Four years is not a long period, but during this time, you can do many interesting things, especially if you work with a twinkle. Four years ago we in the city of Apatity was organized by the club of young technicians. Annually in fourteen circles here, there are about 250 boys and girls. In one of the clubs design and build microvesicle. For more than twenty a variety of structures designed and built metal Cute young technicians.

Four years is not a long period, but during this time, you can do many interesting things, especially if you work with a twinkle. Four years ago we in the city of Apatity was organized by the club of young technicians. Annually in fourteen circles here, there are about 250 boys and girls. In one of the clubs design and build microvesicle. For more than twenty a variety of structures designed and built metal Cute young technicians.

And if the first we collected on the basis of the scooters and children’s bicycles with engines D-4, D-5, D-6, then later had more powerful engines — 125-175 cm3, wheels from the map, the shock absorbers at the front and rear suspensions.

These machines we’ve made a few, but soon realized that micromatics it turns out heavy and cumbersome. In the end I came to the conclusion that the most rational scheme of microvesicle should be a car with an engine sh-52. Such designs are quite smooth running, small dimensions and weight, decent speed and an attractive appearance.

One of the most successful microvesicles designed and built a member of our circle, Anatoly strigalev. He has been in Kuta since 1972. First became interested in modeling the pipeline, have built several models. The debut was successful, and in 1973 Anatoly for the achievements he was awarded a trip to the pioneer camp “Artek”, where at that time held the meeting of young technicians.

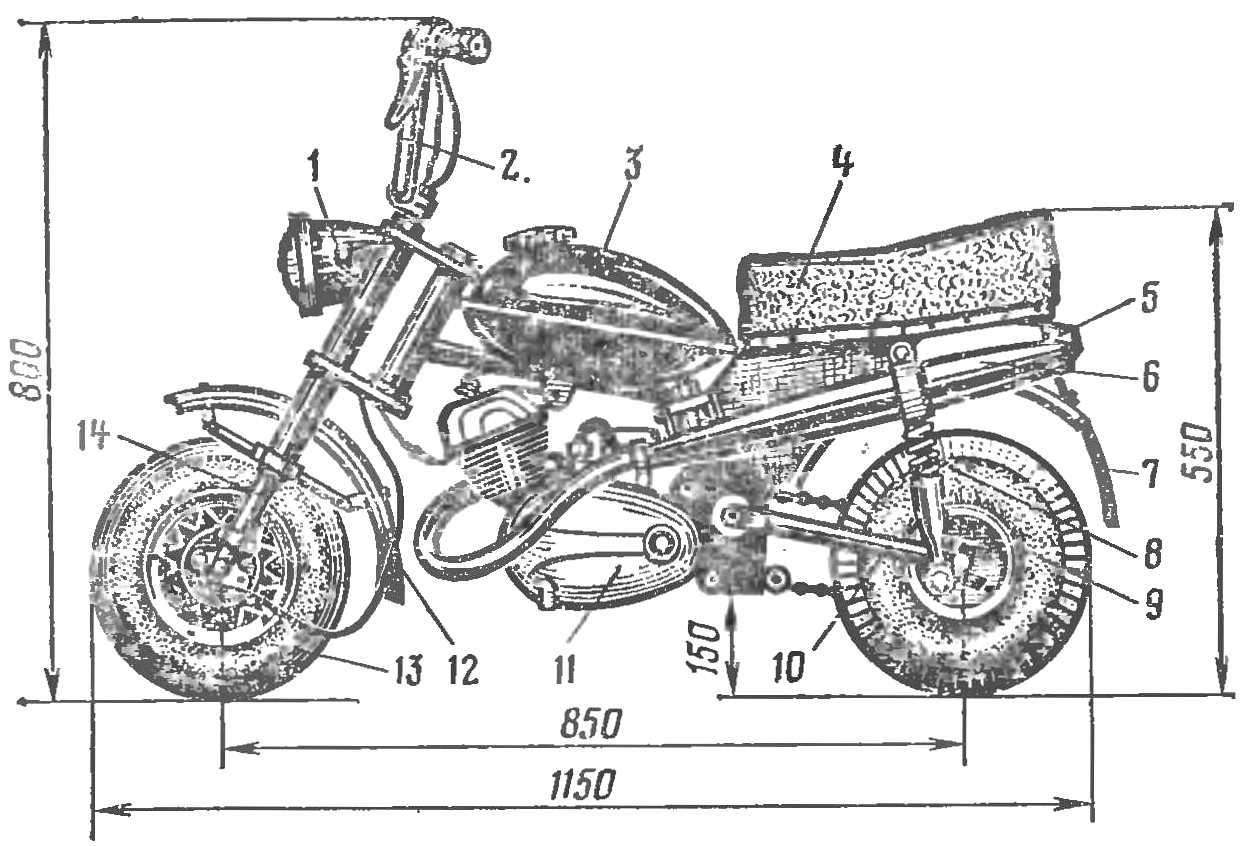

Fig. 1. The layout of microvesicle A. strigaleva:

