A small group of enthusiastic scientists and engineers of the Department of theoretical mechanics of the Kursk Polytechnic Institute, working on the creation of an engine operating without fuel and electricity: they are… replace the flywheel. About these interesting looking we asked to speak to the group leader, doctor of technical Sciences, Professor Nurbay Vladimirovich Gulia, head of the Department of theoretical mechanics Institute.

A small group of enthusiastic scientists and engineers of the Department of theoretical mechanics of the Kursk Polytechnic Institute, working on the creation of an engine operating without fuel and electricity: they are… replace the flywheel. About these interesting looking we asked to speak to the group leader, doctor of technical Sciences, Professor Nurbay Vladimirovich Gulia, head of the Department of theoretical mechanics Institute.

About it today are saying more and more often, calling one of the most promising engines for cars. We are talking about the flywheel or the super flywheel, which when untwisted, then a long time to serve as a drive for various machines. Hopes to it will become clear if we recall the requirements for the transport of the future: it must be economical, harmless, noiseless. He doesn’t need to burn fuel, emit toxic exhaust gases, to transfer heat and throw in the air most of the energy produced”

Perfect in this sense, the motor could be considered as such, which is able to store energy from a cheap stationary source, for example from the mains, and then with high efficiency to give it to propel the vehicle. That is the engine, which serves both the battery energy.

However, the only type of battery to drive the car still was considered to be electrochemical — the same battery that is already on the car. Cage them in combination with the electric motor are widely used to create machines

And what about the flywheel? Maybe about him not know? History shows that attempts to use it were in the distant past.

The first flywheel has created the ancient Sumerian master from the city of Ur more than five thousand years ago. It was a massive Potter’s wheel about a meter in diameter. Spun it by the handle, then rotate by inertia, and Gonchar, meanwhile, was treated with the product. Two thousand years later, the Chinese used huge, almost 10 m in diameter, composite flywheels in their water-lifting structures. Attempts to use flywheels in transport started in the last century. Here I must confess to the reader that in his earlier work (including the last book of the “Flywheel” engines. M., “engineering”, 1976) the first application of flywheels in transportation related to 1860. But it turned out that I was wrong for almost 70 years! My colleague V. S. Sokolov, to whom I Express my deep gratitude, found materials indicating that the first one is a brilliant Russian inventor-self-educated I. P. Kulibin. In his famous “camarade”, along with other technical innovations were applied And the handwheel located horizontally under the truck. When driving “samochody” on a flat road and even more on the descent spun the flywheel, accumulating energy, and then helped the man climbing. Creation date “samochody” flywheel — 1791! There is an assumption that earlier used the flywheel in “self-runaway wheelchair” mechanic Russian Leonty Shamshurenkov (1752). It also was set in motion by muscular force of man and even to easily overcome the climbs. However, the documentary evidence is not found…

1860. A talented inventor, Russian engineer V. I. Shuberskaya applies the flywheel on the railroad. That bot wrote about it in July 1862, the newspaper “the Modern chronicle”:

“Two years ago in the “Journal of communications” was written about the ingenious invention of Mr. Shuberskaya. Makovoz Mr. Shuberskaya, consisting of knobs, it is assumed to use at the shoot and the descent of trains on steep slopes Railways. Moderating the speed of movement during the descent from the mountain and use the saved speed when going uphill, projectile Mr. Shuberskaya enables the Railways with a significant slope, reducing the amount of earthworks and engineering structures. Experiments on a model mahoota were satisfactory, and the inventor intends to start the experiments in the large.”

1883. American Admiral Howell creates a flywheel self-propelled torpedo that can travel a distance of over a kilometer. This torpedo again showed high energy potential of a flywheel for movement of vehicles, including water.

