Garden, summer cottage or a rural farm house without a fence is not enough. And if in the cottages it often just serves as a border between neighbors, the farmstead a farmstead is also a protection against the ingress of livestock and poultry in the garden. But the fences have a gate. So they do not become a loophole available for Pets, these doors are equipped with simple locking devices.

Garden, summer cottage or a rural farm house without a fence is not enough. And if in the cottages it often just serves as a border between neighbors, the farmstead a farmstead is also a protection against the ingress of livestock and poultry in the garden. But the fences have a gate. So they do not become a loophole available for Pets, these doors are equipped with simple locking devices.

I’m on my gate is made simple to manufacture, easy to use, reliable in operation constipation (latch), which offer to readers of the journal “modelist-Konstruktor”.

The fence gate has a frame (piping) dimensions 1500×1000 mm steel area 45x45x4 mm In the middle (height) of the integrated cross member in the form of a brand, composed of two same parts. On it and installed the proposed shut-off device.

The gate is hung on the door (card) hinges-the hinges on the post-jamb is out of square steel pipe 65×40 mm. the half-loop hinges welded to the vertical part of the gate and the supporting post. The second jamb is made of a piece of the same pipe that the reference column.

Canvas gate is made of two wooden boards, solid pine grooved boards (lining) with a thickness of 16 mm. Shields attached to the parts of the strapping and the crossmember bolts M5.

