Of course, those who are interested in unusual aquatic means of transportation, have the right to choose the technology of its production. However, the easiest case happens when vyklevyvanija it from fiberglass in the matrix or the blank using epoxy or polyester resin. In favor of this method is the fact that meticulously to withstand the shape and dimensions of the housing master-homebrew have only once – when working on the blank or the matrix.

To make the blank, should be cut out of plywood with a thickness of about 6 mm set of frames and to fix their keel up on a wood Board using wooden sticks and strips-braces according to these theoretical drawing of the hull.

Further, the space between the frames is filled with cement-sand mortar. By the way, to facilitate the ingots and reduce the amount of cement between the frames fastened trim boards so that the layer of cement-sand mortar was not more than 30 mm. After hardening of a solution the lower part of the bar is aligned with putty and sandpaper, and then painted two or three coats of enamel with intermediate sanding of each layer.

Wikiepedia body shell of fiberglass and epoxy resin. Depending on the thickness of the fiberglass on the shell will need from five to eight layers. Before forming the shell to the disc is applied separation layer of wax mastic or autopolis.

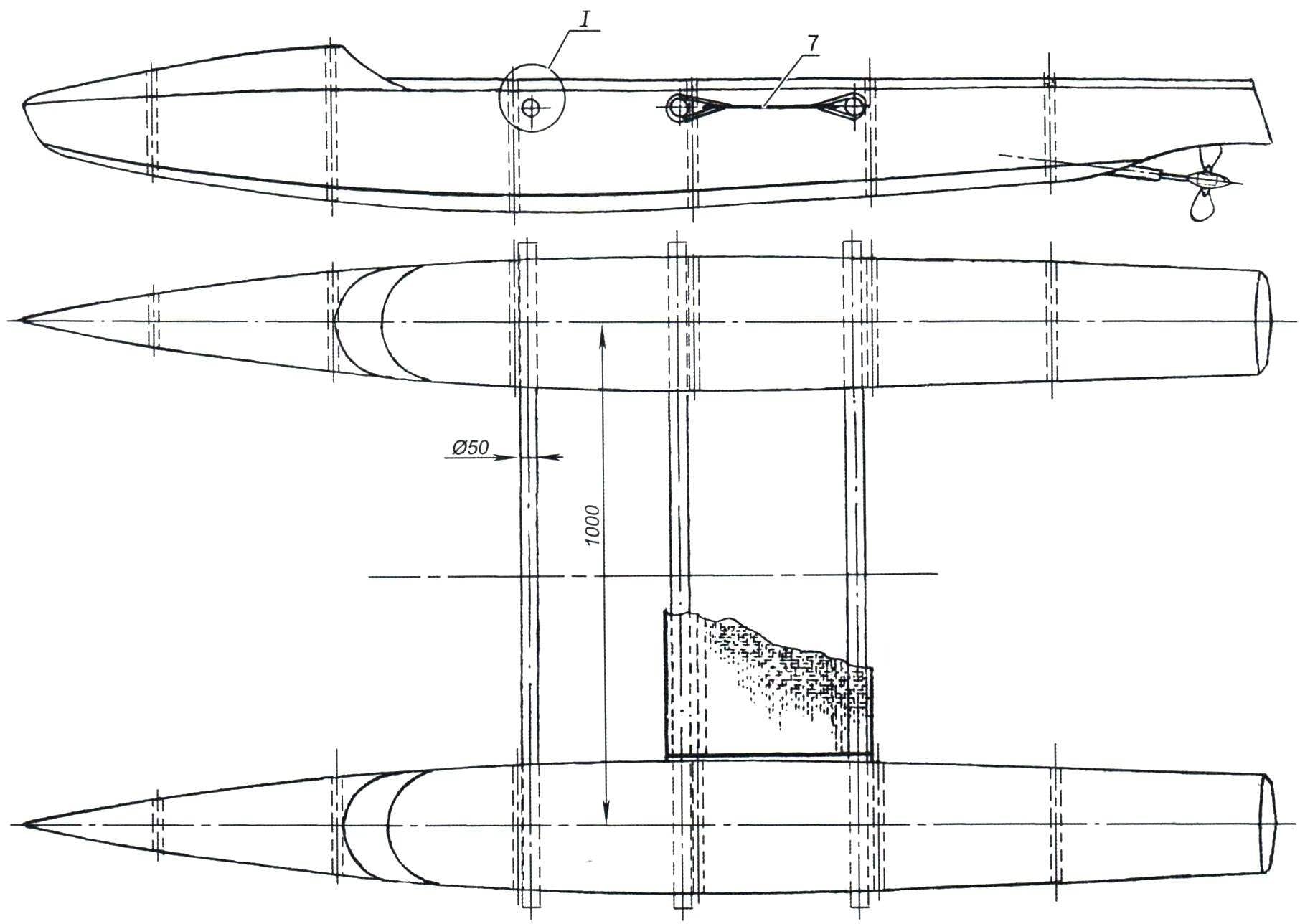

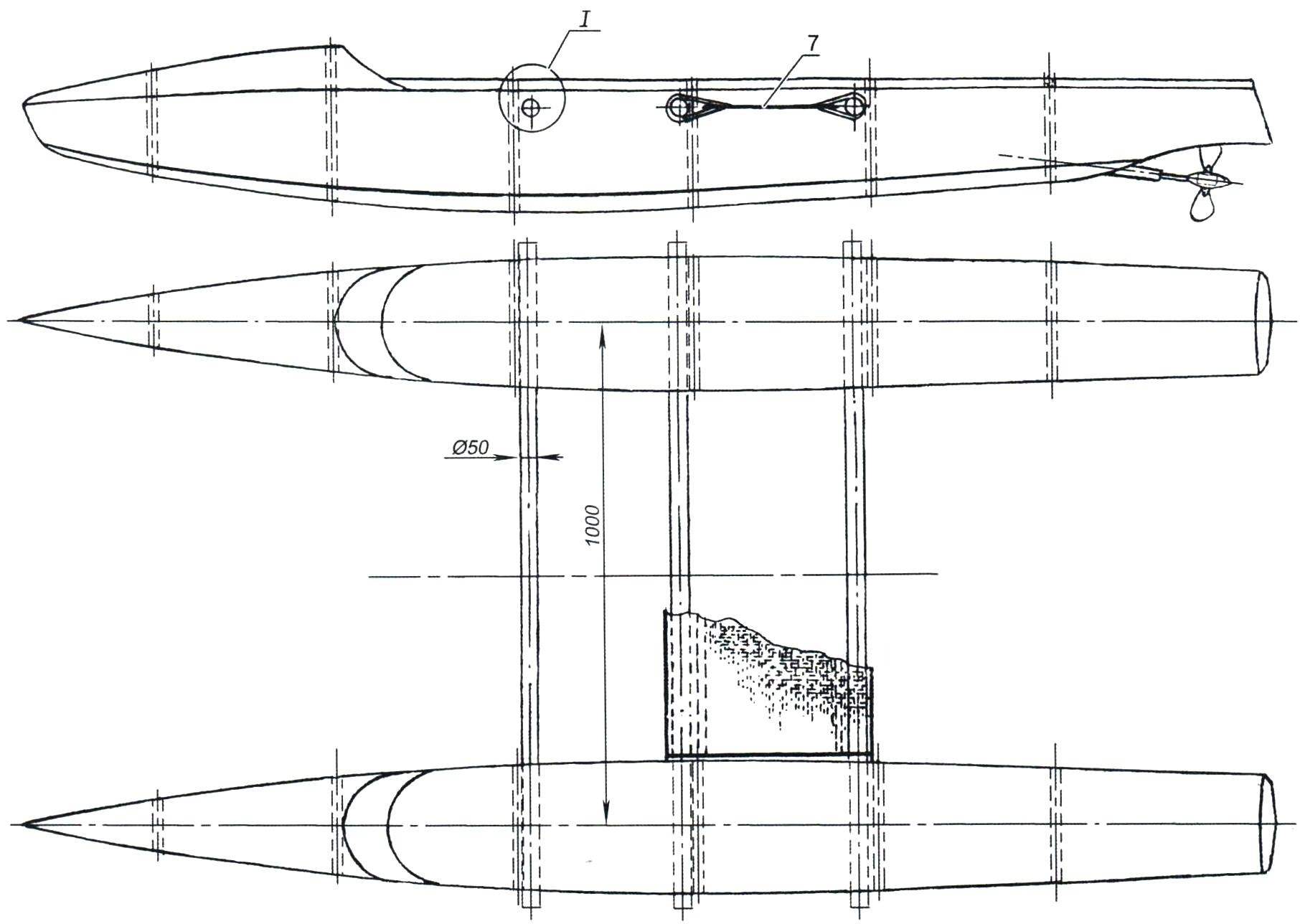