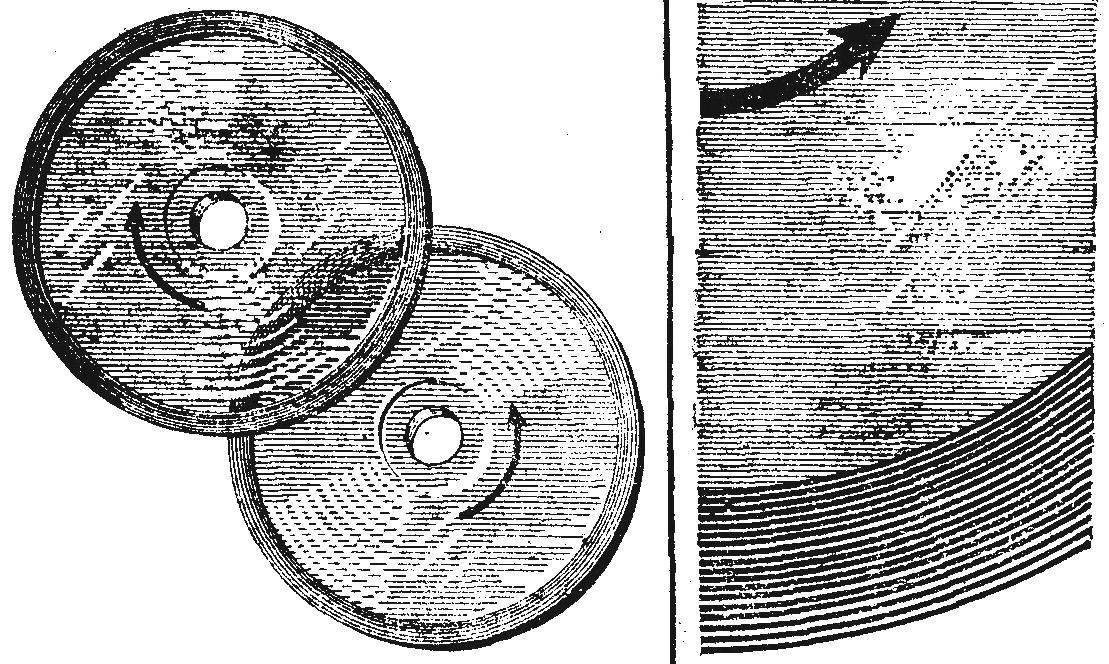

Wire super flywheels produced by the method of coiling discs made of organic glass.

1905. The English Lanchester received a patent No. 7949 invention “…motor in the form of a heavy rapidly rotating flywheel, with the aim of driving the engine crew.”

1909. Appear the fly-wheel monorail two-wheeled carriages P. Shilovsky, L. Brennan, A. Serle. Here the flywheel was used to balance the machine (gyroscopic effect).

1918. Famous Russian a self-taught inventor A. G. Ufimtsev creates inertial battery with the electric drive and the flywheel disc. He dreams of wide application and, in particular, proposes to use the inertial battery for the propulsion of tram.

1945. Swiss firm “Oerlikon” has released a flywheel bus — girobus. The flywheel is spinning at stops. Passed girobus one promotion 2-3 km, then greatly slow down, but was able to crawl to a complete stop for another 2-3 km, then followed a number of transport machinery, using motion energy of the flywheel, domestic mine gerbosi, flywheel truck for interplant transportation, subway trains, even helicopters.

And finally, our days can be called the period of the second birth of the flywheel. Almost simultaneously in our country, in the Kursk Polytechnic Institute, and the United States began to develop the idea of spermagonia of heavy-duty filamentary materials. Created a scientific theory of such flywheels, which is inconceivable without any serious ‘work, built the first prototypes.

How to explain, besides the obvious harmlessness to the environment, increased attention to the flywheel and the rapid growth of research and experimentation in this direction? The answer to such a difficult question can give comparison engine flywheel with others, and primarily with electroaccumulators, in their basic parameters, the Main one specific energy, that is, how it can be accumulated in each kilogram of battery. A regular acid battery that is currently used in electric cars, can contain about 0.1—0.15 megajoules (MJ) of energy for every kilogram of its mass. For the most complex, but promising batteries, where the electrolyte is not acid, and molten alkaline metals (lithium or sodium) that reacts at a temperature of 600-800° with sulfur or chlorine (truly picture worthy of Dante’s Inferno!), this figure may reach 1 MJ per kilogram.

Is he a conventional gasoline automobile engine with a fuel tank designed to run 400 km in Other words, if you replace the petrol motor with the most promising electric accumulators, in the best case, neither the vehicle weight nor his mileage will not change.

And as is the case with the flywheels?

