When in your “arsenal” there is a rowing boat and you have developed a taste for water trips, undoubtedly the thought has crossed your mind more than once to equip it with light and beautiful sails, so that you can feel the pleasant elasticity of the summer breeze in them, holding your almost yacht at a good speed. By publishing drawings that can be used to modify the boat and equip it with real sails, we hope that sailing under them will be no less enjoyable for you than rowing.

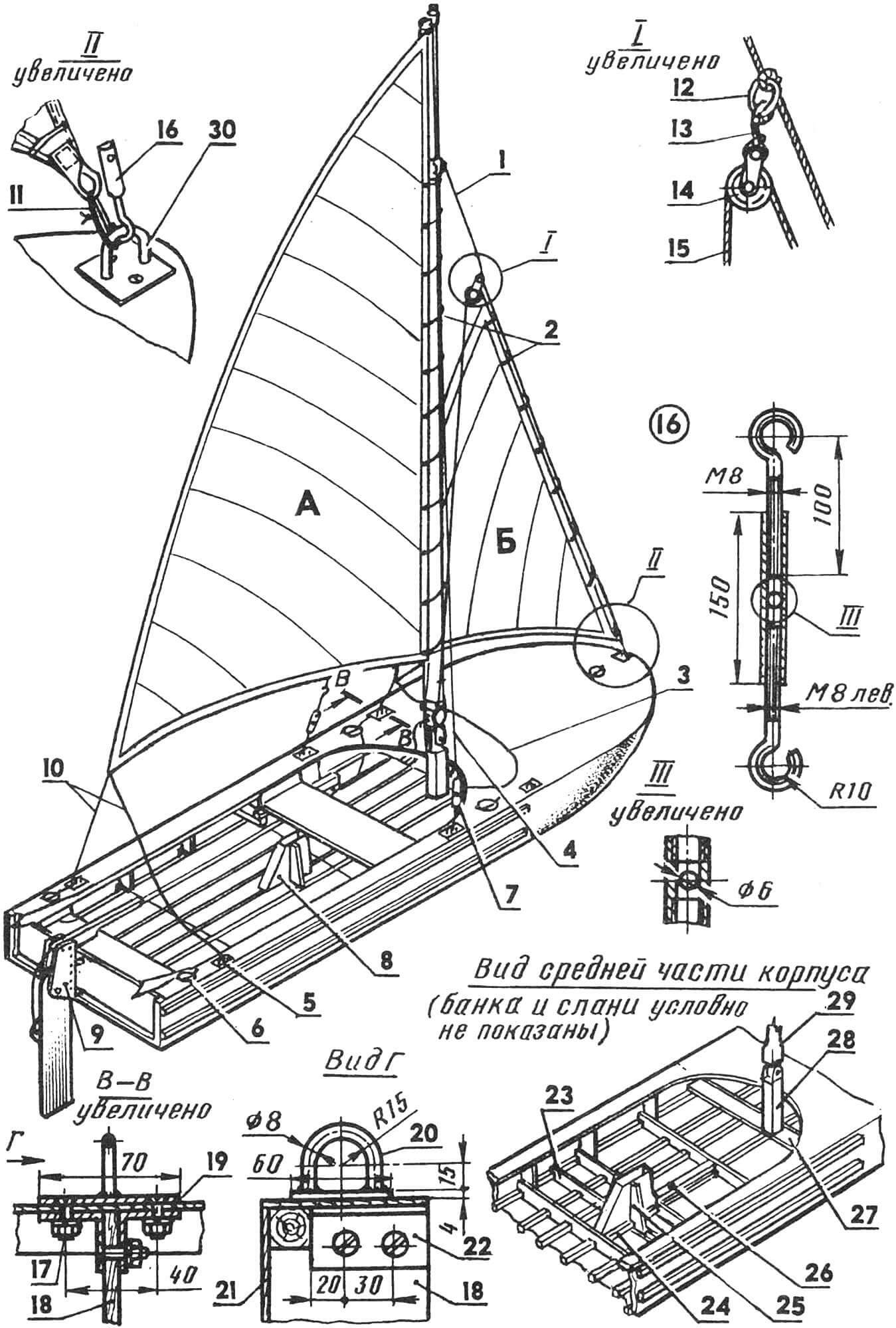

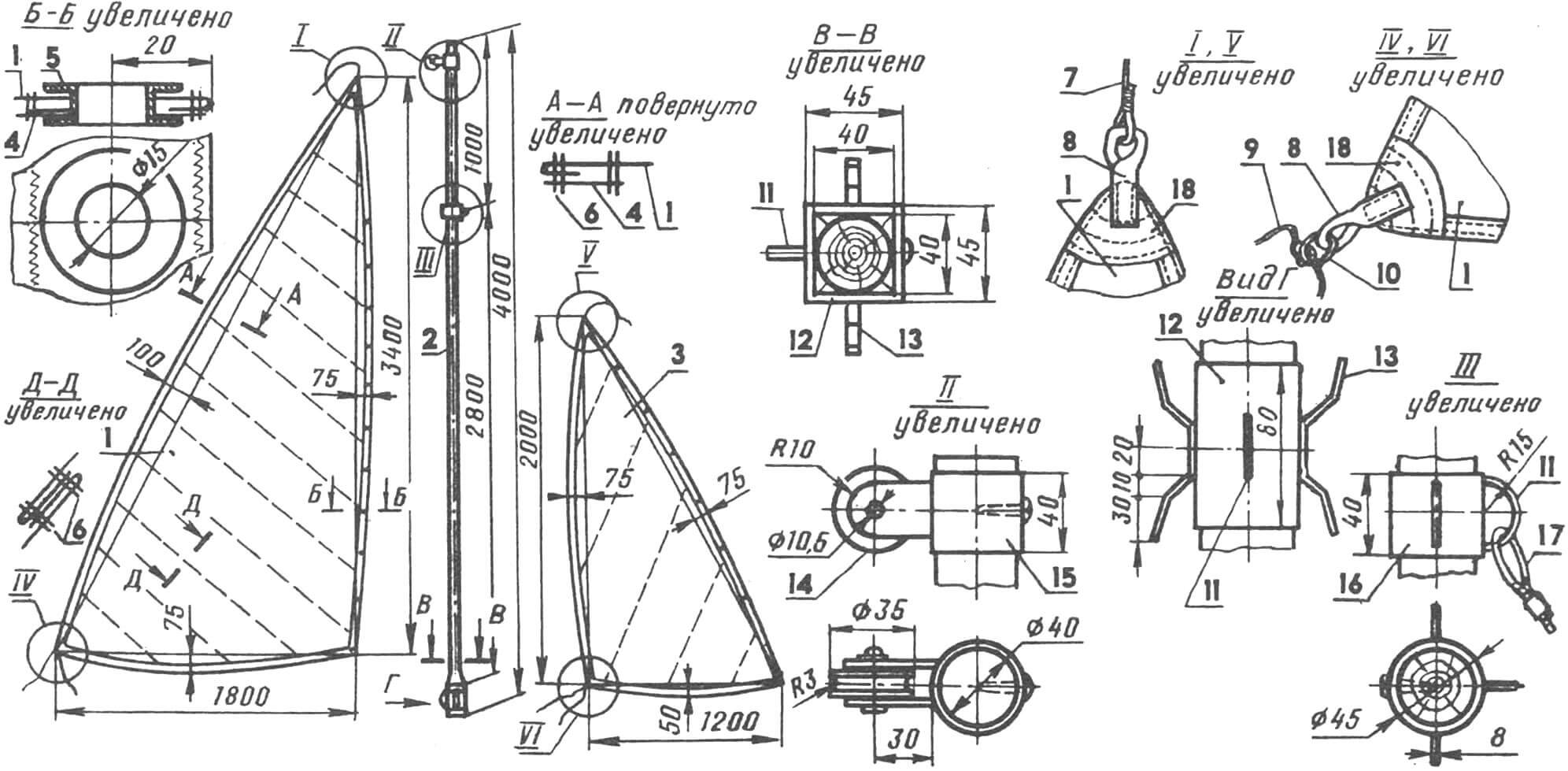

The proposed sail equipment consists of a mainsail and a jib. The first is attached to a four-meter mast using lacing, raised by the mainsail halyard passed through a block, and controlled by mainsheet lines. The jib is similarly attached to the forestay, raised by the jib halyard passed through a block at the top of the forestay. Sail control is carried out by jib sheets threaded through blocks.

The main part of the sail equipment is the wooden mast, hinged and attached to a special support—step, allowing quick installation or removal. It is fixed in the raised position by shrouds and forestay. After hoisting the sails, all free ends are secured on cleats. The mast is made of pine or spruce timber, mainly with a round section with a diameter of 40 mm, and in the lower part—a square section measuring 40×40 mm. Attached to it are: a lower knot with two cleats and a bracket, an upper knot with three brackets, and a block attachment knot for the mainsail halyard.

