Owners of houses with stove heating know how difficult it is to light a cold stove (fireplace or sauna stove), especially in bad windy weather. You’ll literally cry, because the smoke initially often goes not into the chimney, but, on the contrary, into the room. This problem is especially acute for those owners of garden and country houses who visit them in the cold season only when necessary.

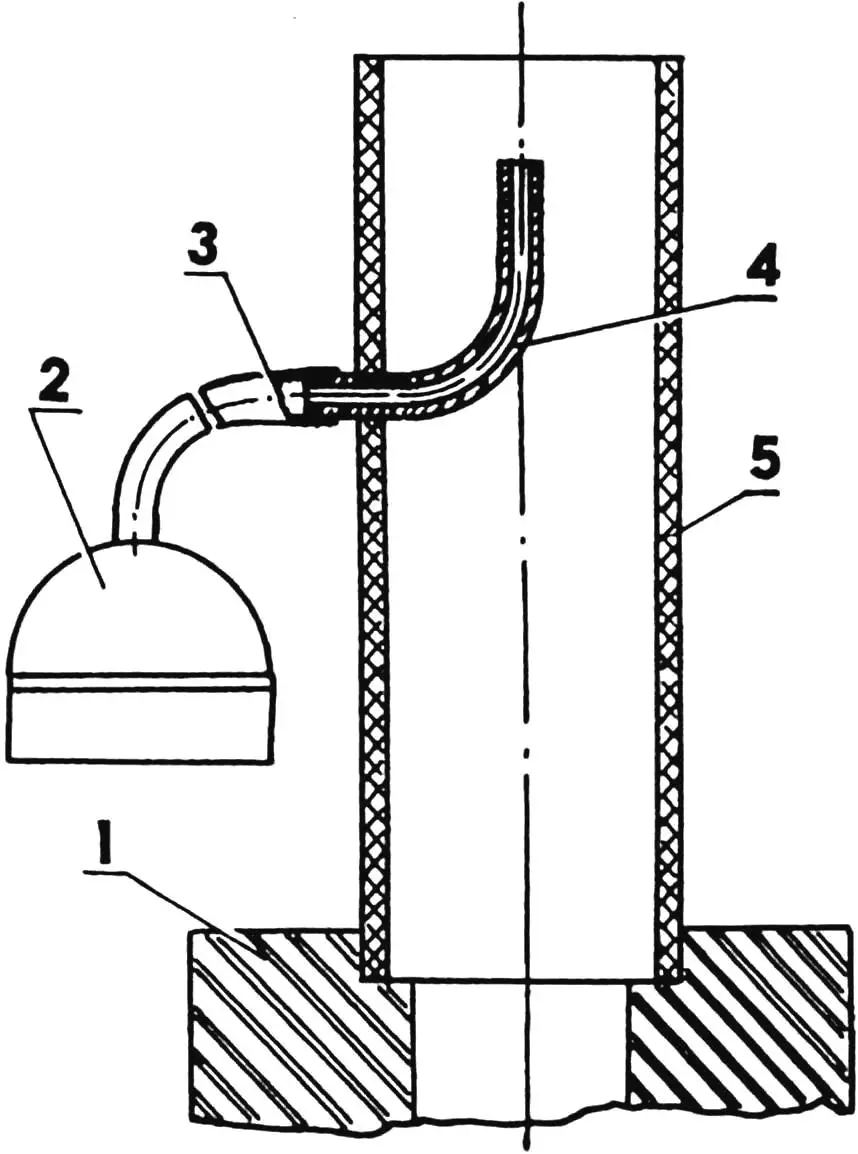

You can get out of this situation if you have electricity by using a vacuum cleaner and a piece of bent steel pipe of suitable length and diameter, which must be installed inside the chimney flue with its lower end exiting through the wall, as shown in the figure. When the vacuum cleaner forces air into the upper part of the pipe, its flow, exiting outward, will create a vacuum and thereby increase the draft.

But if electricity is not available or the vacuum cleaner is not stored in the house, it’s better to solve this issue once and for all.

1 — stove (fireplace, sauna stove); 2 — vacuum cleaner; 3 — flexible hose; 4 — steel pipe; 5 — chimney

A simple structure called a flue cap (weather vane) will help in such a situation, which helps to increase draft even in cases when the pipe does not provide smoke extraction due to insufficient chimney cross-section, low pipe height, excessive number of turning channels in the stove, connection of several heating devices to the pipe, etc.