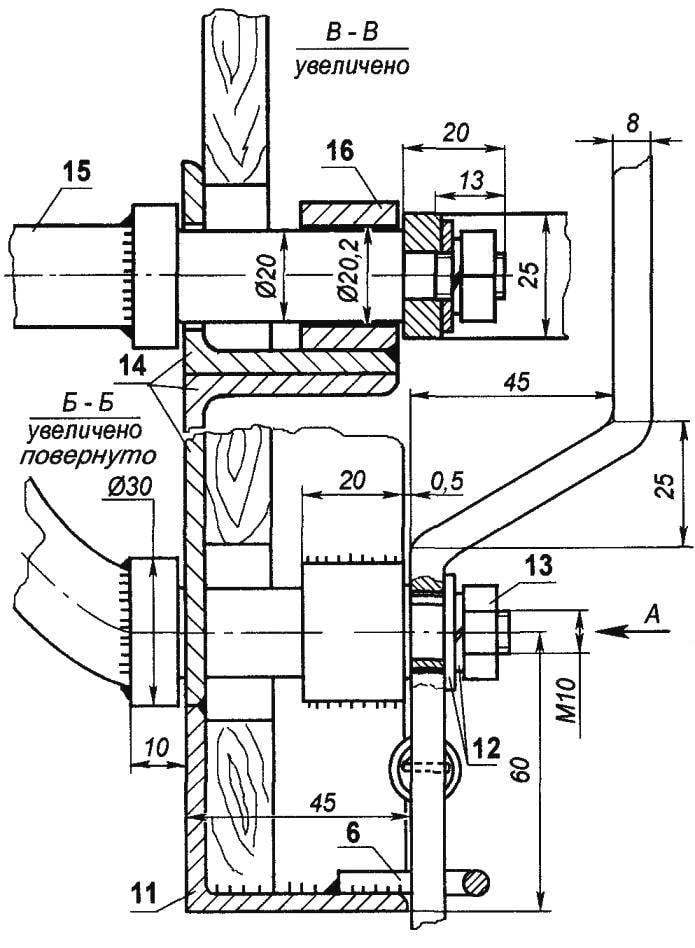

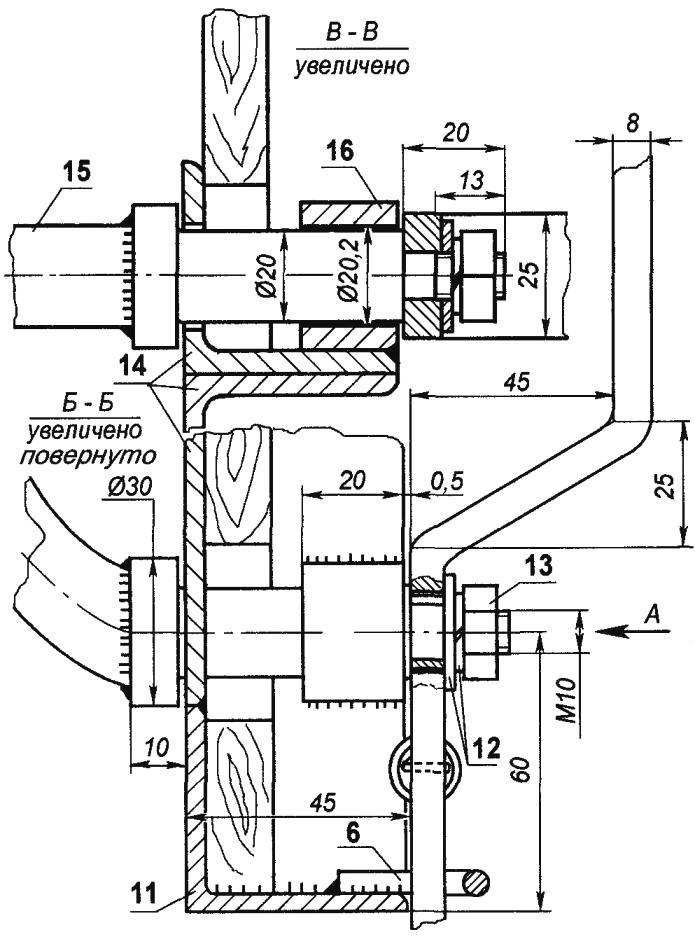

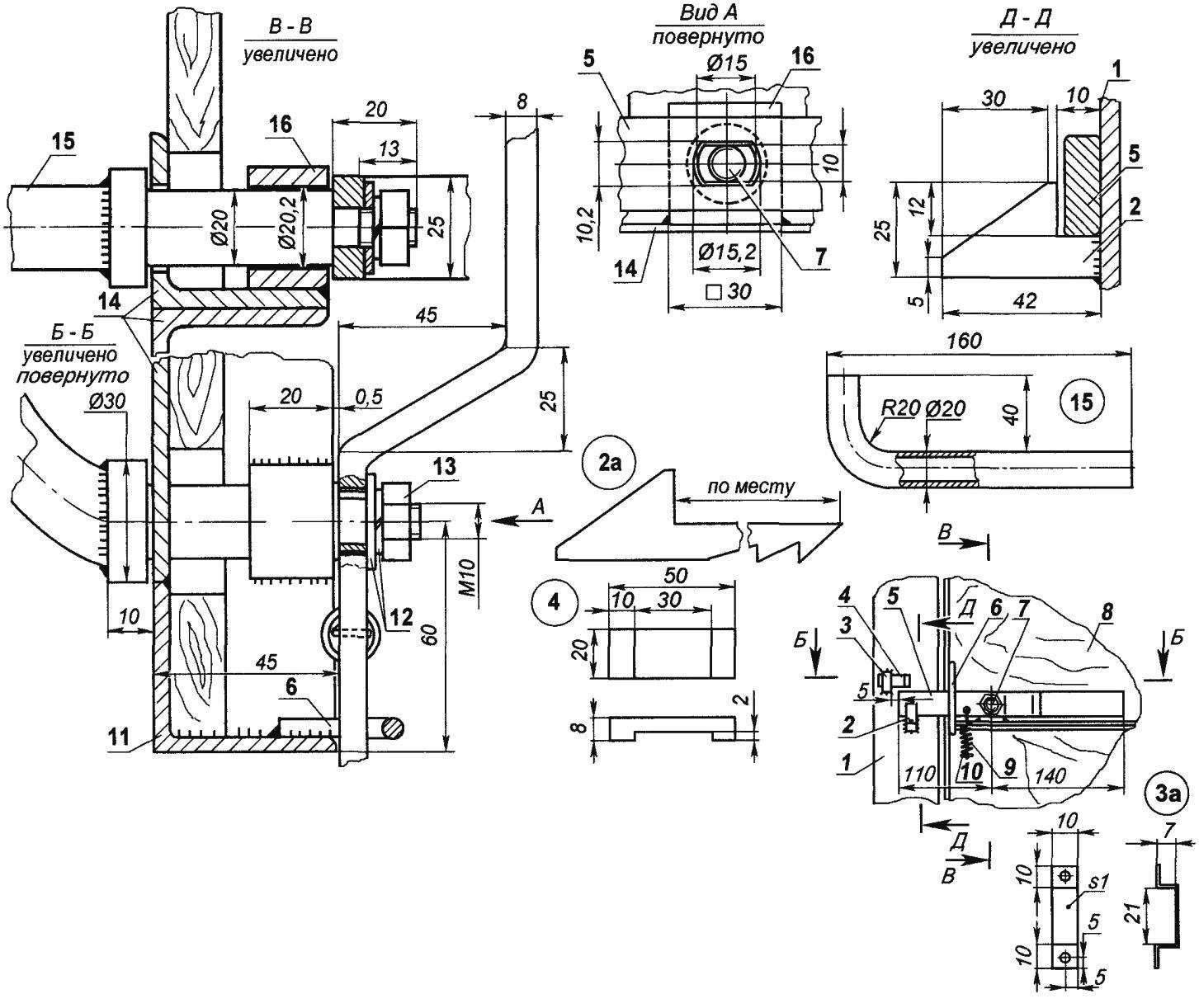

On the upper corner of the tie bar is mounted a locking device, the principal parts of which the latch (inner handle) outer handle, dog, axle and sleeve.

The latch for the garden gate:

1 —fence post (steel pipe 65×40), 2— dog (steel strip 8×25); 2A — variant “dog” for wood post-jamb, 3 – clip retainer (steel sheet sl); 3A — a variant of the retainer brackets for wooden post-jamb, 4 — retainer (steel); 5 — a bolt (8×25 steel strip); 6 — clip latch (steel, wire Ø3); 7 — axle (steel, circle 30), 8 — leaf gate (grooved Board s 16, 2 PCs); 9 — spring (normally compressed); 10 — clip spring (steel wire Ø3); 11 — connection of gates (area 45×45); 12 — flat and spring washer; 13 – nut M10; 14 — cross member (paired area 45×45), 15 — outer handle (tube Ø20); 16 — bushing (steel)

On the vertical shelf cross member near the free edge of the gate (opposite side from the hinges) drilled hole diameter of 20.2 mm and coaxially to the bottom shelf welded sleeve with the same inner bore hole is inserted the axle, and on the inside of her wearing the heck. It is made of steel strip with cross-section mm 8×25 and fixed nut M10 flat and spring washer. To the end of the axis is welded to the outer handle, pre-curved pipe with a diameter of 20 mm. At the ends of both handles wear rubber tube (not shown).

