In last year’s fourth issue of the journal, I read an article about Razakhatskaya V. the machine “Skillful hands”. There is proposed a device for drilling. But it will have to cut off part of the shaft, and the remaining grind down under the cone, which excludes the possibility to use other devices.

In last year’s fourth issue of the journal, I read an article about Razakhatskaya V. the machine “Skillful hands”. There is proposed a device for drilling. But it will have to cut off part of the shaft, and the remaining grind down under the cone, which excludes the possibility to use other devices.

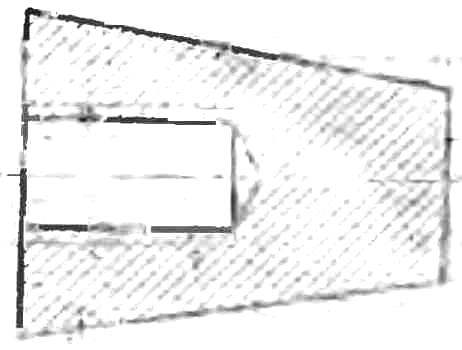

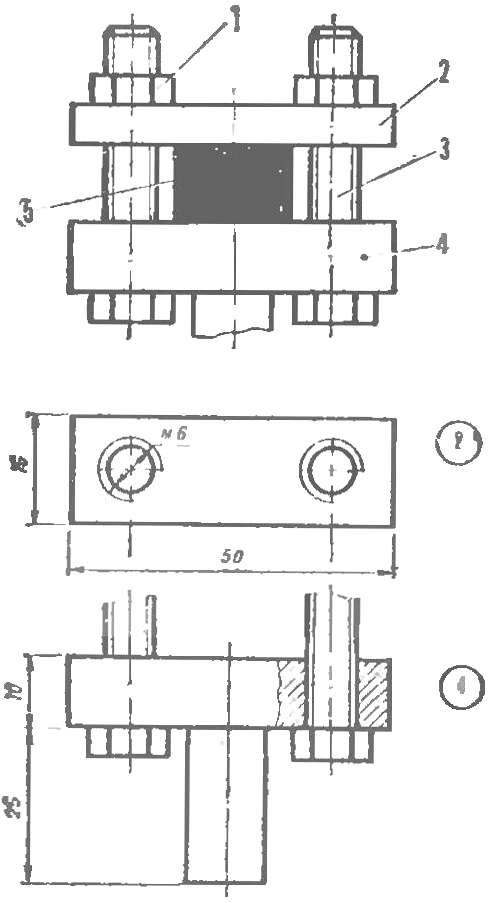

I suggest that the shaft does not change. On a lathe it is necessary to grind a cone (Fig. 1) for the cartridge, and it is exactly on the axis to drill a hole and cut thread, similar to the ones on the shaft. This is the cone to insert into the socket and screwed on the shaft.

Lifting table, which is referred to in this publication can also be improved: make rectangular and provide with two threaded bolts M-6 (Fig. 2). With the help of additional straps and nuts will be easy to attach parts.

Fig. 1. The scheme of the transition cone (threaded part under the motor shaft, a conical — chambered drills).

Fig. 2. Lifting table:

1, 3 — fastening bolt with nut, 2 — strap, 4 — pad table 5 — fixed detail

The wider the table, the greater the detail you can handle. Holes in the table for bolts are drilled on the centerline, so that when drilling the plate is not interfered.

Chuck with taper I have used and very pleased.

