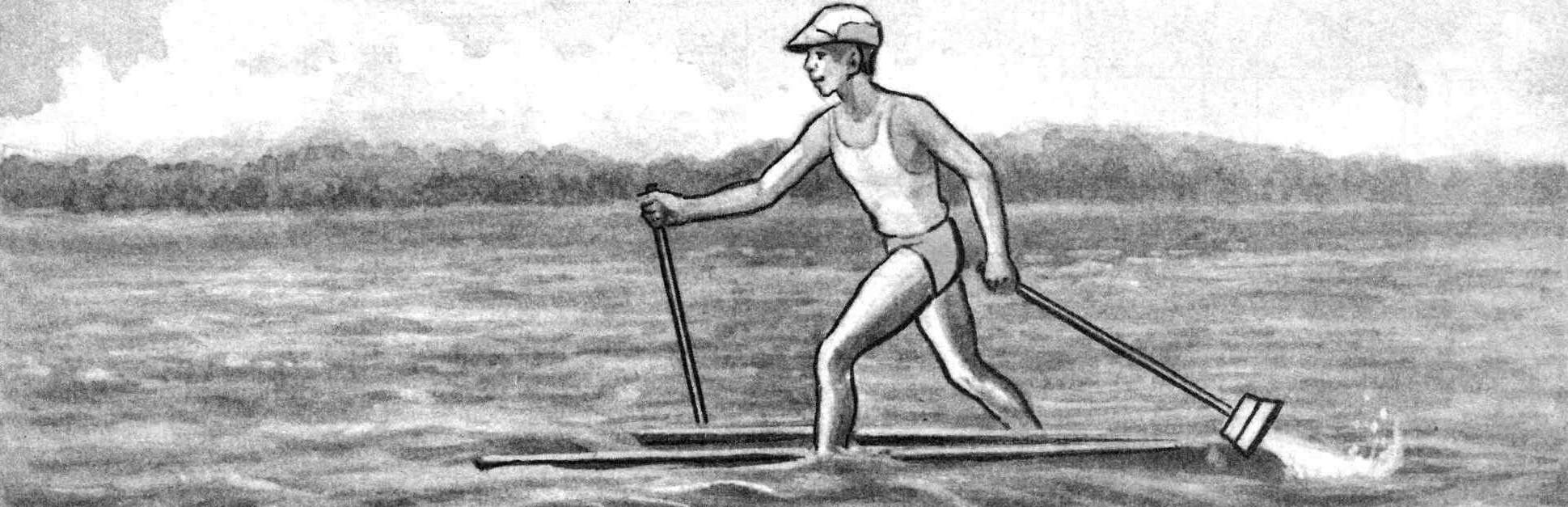

The idea of water ski floats is not new, and yet such a projectile cannot be called ordinary. On the contrary, the sight of a person literally running on the waves invariably causes surprise among those around him. Apparently, the spread of watercraft of this type is hampered by the opinion that skis are not very comfortable and lack comfort compared to a traditional boat. However, as M.A. Ulyashev, the author of the design that will be discussed today, assures, no comfort can replace the sensations that you get from “jogging” along the water surface of the lake!

However, float skis are not only entertainment, but also an excellent sports equipment, and even a good transport for a fisherman or water tourist. After all, it’s not at all difficult to turn them into a catamaran with an oar, and possibly a sailing propulsion. So readers of our magazine who decide to repeat this design will be able to use it as a module for the construction of a larger collapsible vessel.