1 — headlight, 2 — wheel, 3 — tank, 4 — saddle, 5 — brake, 6 — damper, 7 — rear mudguard, 8 rear shock absorber 9 rear wheel, 10 — rear swingarm suspension, 11 — engine, sh-52, 12 — front mudguard, 13 — front wheel, 14 — front shock absorber.

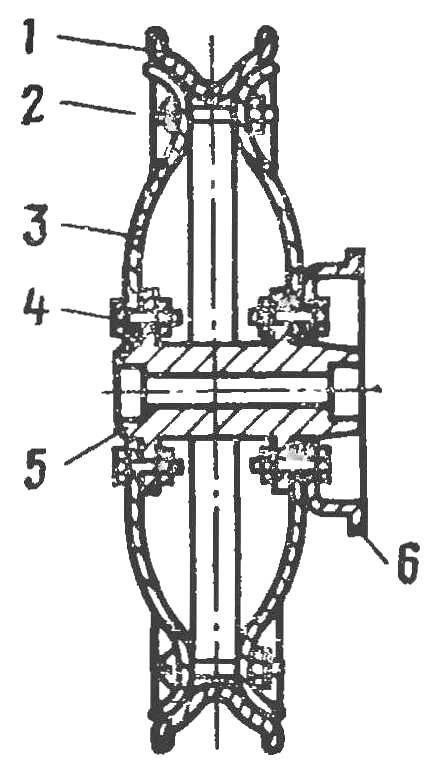

Fig. 2. Front wheel:

1 — the rim of the wheel children scooter, 2 — screw, M5, 3 — disc wheel stroller, 4 — bolt M6, 5 — wheel hub of motorbike, 6 — brake drum motorbike.

My first car A. strigalev has assembled a year later, and the work fascinated him so much that he was not limited to only this design, but was built a few microvesicles of the same class, developed and made in metal many original parts.

Currently Anatoly strigalev — student of the Kirov mining technical school, but this does not prevent him to participate actively in the work Cute.

We offer micromatic Anatolia, in which, we think, most advantageously concentrated our achievements, our experience in the field of micrometallography.

Micromatic, we have developed in the club “Young technician”, is a makeshift structure, which are widely used some of the parts from the scooter. The machine has a shock absorption front and rear forks, sustainable, easy to manage. To learn how to drive it can be literally a quarter of an hour, that’s why it is very suitable for initial driver training for young motorcyclists.

