On the garden or vegetable part does not need a capital house — often a small cost easy structure type outbuilding. In such an environment feel the need for the country part, starting n the construction of future giving, which is often delayed not for one season. However, all such structures are needed only in summer: from late autumn, all winter and until the spring warming, they are empty, open the weather and the evil “visitor”. Now, if they could not only set, but also to clean, fold for storage when the season is over. The idea of this collapsible house water supply without says our reader A. Nizovtsev.

On the garden or vegetable part does not need a capital house — often a small cost easy structure type outbuilding. In such an environment feel the need for the country part, starting n the construction of future giving, which is often delayed not for one season. However, all such structures are needed only in summer: from late autumn, all winter and until the spring warming, they are empty, open the weather and the evil “visitor”. Now, if they could not only set, but also to clean, fold for storage when the season is over. The idea of this collapsible house water supply without says our reader A. Nizovtsev.

The development of a garden plot usually begins with the construction hozbloka. Commonly used ready-made kits for construction. But very often in haste to cobble together a pretty miserable structures, which are then demolished or collapse of their own.

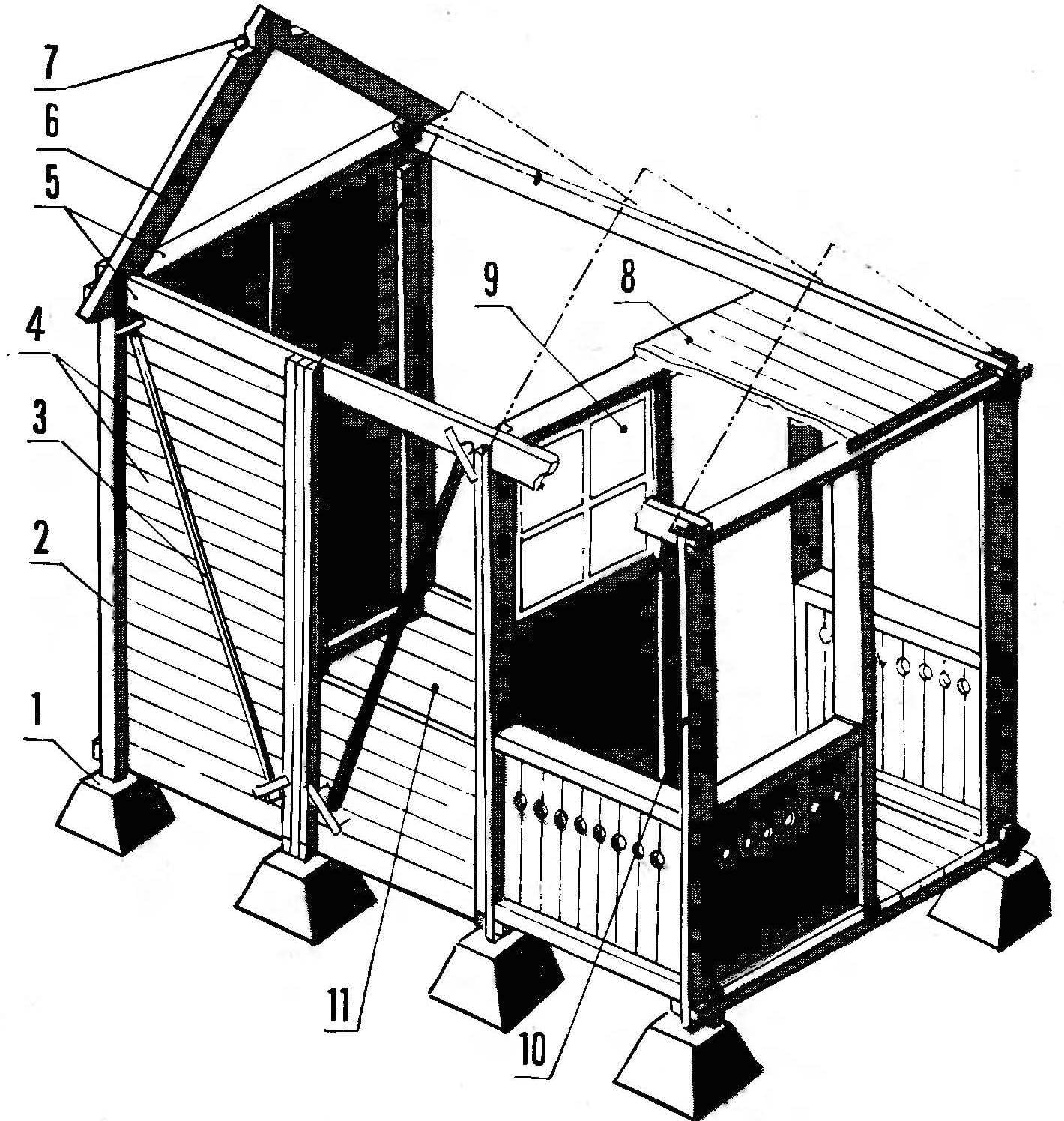

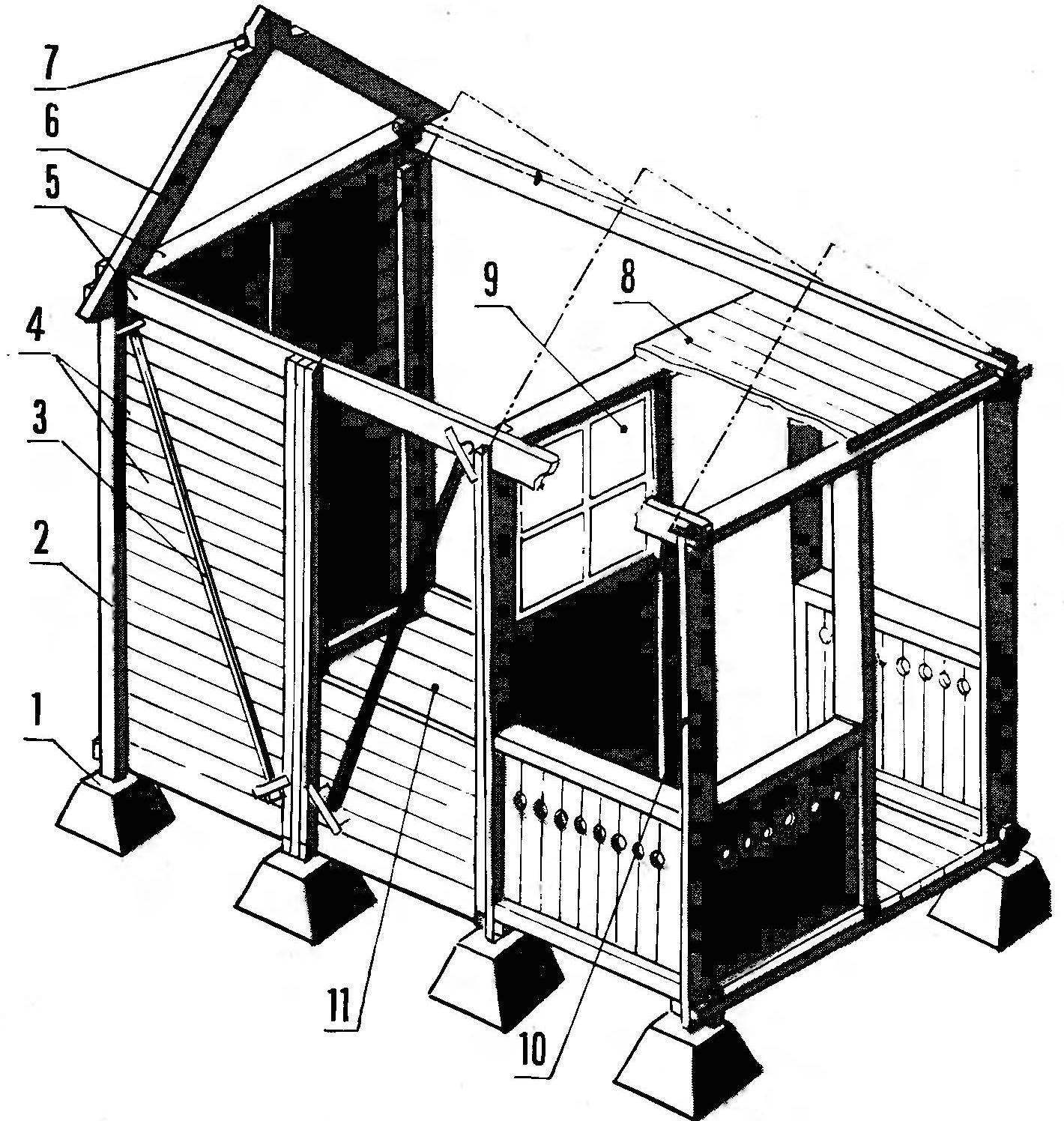

Attention novice developers it is proposed to design a collapsible garden shed, details of which can be made in advance, and Assembly is carried out on the spot in a very short time. Unlike traditional options house is not peretyazhelen bearing elements of the frame. Based on the proposed solution, each can independently determine the final size depending on the available materials, the real needs and possibilities.

Portable outbuilding consists of a room area of 9 sqm and a terrace with an area of 4.5 sq. m. the frame is made of 16 boards with a cross section of 120×40 mm. cross section Dimensions of frame elements can be different, but in the direction of increasing, and thus must be complied with the ratio of thickness to width of 1:3 at least in places of connections of frame elements. Diagram of the supporting frame and the node connection shown in the figures.