It is proved that the ori given the form of a flywheel (e.g., in the form of massive rims) its specific energy depends only on the specific material strength (ratio of strength to specific weight or density). Indeed, the stronger the material and the easier it is, the faster you can spin the flywheel of a material without fear that it will be ruptured by centrifugal vultures. And the higher the speed of rotation of the flywheel, the more (and square!) the stored kinetic energy. Paradoxically, the lightweight flywheel is more profitable heavy, aluminum is more profitable lead!

The flywheel of the conventional steel is approaching to the specific energy to acid batteries. But it is known that the steel wire is 10 times stronger than that of the ingot from which it was made. Therefore, if it would be possible to make the flywheel of the wire, its specific energy would be close to this figure for the most promising electric accumulators.

There are still strands of quartz, boron, graphite, special material “Kevlar”, which are 3-7 times lighter than steel wire at the same strength. It turns out, there is a possibility of 3-7 times higher than in the energy density of the best electric accumulators! Will primetim also obtained, albeit in small quantities, the materials based on quartz, almost 5 times more durable than all of these. It is much more than you can give the batteries. But ultrastrong materials “prognaut” by the day!

It remains to say that you can make a flywheel from fibers even easier than, for example, to forge it. Enough to take the coil of lightweight material (plastic, aluminum) and wind it fiber or wire with gluing. The author developed many methods of winding such flywheels (which we have abroad called “super flywheel”), there are even some that have and the beginning and the end of the wire be on the inside of the rolls, and the most exposed to the external side it turns solid.

Take another important indicator for comparison is power density, i.e. power per kilogram of engine weight. From its magnitude, for example, depends on whether the car is quick to accelerate, to climb or to overtake, To move fast also need an engine with high specific power.

This indicator not only super, but also the most simple flywheels have no equal. Everyone knows that a broken flywheel, if you try to slow down quickly rather break a shaft than to stop. Developed capacity and therefore, high speed, good throttle response of the car is theoretically unlimited, but practically can to hundreds and thousands of times greater than that of electric accumulators.

This combines such advantages as fast, in a matter of minutes, charging the flywheel.

And as the terms of the conservation of energy? Somehow, I think that, whatever was spun the flywheel, it still stops quickly. Of course, on the air due to aerodynamic losses even the super flywheel will stop in a matter of hours. Well, if the flywheel housing to create a vacuum? And besides, to use magnetic bearings? This flywheel will rotate weeks and months, and in ideal conditions. The Earth — the great cosmic spinning top is also a kind of flywheel in a vacuum environment, And rotates-it is, as we usually say, forever.

The following comparative factor — efficiency. And here the flywheel is the best: and as the Energy accumulator and as a motor. He consumes cheap electricity; the efficiency of the flywheel in a vacuum close to 100%. in addition, it can recover the energy (say, downhill). This is a valuable property of the energy — saves about half of all energy and puts the flywheel efficiency is much higher than any other battery.

Advantages of the flywheel and durability, reliability. It is estimated that the longevity of his six times higher than that of the internal combustion engine, and a much higher battery life. Indeed, the flywheel will Become, especially if it is in a vacuum chamber? Except sometimes you have to change the bearings. And if they are magnetic, and these concerns will not.

All makes of flywheel: it does not stall, as the internal combustion engine, not “closes”, as may occur in an electric vehicle. Temperature swings on it too much are not, and the accident will likely fail in any other engine than the flywheel.

Speaking about environmental safety, the flywheel is the most hygienic engine. He did not emit into the environment. At the same time, the publication in the press about the danger of exhaust gases of internal combustion engines for man and the environment are already widespread,

Even electric cars are not quite “innocent” in this regard. It is well known by those who had to charge the batteries. And the so-called “sealed” batteries when the accident can highlight the atmosphere of combustion products of sodium sulfur or lithium in chlorine..,

Here the reader may begin to doubt: not “distinguish” whether the flywheel in the accident something more dangerous — for example, all-piercing shards? Well, consider the security issues.

It turns out that the gap of the flywheel and the super flywheel is not the same thing. If the destruction of the monolithic flywheel is really hazardous shards, the super flywheel in this respect are absolutely safe: pieces of wires or fibers are unable to penetrate even thin casing. Moreover, super flywheels are most often not broken completely. Destroyed only the outer windings and friction of the body automatically stop a rotating mass, a Lot of experiments confirms this.

Anticipate an ironic remark: why not stop the production of internal combustion engines or electric accumulators and does not affect the release of super?

