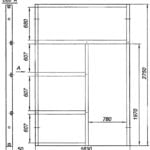

The lower zone begins ahead of a powerful birch boards motor section 12×15 mm, turning then through the diagonal joining two pine under-wing rail cross-section 6×13 mm and further in the rear in a couple of stringers 6×6 mm each. Two front bulkhead is made of plywood thickness of 5 mm, and all the rest — from polished furniture or construction plywood thickness: 3 mm Power covering the forward fuselage is made from aircraft a half-millimeter plywood, and is forced into it flush with the fuselage, gently moving in a zone by using the extended sanding on a mustache and a corresponding adjustment is located underneath the power rails. In the zone of passage of the pins through the wing of the second last frame is enhanced by additional invoice plywood front, top, over it is cut a window for the backup option of placing the power supply equipment. When preteenie tail part that can be useful. The rest of the forward fuselage is made arbitrarily. Here it is only important to reliably separate the cavity of the motor is glued to the bottom of the beams motor plywood wall. The tail pop is closed embedded flush plywood sheathing (thickness of plywood is 1 mm, the layers of shirt vertical), vertical elements of the keel and the bulkhead in the area of the front edge of the stabilizer. The entire tail section from the bottom of the wing is sheathed with millimeter plywood. The same material is laid out lo-gementa the surface under the wing. Area shown on riannah points, is filled with the foam plates with a thickness of 5 mm on the right and the left. During Assembly of the fuselage it is important to provide a sequence of operations, which will stick securely soldered tin fuel tank tightly. The headrest and the lantern is made arbitrarily. The dorsal fin — lime plate, thickness: 3 mm — simultaneously performs the functions of reinforcement of the upper power zone. Before finalizing the design of the bow into the bottom of the beams motor with pre-impregnated chopped screw holes on the resin steel screws M4 for engine mounts. In the plywood sheathing of the sides of the tail is cut longitudinal of the window to exit the control rods. As in the whole fuselage is more than powerful and tough, soft lining carries only a decorative function and can be made of any lightweight film. Under the rear edge of the wing to the frame privertyvaetsja dural biscuit with M6 thread screw mount carrier plaskolite on the fuselage. Weight ready parts chno akrilovogo of the fuselage in the proposed execution together with feathers not more than 400 g.

