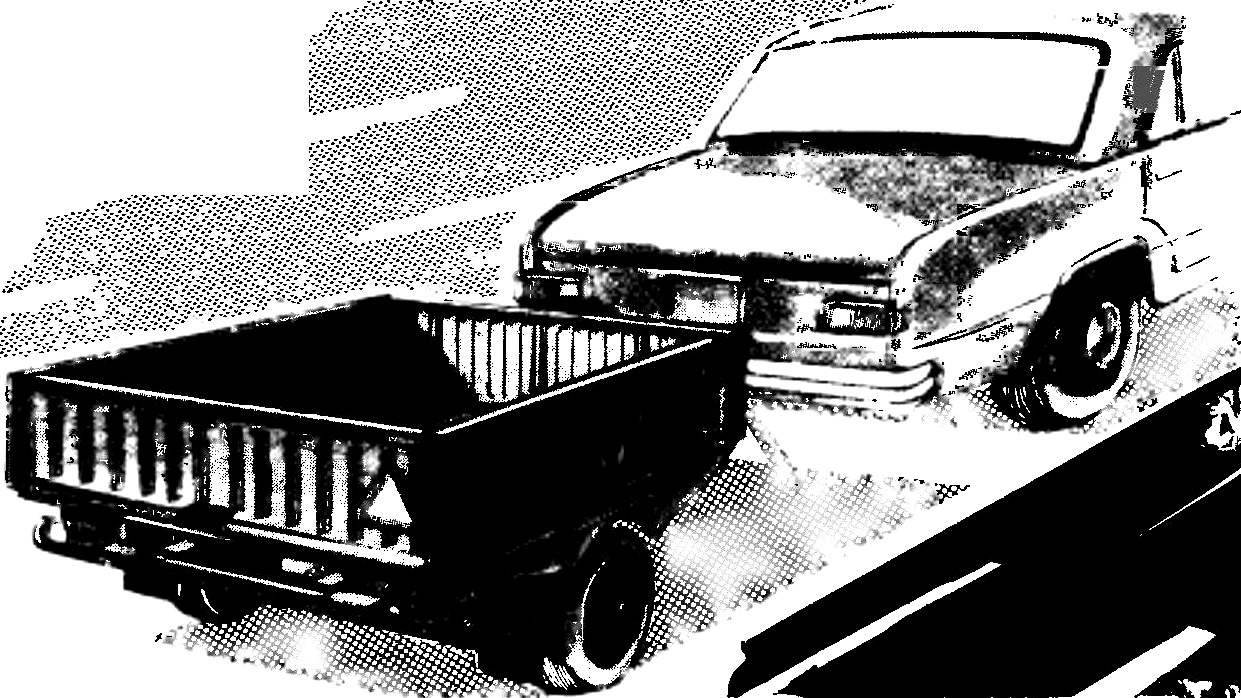

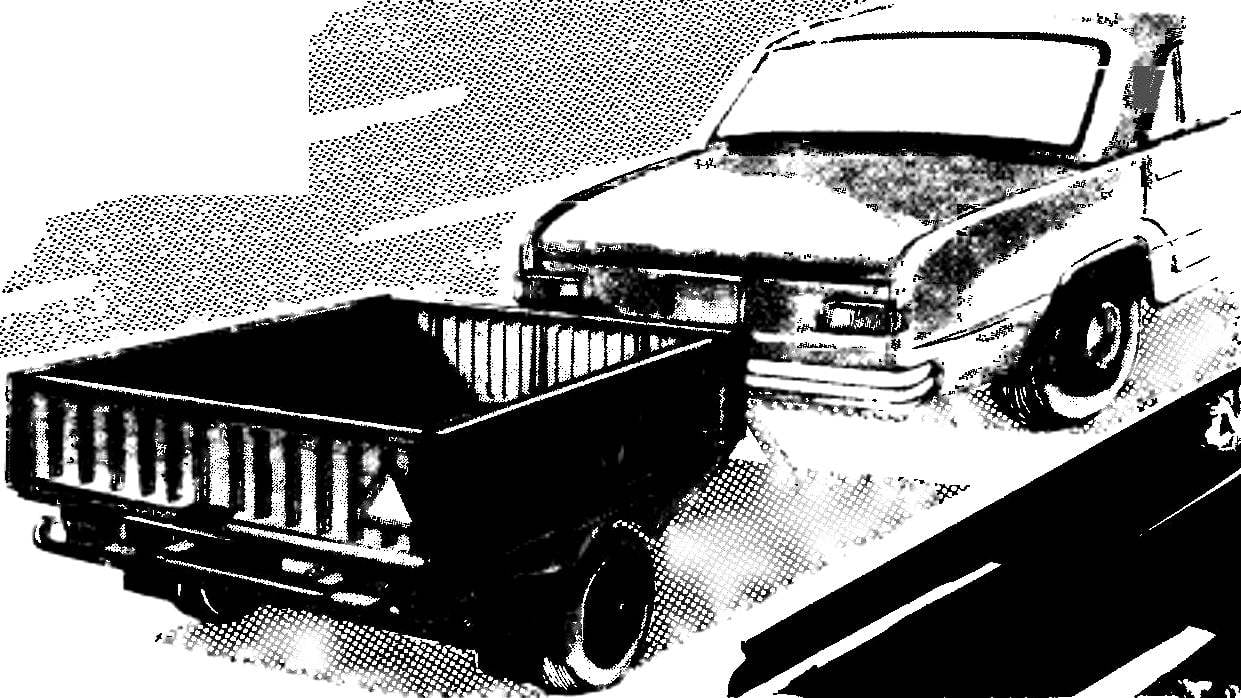

Fig. 1. Cargo trailer for a passenger car:

1 — frame trailer, 2 — inertia braking system of the trailer, 3 — ball hitch, 4 — spare trailer wheel, 5 — body, 6 — bezel made of a steel angle, 7 — trailer wheel (sidecar FDD), 8 — lock folding tailgate trailer, 9 — tailgate, 10 — light unit (Parking light, brake light, turn signal light), 11 — rear bumper, 12 — absorber (from a motorcycle “Ural”), 13 — splash guard 14 — front axle from motorized FDD.

Here the main structural components of the trailer frame with the tongue, the body, torsion bar suspension, braking system, trailer hitch, awning with arches, supporting structure, electrical system and light alarm.

The frame of the trailer — rectangular, welded from steel billets. It consists of two beams-side members and three cross members. All of these parts from a steel channel section 25х50 mm.

Fig. 2. Frame cargo trailer:

1 — spar frame (steel channel 25х50 mm) 2 — front cross member (steel channel 25х50 mm), 3 — the middle cross member (steel channel 25х50мм), 4 — rear cross member (steel channel 25х50 mm), 5 — mounting brackets shock absorbers, 6 — mounting brackets rear bumper, 7 — pole, 8 — coupling device.

The front converging ends of the side members fixed drawbar; on the middle cross member are brackets for mounting shock absorbers; rear mounted brackets for the rear bumper.

The chassis is made using wheels and torsion bar suspension (front axle) from motorized FDD. In addition to the torsion bars, the suspension is supplemented with spring-hydraulic shock absorbers of the motorcycle type “Ural”.

Tow hitch standard, is performed in accordance with ball bearing, mounted on the towing vehicle. The housing of the coupling device attached to the pole is not hard, as on the production trailers, and mobile that allows you to transfer the inertial forces arising during braking, the hydraulic brake system. It works as follows. On a spherical trailer hitch pinned lever, the upper end of which is connected by a rod to the brake master cylinder. When braking the vehicle, the inertial forces tend to