Flywheel engines are still in cradle of development. Conducting research — both theoretical and on the experimental samples of machines. But I’m sure by the time as super flywheels will come to maturity — and it will, I think, at the end of the century, is to burn fuel in engines will have the same archaic, spoken of by D. I. Mendeleev (remember: “you can drown in bills”?..).

The electric accumulators is unlikely to have to replace the flywheels, especially in these conditions, machine operation, which are associated with prolonged downtime. In addition, the symbiosis between the flywheel and electroaccumulators may be in some cases more economical than a separate flywheel or electroaccumulators.

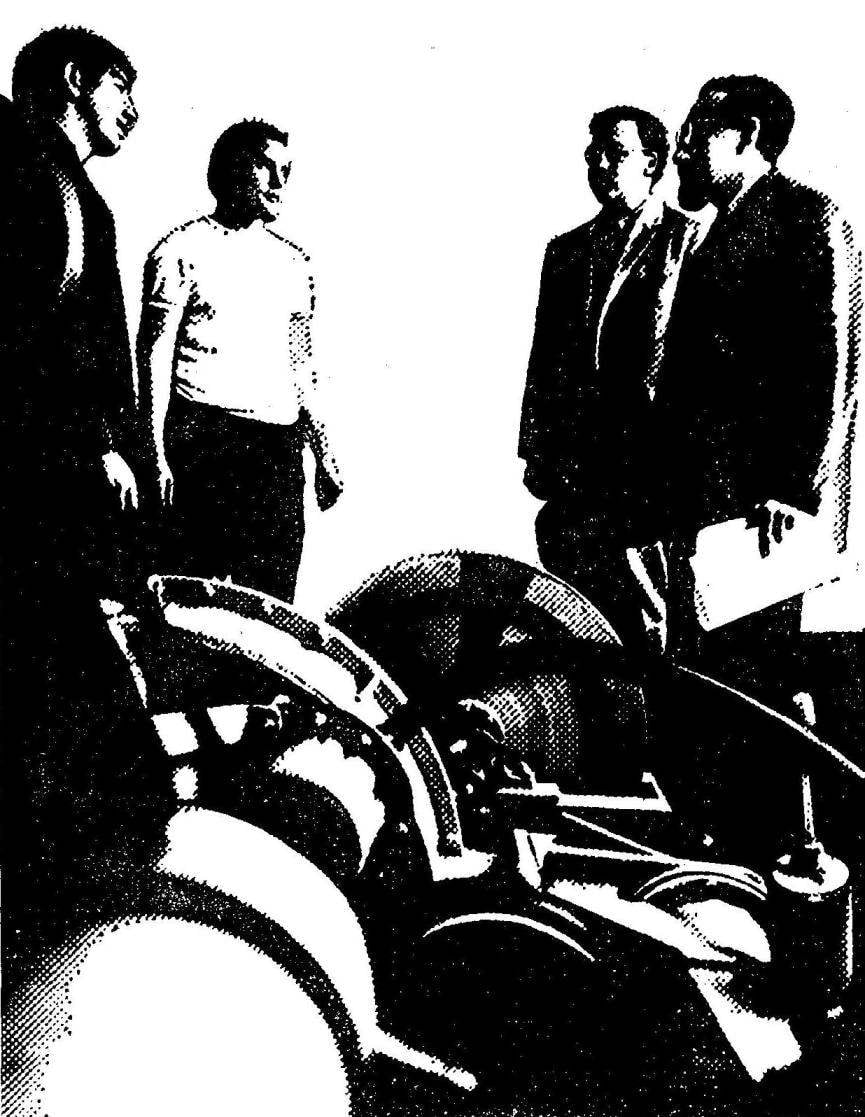

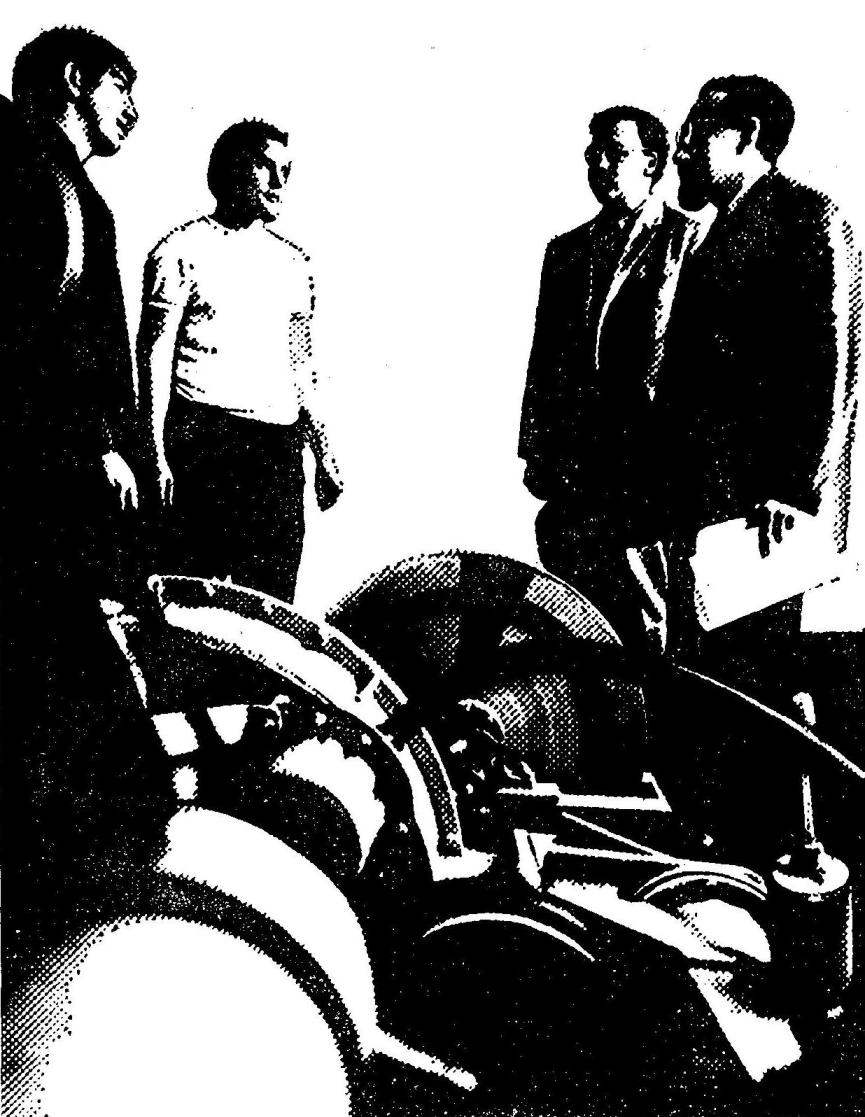

Today, flywheel engines confidently take their first steps. Once the country’s only a small group of enthusiasts who are seriously taking up the flywheels, increasing number of followers and supporters. A considerable contribution to the work on the super flywheels make the students of the Department of theoretical mechanics of the Kursk Polytechnic Institute. Very productively, Oleg Fedoseyev is our theorist, Joseph Yudovsky — inventor and designer, Stanislav Slepuhov — the permanent test of experimental machines and experienced flywheel installations.

Nice to meet the 60 anniversary of October and answering the call of the Komsomol, which became the motto of the all-Union review NTTM, “Five-year plan of efficiency and quality — the enthusiasm and creativity of the young!” we are trying to lead their development to bring them to practice, link with the needs of the national economy. First and foremost is the creation of a flywheel of intrafactory transportation and career.

Why elected such a direction? Because of him an important issue that has not received so far no satisfactory technical solutions. I mean the lack of the necessary both in workshops and in open pits “bezvyhodnoe” transport, which does not accumulate the cloud of exhaust gases. We believe a very promising application for the craft and career of machinery flywheel of engines.

Today is testing, in terms of production truck with this engine. Similar work we performed for an aluminium plant in Bratsk and other enterprises in the country. Received assignments on the development of flywheel of truck-mixer for Sayano-Shushenskaya HPP.

A great help in creating the fly-wheel means of transport can provide young designers, modelers, young technicians, for which no end of fascinating exploration and technical creativity. Including in the creation of micromachines, say, centres, competition for the development of transport for which is held by the magazine. As an example available for the young technicians of the structures we present here the description we have constructed the fly-wheel of the little micro-car.

N. GULIA doctor of technical Sciences