A. PROKHOROV, Kovrov

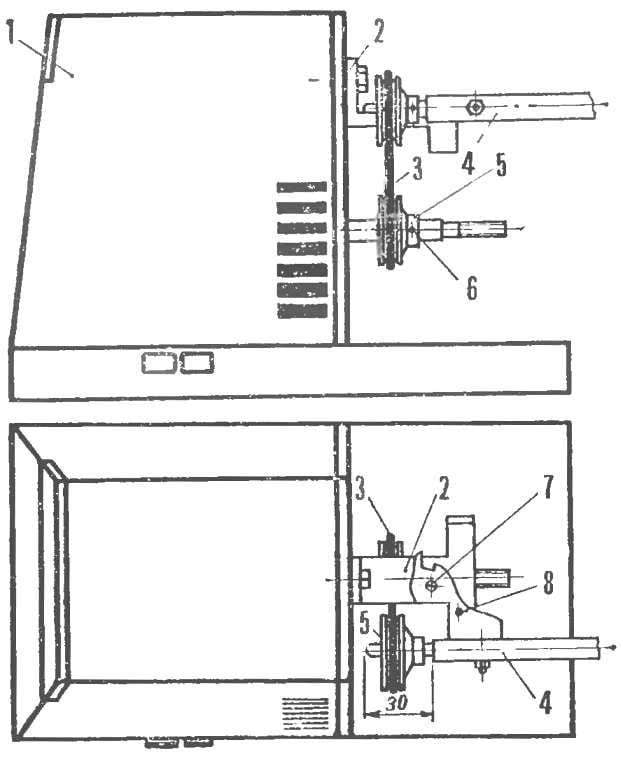

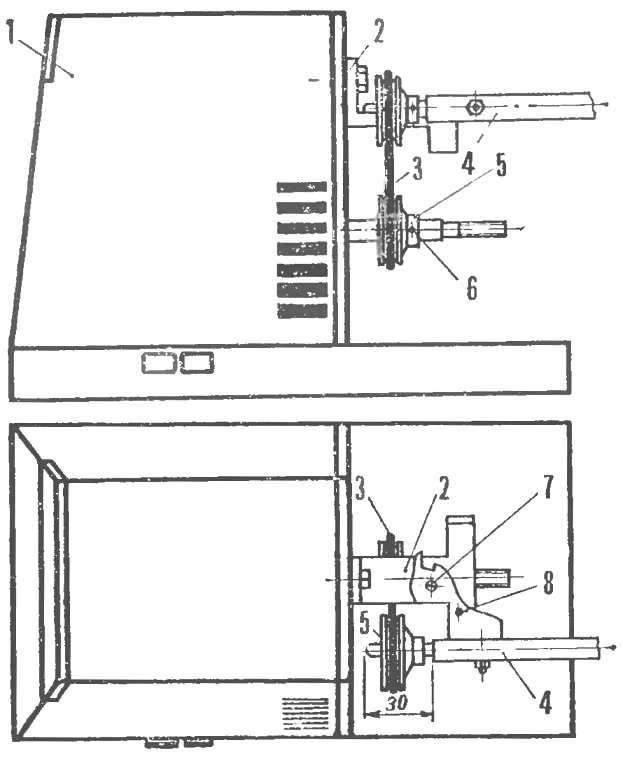

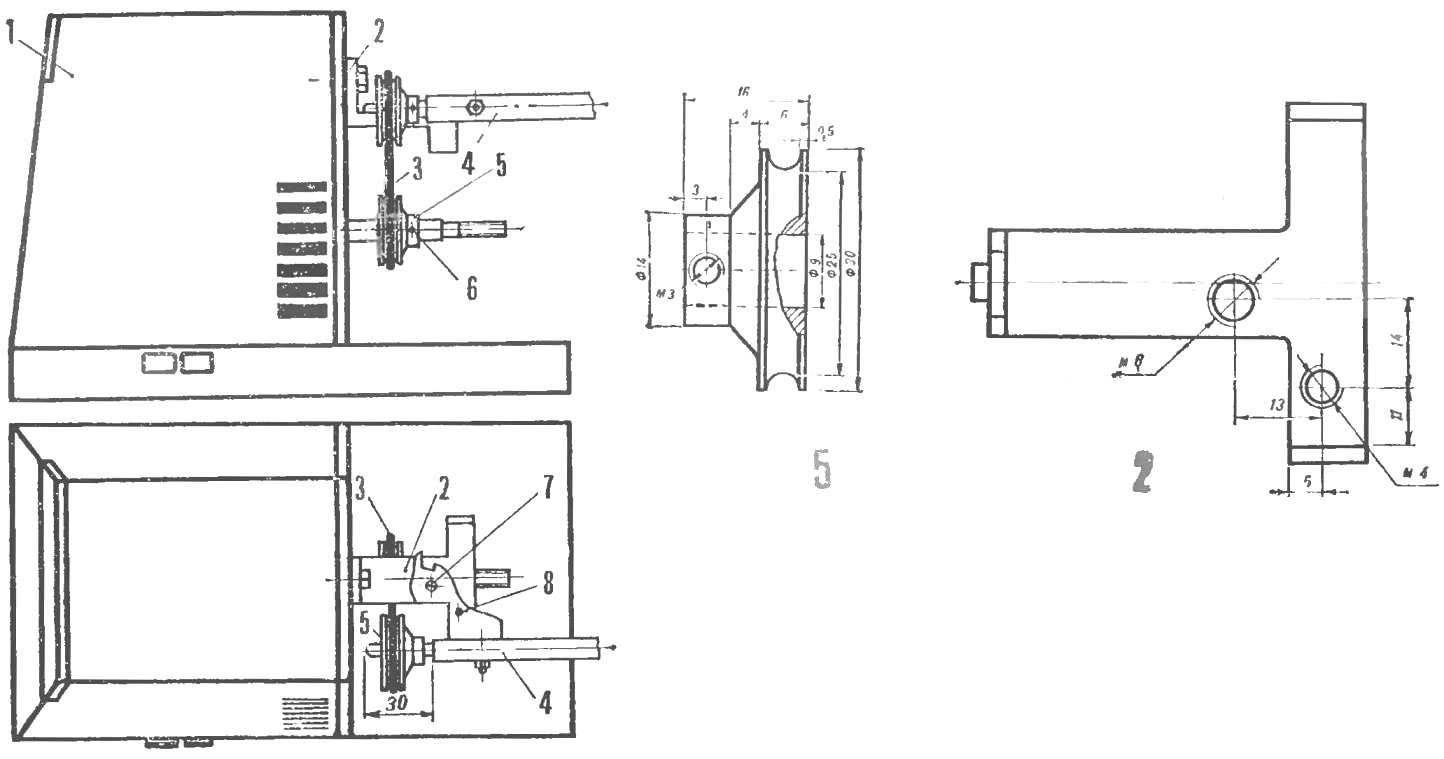

After a simple finishing touch protective cover, designed to protect from circular saws and the manufacture of pulley the machine becomes universal. However, this would require a more flexible shaft dental drill handpieces, burs and Pasika from the tape recorder. Communities view of the machine shown in figure 3.

Improvement of the protective casing (now a mounting bracket and flexible shaft) is that it drilled two holes for thread M4 and M6 for mounting a flexible shaft. The protective casing when it is installed on a regular place. Vertical groove gives the ability to change the tension of the Pasika. The output of the flexible shaft have to be shortened to 30 mm.

Fig. 3. Upgraded machine “Skillful hands”:

1 — body of machine, 2 — a protective cover, used as bracket, 3 — pasik, 4 — shank flexible shaft, 3 pulley, 6 — goujon, 7 — M6 screws, 8 M4 screws.

The pulley can be made of any material, amenable to machining. Suitable pulley from a flexible shaft, if you drilled a hole to 9 mm. Fixed pulley on the shaft of the machine, locking screw, which is screwed into the shaft hole of the machine.

In addition, using the adapter can be mounted on the shaft of the lathe drill Chuck at other diameters. But it is necessary to provide emphasis at the end of the shaft, and then he starts to be (a big cantilever load).

You can do surface planer using the cutter from stanochek for sharpening pencils.

V. CHUDNOVSKY, engineer