The flue cap works on the principle of an ejector, successfully performing the tasks of other exhaust devices, but at the same time does not consume electricity, like a fan smoke extractor, and is not blown by wind, like a deflector. In strong winds, the performance of both alternative devices decreases, while the flue cap, on the contrary, begins to function even more efficiently.

Installation of such a structure is possible on the outlets of ventilation ducts to increase air exchange.

The flue cap is mounted on top of the stove pipe, where a cap is usually installed, which in this case becomes unnecessary, since this structure, in addition to everything, protects the smoke channel not only from direct atmospheric precipitation, but also protects against slanting rain, since its outlet is always located on the leeward side.

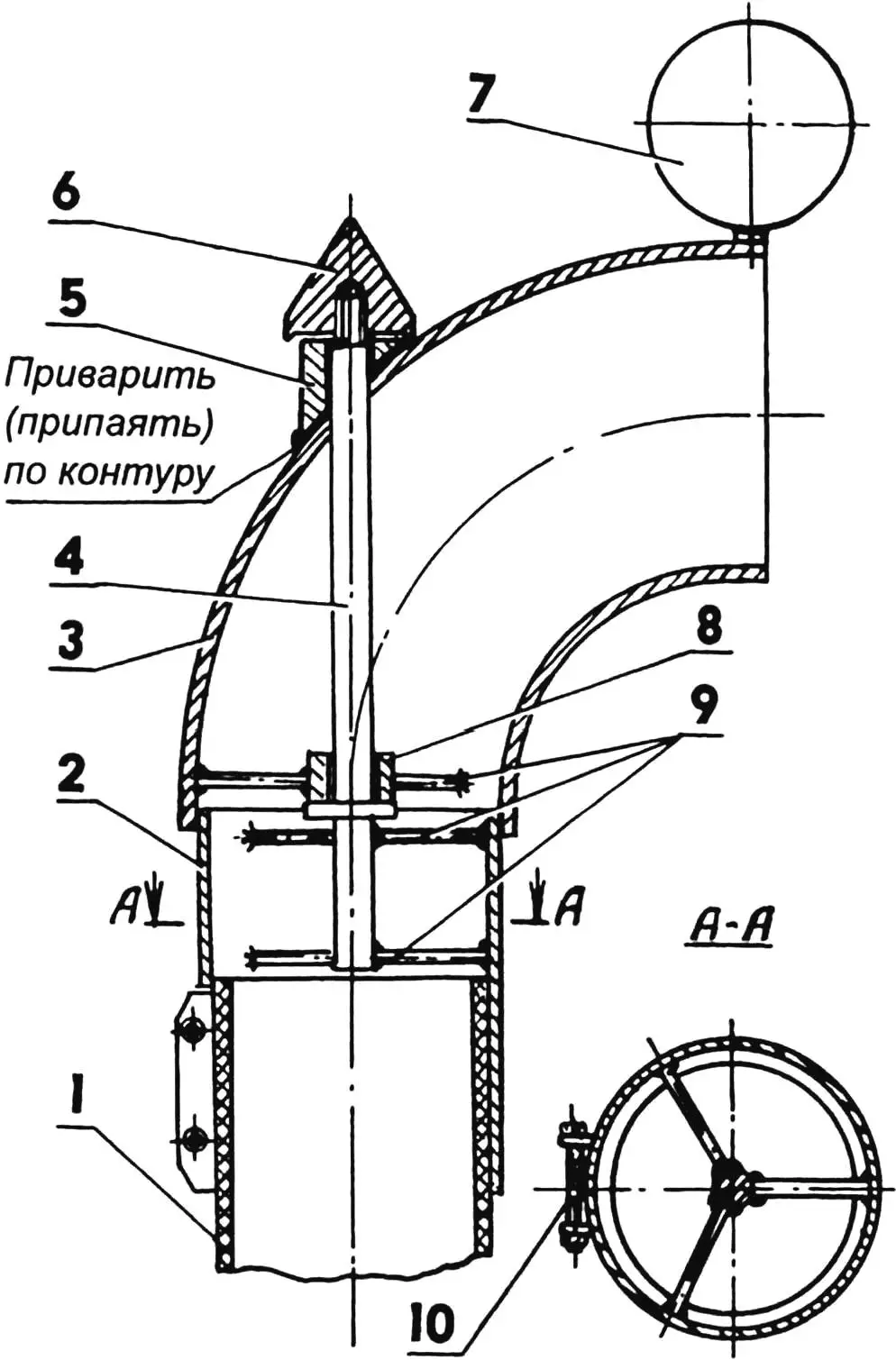

1 — asbestos-cement pipe; 2 — nozzle with clamp; 3 — cap; 4 — axis; 5 — upper bushing; 6 — cap nut; 7 — stabilizer; 8 — lower bushing; 9 — spokes; 10 — bolt

The main part of the flue cap is a rotating cap in the form of a cutout (quarter of a circle) of annular cross-section, which is mounted on an axis using two bushings. The upper bushing is welded (soldered) on the outside directly to the cap, and the lower one is connected to it by three spokes from the inside. The cap is made of thick galvanized sheet metal, the axis and bushings are steel. The device’s axis has a shoulder on which the lower bushing of the cap rests. The upper end of the axis is turned, and a thread is cut on it. After mounting the cap, a cap nut is screwed onto the thread.