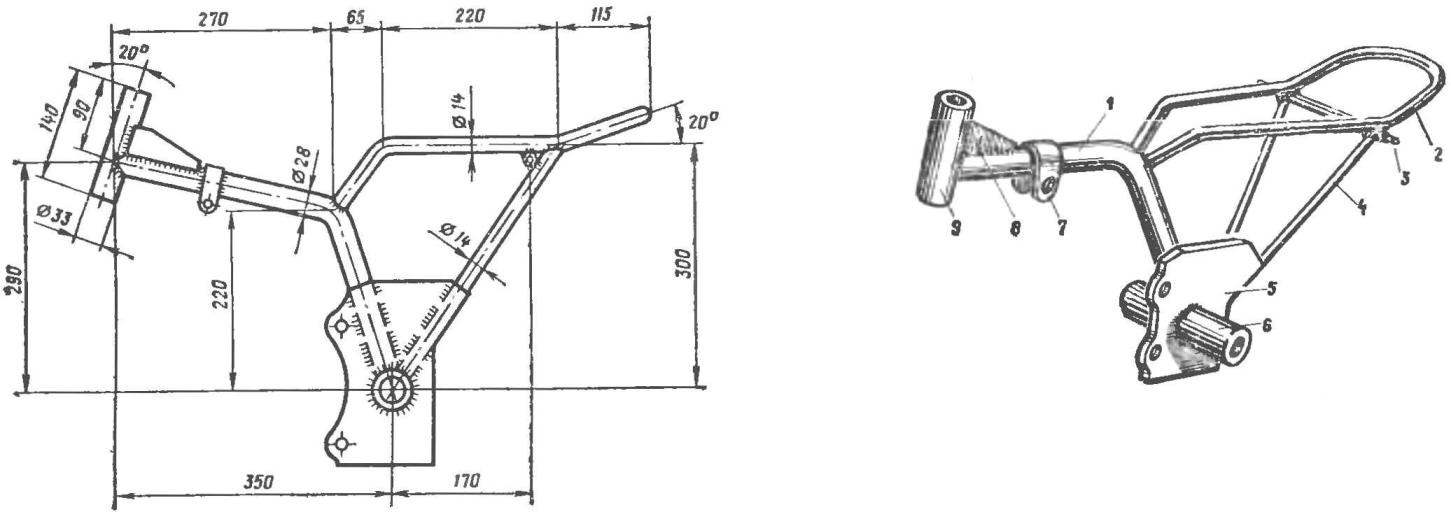

Frame consists mainly of improvised parts and some nodes from moped “Verhovina-3” and “Riga”.

Podsednik made of steel pipes with external Ø 14 mm and length 910 mm. Spinal part of the frame is welded of two pipes — one of them with a diameter of 28 mm and a length of 500 mm and the other Ø 33 mm and a length of 140 mm. the Pipes are welded to each other with the strengthening of the place of welding steel with a scarf. To the lower part of the frame welded to the sleeve axis of the pendulum from the moped “Riga-3”. The engine is fixed to a yoke cut from a steel sheet with a thickness of 3 mm.

The struts connecting the bushing to the axis of the pendulum with podseleniem represent segments of steel pipe Ø 14 mm. At the junction of podselenie and struts welded to the axle shock mount is made of dvenadtsatitsilindrovy steel hexagon with a length of 210 mm. the ends of the hexagon machined to Ø 10 mm.

Fig. 3. Frame microvesicle:

1 — spinal tube frame, 2 — podsednik, 3 — axis rear shock absorbers, 4 struts, 5 — flange mounting motor, 6 — bushing the axis of the pendulum suspension, 7 — clamp, 8 — porch 9 — the steering head.

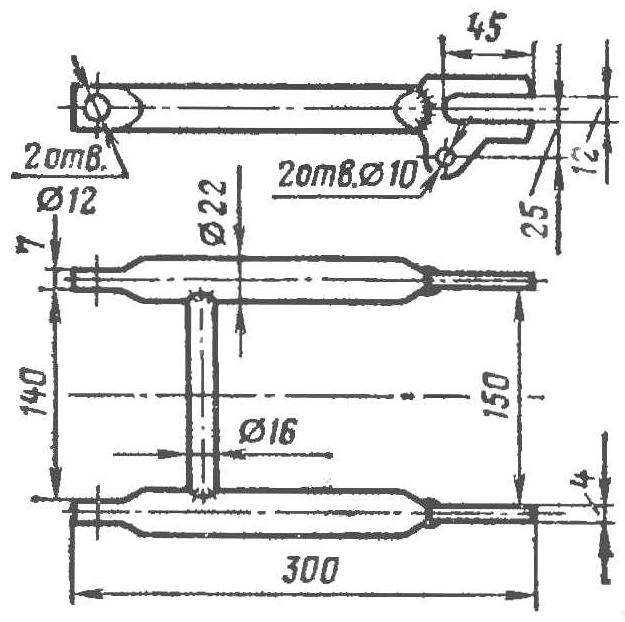

Fig. 4. Podsednik.