Sails: A — mainsail, B — jib; 1 — forestay (10-12 mm diameter capron rope), 2 — lacing strop (3-4 mm diameter capron rope), 3 — jib sheet (6-8 mm diameter capron rope), 4 — shroud (10-12 mm diameter capron rope), 5 — thwart, 6 — cleat, 7 — screw shackle, 8 — daggerboard well, 9 — steering device, 10 — mainsheet (10-12 mm diameter capron rope), 11 — soft shackle (3-4 mm diameter capron rope), 12 — ring (3-4 mm diameter steel wire), 13 — loop (6-8 mm diameter capron rope), 14 — jib halyard block, 15 — jib halyard (6-8 mm diameter capron rope), 16 — bow screw shackle and sleeve (St3, pipe 15×4.5 mm), 17 — screw M6x20, 18 — shroud, 19 — base (St3), 20 — bracket (St3), 21 — side planking, 22 — reinforcing overlay (angle, duralumin, 40x40x3 mm), 23 — additional shroud, 24 — spar (pine, 25x25x800 mm), 25 — patch (pine, thickness 10 mm), 26 — daggerboard well tunnel, 27 — support beam (pine, 70x20x1000 mm), 28 — step, 29 — mast, 30 — bow putens.

Shrouds and forestay are of the same construction and are made of capron rope with loops (eyes) at the ends. If you want to make them detachable from the mast, the upper ends should be equipped with carabiners. The required tension of shrouds and forestay is achieved using turnbuckles.

Pay attention to the sails; this is the most complex, responsible part of the equipment. Besides, they should give your boat elegance and attractiveness. For sails, it is advisable to choose a thin, durable, airtight fabric made of Lavsan (or nylon), with a weight of 110…130 g/m² or 150…180 g/m², preferably in several colors. The canvases are sewn with capron threads No. 60/3 or reinforced cotton No. 45.