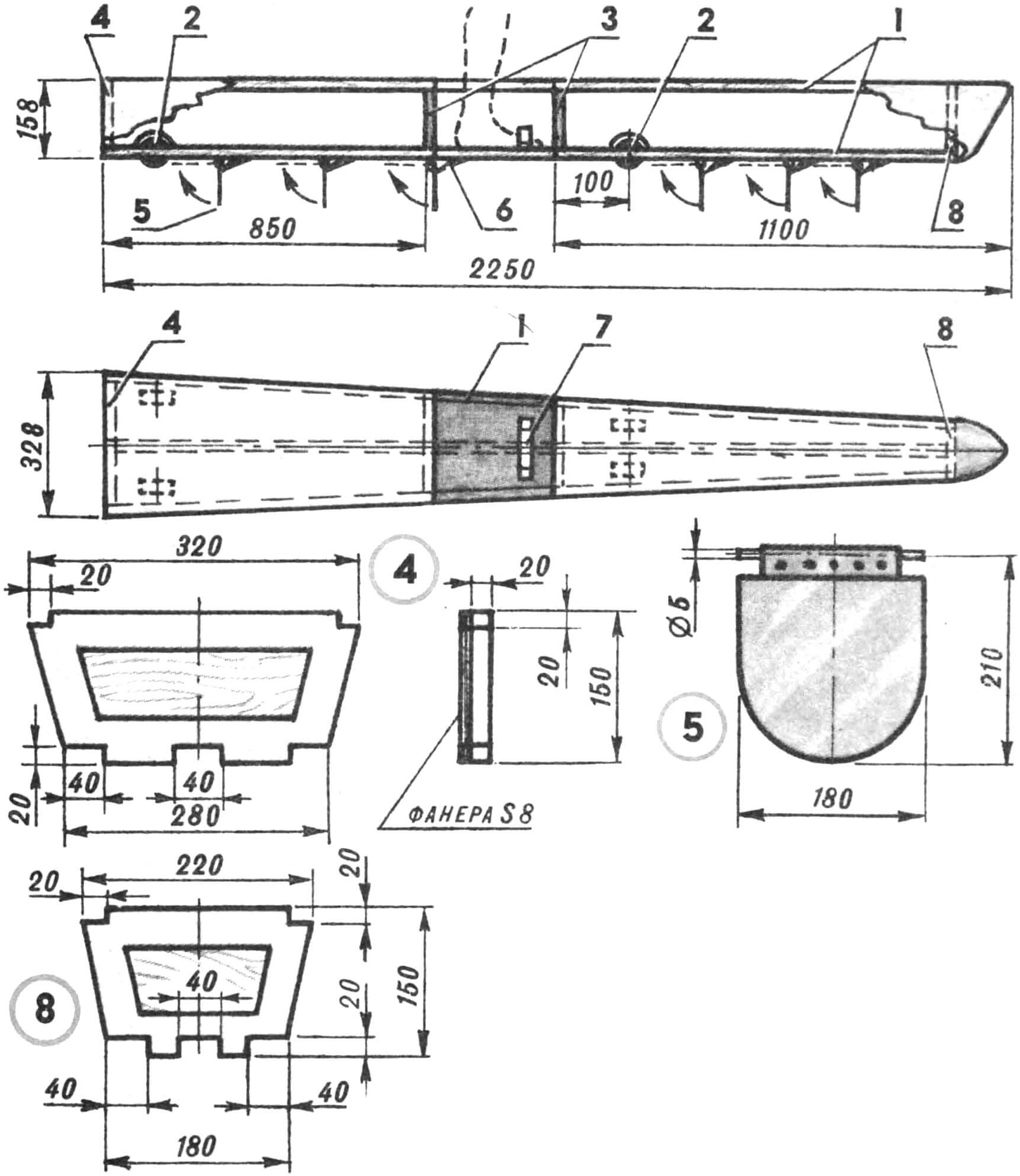

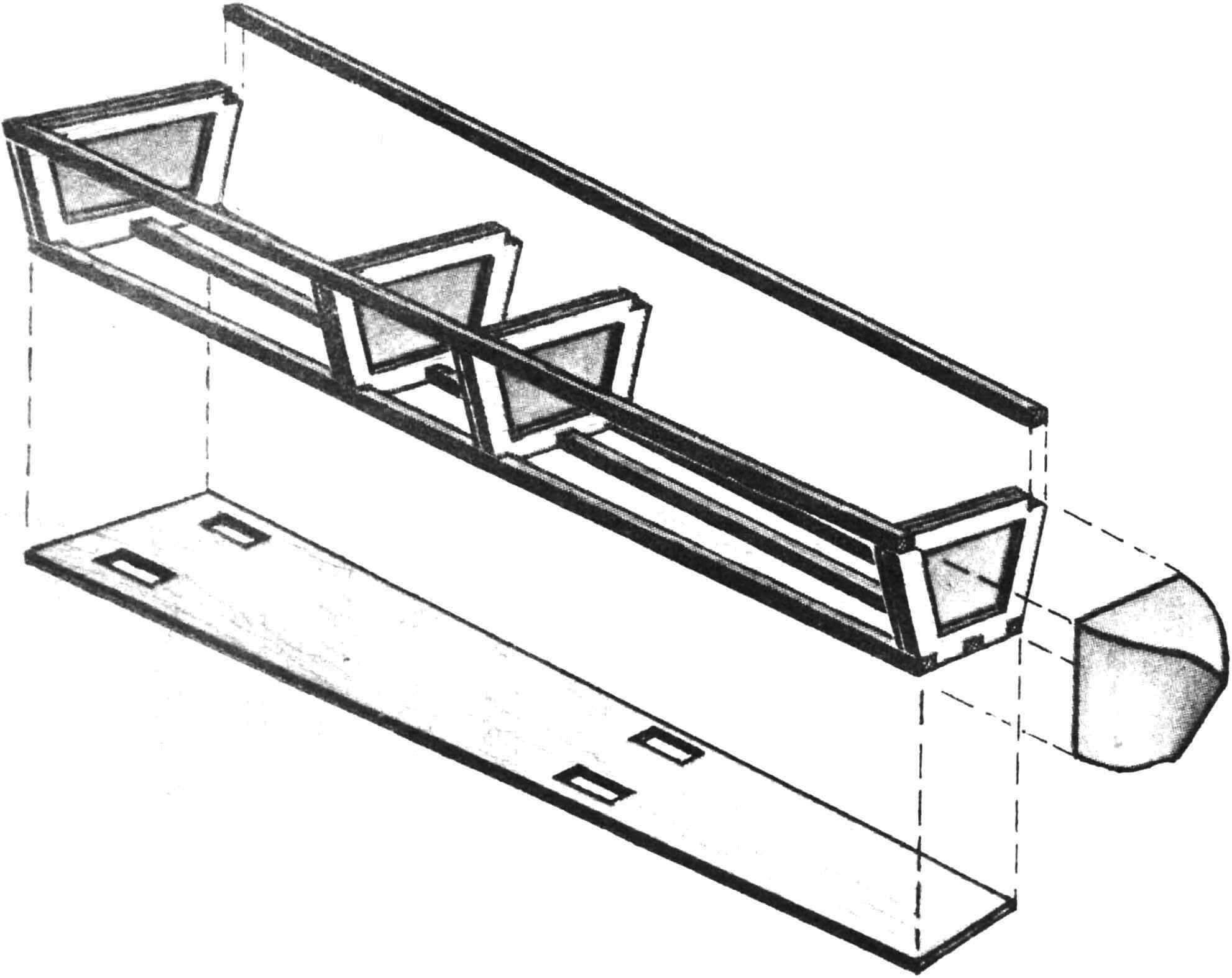

1 — stringers, 2 — auxiliary wheels, 3 — middle frames, 4 — transom, 5 — blade, 6 — blade stop, 7 — leg attachment, 8 — front frame.

When starting to make skis, I decided to use only the simplest equipment and readily available materials. This determined the design as a whole. Of course, it would be possible to glue float skis out of fiberglass, but in this case, the weight savings would hardly cover the high cost and complexity of such technology. And the resulting watercraft can be repeated even by an untrained lover of technical creativity.

Each ski is made of wood. The basis of the frame is five stringer slats and four frames (one of them is a transom). The lower – bottom – stringers have a cross-section of 40X20 mm, and the two upper ones – 20X20 mm. Frames are frames made of slats with a cross section of 40X20 mm, closed on one side with a diaphragm – plywood or thin plastic. Since slats of the required length are not easy to find, the stringers can be composite, but it is advisable to reinforce the joint along the perimeter with tin.

It is best to fill the entire space of the float inside the frame with pieces of foam plastic, gluing them with epoxy resin or shoe glue. However, you can do without polystyrene foam and cover the frame with plywood, of course, ensuring its tightness.