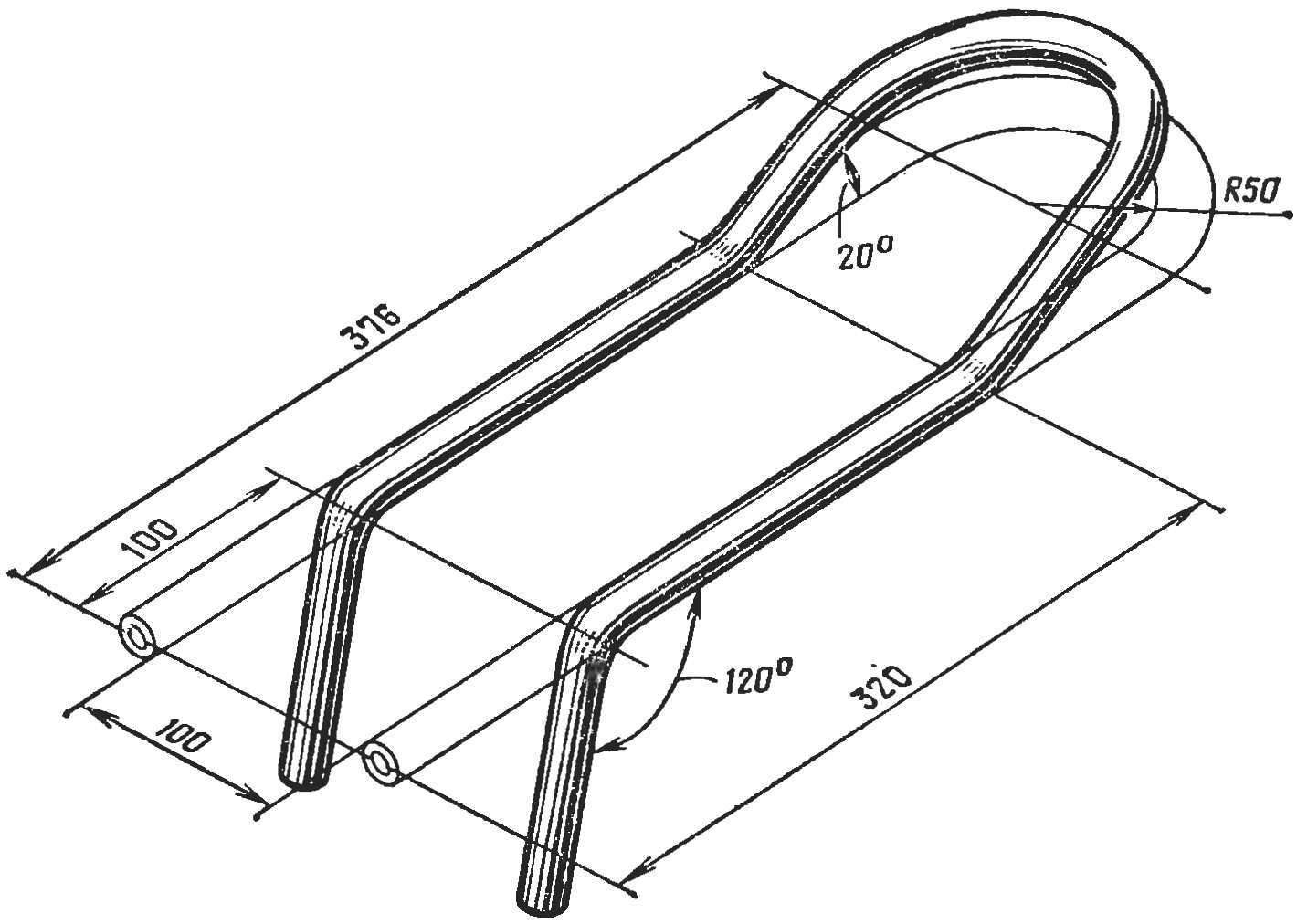

Fig. 5. Rear pendulum suspension.

Front forks — moped “Riga-7”. Had to modify: shorten feathers and stems so that the overall length (complete) was 500 mm.

The rear swingarm is welded from steel tubes Ø 22 mm. and 16 On one end of the pendulum drilled holes Ø 12 mm (the axis of the pendulum), and the other ends are inserted into the eyelets of steel sheet of thickness 4 mm. They should be made so that the axis of attachment of the grommets below the axis of the rear wheel by 25 mm.

Front wheel assembled from the rim samokatnaya wheels, two drive wheels from the pram and hub with brake drum on the motorbike. One of the disks attached to the hub with four bolts with M6 thread and the other six M5 bolts. In addition, on the second disc of the same bolts and screwed the brake drum. Rim is clamped between the discs with six M5 bolts. This wheel design is quite efficient. The chamber and the lid are standard — from scooter.

The rear wheel from the card. Its size 280X85 mm. wheel Hub rear wheel is designed similarly to the hub of microvesicle “Dwarf” (“M-K”, 1976, No. 12). The wheel is mounted on sprocket 24 tooth provides “kid” max speed about 60 km/h.

Headlights and fuel tank from a moped “Riga-7”, tail light of an old motorcycle. Saddle sponge rubber, foam and artificial leather.

A. STRIGALEV