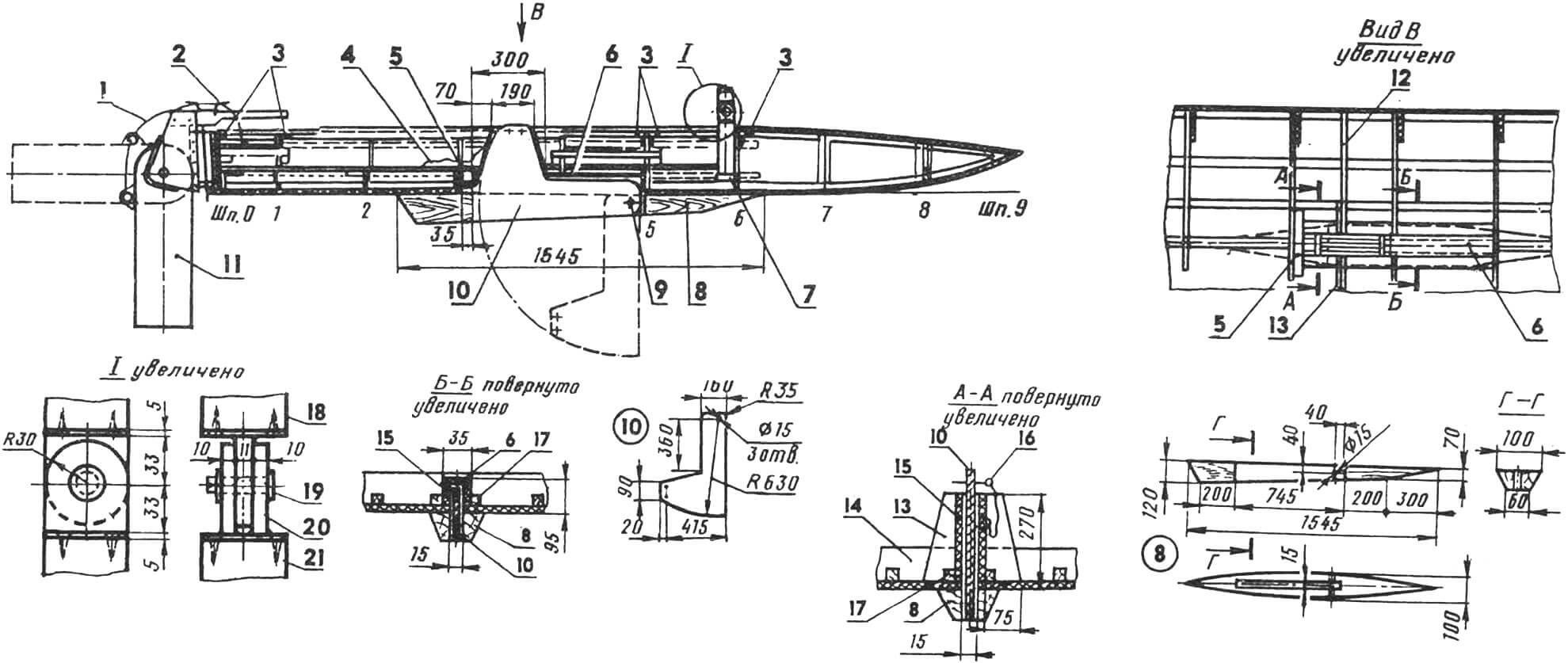

1 — surling (3-4 mm diameter capron rope), 2 — thwart, 3 — brackets (angle, duralumin, 40x40x3 mm), 4 — daggerboard tackle (3-4 mm diameter capron rope), 5 — crossbar (pine, 25x25x350 mm), 6 — daggerboard well cover (plywood 10 mm thick), 7 — support beam, 8 — keel timber (pine), 9 — bolt M14x130, 10 — daggerboard (duralumin, sheet thickness 5 mm), 11 — steering device, 12 — additional shroud, 13 — patch, 14 — shroud, 15 — daggerboard well side (plywood 10 mm thick), 16 — pin (St3, wire diameter 5-6 mm), 17 — spar, 18 — mast, (pine, diameter 40 mm), 19 — pin (St3, rod diameter 14×40 mm, pin diameter 2.5 mm), 20 — hinge ear, 21 — step (pine, 40x40x250 mm).

Sail seams are reinforced with tape, and corners are strengthened with butts made of the same fabric. Holes with a pitch of 250…300 mm are punched on the front butts, and metal eyelets are installed. Loops made of capron tape are sewn onto all sail corners.

Gaff and throat corners of the jib and mainsail are connected by soft turnbuckles to the rings of the forestay puten and the lower fixing knot of the mast, respectively.