Design of self-propelled float:

1,4, 6, 7, 9, 10, 19 – bulkheads (plywood s8); 2 – shell of the float (glass); 3 — 12-volt battery with a capacity of 30 — And 40-h; 5 – boot; 8 – power unit; 11 – tunnel (Vileika of fiberglass and epoxy resin); 12-pad (plywood s10); 13,14,15,20-stringers (pine slats 20×20); 16 – Kiel (pine rail 30×50); 17, 18 – poliks (plywood s8)

Molding casing, it is desirable to produce without interruptions, otherwise the shell is in the process of operation will delaminate and leak. Note that polymerization of epoxy takes two to four hours at room temperature and standard ratio of epoxy and hardener 8:1.

After curing of the binder shell is removed from the billet and inside the future the housing of the float is glued to the frame, consisting of a keel (pine rail cross-section 20×50 mm), frames (6 mm plywood) and stringers (pine slats 15×15 mm).

Further, between the frames 2 and 3 and between frames 3 and 4 establish the grounds of the plywood thickness 8 – 10 mm, the first for battery and the second for leg “skier” – unless, of course, floats are used as self-propelled gidroliz.

The basis of the power unit of each of the floats is a 12-volt battery with a capacity of up to 30 A*h in conjunction with the electric motor used in the cooling system of the car (for example, VAZ-2109) to drive the fan.

