The arched structure, under all other equal conditions, will always be stronger, more reliable, and cheaper than structures of other types—especially when the arch itself consists of rods working only in tension and compression. This was appreciated by the famous mechanic Kulibin, who created a large-scale model of an arched bridge to connect the banks of the Neva River.

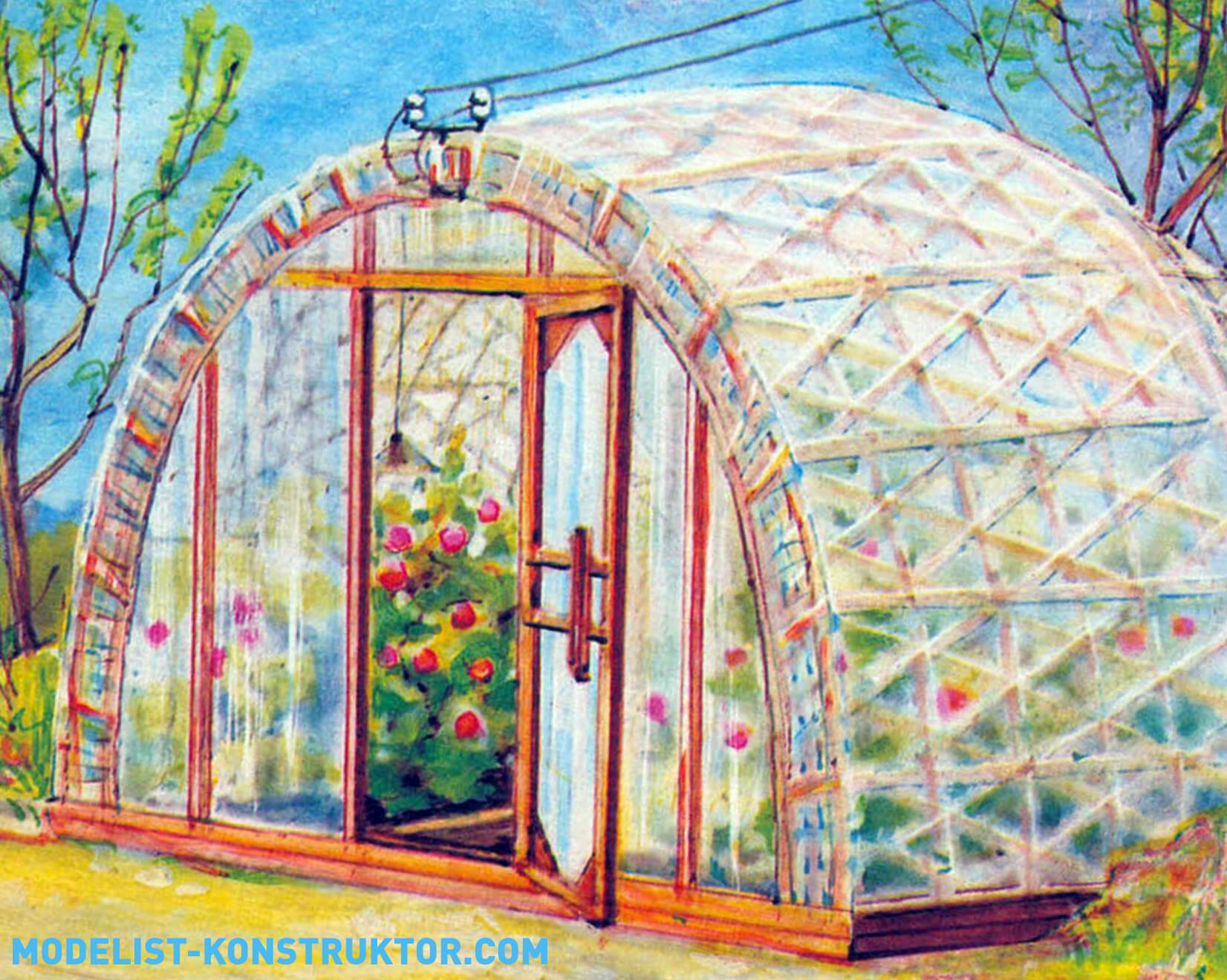

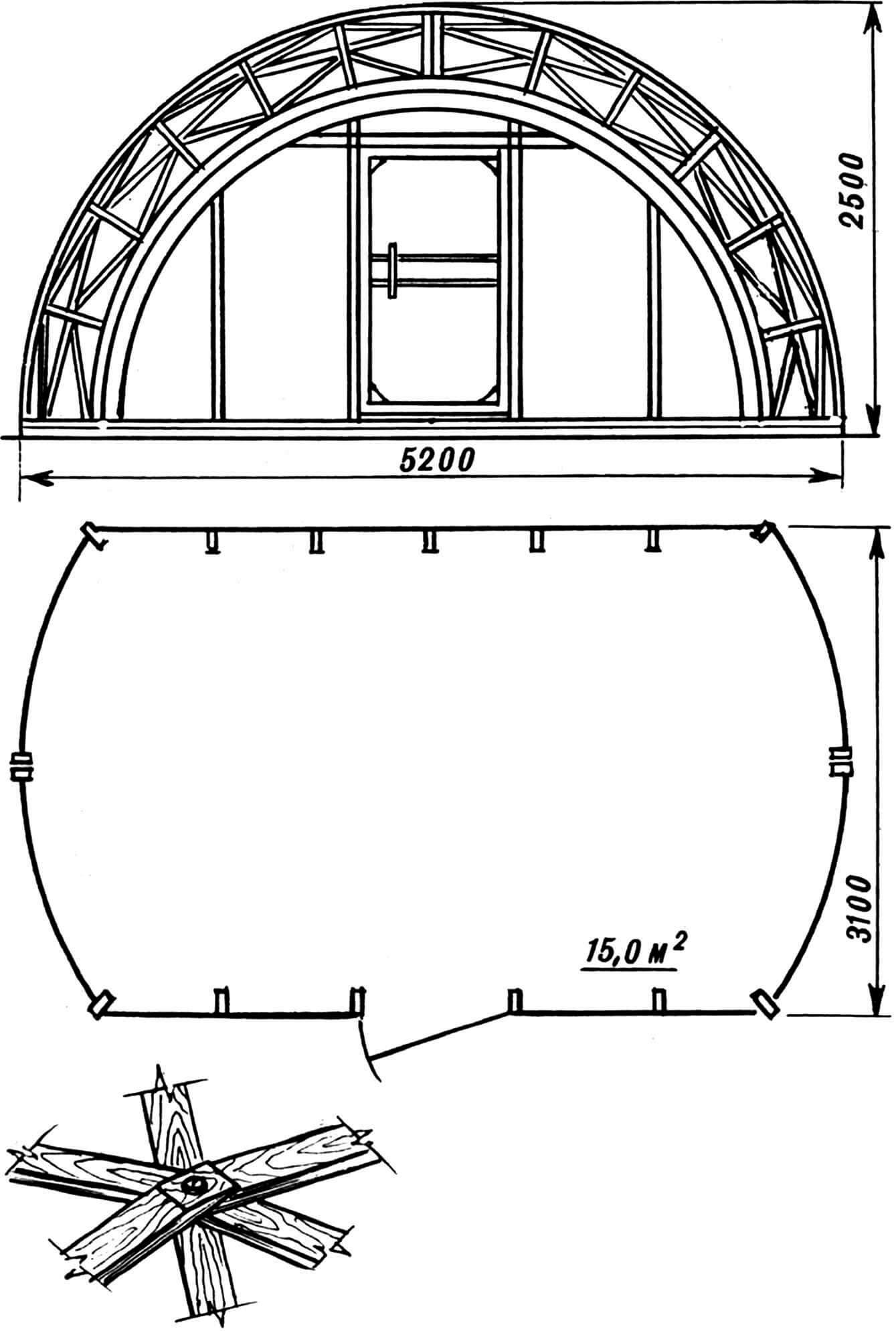

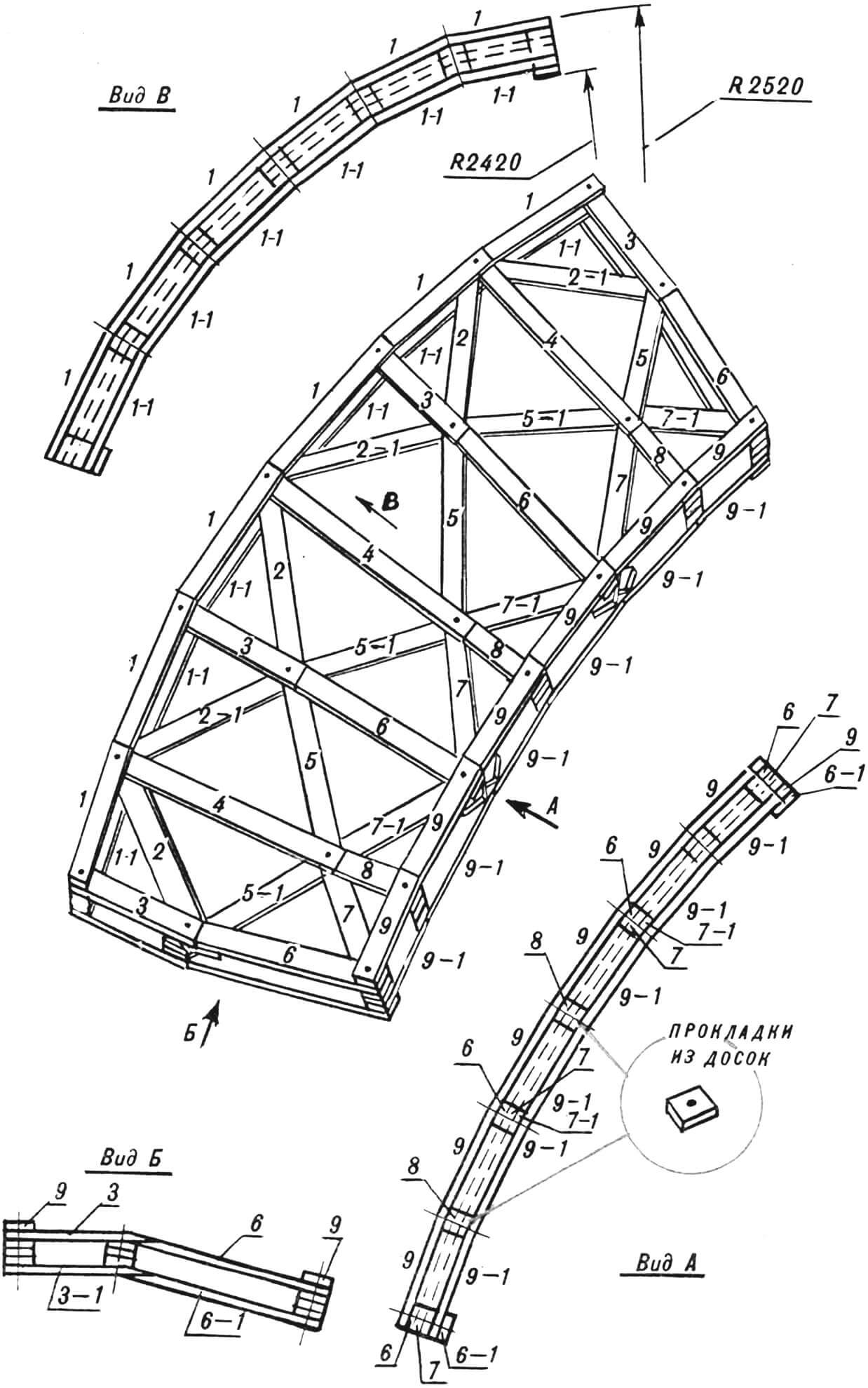

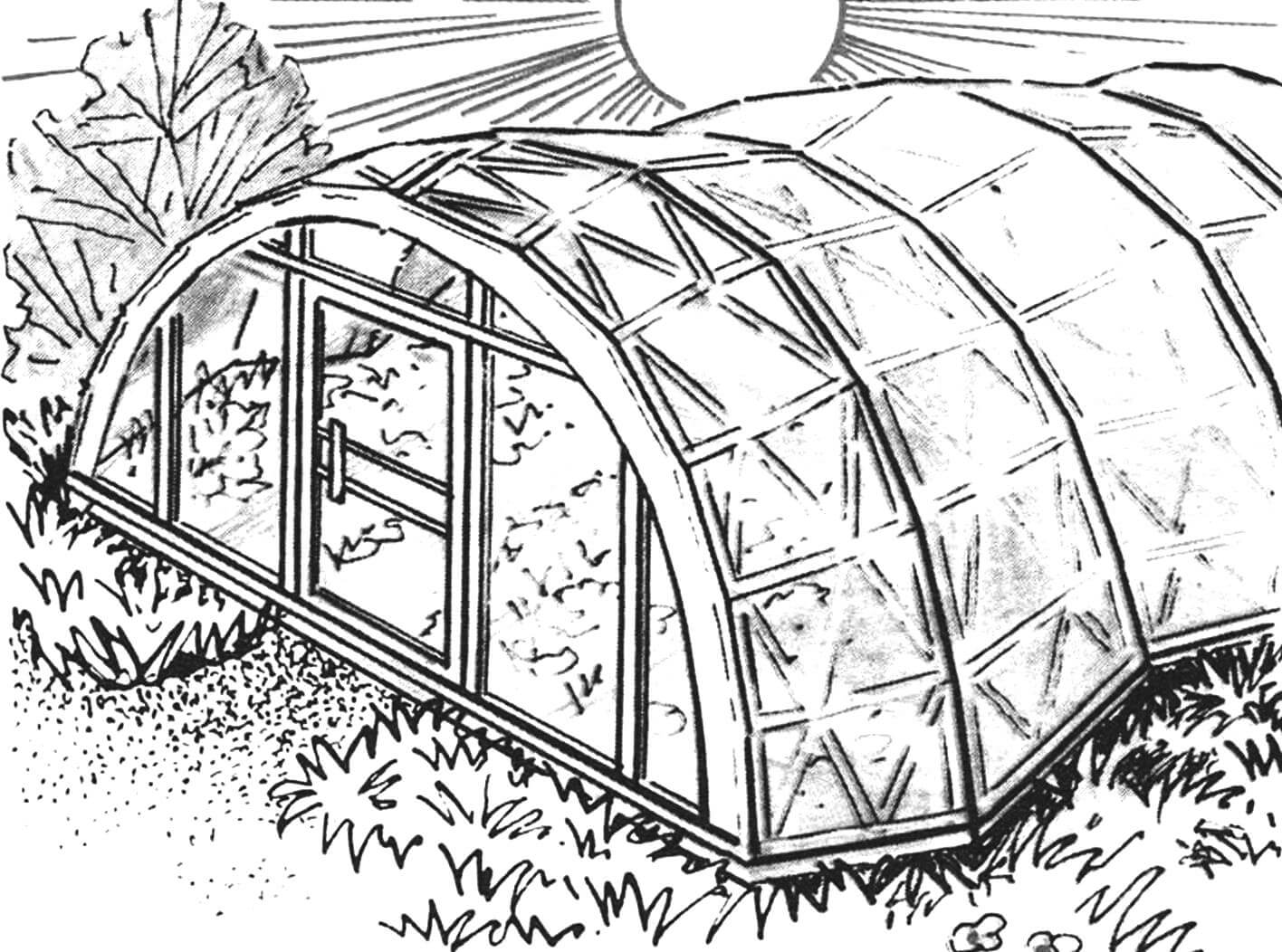

The original arched structure suitable for creating greenhouses, conservatories, canopies, garages, and other buildings was successfully created by our magazine’s reader from Novgorod, S. Yu. Makurin. The module of such a vault is a rod structure consisting of 240 wooden rods (rails) with a cross-section of 20×50 mm and a length of 0.5 to 1 meter (material volume — 0.2 cubic meters). The module’s area is 15 square meters. By connecting such modules, arched structures of any area and various configurations can be obtained.