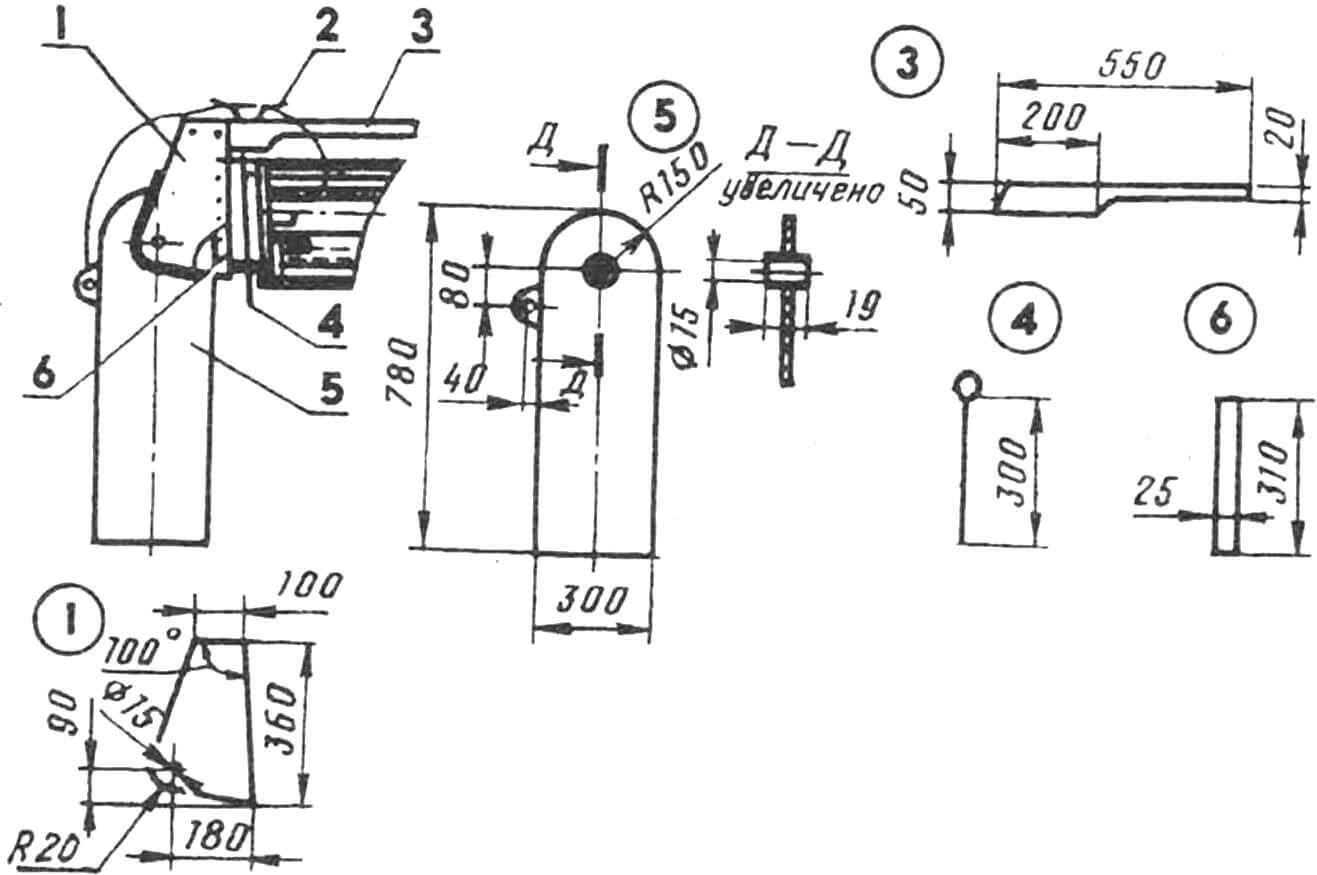

1 — side of the baller box (duralumin, sheet thickness 3-4 mm, 2 pcs.), 2 — thwart, 3 — rumpel (pine, section 50×20 mm), 4 — pin (St3, wire diameter 5-6 mm), 5 — rudder blade (duralumin, sheet thickness 5 mm), 6 — spacer (pine, section 20×25 mm).

Putenes and thwart knees have the same construction. They are made of steel sheet and an 8 mm diameter rod. To improve the sailing qualities of the sailboat, an aluminum daggerboard is installed—a 10 mm thick sheet. The daggerboard well is placed between stringers #3 and #5. In this case, part of the middle stringer is removed, a 35 mm wide slot is made in stringer #4, and in the boat’s bottom along its axis, at a length of 745 mm, a 15 mm wide slot is made. The sides, cover, front, and rear walls of the daggerboard well are cut from plywood and glued with epoxy glue. The keel is planed from timber, a slot is cut in it, and a hole is drilled for the daggerboard axis. Then, all surfaces of the keel are carefully processed and sanded.

After attaching the daggerboard well, the keel timber, and complete hardening of the glue, all external and internal surfaces of the well are covered with several layers of hot linseed oil or parquet lacquer.

1 — mainsail, 2 — mast, 3 — jib, 4 — reinforcing tape (capron tape 35-40 mm wide), 5 — eyelets, 6 — “zigzag” seams, 7 — mainsail halyard and jib halyard (6-8 mm diameter capron rope), 8 — loop (capron tape 15-20 mm wide), 9 — mainsheet and jib sheets, 10 — ring of mainsheet and jib sheets (3-4 mm diameter steel wire), 11 — bracket (steel, rod diameter 8-10 mm), 12 — lower fixing knot (steel sheet thickness 2-2.5 mm), 13 — thwart, 14 — mainsail halyard block, 15 — block attachment knot (St3, pipe 45×2.5 mm), 16 — upper fixing knot (St3, pipe 45×2.5 mm), 17 — upper eye of the forestay, 18 — butt (capron fabric).

In one of the lower holes of the daggerboard (after its installation), a daggerboard tackle is passed through, and in the other, a pin is passed to fix the dagger in the raised position.

The boat’s steering assembly is hung on brackets attached to the transom board. It consists of an aluminum rudder blade mounted on an axis (M15x40 bolt) in a baller box. The box consists of two side pieces pulled together through a wooden spacer and a rumpel with M3 bolts. The latter is equipped with a thwart, on which a surling is fixed, intended for raising the rudder blade.

Wooden parts of the steering assembly, mast, and holes in the boat’s hull before final assembly are also coated several times with hot linseed oil or parquet lacquer to make them water-resistant.

Refresh the paint on your boat, attach new equipment to it, and you can launch it into the water. If you haven’t sailed before, we recommend practicing sailing such a boat in shallow water and not far from the shore.

Happy sailing!

Based on materials from the “Technium” magazine (Romania)