For “automation” reverse latch is spring loaded (normally compressed), the end of which is wound the brace driven into the lower Board shield wickets. To ensure free expansion and contraction of the spring in the horizontal shelves of angles crossmember is made semi-circular sample of radius slightly larger than that of the spring To limit the stroke of latch up towards the corner of the vertical strapping of gates welded wire clip. Hook closing device (or as it is commonly called, “the dog”) is welded to the post (jamb) gate Nose “dog” cut off on a cone: when closing the wicket the heck they lifted, and then falls into the groove and locks the gate. Unlocking is made by pressing on the handle, whether internal or external.

For additional fixing of the closed position of the locking device it is provided with another stopper It is a small sabovcik, which is installed just above and a bit to the side from the end of the latch, on the same pole as the dog, and secured a free bracket that is welded to the pole To sabovcik flew from brackets on the left ends of the small ribs.

The gate is hung on a pole with a small warp from him with the intention to shut down under its own weight. And the last one. The latch can be used for completely wooden gate with wooden posts. While the latch is easy to mount on a single segment of the steel area, and area to attach to the leaf gate That’s just “dog” have to do with extended rear pin, which when assembling the heck needs to drive into a pole. Bracket stopper should be done with the legs and through corresponding holes in them to tighten the screws to the post.

A. MATVEICHUK, Zavodoukovsk, Tyumen region.