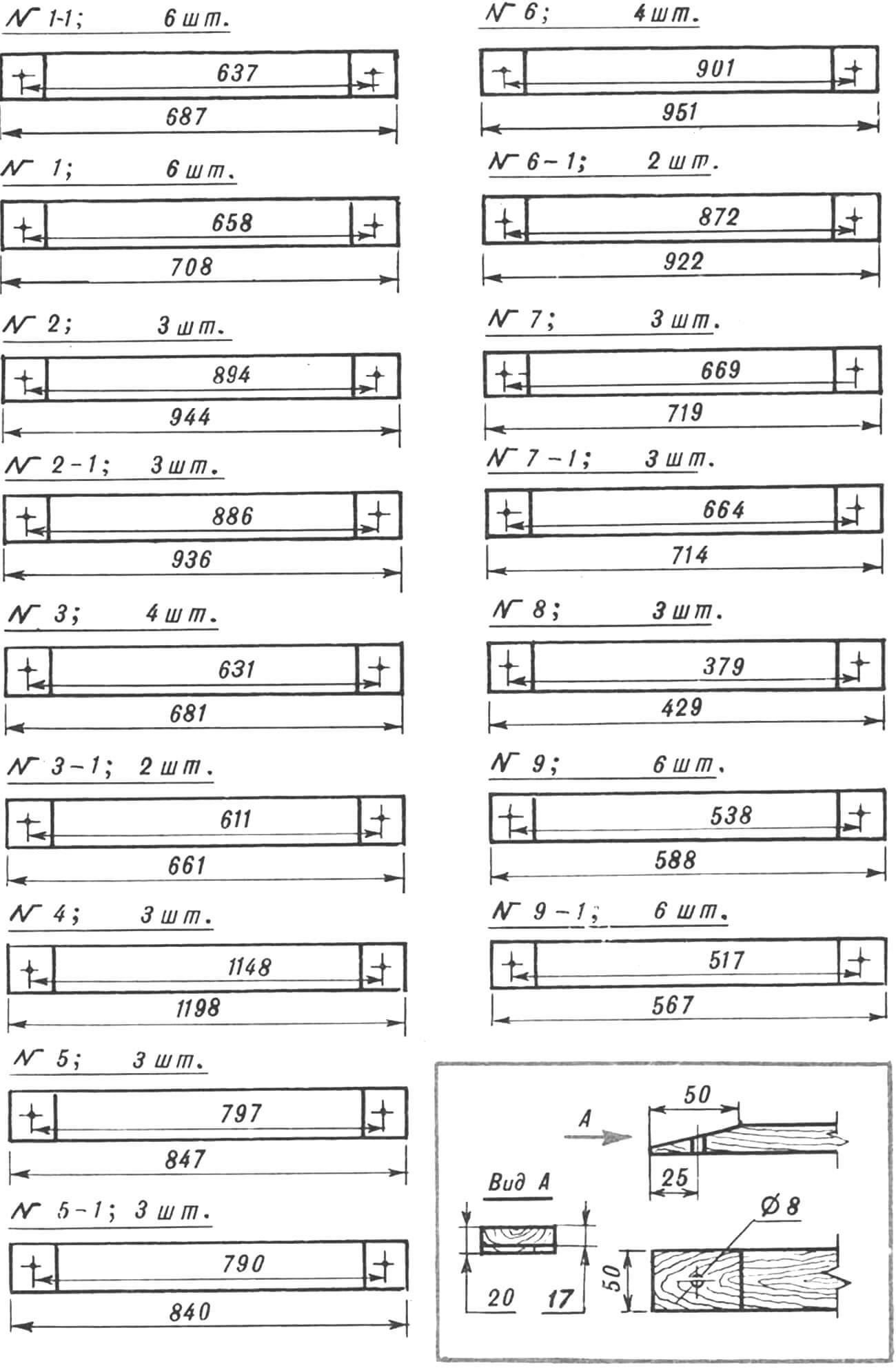

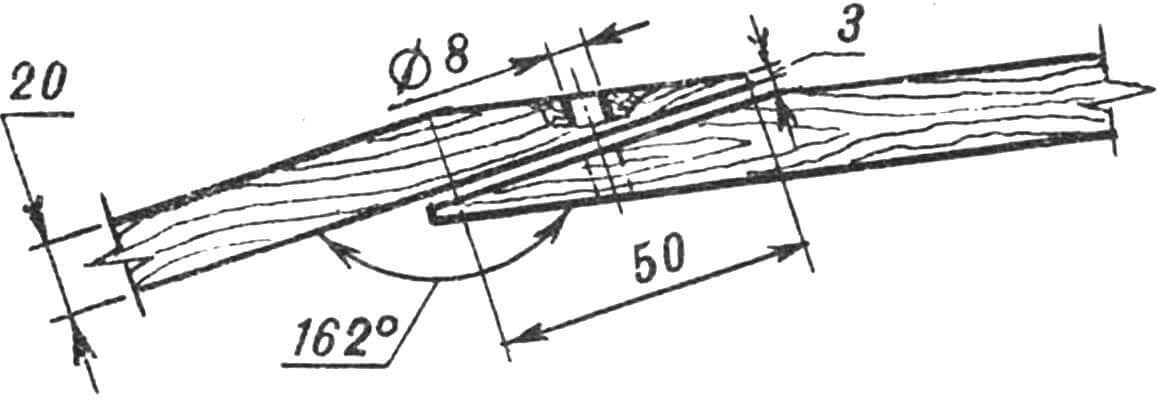

The frame of the arched vault is assembled from relatively short rods (rails) with a cross-section of 20×50 mm, the ends of which are trimmed so that an angle of 162 degrees is formed between the mating rods. This angle provides a chamfer, the legs of which are 50 mm and 17 mm, respectively. In total, for each of the modules, it is necessary to prepare 60 rods of 16 different sizes according to table No. 1. It is also necessary to prepare 16 bolts with M5 or M6 threads and a length of 150 mm, and 5 bolts (also with M5 or M6 threads) with a length of 90 mm, with the corresponding number of nuts and washers. Wooden pads with dimensions of 20x50x50 mm will also be needed.

The assembly of the frame is recommended to start with the assembly of the edge contour of the typical element from parts 1 and 1-1. For this, according to the assembly diagram, the details are laid out on a relatively flat area together with the adjacent rods according to the assembly diagram. All elements are joined together with the help of metal overlays (with a pair of holes in each), which are put on the protruding ends of the bolts and pressed with nuts.

