Parameters and characteristics of the model correspond to the categories Ѕ8А and Ѕ8В. The diameter of the container under the engine selected in accordance with a cross-section of the sleeve (MRD-2,5-3-3 or MRD-5-3-3). We present several design and technological recommendations for the production model.

Parameters and characteristics of the model correspond to the categories Ѕ8А and Ѕ8В. The diameter of the container under the engine selected in accordance with a cross-section of the sleeve (MRD-2,5-3-3 or MRD-5-3-3). We present several design and technological recommendations for the production model.

In accordance with the requirements of this class the motor after operation must remain in the container, so the tube must be made more durable than the rocket modeling other types. The nose cone of the container is carved from solid balsa. Immediately after fairing in the tube container, cut the bottom of the hole Ø 8 mm. the Pole of the container and the fuselage carved from balsa plates 4 mm thick. After gluing, they need four to cover the liquid Amalita with intermediate sanding with fine emery paper. Rear part of the fuselage on both sides enhanced with overlays of plywood with a thickness of 1 mm.

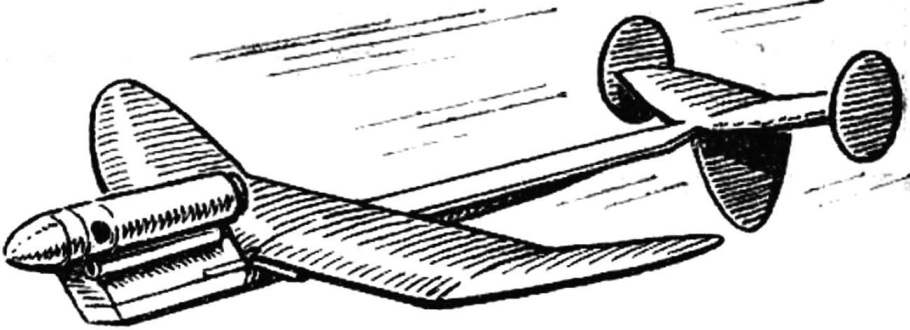

Guide on which slides the wing when balancing the model, cut out of plywood with a thickness of 0.6 mm and covered with three layers of Amalita. Wing balsa plate thickness of 7 mm. After processing and lacquer coating it is cut in three pieces (two consoles and center section), and then glued together to form the required angle “V”. Then out of plywood with a thickness of 1 mm should be cut two gaskets and two castles. First wing glued to the strip (it is necessary to control the ease of movement of the wing along the rail) and then the plywood strips to the castle. The final stage: a rail with the wing fixed on the fuselage.