The axis is mounted strictly vertically in the center of a cylindrical nozzle using spokes welded at two levels.

The nozzle — together with a clamp made of steel pipe with an internal diameter equal to the external diameter of the chimney, on the top of which the flue cap is mounted.

A vertical stabilizer is attached to the cap at its very top, which ensures that the flue cap’s outlet is always positioned into the wind. This part can depict various figures and serve as decoration for the pipe, giving a certain individuality to the house.

The general structure of the flue cap is clear from the drawing. The dimensions of the structure and the sizes of its parts are determined on site.

It is easiest to install the flue cap on a round pipe, for example, an asbestos-cement pipe, which are currently widely used in stoves not only in garden but also in residential houses, as they are quite light and do not require separate foundations or reinforcement of the stove. Moreover, the inner surface of these pipes is relatively smooth and ensures unobstructed smoke exit without turbulence.

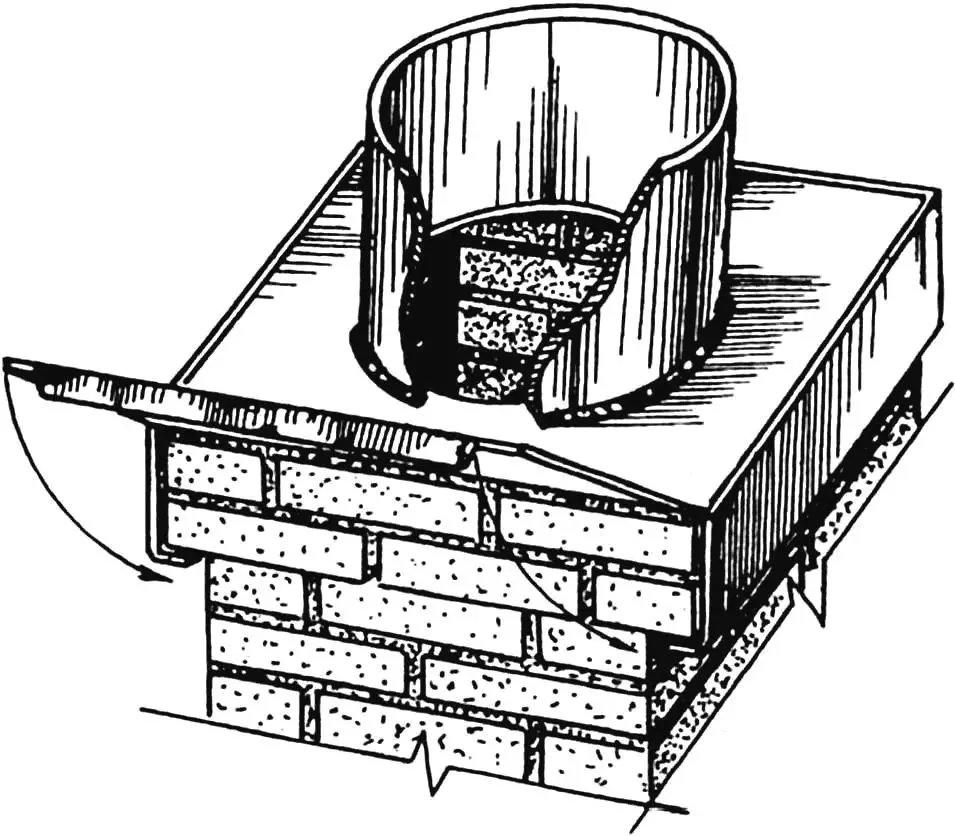

If the pipe is brick, then you need to make a steel adapter that will allow transitioning from its square or rectangular cross-section to a round one, and securely fasten it to the head. Then mount the nozzle on the cylindrical part of the adapter and tighten it with a clamp, or, dispensing with this part altogether, weld the flue cap spokes directly to the adapter cylinder.

«Modelist-Konstruktor» No. 8’2002, V. KORNEYEV