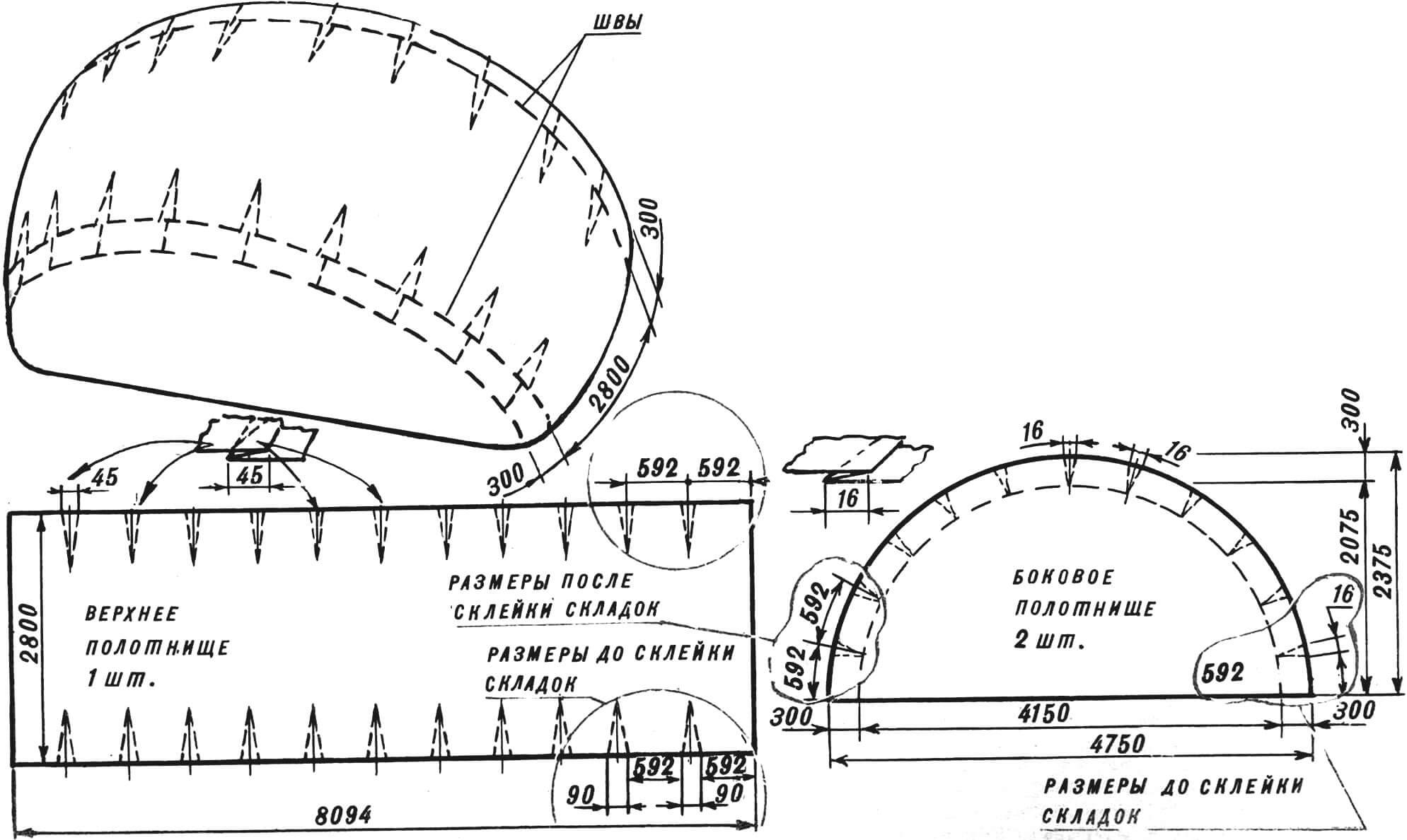

If the arched structure is constructed for a greenhouse or conservatory, then a monolithic transparent film covering is provided. In this case, it is best to use a 260-centimeter-wide polyethylene film—only 17.6 meters of this material will be needed for one greenhouse module. To obtain a spherical surface of the shell, folds with a width of 90 mm and a step of 592 mm are laid along the entire length of the canvas and glued with sticky tape. By the way, for gluing the shell under one module, about 50 meters of such tape will be needed.

Similarly, the side canvases are cut out—each of them represents a semicircle, on the periphery of which folds are also laid—their width is 16 mm, and the step is 592 mm.

The side and central canvases are preliminarily tacked with a single-thread stitch (stitch pitch – 10 mm), and then connected with sticky tape. Finally, the polyethylene cover is secured to the frame with nylon cords, forming a kind of mesh.

Table I

| Element No. | A (mm) | B (mm) | Quantity | Total Length (m) |

|---|---|---|---|---|

| 1-1 | 637 | 687 | 6 | 4.122 |

| 1 | 658 | 708 | 6 | 4.248 |

| 2 | 894 | 944 | 3 | 2.832 |

| 2-1 | 886 | 936 | 3 | 2.808 |

| 3 | 631 | 681 | 4 | 2.724 |

| 3-1 | 611 | 661 | 2 | 1.332 |

| 4 | 1148 | 1198 | 3 | 3.594 |

| 5 | 797 | 847 | 3 | 2.541 |

| 5-1 | 790 | 840 | 3 | 2.520 |

| 6 | 901 | 951 | 4 | 3.804 |

| 6-1 | 872 | 922 | 2 | 1.844 |

| 7 | 669 | 719 | 3 | 2.157 |

| 7-1 | 664 | 714 | 3 | 2.142 |

| 8 | 379 | 429 | 3 | 1.287 |

| 9 | 538 | 588 | 6 | 3.528 |

| 9-1 | 517 | 567 | 6 | 3.402 |

The above-described technology applies to the construction consisting of one module. However, there are no problems in creating a greenhouse or conservatory from two, three, or more modules.

Characteristics of the arched greenhouse

Total length — 44.875 m

Total volume — 0.0449 m3

Mass of a module consisting of four elements — 107.7 kg

S. Makurin