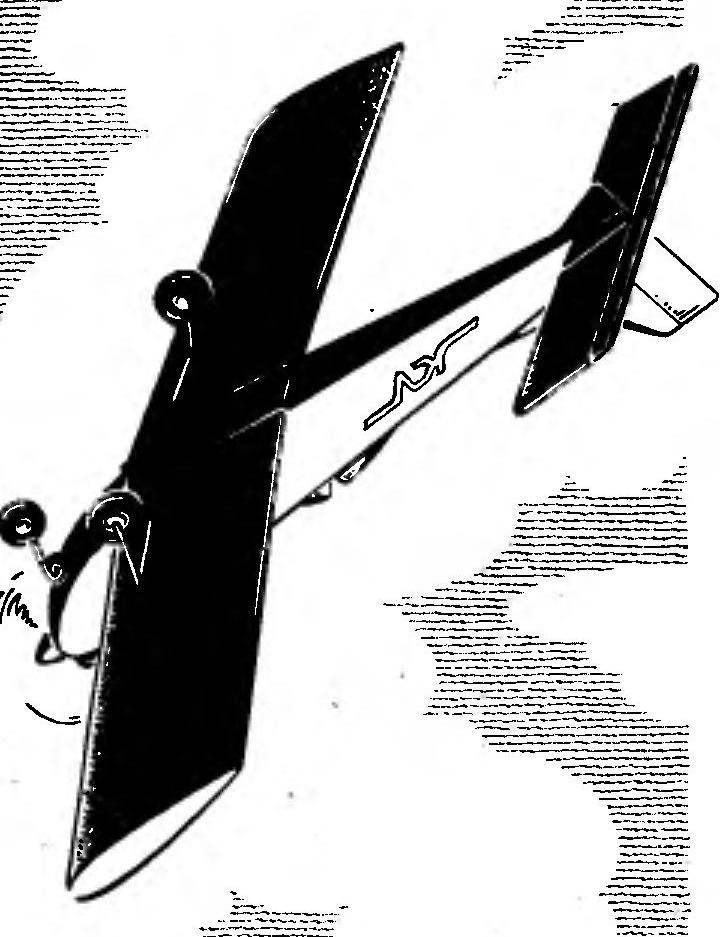

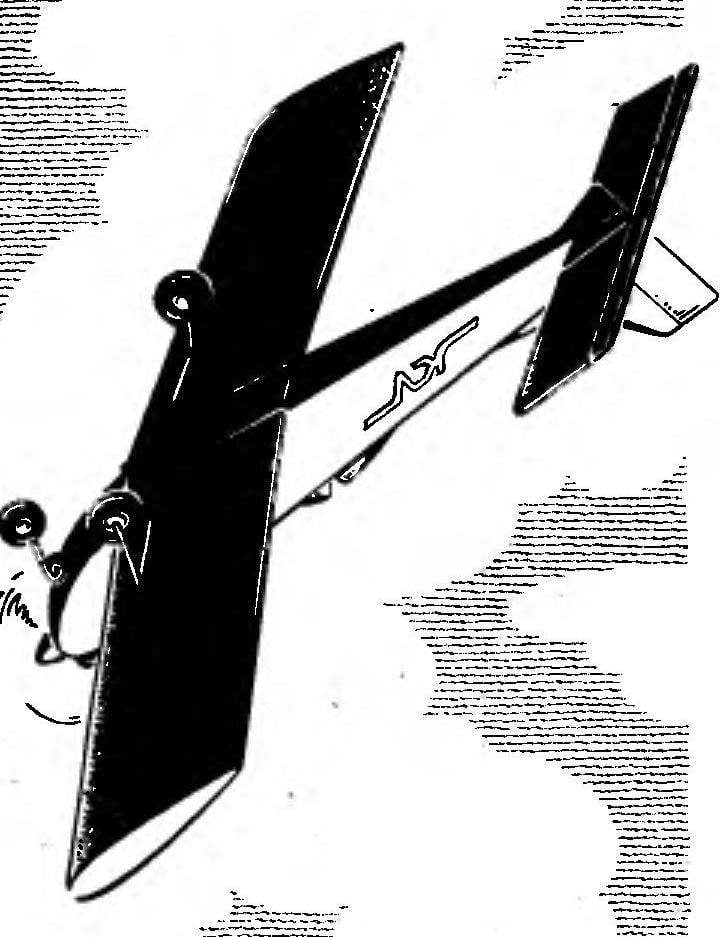

Two wings, like the fuselage, also characterized by non-traditional power scheme. The front edge is formed by the pine monoporosa a cross section of 12 × 20 mm, tongshui on the edge of the wing to 10 x 16 mm. the Terminal parts of the wing are closed by reinforced ribs of lime with a thickness of 8-10 mm (lightweight), sheathed with the outer sides millimeter plywood. All scarves are not docked to the ribs, and drawn through the slits in their noses and shanks. Flaps-ailerons pine, cross-section 5 x 30…35 mm. They have a wedge-shaped profile gives the thickness of the trailing edge at least 2 mm.

Very unusual on this model posted and apparatus. Almost all of it is mounted in the Central zone of the wing, which due to its powerful design better protects expensive nodes in extreme situations than the fuselage. On the created model instance between the cellular Central ribs glued the frames, and the edges of the auxiliary lugs that enable them to bind to the frame top and bottom covering from millimeter plywood with a transverse direction of the fibers of the shirt. Before applying panels indicated on the drawings cavity spread foam stamps PHV. The skins are made for only one window compartment above the servos. Through a first forward inserted power supply unit (preceded by a protective pad of dense foam rubber), then back — wrapped in a thin foam rubber to the receiver, and then, finally, comes the unit servos on a single dural curly Board. The latter relies on not shown in the figures of the boss — their shape and position depend on the specific size of the nodes of the instrument. The ailerons are driven by a pair of brackets, wire, OBC 0 to 3 mm, carried out using thin-walled brass tube. Mm plywood sheathing of the Central zone of the wing extended back to converge together and form a semblance of a fairing. Wing ready to sand and is covered on the glue “Moment” or N-88 Mylar film with a minimum thickness of 0,04 mm. After stretching of the film and editing formed the unique strength and hardness in a twist design with a total weight of about 400 g In the appropriate places on the front edge are glued beech pins for fixing of the wing to the fuselage, and the rear edge of the drilled hole for the screw MB. When cording polyester please note that at the joints the film should molestias each other by not less than 15 mm To the trailing edge it proclaimed.I’m only at the rear end. A finishing operation, painting and installation of special polutropos under the rack chassis in the corners between the power edge and beech insert. The holes for the screws clamping plates drilling only in beech.