Stern tube the device consists of a shaft tube, both sides of which are pressed Teflon or textolite bushing – sliding bearings, and the propeller shaft.

The power unit is self-propelled float:

1 – motor; 2 – shaft of the motor; 3,5 – flanges of the connector; 4 – pin; 6 – bolt-lock nut; 7 – propeller shaft; 8, 11 – bushing shaft tube; 9 – a stern pipe; 10 – grease; 12 – pin; 13 – cover of the fairing; 14 – the screw of fastening of a cover; 15 — Bush of the propeller blade; 16 — rivet; 17—blade propeller; 18 — a nut of fastening of a propeller blade; 19 — a nut of fastening of a propeller

The cavity between the shaft and stern tube lubricated with grease type tsiatim. Connect the motor shaft and the propeller shaft with rubber couplings consist of pairs of steel flanges, each of which is mounted on two steel pins, and rubber disc thickness 10 mm with four holes for pins.

Accurately calculate the parameters of the propeller is difficult – better to make a propeller with adjustable step. Its basis is the hub of streamlined shapes carved on a lathe out of aluminum, inside which the selected groove and drilled three holes: one is designed for interfacing the hub with the propeller shaft, the other to secure the bushings of propeller blades. The blades are made of sheets of aluminum with a thickness of 4 mm; the profile is convex-concave, asymmetric, rounded in front and pointed behind. Sleeve blades-steel blades are attached to them with aluminum rivets.

