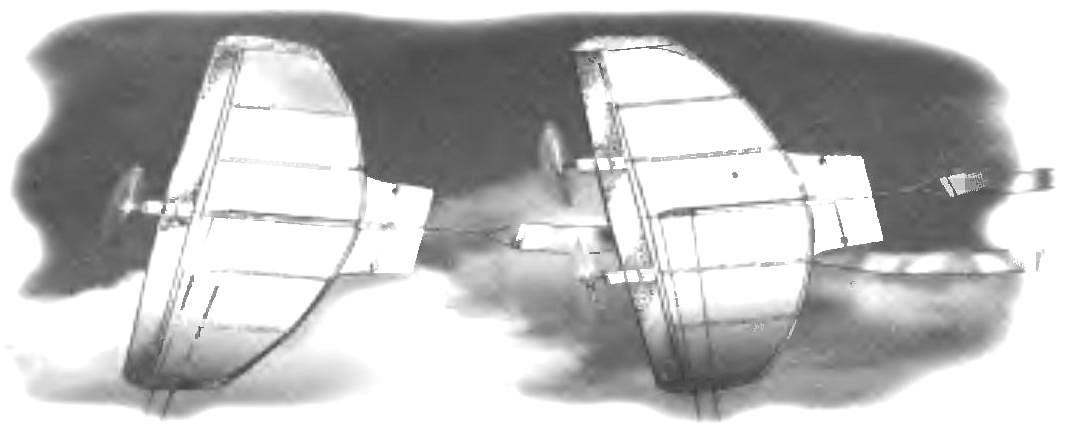

The twin-engine variant of the model of “air combat”

In the ideal case, the voltage with the engine running, should be about 10 In (remember, its working voltage is 7.2 V). If a 12-volt battery does not provide this voltage, you should either increase the cross section of the cord conductors, or migrate to a more powerful battery.

The wing is fitted by a thin metallized Mylar film (with glue BF-2, BF-6, or “the Moment” and with the use of iron).

On the basis of this “bouzouki” can be made twin-engine version with increased power to weight ratio — this model can use more experienced “warriors”.

Flying models — including a twin-engine variant is not difficult. To run the model, you need two: after engine assistant performs stuffing “bouzouki” tangential to the circumference of the flight.

Pilotage requires a platform with a diameter of about 20 m. the Model is kept steadily in the air, while carrying out most of the shapes flying. To conduct the air battle models fixed paper tape with a length of about 3 m.

I. SERGEEV