In the compartment between the two middle frames there is a simple mount for the leg. It should be borne in mind that in cool weather it is not very pleasant to go swimming on bare feet, so the mount should be adjustable, capable of “accommodating” a rubber boot if necessary. It is advisable to fill the free space of the compartment with foam plastic, remembering, however, that the leg should be removed from the socket completely freely.

At the bottom, each ski is equipped with six folding plate blades made of 1 mm thick duralumin. Each blade is mounted on an axis in two support clamps. A special stop-limiter is attached in front of it – so that the blade tilts at an angle of 80…90°.

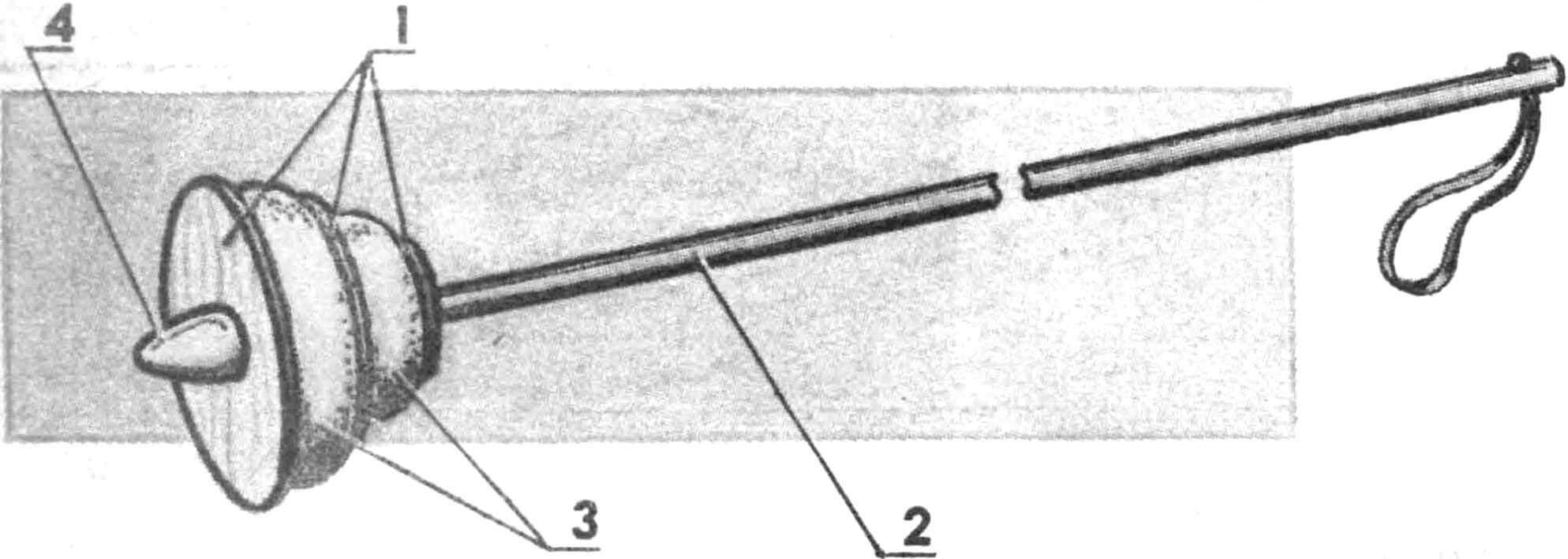

1 – plywood washers, 2 – rod, 3 – foam disks, 4 – tip.

For movement on land, two pairs of auxiliary wheels are provided on the bottom of the ski. I made them from a round log; The diameter of each wheel is 120 mm, the width is 40 mm. I do not provide a drawing of their installation, since this unit can be made more perfect. If the ski is not filled with foam plastic, but sheathed with plywood, the wheel inside must be closed with a sealed casing.

I made the stick floats from polystyrene foam, placing it between plywood washers and securing it with small nails with glue.

And one last thing. If you are going to ski on large bodies of water, where sometimes rough waters arise, then it is advisable to strengthen the ballast on the bottom of the skis in the form of metal strips weighing 2…5 kg. This will give the floats greater stability.

M. ULYASHEV, Cheboksary