To make such a device everyone can. All of his “mechanics” consists of a rotor of a wind turbine and 12-blade fan. He and the other installed on the axis of the bearing unit, which is a nut from a front wheel of a Bicycle. Latest with M4 bolts and nuts fixed in the center of the circle, cut from a sheet of plywood with a thickness of 8 mm.

Rotor wind turbine is assembled from a pair of half-cylinders and two discs of 6 mm plywood. A good rod will serve as the half-cylinders of old aluminum pot or a bucket. Also suitable and an appropriate size pot, plastic. The pan is carefully cut on a diametrical plane and secured between a pair of plywood disks, as shown on the drawings.

Country softclose with microventilation:

1 – microventilation; 2 – softclose; 3 – vent; 4 – rowed

Design vetrogeneratory:

1 – turbine rotor; 2 – a nut of fastening of the turbine shaft; 3 – the bearing (bushing from the front wheel of a Bicycle); 4 – fan impeller (steel or dural sheet s2); 5 – screw-self tapping mounting microventilation in the ventilation pipe (12 PCs); 6 – vent tube (box of square section, hammered together from boards s20); 7 – nut of fastening the impeller to the shaft; 8 – receiver (plastic basin); 9 – bolts and nuts M5 mounting the bearing unit on the cover of the receiver (3 sets); 10 – cover of the receiver (plywood s8)

Half-cylinders of the rotor of the wind turbine are cut in suitable size aluminum pans or buckets

Assembly of a wind turbine:

1,2 – end plates (plywood, s8); 3, 4 – semicylinders of the rotor; 5 – area for docking the half-cylinders and washers (6 PCs); 6 – the half-cylinders fasteners and washers (M5 bolt with nuts, 12 sets)

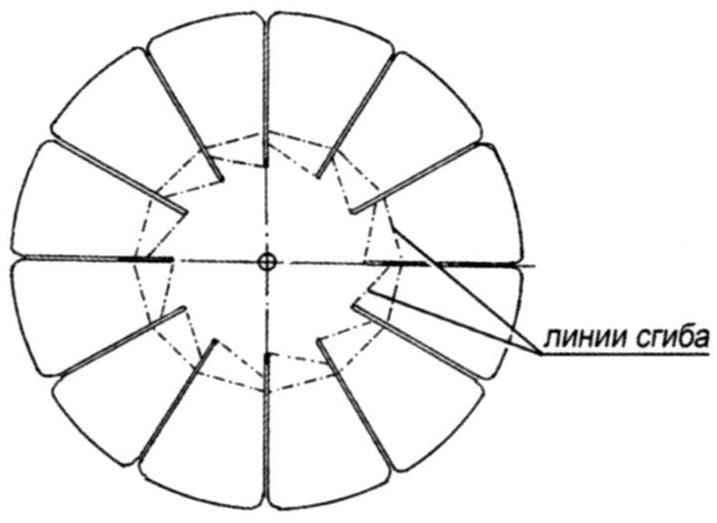

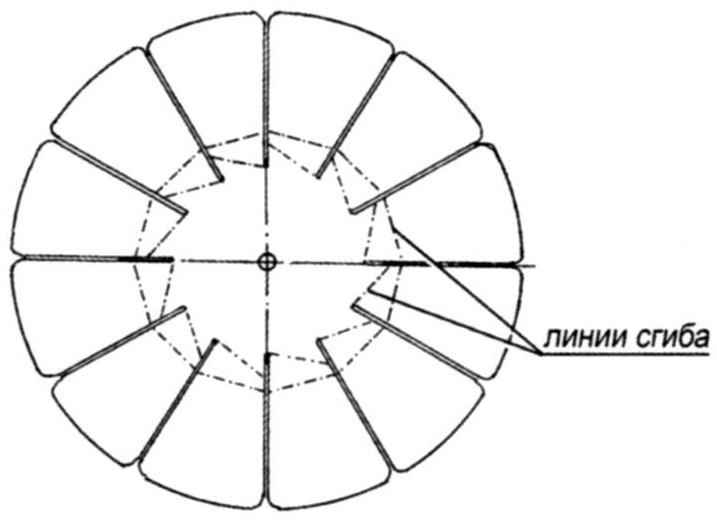

Manufacturer of impeller

(A – blank, B – ready impeller)

Fan blade – 12-lo-pasten; to make it of steel or dural sheet with a thickness of about 2 mm. After production of flat blanks each blade of the impeller is bent twice, as shown in photos, approximately 90 degrees, and the direction of bending will depend on what fan you need inlet or exhaust.

Microventilation is installed on top of a kind of receiver, which is a small plastic basin in the bottom of which is cut a hole for the vent pipe (asbestos cement or hammered together from boards). At the top of the receiver (above the impeller) cut holes for the output (or intake) air.

The finished Assembly is secured over the vent pipe and it is continuously (and totally free!) to ventilate your bathroom or cellar.

I. KHOROSHEVSKAYA

Recommend to read PILE OF FIREWOOD On a farmstead or cottage with furnace heating or a fireplace a trip to the woodshed for the replenishment of fuel is usually reduced to the delivery of logs just in the hands, which is... TEMPLATE – SMOOTHER The slats at different heights, the distance between them varies — and is already spoiled the impression of a botched fence. To avoid this, I made a controller-gon, on a vertical bracket...

The ventilation needs of many suburban buildings. Without it, mold in houses and sheds, get wet cellars and basements, and only use luftblasen, where there is no fan, to put it mildly, uncomfortable.

The ventilation needs of many suburban buildings. Without it, mold in houses and sheds, get wet cellars and basements, and only use luftblasen, where there is no fan, to put it mildly, uncomfortable.