The elements of horizontal and vertical models are identical in schematic and design. Edges and endings, and insert made of light pine plates with a thickness of 5 mm. Finished Reiki embedded “dovetail” into the front edge, and rear diamond-shaped, having a preliminary cross section of 7×7 mm, connected by scarves. For reliability, the joints are flat with edges winglets also cut.

Note that elevators and directions it is best to make only after complete Assembly and balancing of the model. Due to material selection and construction of these parts will be the easiest way to achieve the desired alignment.

Tightly seal the fuel tank in connection with its subsequent unavailability must be soldered from tinned sheet thickness 0.3 mm more than reliable. As Ploiesti flight tracking system kit fuel through into the front wall of the tank a large brass tube, clearly seen in the drawings. This technique allows not only to reliably seal this part of the tank in the hole near the frame and thus prevent the entry of fuel mixture into the cavity of the fuselage, but if necessary it is easy to control and replace the tracking system.

Landing gear are bent from wire, allied with a diameter of 4 mm. As already mentioned, the strut (removable) invested in glued into the wing Logement polutrusy and pressed steel plates with screws. At the ends of the struts or conventional model wheel with a diameter of about 60…70 mm, or a kind of ski-altenately. For the latter you will need to make your own pair of racks, but it makes sense — these skis during takeoff and landing on the grass behave better than conventional wheels, and easier latest.

Weight of the model approximately as follows: the fuselage Assembly 400 g, the wing is the same chassis with ski-fairings — 100 g, onboard part of the control equipment up to 400 g, the motor set — 300 grams (“rainbow-7” wooden propeller, lightweight spinner, muffler, and radiolaboratory). Total — 1600 as a result of calculations we get the amazing value of the specific load on the bearing surface 34 g/dm2 in the amount of 41.5 g/dm2 wing. In addition to low specific load is very low and the engine load that allows you not only to fly in an unusually low speed, but also to have considerable excess thrust at all flight modes. For brought ambulancewoman “Rainbow 7” with a lightweight piston, as and for MDS-6,5, we can recommend a wooden propeller with a diameter of about 270 mm and a pitch of the order of 130 — 150 mm.

Talk about a good design, you can finish your sentence: try to make the next step in prereconstruction this machine. Perhaps it will relate to the equipment (by the way, on the proposed modification of the wing includes a wheel-the cars-drive ailerons and rudder), or the schema and layout of the chassis. But overall this stuff. Now talking about larger changes. These include, for example, attempts widespread use balsa instead of pine while preserving the power circuit model. The theory says with the same original design strength balsa nodes this scheme can be two times lighter than pine. The thickness of, for example, the upper zone of the fuselage reach 10 mm, and the cross-section of the power monocracy wing 18 x 30 mm (not to mention the plywood parts, the thickness of which after the transition to the balsa can be increased three to four times). Rate not only the possibility of further simplification of the model, but also corresponding sharp decrease in the expense of this expensive wood.

V. TIKHOMIROV, master of sports

Recommend to read

“FALSHSTENA” WITH A DOORWAY

“FALSHSTENA” WITH A DOORWAY

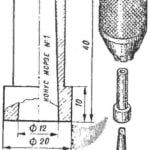

Many citizens in the Soviet Union had to pass through the panel, "building", built in the second half of the last century. These homes are designed for 50 years of operation, will... UNDER MORSE TAPER

UNDER MORSE TAPER

The industry produces at capital drilling machines model 2М112 equipped with cartridges of type 2B for drill diameter up to 16 mm with straight shank. However, this shank us made drill...