compress the two springs, the calculated force is 500 kgf; the coupling device thus moves on two rails. The progress springs are about 50 mm. When this occurs, the injection of brake fluid from the master brake cylinder in the brake system and thus the braking of the trailer. It is characteristic that its braking system is adjusted so that wheel lock does not occur even during emergency braking of the car.

Fig. 3. Inertial brake system of truck trailer:

1 — bracket, 2 — stop, 3 — beam, 4 — axis, 5 — Bush, 6 — Klondike, 7 — blank, 8 — fork 9 — stem, 10 — the case of the coupling device, 11 — stand, 12 — pad, 13 — hour, 14 — bolt, 15 — bolt M8 nut M8 16, 17 – nut M6 18 — a washer with an internal diameter of 8 mm, 19 — pin, 20 — oiler, 21 — spring, 22 — brake master cylinder 23 — frame of the trailer.

The body of the trailer is welded from sheet steel 0.7 mm thick; ribs and the upper edge of the body is reinforced steel corners. Underbody — desyatiletnego plywood with steel strengthening bands. On the upper studs of the sides provided nests for installation of arcs and hooks fastening of an awning.

The trailer is equipped with a spare wheel fixed on the front wall of the body.

Wiring is made via the single-wire scheme of connection to the onboard network of the car of all the necessary beam — position lamps, stop lamps and turn signal. On the front side and rear side mounted reflectors-reflectors.

Technical data of trailer:

curb trailer weight, kg: 100

overall dimensions of platform, mm:

length………..1530

width……….1400

height…….350

overall trailer height, mm: 945

the floor space of the platform, m2 : 2,06

body volume, m3 : 0,62

weight of transported cargo, kg: 350

A. FILIPPOV, G. Sosnovoborsk, Krasnoyarsk Krai

Recommend to read LOBED ON PILOTAGE What are the only propellers is not built by modelers. Due attention was paid to the three blade. Why not try to install them on a modern cord "acrobat"? If Yes, will any benefit from... MYCHITE LOUDER Among the many toys in the electronics, is able to mimic the sounds of animals, is very amusing. For example, a toy cow, imitating mooing, or a pig, saying, "let's Go home, I'm hungry!"...