Selection of the optimal installation angle of the blades is carried out after the descent of the float on the water, in the process of trial runs the motor at different angles of the blades of the propeller. To determine the thrust of the screw can be the simplest dynamometer household spring scales. Given the low speed of the float, the maximum thrust will correspond to the optimal angle of the blades of the screw.

After determining the optimum angle of the blades, the hub is closed by a lid which is fixed with long screws M5.

The top of the floats are moulded on a separate disc on the same technology as the shell floats. Between frames 5 and 6 from pine slats 10×40 mm is formed in the coaming is the vertical fence of the hatch, designed for installation and maintenance of the motor. The same hatch and battery compartment is located between frames 2 and 3. Cover hatches should have a reliable seal preventing the splashing of electrical equipment with water. By the way, the wiring should be cable in two-layer shell, and a connector to connect the toggle switch control must be sealed.

Pleasure catamaran on the basis of self-propelled floats:

1 – cross member (wood, bar d50); 2 – poluchaut (steel, rod d6); 3 – bulkhead; 4 – nut M6 with washer; 5 – a plate (plywood s10); 6 – stringer; 7 – bench (awning fabric)

Ski pole

The compartment, located between the frames 3 and 4 is designed for leg “skier” – in the lower part, police plywood, screws, screws fixed plastic overshoe – this popular when performing utility work in suburban areas. And when driving the water does not leak into the hull of the floats, it makes sense to make from thin synthetic fabric, which comes to jackets, a kind of sleeve with elastic at the top and fasten them to the coamings of the hatches.

Managed by ski-electric two switches, each of which has three fixed positions – “forward”, “stop” and “back”. Selecting the right toggle will not succeed, you can make a homemade switch.

At first, it is useful to join the ski-floats two starcame in the front and rear parts thereof so that the distance between the skis did not exceed half a meter – otherwise the floats shifting to the sides, and “skier” will be in the water. And yet, to maintain balance when moving will help you a pair of ski poles, which in the lower part instead of the usual rings set of conical plastic pots-pots. They will help you to reach the coast, if a power plant suddenly zakapriznichal.

As mentioned above, a few self-propelled floats can be converted to a compact pleasure electrocautery. You only need to connect the floats to the bridge, consisting of three round wooden cross-beams with a diameter of 50 mm. To the frames 2, 3 and 4 are fastened with poligonului, bent in the form of letters and cut from 6 mm steel rod at both ends which made the M6 thread. On a couple of the rear cross-beams of the bridge stretched the cloth of thick fabric turns out quite convenient bench.

To sail on a catamaran can be the same as ski – commutation of the motors.

I. MNEVNIKI

Recommend to read Candle-impromptu It took a long warm-up fine detail, but what? Matches? Do not impossible to satiate, and uncomfortable, and the candle was not at hand. Rescued, as always in such cases, the savvy.... THE SECOND “BREATH” BIRDS First image of indoor model airplanes made of bird feathers, I saw in the years of the great Patriotic war, even as a boy. Father was at the front, and my mother and my younger sister... Scroll back to top

The boats, which we would like to introduce to the readers, it can be attributed to the category of small vessels. And how else to call a couple of universal self-propelled floats, which are easy to use and as gidroliz, and double pleasure catamaran. As can be seen from the drawings, each of the floats is a miniature boat with a power unit including battery, motor and propeller. Displacement of one float is about 140 kg, which allows not only to equip its power plant, but also allows for “skier” when you need to rely only on a single float, not fearing that he will go under water.

The boats, which we would like to introduce to the readers, it can be attributed to the category of small vessels. And how else to call a couple of universal self-propelled floats, which are easy to use and as gidroliz, and double pleasure catamaran. As can be seen from the drawings, each of the floats is a miniature boat with a power unit including battery, motor and propeller. Displacement of one float is about 140 kg, which allows not only to equip its power plant, but also allows for “skier” when you need to rely only on a single float, not fearing that he will go under water.